Kamishibai boards, originating from Japan, are a traditional storytelling tool that combines visual and verbal communication to engage audiences, particularly children. The term "kamishibai" translates to "paper drama" or "paper theater," reflecting its fundamental components: illustrated cards and a small wooden stage. Despite its historical roots, kamishibai continues to captivate audiences worldwide as a form of interactive and immersive storytelling.

At the heart of the kamishibai tradition are the illustrated cards, known as "kamishibai cards" or "kamishibai slides." These cards typically feature colorful and detailed illustrations on one side, accompanied by corresponding text on the reverse. Each card represents a scene or a segment of the story, allowing the storyteller to progress the narrative by sequentially revealing and narrating each card.

The Kamishibai Boards serve as a stage or frame for presenting the illustrated cards. Traditionally, these boards are constructed from wood and feature a rectangular opening at the center where the cards are inserted and displayed. The boards are designed to hold the cards securely while allowing the storyteller to smoothly advance through the narrative by pulling out one card at a time.

One distinctive aspect of kamishibai storytelling is its interactive nature. The storyteller typically travels from one location to another, often using a bicycle or cart equipped with a kamishibai board. Upon arriving at a designated spot, the storyteller sets up the board, attracting the attention of children and other passersby. As the story unfolds, the audience becomes actively engaged, participating in the experience by responding to questions, making predictions, or expressing emotions prompted by the narrative.

Kamishibai stories encompass a wide range of themes and genres, including folktales, fairy tales, historical narratives, and original stories created by contemporary artists. These stories often incorporate moral lessons, cultural values, and elements of fantasy or adventure, making them both entertaining and educational. Additionally, the visual nature of kamishibai allows for accessibility across different age groups and linguistic backgrounds, transcending language barriers through the universal language of imagery.

Beyond its cultural and artistic significance, kamishibai also holds practical value as a tool for literacy development and language learning. By combining visual cues with spoken narration, kamishibai enhances comprehension, vocabulary acquisition, and storytelling skills in young learners. Furthermore, its interactive format fosters social interaction and collaborative learning, encouraging children to engage with peers and adults in meaningful dialogue about the story's themes and messages.

kamishibai has experienced a resurgence in popularity, both in Japan and internationally, thanks to its appeal as a nostalgic form of entertainment and its potential as an educational resource. Contemporary artists and educators continue to explore innovative ways to adapt and modernise kamishibai for diverse audiences, incorporating multimedia elements, interactive technology, and digital platforms while preserving its cultural heritage and storytelling tradition.

Kamishibai Boards represent more than just a storytelling tool; they embody a rich cultural legacy and a versatile medium for communication, education, and entertainment. With its unique blend of visual artistry, oral tradition, and audience participation, kamishibai continues to enchant and inspire audiences of all ages, keeping the spirit of storytelling alive in an ever-changing world.

