Best Cloud-Based OEE Software for Manufacturing

Real-Time Monitoring | Optimise Equipment Performance | Reduce Waste & Downtime | Enhance Productivity

What is OEE in the manufacturing industry?

Overall Equipment Effectiveness (OEE) is a key manufacturing metric that measures the efficiency and productivity of equipment. It is calculated using three factors: availability, performance, and quality. A higher OEE indicates optimal production with minimal downtime, speed loss, and defects.

- Availability: Measures the actual running time of equipment compared to planned production time. It accounts for downtime losses such as breakdowns and setup changes.

- Performance: Assesses whether equipment is operating at its maximum speed by identifying slow cycles and minor stoppages.

- Quality: Evaluates the percentage of good units produced versus defective ones, ensuring minimal waste.

OEE Formula:

OEE (%) = Availability × Performance × Quality

Book Free Demo

Why Choose Our OEE Software?

- Real-Time Monitoring & Analytics– Track your production efficiency, downtime, and machine performance with live data.

- Reduce Downtime & Maximise Productivity– Minimise unplanned stoppages and keep your machines running at peak efficiency.

- Cloud-Based Accessibility– Monitor production from anywhere with our cloud-based platform.

- Data-Driven Decision Making– Leverage powerful analytics and performance metrics to improve decision-making.

- Improve Overall Equipment Effectiveness (OEE)– Measure availability, performance, and quality in one integrated platform.

Components of the OEE Framework

The OEE (Overall Equipment Effectiveness) framework consists of three core components that measure manufacturing efficiency: Availability, Performance, and Quality. Each component identifies specific areas for improvement.

- Availability: Availability measures the percentage of scheduled production time that the equipment is running. It accounts for unplanned and planned downtime, such as breakdowns, changeovers, and maintenance.

- Performance: Performance evaluates how efficiently equipment operates compared to its maximum potential speed. It considers factors like slow cycles and minor stops that reduce production output.

- Quality: Quality reflects the percentage of good products produced without defects. It accounts for scrap, rework, and startup losses, ensuring that only high-quality products contribute to productivity.

- OEE Calculation: The OEE score is calculated by multiplying the three components:-OEE (%) = Availability × Performance × Quality

