The Kanban system, originating from Lean manufacturing principles, is a visual workflow management method aimed at optimizing efficiency and productivity. While its primary focus is on improving operational processes, Kanban also offers significant environmental benefits. By reducing waste, optimizing resource utilization, and enhancing overall efficiency, the Kanban system contributes to more sustainable and environmentally friendly business practices.

Key Principles of Kanban

Before delving into its environmental impacts, it's essential to understand the core principles of the Kanban system:

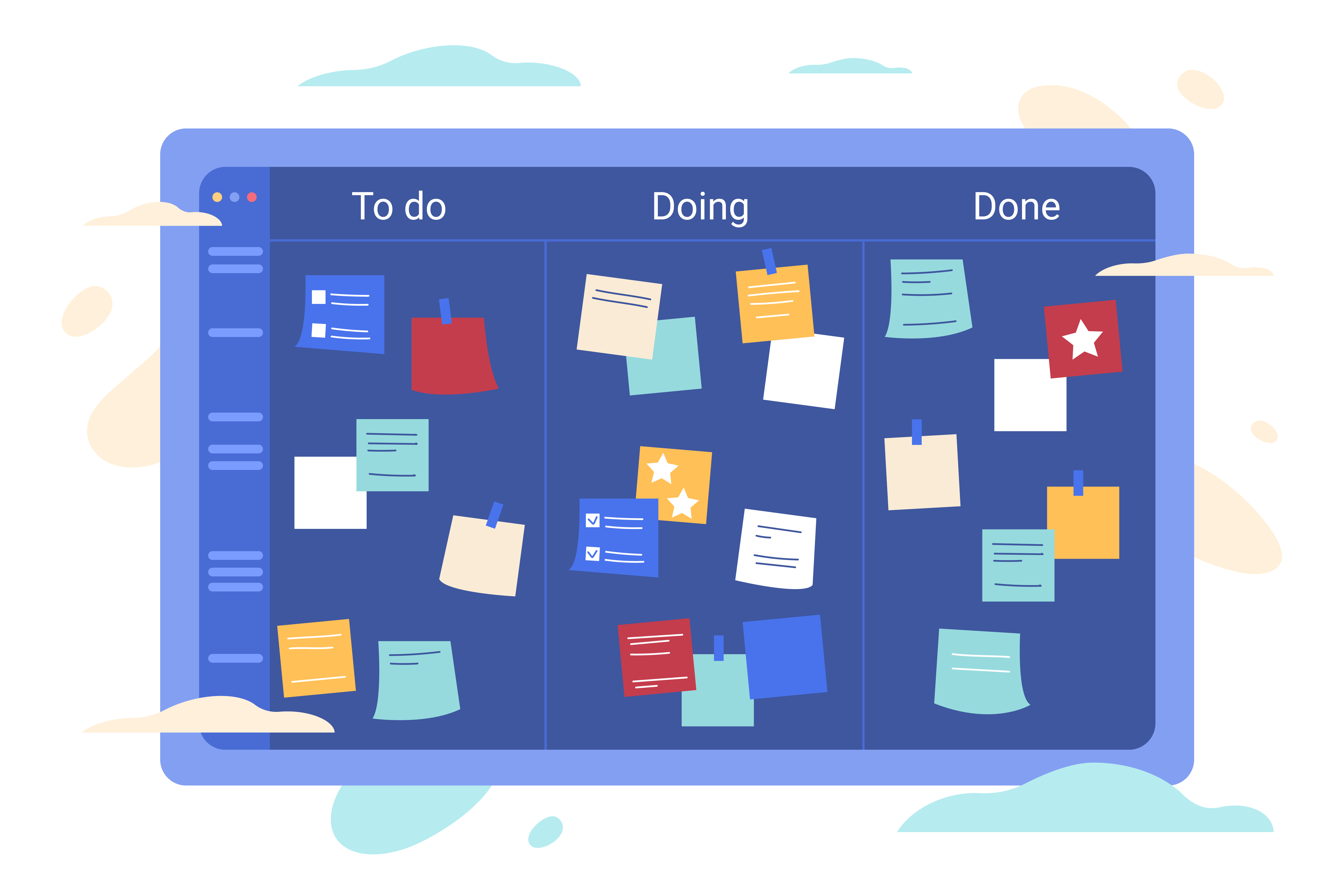

- Visualize the Workflow: Use visual boards to represent tasks and their progress. This visualization helps identify bottlenecks and areas for improvement.