What Is a Kamishibai Board? A Simple Introduction to Visual Management

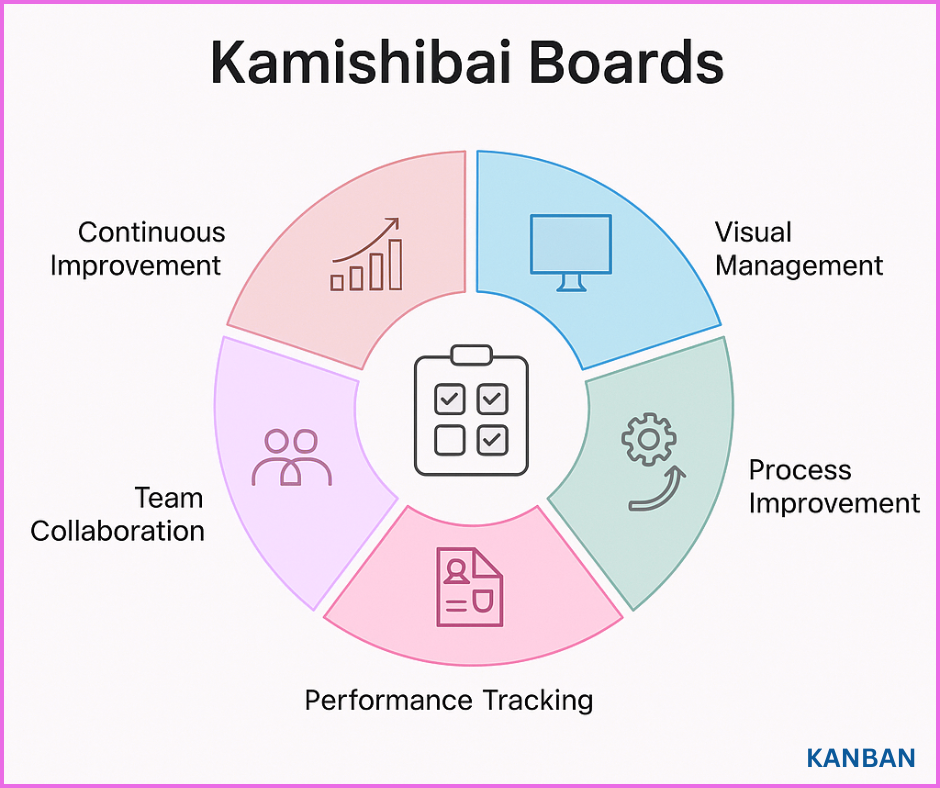

A Kamishibai board is a simple yet effective visual management tool used in lean manufacturing to help track tasks, ensure quality, and maintain operational efficiency. This board is designed to provide an easy way for teams to monitor and improve processes in real-time. The Kamishibai Board gets its name from a Japanese term meaning "paper theatre," where visual cards are moved or flipped to indicate progress or the completion of tasks.

How Does a Kamishibai Board Work?

The Kamishibai board typically consists of a series of cards that represent specific tasks or checks. These cards are often colour-coded to indicate different statuses, such as completed, in-progress, or pending. At regular intervals, the team leader or responsible person will review the board, check off tasks, and update the status of each card. This visual system ensures that everyone is aware of the current state of work and can act quickly to resolve any issues.

The Benefits of Using a Kamishibai Board

Using a Kamishibai board offers several key benefits. Firstly, it enhances communication across teams by providing a clear, easily accessible overview of ongoing tasks. Secondly, it promotes accountability, as team members can see what is expected and track progress visually. Finally, the Kamishibai Board helps identify bottlenecks or areas for improvement, contributing to continuous improvement and process optimisation.

Overall, a Kamishibai board is a valuable tool in visual management that supports efficiency, accountability, and transparency in any organisation.

The Role of Kamishibai Boards in Continuous Improvement

Kamishibai boards play a crucial role in driving continuous improvement within organisations, especially in lean manufacturing environments. By providing a clear, visual way to track tasks, activities, and processes, these boards promote transparency, accountability, and real-time problem-solving, all essential for ongoing improvements.

Visual Management for Better Tracking

At the heart of a Kamishibai Board is its ability to visually display the status of various tasks and checks. The use of coloured cards to represent different stages or statuses helps employees quickly identify areas that need attention. By regularly reviewing the board, teams can easily spot problems or bottlenecks and take immediate action to resolve them. This visual management ensures that no issue goes unnoticed, fostering a culture of continuous improvement.

Encouraging Accountability and Ownership

Kamishibai boards encourage employees to take responsibility for their work. As each task is checked off and moved through the process, team members are held accountable for their contributions. This ownership leads to greater attention to detail and a commitment to improving performance, whether through optimising processes, improving quality, or reducing waste.

Ultimately, Kamishibai boards are more than just tracking tools—they are catalysts for continuous improvement. By enhancing communication, increasing accountability, and promoting real-time problem-solving, they help organisations move towards their long-term goals of efficiency and excellence.

How Kamishibai Boards Help Visualise Quality Control Processes

Kamishibai boards are an essential tool for visualising quality control processes within organisations, especially in environments focused on lean practices. By offering a simple yet effective visual representation, these boards help teams track quality checks and ensure that every step of the production process meets the required standards.