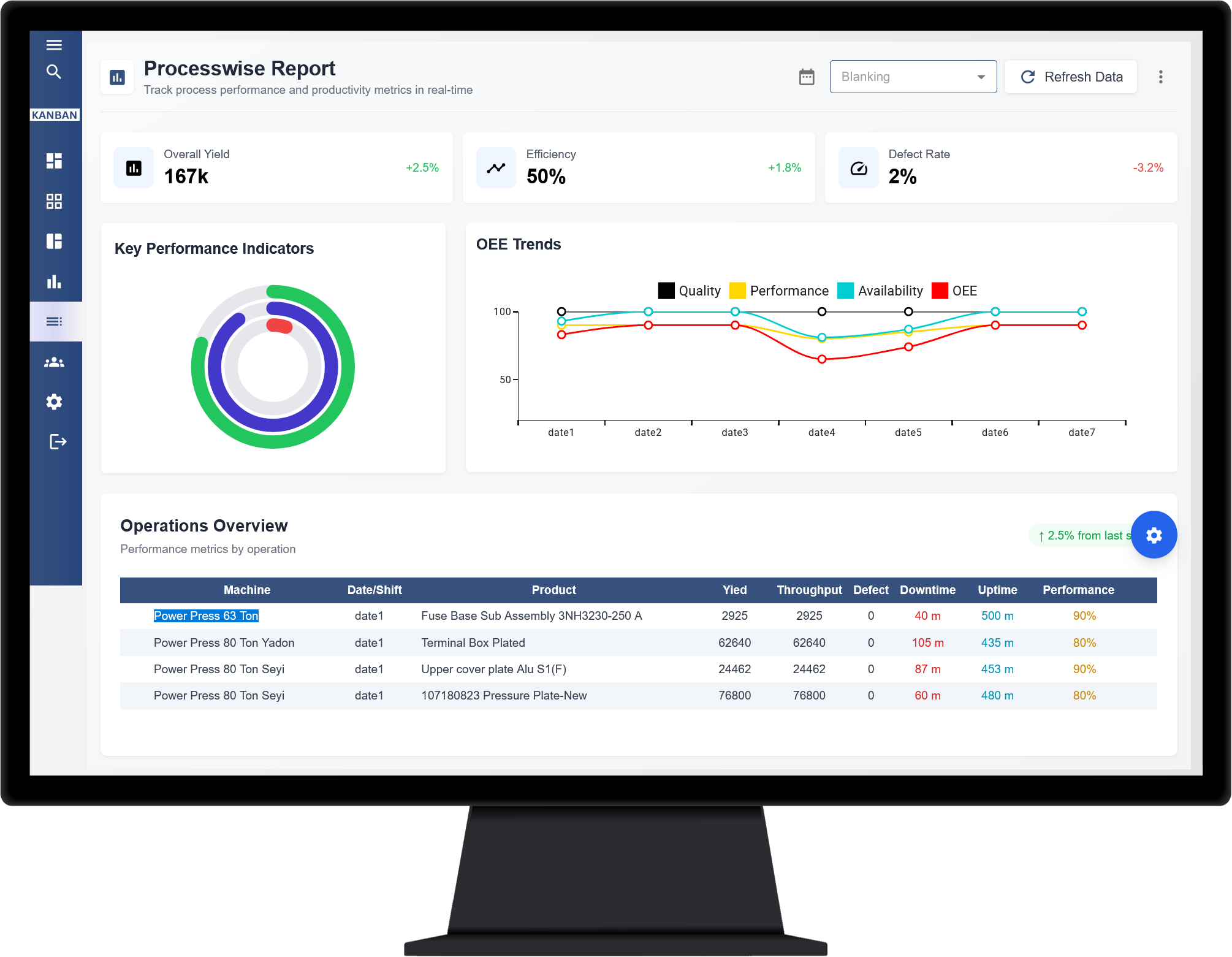

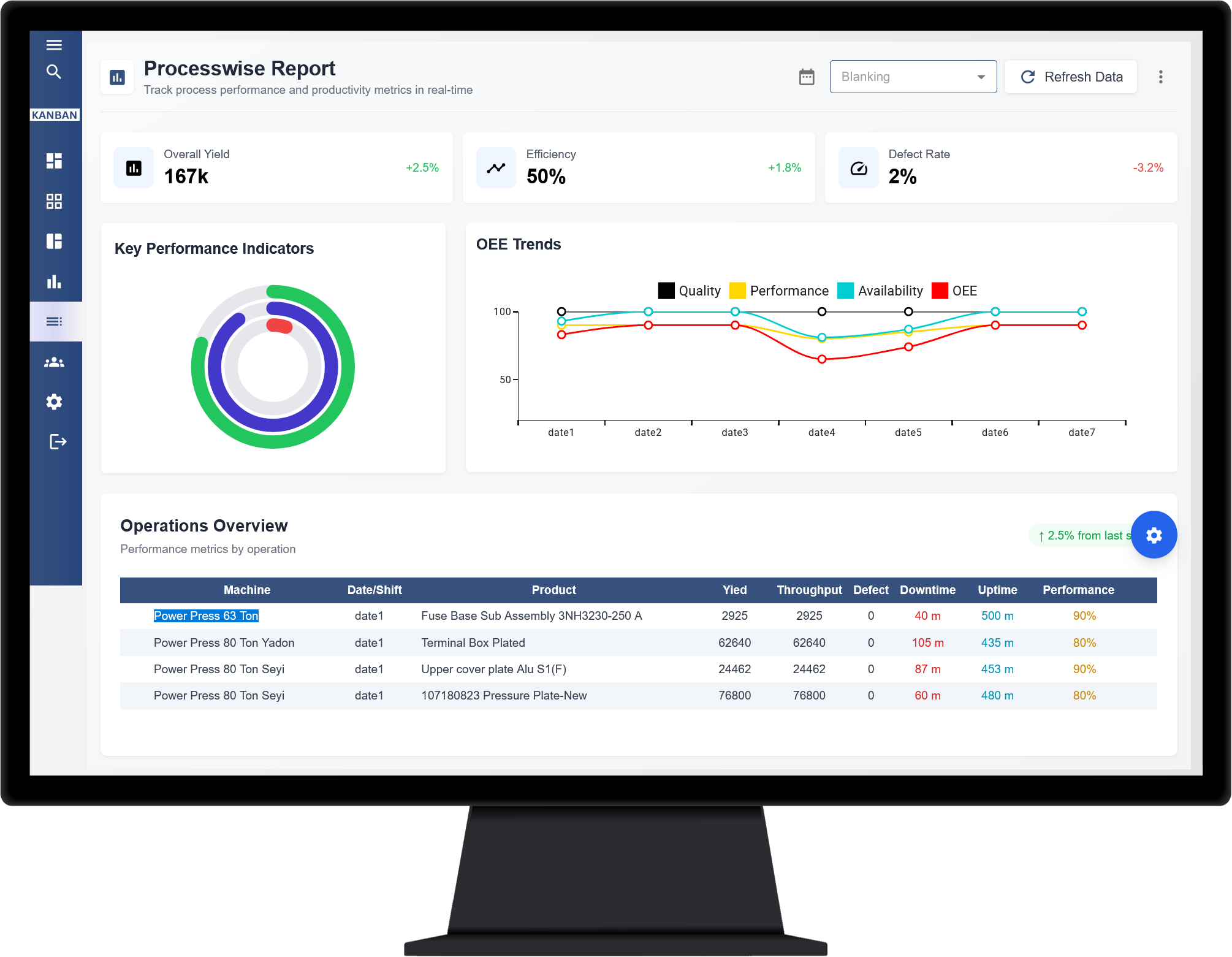

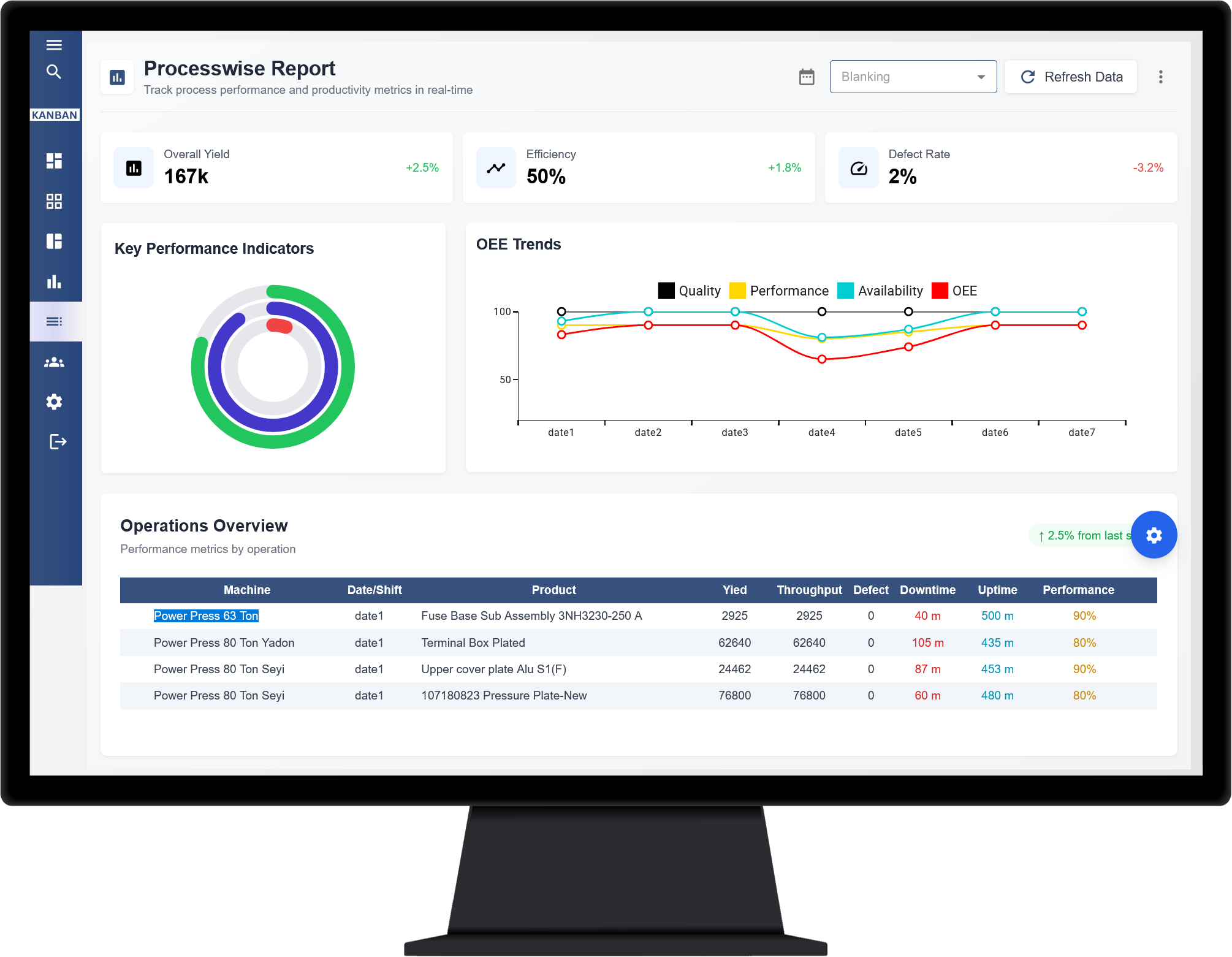

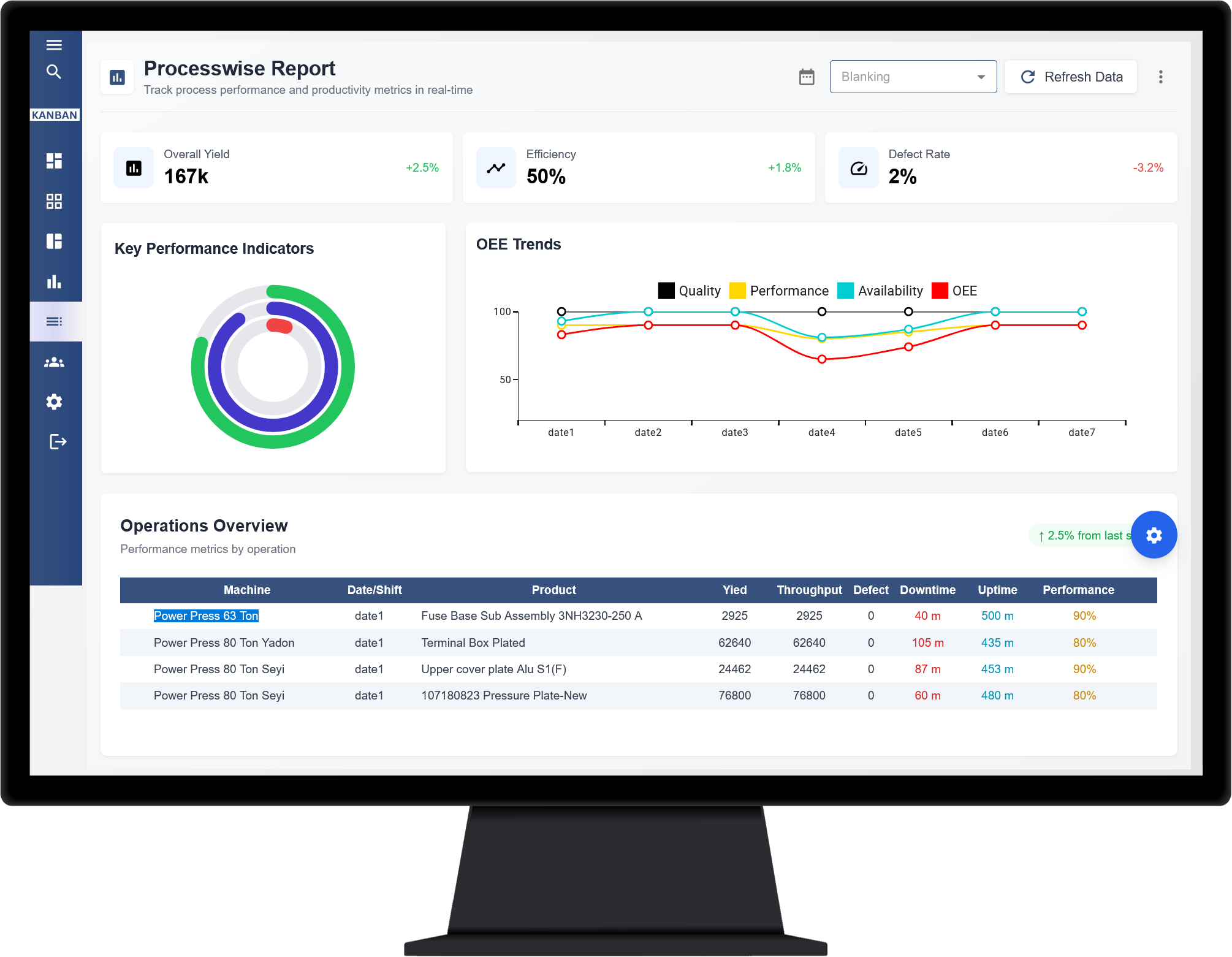

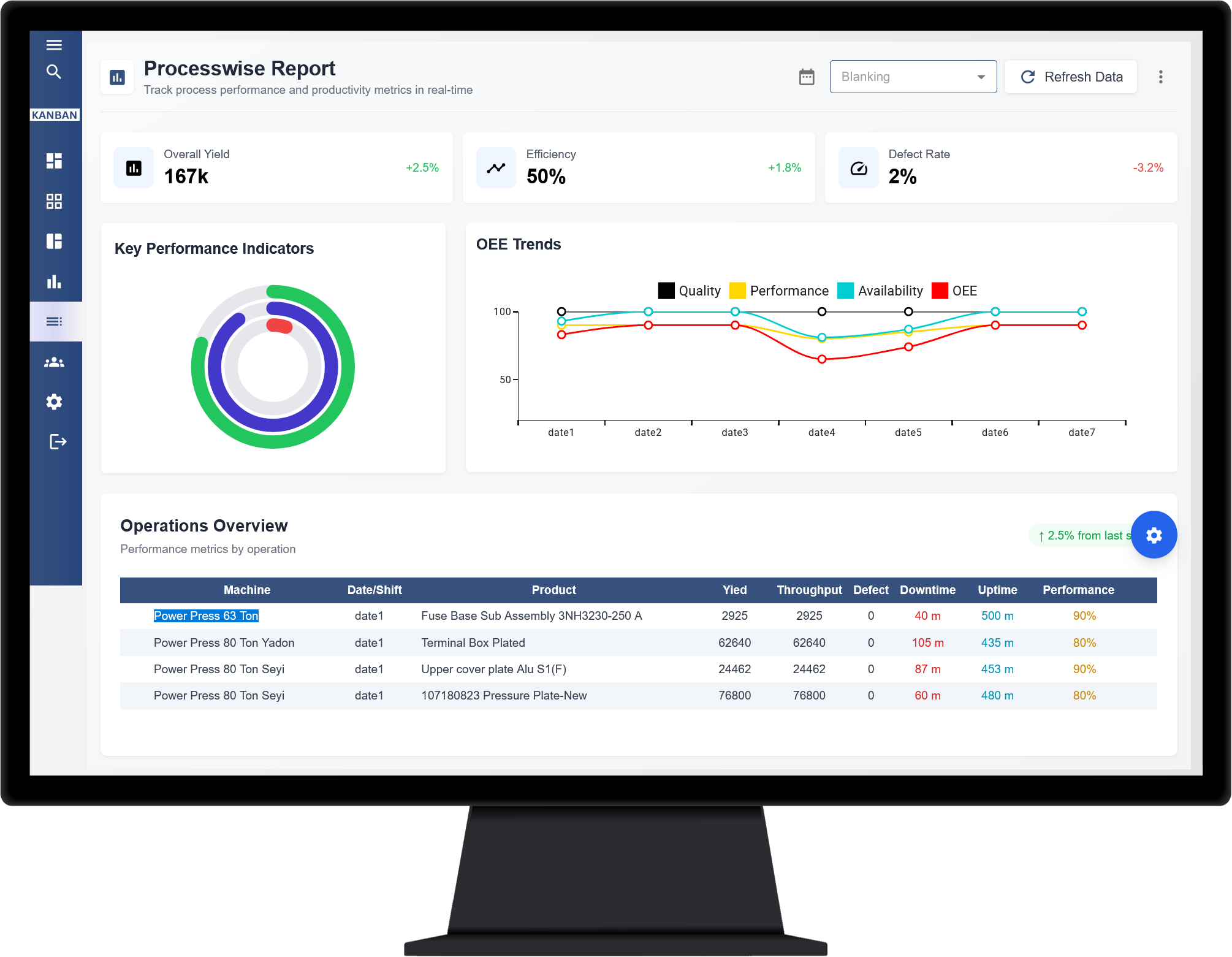

Key Features of Our OEE Software

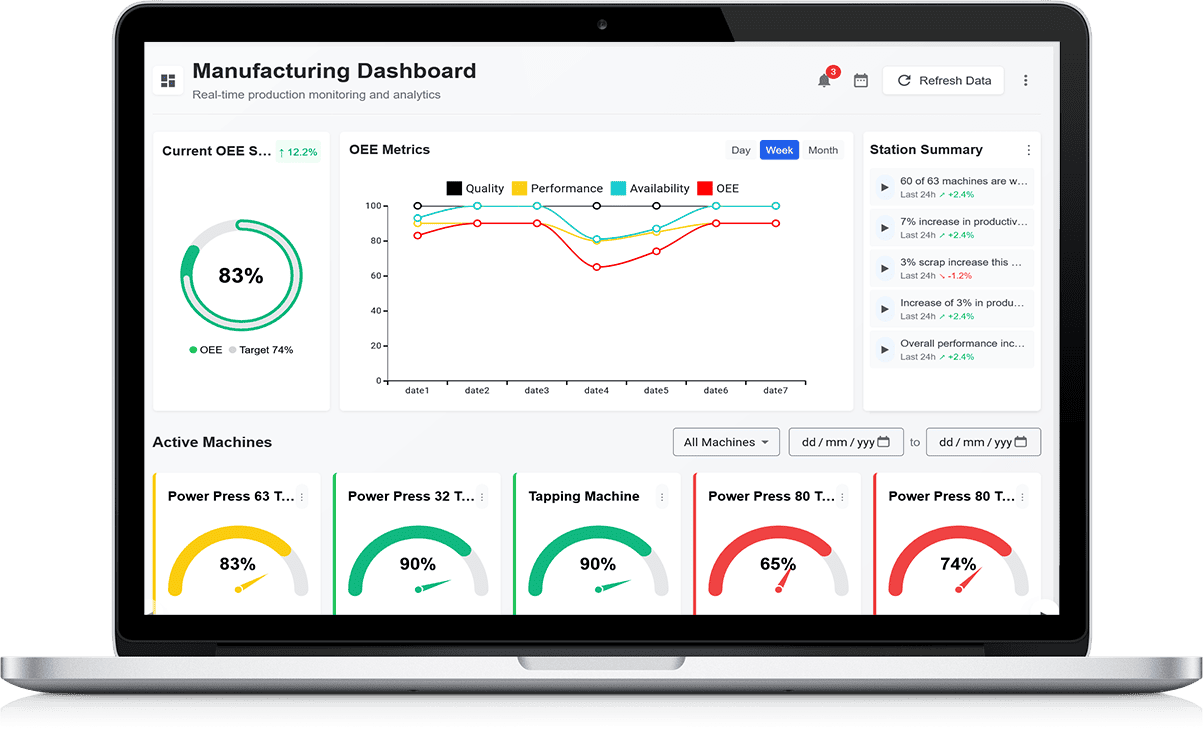

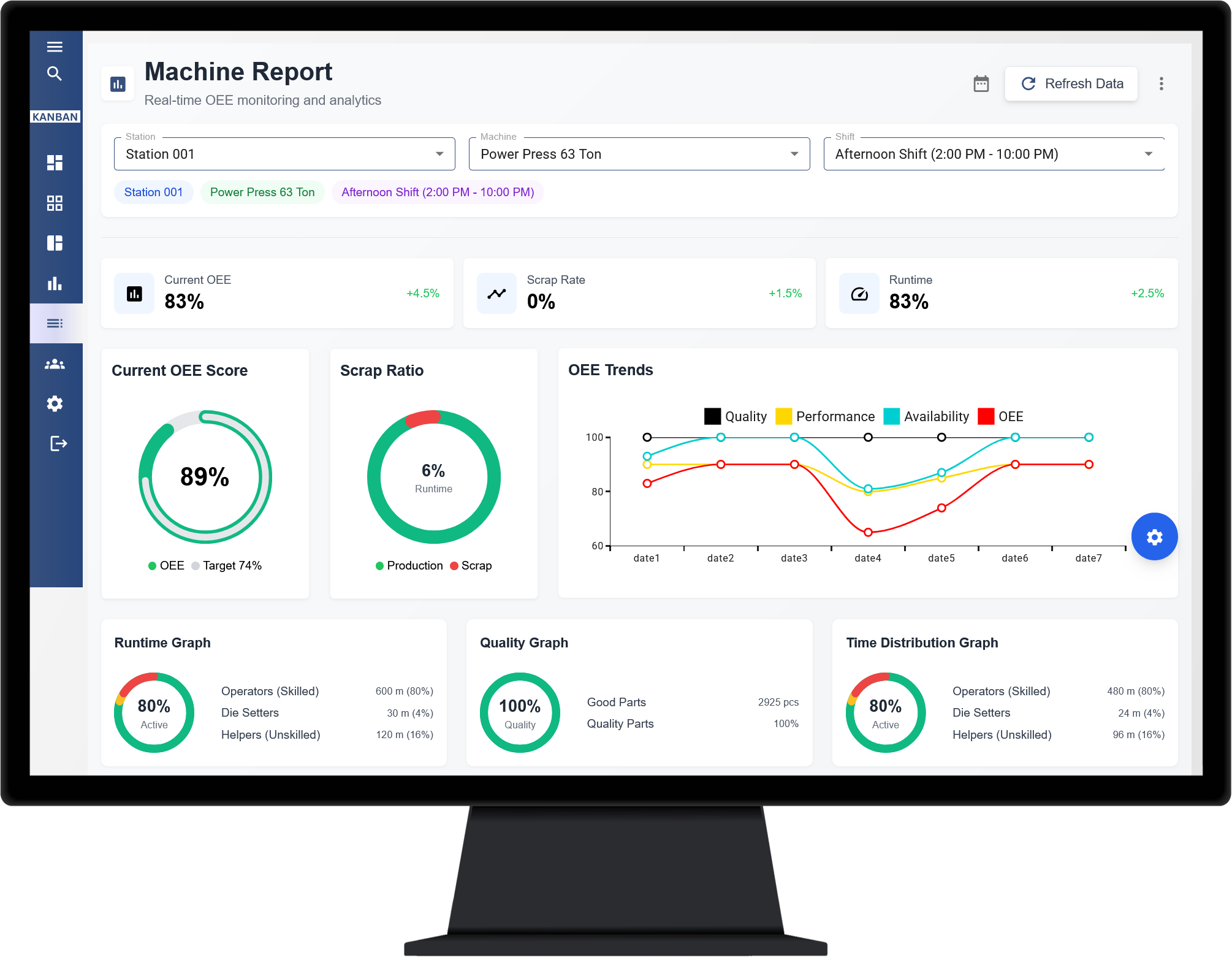

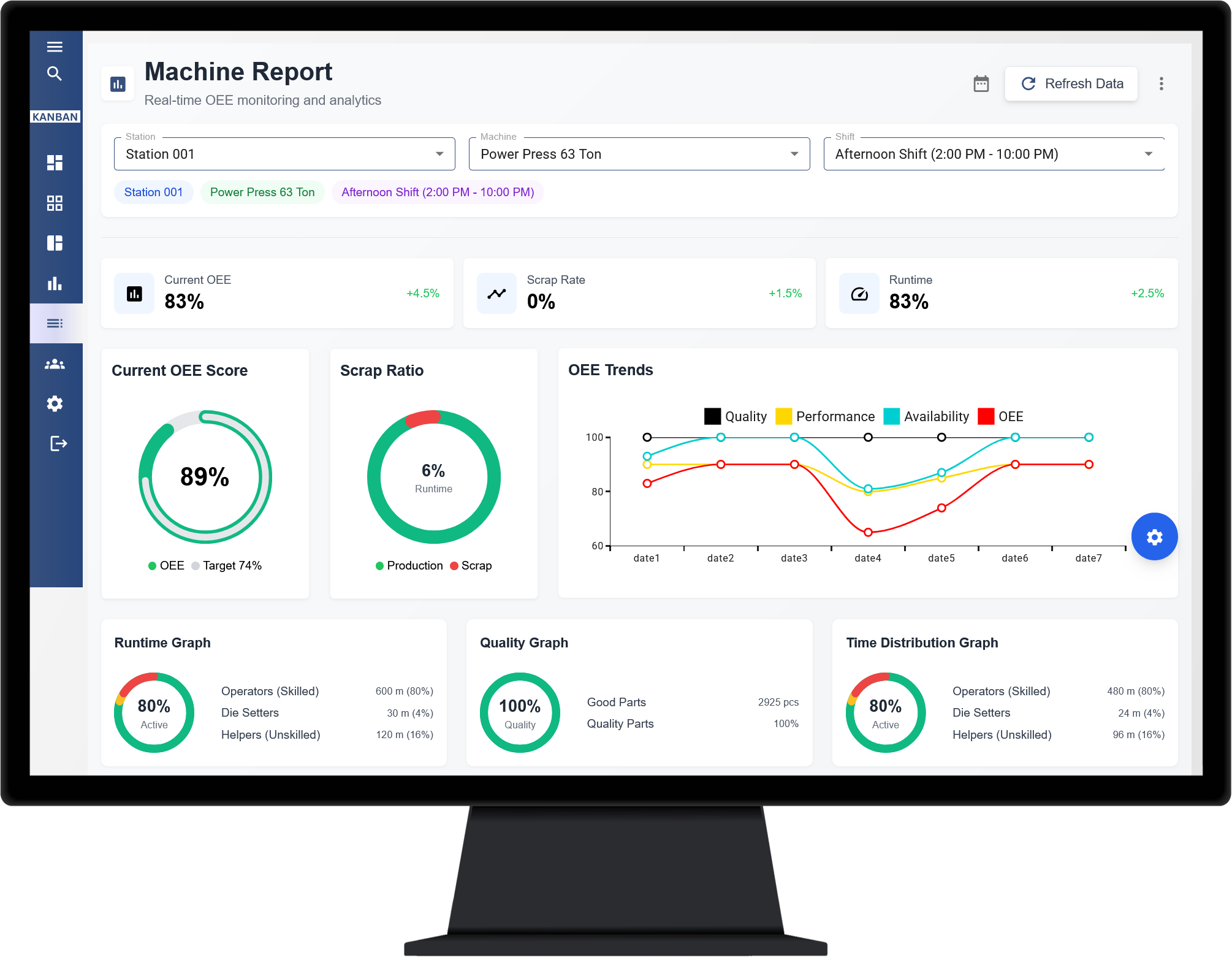

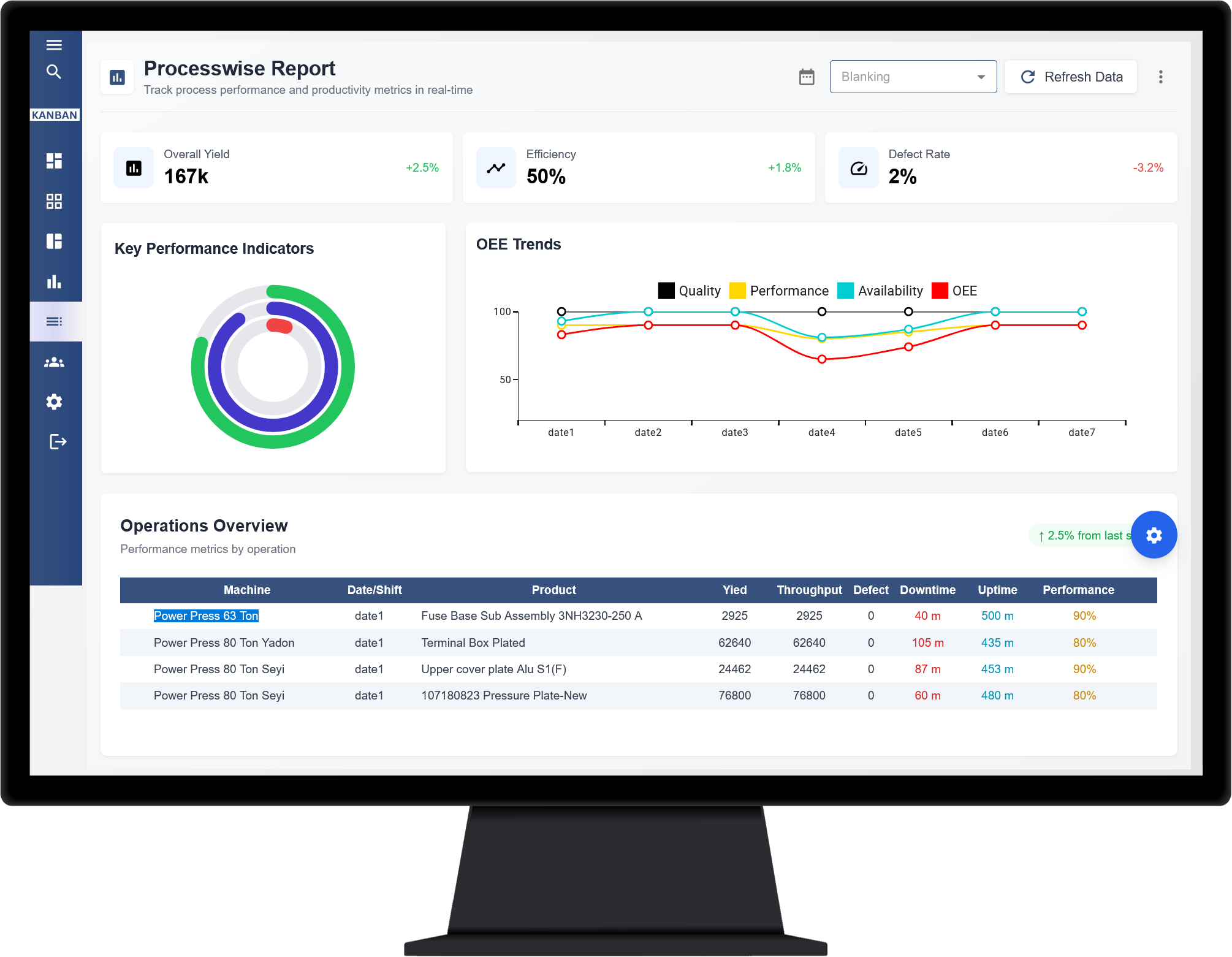