- Limit Work in Progress (WIP): Set limits on the number of tasks in progress to ensure a smooth and efficient workflow. This prevents overproduction and reduces waste.

- Focus on Flow: Aim for a continuous and predictable flow of tasks through the system. This focus minimizes delays and improves efficiency.

- Continuous Improvement: Regularly review and optimize the workflow based on feedback and performance data. This principle, known as Kaizen, is central to Lean methodologies.

Environmental Impacts of Kanban

1.Reduction of Waste

Minimized Overproduction: By limiting WIP and aligning production closely with demand, Kanban reduces the risk of overproduction, a common source of waste in manufacturing and service industries.

Decreased Defects: Continuous monitoring and improvement of the workflow help in early detection and correction of defects, leading to less material wastage.

Optimized Inventory: Kanban systems promote just-in-time inventory practices, ensuring that materials are only ordered and stocked as needed. This reduces excess inventory, which often leads to waste.

2.Efficient Resource Utilization

Optimal Use of Raw Materials: By streamlining processes and reducing waste, Kanban ensures that raw materials are used more efficiently, reducing the environmental footprint associated with extracting and processing these materials.

Energy Efficiency: Improved workflow and reduced waste mean that less energy is required for production. Efficient use of machinery and reduction in idle time also contribute to lower energy consumption.

3.Improved Production Processes

Enhanced Workflow: Kanban’s focus on visualizing and optimizing the workflow leads to smoother and more predictable production processes. This minimizes the stops and starts that can waste energy and resources.

Reduced Emissions: Streamlined processes and efficient use of resources result in lower emissions of greenhouse gases and other pollutants. This is particularly significant in manufacturing industries where production processes can be energy-intensive.

4.Sustainable Inventory Management

Reduced Storage Needs: Just-in-time inventory practices reduce the need for large storage facilities, which often require significant energy for lighting, heating, or cooling.

Lower Spoilage and Obsolescence: With inventory closely matching demand, the risk of materials or products becoming obsolete or spoiling before use is reduced, leading to less waste.

5.Enhanced Recycling and Reuse

Closed-Loop Systems: Kanban encourages the development of closed-loop systems where waste materials are recycled or reused within the production process. This reduces the need for new raw materials and minimizes waste disposal.

Material Tracking: Visual management tools in Kanban systems often include detailed tracking of materials, making it easier to identify and segregate recyclable materials.

6.Improved Supplier Relationships

Collaborative Efforts: Kanban systems often involve close collaboration with suppliers to ensure timely delivery of materials. This collaboration can lead to shared sustainability goals and practices.

Reduced Transportation Impact: Just-in-time deliveries reduce the need for frequent transportation of large quantities of materials, thereby lowering the carbon footprint associated with transportation.

7.Support for Lean Manufacturing

Lean Principles: Kanban is a key component of Lean manufacturing, which emphasizes waste reduction, continuous improvement, and efficient use of resources. Lean practices are inherently aligned with sustainability goals.

Employee Engagement: The Kanban system involves employees in continuous improvement processes, fostering a culture of sustainability and environmental responsibility at all levels of the organization.

The Kanban system, with its emphasis on visual management, continuous improvement, and waste reduction, offers substantial environmental benefits. By optimizing resource use, minimizing waste, and enhancing production efficiency, Kanban contributes to more sustainable business practices. As organizations increasingly prioritize environmental sustainability, the Kanban system provides a practical and effective tool for achieving these goals while also enhancing operational performance.