Improved Transparency in Quality Control

With Kamishibai boards, all quality control checks are clearly displayed, making it easy for team members to see what tasks are in progress, what’s been completed, and where attention is needed. The use of colour-coded cards or labels enables quick identification of any issues or delays, creating transparency in the quality control process. This immediate visibility ensures that problems are addressed promptly, preventing defects from slipping through unnoticed.

Encouraging Consistency in Quality Checks

By incorporating Kamishibai boards into regular workflows, organisations can establish a consistent approach to quality control. The boards can outline key checkpoints, from raw material inspection to final product testing, ensuring that all necessary quality standards are met at each stage. This consistency helps prevent errors and reduces variability in production, ultimately leading to higher product quality and customer satisfaction.

In summary, Kamishibai boards offer a visual, efficient way to manage and improve quality control processes. By enhancing visibility and consistency, they help maintain high standards, reduce waste, and contribute to overall operational excellence.

Using Kamishibai for Standardised Work Audits in Manufacturing

Kamishibai boards are increasingly being used in manufacturing environments to streamline and standardise work audits. These boards provide a clear, visual tool that helps teams monitor and maintain consistency across all work processes, ensuring that each task is completed according to established standards.

Improving Audit Efficiency

By using Kamishibai boards for standardised work audits, manufacturers can make the audit process more efficient. The boards display pre-set audit tasks that need to be checked at regular intervals, such as equipment inspections or safety protocol reviews. With the visual nature of Kamishibai, audits can be conducted more quickly, and the status of each task is immediately visible, which helps ensure that nothing is overlooked.

Driving Continuous Improvement

Kamishibai boards encourage continuous improvement by making audit results clear and easy to track. If an audit reveals an issue, the board can highlight areas that need attention. This immediate feedback loop enables teams to address issues before they escalate, fostering a culture of continuous improvement. Moreover, regular audits ensure that standardised work processes are being followed, reducing variability and increasing product quality.

Kamishibai boards play a key role in maintaining standardised work in manufacturing. They help improve audit efficiency, ensure adherence to best practices, and drive continuous improvement across production lines, ultimately enhancing operational performance.

Kamishibai Boards vs Traditional Checklists: Which Is More Effective?

When it comes to improving workflow and maintaining consistent quality in manufacturing, both Kamishibai boards and traditional checklists play vital roles. However, the question arises: which is more effective for ensuring tasks are completed accurately and on time?

Visual Appeal of Kamishibai Boards

Kamishibai boards are a powerful visual tool that makes task tracking and audits more engaging and intuitive. Unlike traditional checklists, which may be easily overlooked or forgotten, Kamishibai boards display the status of tasks in real time. This visual representation allows teams to instantly see which tasks are pending, in progress, or completed. It also helps in identifying any issues promptly, fostering quick corrective actions.

Clarity and Ease of Use

While traditional checklists are functional, they often lack the immediacy and visibility of Kamishibai boards. Checklists can be easily misplaced or ignored, especially in busy environments. Kamishibai Boards, on the other hand, are typically placed in high-traffic areas, keeping tasks front and centre. This consistent visual reminder makes it easier for workers to stay on top of their responsibilities and maintain compliance with standardised processes.

Which Is More Effective?

Kamishibai boards tend to offer more long-term effectiveness compared to traditional checklists. The combination of visual tracking, real-time updates, and clear feedback fosters a culture of accountability and continuous improvement. While checklists may still have a place in certain environments, Kamishibai Boards provide a more dynamic and engaging way to manage tasks and ensure consistent results.

The Benefits of Real-Time Feedback with Kamishibai Boards

Kamishibai Boards offer a powerful way to integrate real-time feedback into your operational processes. By visually tracking tasks and performance in real-time, they enable teams to quickly identify areas for improvement and make immediate adjustments. This timely feedback is crucial for maintaining high-quality standards and efficient workflows in manufacturing environments.

Immediate Issue Detection

One of the key benefits of using Kamishibai boards is the ability to detect issues immediately. Since the board is updated regularly, any discrepancies or problems can be spotted quickly. This allows teams to take corrective actions on the spot, preventing issues from escalating and ensuring that processes stay on track. Real-time feedback enhances the ability to respond to challenges in a proactive manner, minimising downtime and improving overall productivity.