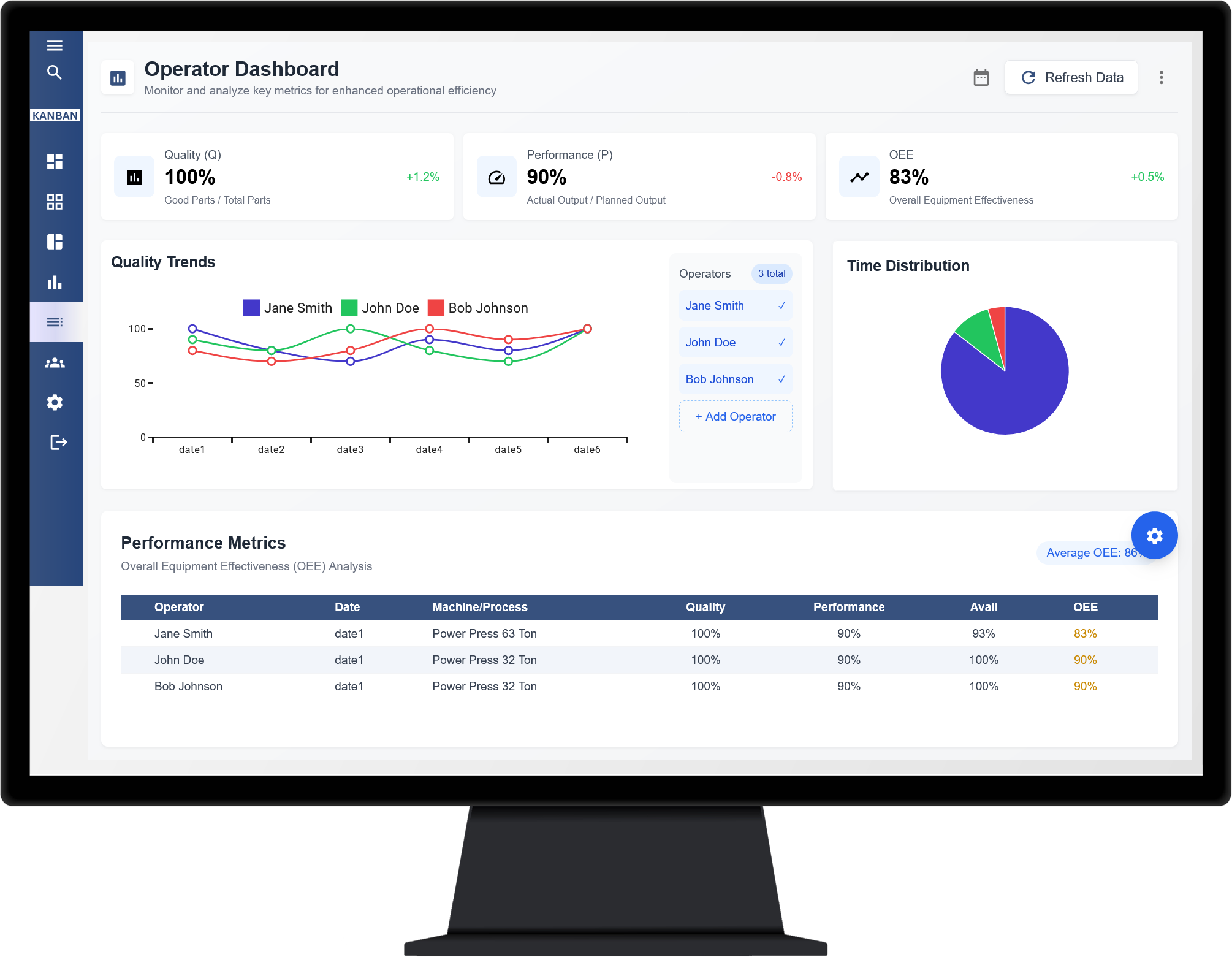

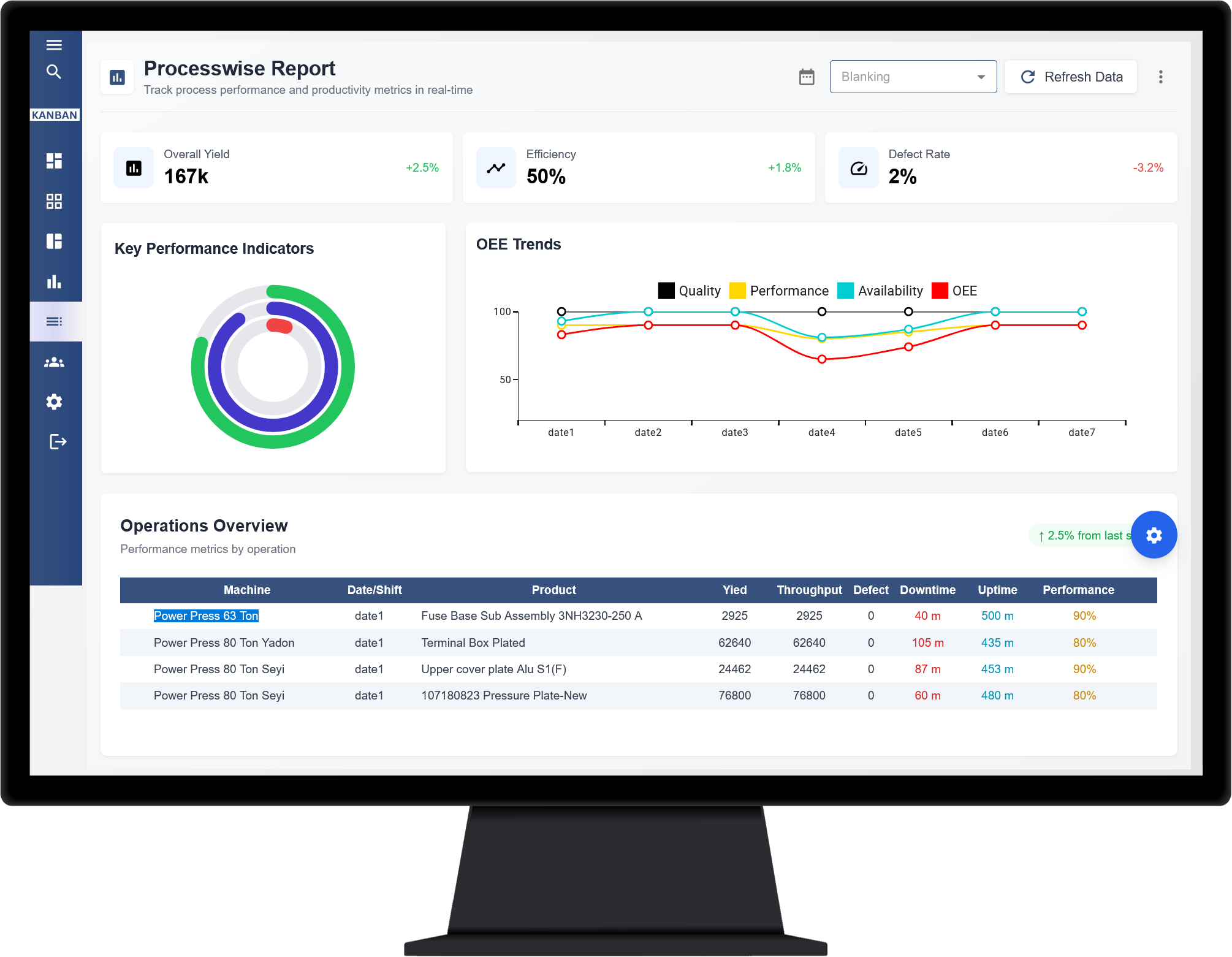

- Live Dashboard: Get an at-a-glance view of real-time production performance.

- Automated Data Collection: Eliminate manual tracking errors with automated OEE calculations.

- Customisable Reports: Generate detailed reports on efficiency, downtime, and productivity trends.