Improved Accountability and Transparency

Real-time feedback through Kamishibai boards promotes accountability among team members. The visual nature of the board makes it clear who is responsible for each task, and progress is easily monitored. This transparency helps ensure that everyone is on the same page and that tasks are completed according to standards. It also encourages a culture of continuous improvement, as teams are regularly reminded of their performance and areas for improvement.

Real-time feedback with Kamishibai Boards is a valuable tool for improving quality, accountability, and efficiency. By enabling quick detection of issues and fostering a culture of improvement, Kamishibai Boards help teams stay agile and focused on achieving operational excellence.

Setting Up a Kamishibai Board: A Step-by-Step Guide

Setting up a Kamishibai board is a straightforward process that can significantly improve your team's workflow and quality control. Follow this simple guide to get started and ensure you set up your board effectively for optimal results.

Step 1: Define Your Objectives

Before you begin, clarify the specific goals you want to achieve with your Kamishibai board. Are you focusing on improving quality control, standardising work processes, or increasing accountability? Having clear objectives will help you structure the board to meet your needs.

Step 2: Choose Your Board Type

Kamishibai Boards can be physical or digital. For physical boards, use a large, visible space where team members can easily update and view information. For digital boards, choose software that allows for easy tracking and visualisation of tasks and progress.

Step 3: Organise Your Tasks

Divide your tasks into categories such as “Completed,” “In Progress,” and “Pending.” Each task should be visually represented, either as cards or sticky notes, and include key details like deadlines, responsible team members, and performance targets. Colour coding can be helpful for prioritisation.

Step 4: Assign Auditors

Assign specific team members to audit tasks regularly. These auditors will be responsible for reviewing the tasks, providing feedback, and ensuring that quality standards are met. Their role is essential for ensuring the board stays accurate and useful.

Step 5: Regularly Update and Review

Ensure that the board is updated frequently. Hold regular reviews to assess the board’s effectiveness, make adjustments, and encourage continuous improvement.

By following these steps, you can set up a Kamishibai board that fosters transparency, accountability, and continuous improvement, helping your team stay focused on quality and efficiency.

Kamishibai and Kaizen: How They Work Together for Improvement

Kamishibai and Kaizen are two powerful tools that, when combined, can significantly enhance continuous improvement processes in your organisation. While each method offers unique benefits, together they create a robust system for quality control and operational excellence.

What is Kamishibai?

Kamishibai is a visual management tool that helps teams track tasks, monitor progress, and ensure standards are met. It typically involves using a board with cards or notes representing specific tasks or audits, making it easy to see the status of various activities at a glance. This tool ensures transparency, accountability, and real-time feedback.

What is Kaizen?

Kaizen, meaning "continuous improvement" in Japanese, is a philosophy that focuses on making small, incremental changes to improve efficiency, quality, and productivity. It encourages team involvement at all levels, fostering a culture of collaboration and ongoing development.

How They Work Together

When combined, Kamishibai and Kaizen support a continuous cycle of improvement. Kamishibai provides a visual, structured approach to track tasks and audits, while Kaizen drives the mindset of constant progress. Using Kamishibai Boards during Kaizen events allows teams to clearly identify areas that need attention, track progress, and implement improvements more efficiently. This synergy promotes faster problem resolution and enhances overall quality control.

By integrating Kamishibai into your Kaizen approach, you create a dynamic system that not only highlights issues but also fosters a culture of ongoing improvement.

Kamishibai Board Examples in Lean Manufacturing

Kamishibai boards are essential tools in lean manufacturing, offering a visual and structured approach to monitor quality and ensure processes meet the required standards. By incorporating Kamishibai Boards into your workflow, you can drive efficiency, improve communication, and support continuous improvement efforts.

Example 1: Standardised Work Audits

One common use of Kamishibai boards in lean manufacturing is for standardised work audits. In this case, tasks or processes are visually represented on the board, and audits are conducted regularly to ensure they are being followed correctly. The board allows team members to quickly identify areas that need attention, ensuring compliance with established procedures and reducing variability in operations.

Example 2: Equipment Maintenance Checks

Kamishibai Boards are also used for tracking routine equipment maintenance checks. By placing maintenance schedules and tasks on the board, it is easier to manage equipment upkeep, ensuring that machines are operating at their best. The visual nature of the board provides a clear overview of which maintenance tasks have been completed and which ones are due, helping prevent costly downtime.

Example 3: Quality Control Monitoring

Another example of Kamishibai boards in action is in quality control monitoring. Quality checks are often visualised on the board, with each step of the process being verified regularly. This allows teams to catch any deviations early and take corrective actions before they affect production quality, maintaining high standards across all processes.

Kamishibai Boards are versatile and effective in lean manufacturing, ensuring transparency, accountability, and a culture of continuous improvement.

How Kamishibai Boards Promote Employee Engagement and Ownership

Kamishibai Boards are not just tools for visual management—they play a key role in promoting employee engagement and ownership in the workplace. By using these boards to track tasks, audits, and performance, employees are empowered to take responsibility for their work and contribute to continuous improvement efforts.

Active Participation in Audits

One of the key ways Kamishibai boards foster engagement is through active participation in audits. Employees are assigned specific tasks or processes to monitor, ensuring they remain accountable for their actions. This involvement in routine audits encourages a sense of ownership, as team members feel responsible for maintaining high standards and ensuring the smooth running of operations.

Encouraging Feedback and Communication

Kamishibai boards also encourage regular feedback and open communication. As employees review and update tasks on the board, they are prompted to provide valuable insights into areas for improvement. This collaborative environment helps break down silos and encourages teamwork, where employees feel their contributions matter in the decision-making process.

Building a Culture of Ownership

By giving employees a direct role in tracking and improving processes, Kamishibai Boards build a culture of ownership. When employees are trusted with monitoring and improving quality, they feel more connected to the overall goals of the organisation. This heightened sense of responsibility can lead to improved morale, job satisfaction, and a greater commitment to delivering results.

Incorporating Kamishibai boards into your operations is a powerful way to enhance employee engagement and foster a more accountable, motivated workforce.

Integrating Kamishibai Boards with Other Lean Tools like 5S

Integrating Kamishibai Boards with other lean tools, such as 5S, can significantly enhance the effectiveness of your continuous improvement efforts. Kamishibai boards serve as visual management tools, while 5S focuses on maintaining an organised, efficient workspace. Together, they promote operational excellence by improving both the process and the environment in which work is done.

Streamlining Audits with 5S

5S, which stands for Sort, Set in Order, Shine, Standardise, and Sustain, is designed to improve workplace organisation and reduce waste. When combined with Kamishibai Boards, 5S audits can be tracked and monitored in real-time. Employees can use the Kamishibai board to visually record their 5S audit tasks, making it easier to identify areas that need improvement and track progress. This integration ensures that 5S practices are maintained consistently over time.

Boosting Accountability and Ownership

By integrating Kamishibai boards into the 5S process, employees are given clear responsibility for specific audits or tasks. The visual nature of Kamishibai Boards encourages employees to engage in routine checks and updates, making them feel more accountable for the cleanliness and organisation of their workspaces. This active involvement not only supports 5S but also fosters a culture of ownership and responsibility.

Supporting Continuous Improvement

When Kamishibai boards and 5S are combined, they create a seamless feedback loop that supports continuous improvement. Employees can easily identify issues, report them, and take corrective actions, driving sustainable improvements. The integration of these tools creates a dynamic system for tracking performance and making ongoing enhancements to both processes and workplace organisation.

Digital Kamishibai Boards: Adapting Traditional Tools to Modern Workplaces

Kamishibai Boards, traditionally used in lean manufacturing to monitor processes and ensure consistent performance, are now being adapted to the digital world. Digital Kamishibai boards bring the benefits of real-time updates, remote accessibility, and streamlined data collection to modern workplaces, making them an even more powerful tool for continuous improvement.

Real-Time Monitoring and Feedback

One of the main advantages of digital Kamishibai Boards is the ability to provide real-time feedback. Unlike physical boards, which require manual updates, digital boards can instantly display any changes or issues, allowing teams to address problems as they arise. This improves response times and ensures that corrective actions are taken promptly, enhancing overall operational efficiency.