- Predictive Maintenance: Identify potential equipment failures before they happen.

- Seamless Integration: Connect with existing ERP, MES, and IoT systems.

- Multi-Device Support: Access your OEE data from desktops, tablets, and mobile devices.

How Our Cloud OEE Software Works

Cloud OEE software works by collecting, storing, and visualising real-time data from machines and production lines, analysing it to identify inefficiencies and track key metrics, and ultimately enabling proactive steps to reduce downtime and improve overall equipment effectiveness (OEE).

- Monitor: Collect real-time machine data and visualise performance.

- Analyse: Identify inefficiencies and track OEE metrics.

- Optimise: Take proactive steps to reduce downtime and improve efficiency.

- Improve: Continuously refine production strategies for long-term success.

Industries We Serve

Overall Equipment Effectiveness (OEE) is a manufacturing metric that measures how efficiently and effectively production equipment is utilised, calculated as the product of availability, performance, and quality.

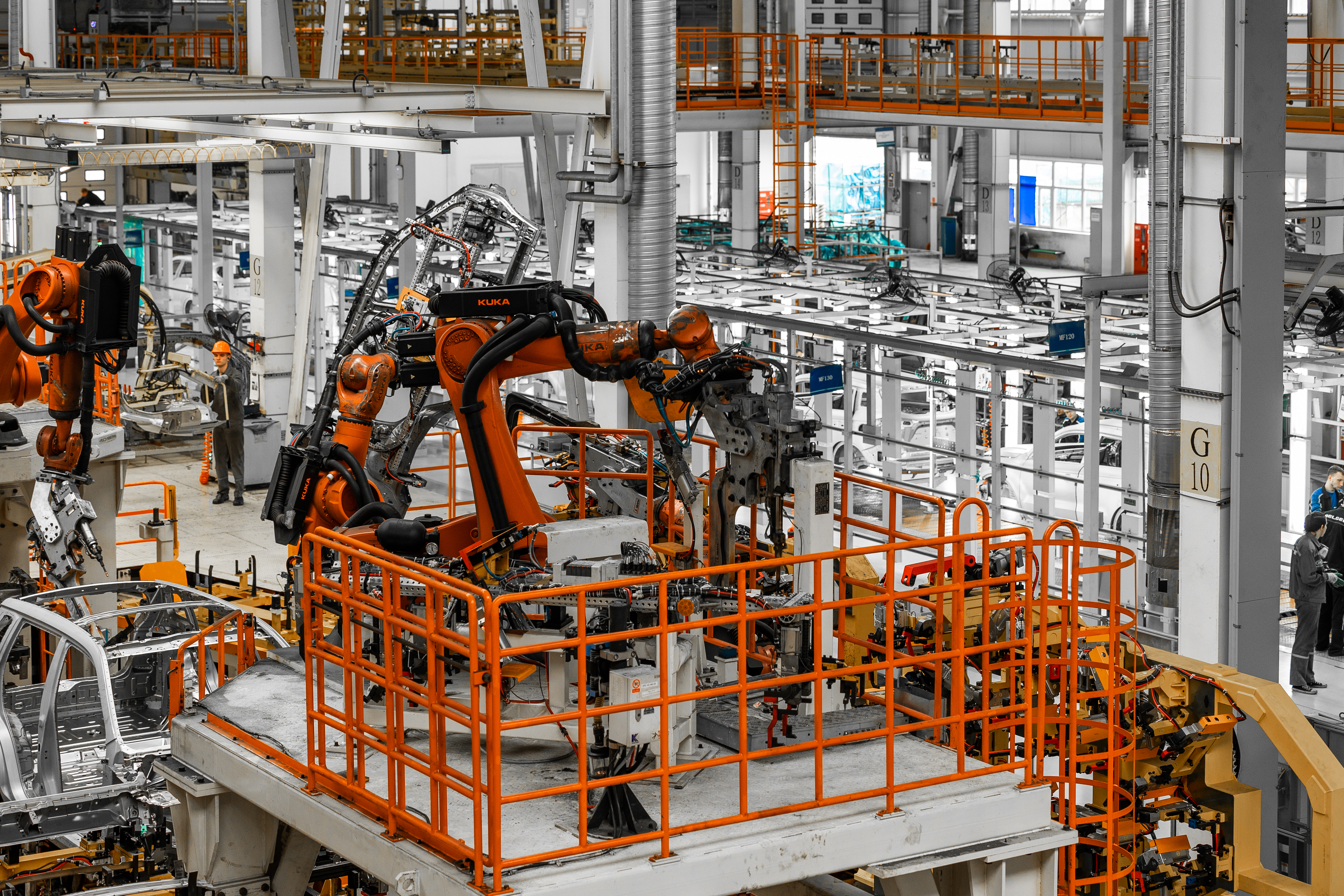

- Automotive Manufacturing: Optimise assembly lines and reduce defects.