Remote Accessibility and Collaboration

In today’s increasingly remote and hybrid work environments, digital Kamishibai boards make it easy for teams across different locations to stay connected and engaged. With digital boards, staff can easily view performance data, conduct audits, and monitor progress from anywhere. This level of accessibility fosters better collaboration, regardless of location.

Efficient Data Management

Digital Kamishibai Boards also simplify data management. The collected information can be automatically stored and analysed, providing valuable insights into trends and areas for improvement. This data can be used to inform future decisions, helping teams make data-driven improvements to their processes and maintain a high standard of quality control.

How Kamishibai Boards Help Identify Process Gaps and Areas for Improvement

Kamishibai boards are a powerful visual management tool used in lean manufacturing to monitor and improve processes. By providing a clear and structured approach to audits, these boards help teams easily identify process gaps and areas for improvement, ensuring ongoing operational efficiency and quality control.

Visual Representation of Standardised Work

Kamishibai Boards display standardised work procedures and audit checklists in a visual format. Regular audits conducted using these boards help detect deviations from the standard, making it easy to spot areas where processes are not being followed correctly. This visualisation ensures that all team members are aware of the correct procedures and highlights any gaps in adherence to them.

Highlighting Bottlenecks and Delays

By tracking specific processes and tasks, Kamishibai boards can identify bottlenecks or delays in the workflow. These issues are often the result of inefficiencies, lack of resources, or unbalanced workloads. The board’s visual format allows teams to quickly pinpoint these challenges, enabling them to take corrective actions before they escalate.

Continuous Improvement and Problem-Solving

Kamishibai boards encourage a culture of continuous improvement. As issues are identified, teams can take immediate action to resolve them, leading to better performance. The boards also foster open communication, allowing team members to share insights and suggest improvements, which drives ongoing process optimisation and better outcomes over time.

Kamishibai in Non-Manufacturing Industries: Applications Beyond the Factory Floor

While Kamishibai boards are widely used in manufacturing to enhance visual management, their applications extend far beyond the factory floor. These boards are increasingly being adopted in non-manufacturing industries to improve processes, ensure consistency, and foster continuous improvement across various sectors.

Healthcare: Streamlining Processes and Ensuring Compliance

In healthcare, Kamishibai boards are used to monitor patient care processes and ensure adherence to protocols. By visualising tasks and daily activities, they help identify areas where standards are not being met and ensure compliance with safety and quality regulations. This application improves patient safety, reduces errors, and promotes consistent care delivery.

Retail: Enhancing Customer Service and Operational Efficiency

Retail businesses use Kamishibai boards to manage stock levels, track sales processes, and monitor customer service standards. These boards help identify gaps in staff performance and highlight areas where customer service can be improved. They also streamline inventory control by providing clear, visual cues to the team about restocking needs or upcoming promotions.

Office Environments: Optimising Administrative Workflows

In office environments, Kamishibai boards can be used to manage tasks, monitor workflow efficiency, and ensure that deadlines are met. They provide a visual representation of ongoing projects and highlight potential bottlenecks or delays. This enables teams to take corrective action swiftly and keep administrative operations running smoothly.

Measuring the Effectiveness of Kamishibai Boards in Continuous Improvement Programs

Kamishibai boards are an excellent tool for continuous improvement, offering a visual method for monitoring tasks, tracking progress, and identifying areas that need attention. However, to ensure that these boards truly contribute to improvement, it is essential to measure their effectiveness.

Tracking Compliance and Adherence to Standards

One of the primary ways to measure the effectiveness of Kamishibai boards is by tracking compliance with established standards. For example, in manufacturing or healthcare environments, these boards help ensure that daily audits and checks are completed as per the set schedule. By regularly reviewing the results, organisations can assess whether staff are following procedures and where any discrepancies occur.

Identifying Gaps in Processes

Kamishibai boards help highlight process gaps by visualising areas that are frequently not completed or require additional focus. By evaluating which tasks are delayed or skipped, organisations can pinpoint problem areas, enabling quick intervention and adjustments to the workflow. Over time, this helps improve overall efficiency and effectiveness.

Engaging Employees in Improvement Initiatives

Another measure of effectiveness is employee engagement. Kamishibai boards encourage active participation by staff members, as they are often used to facilitate audits and provide real-time feedback. The more employees are involved in identifying issues and contributing to improvements, the more successful the continuous improvement program will be.

The effectiveness of Kamishibai boards can be measured through compliance tracking, identification of process gaps, and employee engagement. By consistently monitoring these factors, organisations can ensure that their continuous improvement efforts remain on track and deliver tangible results.

What is the Kamishibai Technique?

The Kamishibai technique is a powerful visual management tool used primarily in continuous improvement processes, particularly in manufacturing and operational environments. Originating from the Japanese term "kami" (paper) and "shibai" (theatre), the Kamishibai technique involves the use of a simple board to monitor processes and tasks in real time. It provides a structured approach to ensure that work standards are followed, and quality controls are maintained consistently.

How Does the Kamishibai Technique Work?

At its core, the Kamishibai technique uses a visual board with cards that represent tasks or checkpoints. These cards are reviewed regularly to verify that processes are being completed correctly and on schedule. When a task or process is checked, a card is moved or marked as completed. This visual feedback helps teams identify issues quickly and take corrective actions before problems escalate.

Why Use the Kamishibai Technique?

The main benefit of the Kamishibai technique is its simplicity and real-time application. It enables teams to quickly spot discrepancies or non-compliance with standards, ensuring that issues are addressed promptly. The technique also promotes accountability, as employees can easily see their progress and the status of various tasks. By using the Kamishibai board regularly, organisations can drive continuous improvement and maintain high standards of work.

Overall, the Kamishibai technique is an effective, visual, and interactive approach to maintaining quality and consistency in various operational environments. It fosters teamwork, accountability, and proactive problem-solving.

What is the Kamishibai Standard?

The Kamishibai standard is a visual management system used in lean manufacturing and continuous improvement initiatives. This standard involves creating a set of clear, structured guidelines that help ensure tasks and processes are carried out according to established protocols. The Kamishibai standard is primarily used for monitoring work performance, maintaining quality, and identifying areas for improvement in real time.

How Does the Kamishibai Standard Work?

In a Kamishibai system, tasks or work processes are assigned to specific cards that represent important checks or audits. These cards are placed on a board, and team members regularly review and verify whether the work has been completed according to the set standard. If a process is followed correctly, the card is moved or marked as complete; if there is a deviation or issue, corrective action can be taken immediately.

Why is the Kamishibai Standard Important?

The Kamishibai standard helps organisations maintain consistency, prevent errors, and ensure compliance with work protocols. By using a visual board to track and monitor work, teams are better able to identify issues early, before they become larger problems. This proactive approach supports continuous improvement by fostering accountability, clarity, and real-time feedback.

Overall, the Kamishibai standard is a simple but effective way to manage quality control and drive operational excellence within a team or organisation. It promotes a culture of continuous improvement and ensures high standards are maintained consistently.

What is the Difference Between Kanban and Kamishibai?

Kanban and Kamishibai are both visual management tools used in lean manufacturing and continuous improvement processes, but they serve different purposes and operate in unique ways. Understanding their differences can help businesses select the right tool for their needs.

Kanban: Visualising Workflow and Managing Inventory

Kanban is primarily used to visualise the flow of work and manage inventory in a production system. It uses cards, signals, or boards to track tasks or materials. Kanban helps ensure that work is only pulled into a process when there is capacity, preventing overproduction and reducing waste. It’s a powerful tool for managing production schedules and inventory levels in real time.

Kamishibai: Ensuring Compliance and Quality Control

Kamishibai, on the other hand, is focused on ensuring compliance with standard operating procedures and maintaining quality control. It involves the use of visual cards on a board, which are regularly reviewed to check if tasks or processes are being carried out correctly. Kamishibai is often used for audits, standard work checks, and maintaining high-quality standards in production environments.

Key Differences

The main difference between Kanban and Kamishibai lies in their purpose. Kanban is used to manage inventory flow and production scheduling, while Kamishibai is used to monitor compliance, check quality, and ensure standard operating procedures are followed. Both tools promote visual management and contribute to continuous improvement, but they address different aspects of operations.