- Food & Beverage Production: Ensure consistent quality and minimise downtime.

- Pharmaceutical Manufacturing: Maintain compliance while maximising productivity.

- Metal & Heavy Machinery: Improve uptime and reduce material waste.

- Electronics & Semiconductor: Achieve precision and efficiency in high-tech production.

How to Implement OEE?

- Define Objectives: Identify the goals of implementing OEE, such as reducing downtime, improving production efficiency, or enhancing quality.

- Choose the Right OEE Software: Select software that integrates with your existing production systems and provides real-time monitoring, reporting, and analytics.

- Collect Baseline Data: Measure current equipment performance, availability, and quality to establish a baseline for improvement.

- Configure Production Parameters: Set up production lines, equipment, shift schedules, and target cycle times in the software.

- Automate Data Collection: Use IoT sensors, PLCs, or manual inputs to collect real-time production data, including downtime, cycle time, and defects.

- Monitor Performance: Track OEE metrics continuously and identify the root causes of inefficiencies using real-time dashboards and reports.

- Take Action for Improvement: Analyse OEE reports, address production bottlenecks, optimise workflows, and implement continuous improvement initiatives.

- Review and Optimise: Conduct regular reviews, adjust targets, and implement best practices for sustainable improvements.

Why Use OEE Monitoring Software?

- Real-Time Performance Tracking: Monitor equipment availability, performance, and quality in real-time to identify inefficiencies instantly.

- Data-Driven Decision-Making: Generate detailed reports and analytics to make informed decisions and prioritise improvement efforts.

- Reduced Downtime: Identify recurring causes of unplanned downtime and implement preventive maintenance strategies.

- Improved Production Efficiency: Optimise cycle times, reduce bottlenecks, and increase production throughput.

- Enhanced Quality Control: Detect and address quality issues early to minimise defects and rework.

- Increased ROI: Improve overall production efficiency, leading to cost savings and higher profitability.

- Continuous Improvement: Support Lean and Six Sigma initiatives by providing insights into operational performance and areas for improvement.

How OEE Software Helps Your Manufacturing Operations

- Real-Time Performance Monitoring: OEE software provides real-time insights into equipment availability, performance, and quality, allowing manufacturers to identify bottlenecks and inefficiencies instantly.

- Improved Equipment Utilisation: By tracking machine uptime and downtime, OEE software helps optimise equipment usage, ensuring production lines run at maximum capacity.

- Collect Baseline Data: Measure current equipment performance, availability, and quality to establish a baseline for improvement.

- Accurate Production Insights: The software collects data on production rates, cycle times, and defect counts, enabling accurate performance analysis and better decision-making.

- Reduced Downtime: OEE software identifies the root causes of unplanned downtime, allowing maintenance teams to address issues quickly and implement preventive measures.

- Enhanced Quality Control: By monitoring defect rates and product quality, OEE software helps maintain high production standards while reducing rework and waste.

- Increased Productivity: With automated data collection and analysis, manufacturers can streamline workflows, optimise shift planning, and increase overall productivity.

- Data-Driven Decision-Making: OEE dashboards and reports provide actionable insights, empowering managers to make informed decisions for continuous improvement.

- Improved ROI: By enhancing efficiency, reducing waste, and improving output quality, OEE software drives higher profitability and faster return on investment.

The industry's preferred OEE Software Solution

- Comprehensive Performance Tracking: OEE software provides real-time visibility into equipment availability, performance, and quality, enabling manufacturers to identify and resolve inefficiencies quickly.

- Seamless System Integration: The software integrates easily with existing production systems, including ERP and MES platforms, ensuring smooth data flow and accurate performance insights.

- Advanced Analytics and Reporting: With detailed dashboards and customisable reports, OEE software empowers decision-makers with actionable insights for continuous improvement.

- Automated Data Collection: OEE software automates data gathering from machines and production lines, reducing manual effort and minimising the risk of errors.

- Downtime and Defect Analysis: The software identifies root causes of downtime and product defects, enabling maintenance teams to implement effective corrective measures.

- Customisable Alerts and Notifications: Real-time alerts notify operators and managers of performance issues, ensuring quick response and minimal disruption to production.

- Increased Productivity and ROI: By optimising equipment utilisation, reducing waste, and improving output quality, OEE software drives higher productivity and faster return on investment.

- Scalable and User-Friendly: Designed to support operations of all sizes, the software offers an intuitive interface and flexible deployment options to meet industry needs.

Six Big Losses in Overall Equipment Effectiveness (OEE)

- Unplanned Downtime: This includes unexpected equipment failures and breakdowns that halt production, impacting availability and reducing overall efficiency.

- Planned Downtime: Scheduled maintenance, tool changes, and setup adjustments fall under planned downtime, often longer than necessary without optimisation.

- Small Stops: Frequent minor stoppages due to misfeeds, sensor issues, or temporary jams reduce performance and interrupt production flow.

- Slow Cycles: Running equipment below the optimal speed, often due to worn-out tools, poor materials, or improper settings, affects overall performance.

- Production Defects: Defective products produced during normal operation lead to quality losses, increasing waste and rework time.

- Startup Losses: Quality issues during machine startup, such as warm-up periods, incorrect settings, or initial material defects, impact production efficiency.

Optimise Your Operations with OEE Software

Track equipment performance, reduce downtime, and boost efficiency with OEE software. Gain actionable insights to drive continuous improvement.

What is Cloud-Based OEE Software?

Cloud-based OEE (Overall Equipment Effectiveness) software is a software-as-a-service (SaaS) solution that monitors, analyses, and improves production efficiency by tracking key performance indicators (KPIs) and providing real-time insights into equipment performance.

What are the key features of Cloud-Based OEE Software?

Cloud-Based Overall Equipment Effectiveness (OEE) software helps manufacturers monitor performance, optimise workflows, and improve efficiency through real-time insights and automation.

1. Real-Time Performance Tracking

- Monitors production data, uptime, and downtime in real time.

- Provides live dashboards for instant visibility into operations.

2. Automated Data Collection

- Eliminates manual data entry, reducing errors and inefficiencies.

- Captures machine performance metrics, cycle times, and defect rates.

3. Predictive Maintenance

- Uses AI-driven analytics to predict equipment failures.

- Automates maintenance alerts to prevent unplanned downtime.

4. Customisable Dashboards

- Allows users to tailor dashboards based on specific KPIs.

- Enhances visibility and focus on critical performance metrics.

5. Seamless Integration

- Integrates with existing ERP, MES, and IoT systems.

- Ensures smooth data flow across multiple platforms.

6. Cloud Accessibility & Remote Monitoring

- Allows teams to access production data from any device, anywhere.

- Enables remote monitoring for quick decision-making.

7. Advanced Reporting & Analytics

- Generates detailed reports on production efficiency and quality.

- Helps identify trends and areas for continuous improvement.

8. Enhanced Quality Control

- Monitors defect rates and ensures consistent product quality.

- Facilitates root cause analysis for process optimisation.

How does Cloud-Based OEE Software improve manufacturing efficiency?

Cloud-Based Overall Equipment Effectiveness (OEE) software enhances manufacturing efficiency by providing real-time monitoring, reducing downtime, and optimising production workflows. It leverages automation, analytics, and remote accessibility to streamline operations.

1. Real-Time Performance Monitoring

- Tracks machine uptime, downtime, and production efficiency in real time.

- Provides instant visibility into key performance metrics.

2. Automated Data Collection

- Eliminates manual data entry, reducing errors and inefficiencies.

- Continuously captures machine performance, cycle times, and defects.

3. Predictive Maintenance & Reduced Downtime

- Uses AI-driven insights to predict equipment failures before they occur.

- Automates maintenance alerts to minimise unplanned downtime.

4. Optimised Production Scheduling

- Improves production planning with real-time workflow optimisation.

- Reduces bottlenecks and ensures on-time delivery.

5. Enhanced Quality Control

- Monitors defect rates and identifies root causes of quality issues.

- Improves product consistency through automated quality checks.

6. Cloud Accessibility & Remote Monitoring

- Allows managers to track production data from any location.

- Enables quick decision-making with mobile-friendly dashboards.

7. Data-Driven Continuous Improvement

- Provides actionable insights for ongoing process improvements.

- Helps teams implement lean manufacturing strategies.

Can Cloud-Based OEE Software help reduce downtime?

Yes, by monitoring equipment health and providing early warnings of potential failures, Cloud-Based OEE software can help prevent unplanned downtime and optimise maintenance schedules.

What benefits does Cloud-Based OEE Software offer to manufacturers?

Cloud-based Overall Equipment Effectiveness (OEE) software provides manufacturers with real-time insights, improved efficiency, and data-driven decision-making. It enhances production performance by tracking key metrics such as availability, performance, and quality.

1. Real-Time Performance Monitoring

- Tracks machine uptime, downtime, and production rates.

- Provides instant access to critical performance metrics.

2. Increased Equipment Efficiency

- Identifies inefficiencies and reduces machine idle time.

- Helps implement predictive maintenance to prevent breakdowns.

3. Data-Driven Decision Making

- Uses AI and analytics to optimise production processes.

- Enables better resource allocation based on real-time data.

4. Cost Reduction & Waste Minimisation

- Reduces operational costs by improving machine utilisation.

- Helps minimise defects and material waste.

5. Seamless Cloud Accessibility

- Allows teams to access data from any device, anywhere.

- Enables remote monitoring and quick response to issues.

6. Improved Compliance & Reporting

- Automates reporting for regulatory compliance and audits.

- Provides accurate and consistent production records.

7. Enhanced Productivity & Collaboration

- Centralises performance data, improving cross-team coordination.

- Helps teams collaborate on continuous improvement initiatives.

How does Cloud-Based OEE Software track machine performance?

Cloud-based Overall Equipment Effectiveness (OEE) software continuously monitors machine performance by collecting real-time data, analysing key metrics, and generating actionable insights. This enhances efficiency, reduces downtime, and improves overall productivity.

1. Real-Time Data Collection

- Captures live machine data through IoT sensors, PLCs, and SCADA systems.

- Measures availability, performance, and quality metrics without manual input.

2. Automatic Performance Monitoring

- Tracks machine uptime and downtime to identify bottlenecks and inefficiencies.

- Monitors cycle times, speed, and production output to optimise operations.

3. Live Dashboards & Reports

- Displays performance metrics using charts, graphs, and KPI dashboards.

- Provides a clear overview of machine efficiency, defects, and utilisation rates.

4. Predictive Maintenance & Alerts

- Uses AI and historical data to predict failures before they happen.

- Sends real-time alerts for maintenance needs, preventing costly breakdowns.

5. Integration with ERP & MES Systems

- Connects with Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES).

- Ensures seamless data sharing for better decision-making and workflow automation.

6. Cloud-Based Accessibility

- Allows users to monitor machine performance from any location, on any device.

- Supports remote troubleshooting and faster response times.

Is Cloud-Based OEE Software scalable for different production sizes?

Yes, it is scalable, allowing small, medium, and large manufacturers to use the software to monitor and improve equipment performance at any production scale.

How does Cloud-Based OEE Software enhance real-time data tracking?

Cloud-based Overall Equipment Effectiveness (OEE) software enhances real-time data tracking by providing instant visibility into production performance, minimising downtime, and enabling data-driven decision-making. Here’s how:

1. Live Equipment Monitoring

- Continuously tracks availability, performance, and quality metrics from machines and production lines.

- Provides operators and managers with instant access to key performance indicators (KPIs).

2. Instant Alerts & Notifications

- Sends real-time alerts for equipment malfunctions, downtime, or performance deviations.

- Enables quick response to potential issues, reducing production delays.

3. Cloud-Based Accessibility

- Allows authorised users to monitor OEE metrics from any device, anywhere.

- Improves collaboration between teams across multiple locations.

4. Seamless Integration with IoT & Sensors

- Connects with IoT-enabled devices, SCADA, MES, and ERP systems for automated data collection.

- Eliminates manual data entry errors and ensures accurate real-time tracking.

5. Data Visualisation Through Dashboards

- Displays real-time performance metrics using charts, graphs, and reports.

- Helps stakeholders quickly identify inefficiencies and trends.

6. Predictive Insights for Continuous Improvement

- Uses AI-driven analytics to predict equipment failures and performance fluctuations.

- Helps organisations implement proactive maintenance strategies to prevent downtime.

7. Automated Reporting & Data Accuracy

- Automatically logs real-time data for compliance and historical analysis.

- Ensures accurate, consistent, and reliable performance tracking.

Can Cloud-Based OEE Software integrate with other manufacturing systems?

Yes, it can integrate with other systems like MES (Manufacturing Execution Systems), ERP (Enterprise Resource Planning), and SCADA (Supervisory Control and Data Acquisition) to provide a comprehensive view of operations.

How does Cloud-Based OEE Software improve overall equipment effectiveness?

Cloud-based Overall Equipment Effectiveness (OEE) software enhances operational efficiency by providing real-time monitoring, data-driven insights, and automated reporting. It helps organisations maximise equipment performance, reduce downtime, and optimise production processes. Here’s how:

Key Benefits of Cloud-Based OEE Software

- Real-Time Performance Monitoring: Tracks availability, performance, and quality metrics instantly, enabling quick decision-making and corrective actions.

- Reduced Downtime with Predictive Maintenance: Uses historical data to predict equipment failures and triggers automated alerts to minimise unplanned downtime.

- Data-Driven Decision Making: Provides insights into inefficiencies, bottlenecks, and production losses to support continuous improvement.

- Automated Reporting & Compliance Tracking: Generates accurate reports instantly, eliminating manual errors and ensuring regulatory compliance.

- Scalability & Remote Accessibility: Enables access from any device, allowing organisations to monitor equipment effectiveness across multiple locations.

- Seamless Integration with Existing Systems: Integrates with ERP, MES, and IoT devices for a unified production monitoring system.

- Continuous Improvement & Performance Optimisation: Tracks OEE trends over time, helping businesses enhance equipment utilisation and reduce waste.

What are the cost-saving benefits of using Cloud-Based OEE Software?

Cloud-based OEE software offers cost savings by reducing downtime, optimising resource utilisation, enabling predictive maintenance, and facilitating the identification and elimination of inefficiencies in the manufacturing process.

How does Cloud-Based OEE Software help with predictive maintenance?

Cloud-Based Overall Equipment Effectiveness (OEE) software plays a crucial role in predictive maintenance by leveraging real-time data, analytics, and automation to detect potential issues before they lead to costly failures.

1. Real-Time Condition Monitoring

- Continuously tracks equipment performance, temperature, and vibration levels.

- Provides instant alerts when deviations indicate potential failures.

2. AI-Driven Predictive Analytics

- Uses machine learning algorithms to analyse historical data and predict breakdowns.

- Identifies patterns that signal potential equipment malfunctions.

3. Automated Maintenance Scheduling

- Generates automated maintenance alerts based on equipment performance trends.

- Reduces unplanned downtime by enabling proactive servicing.

4. Integration with IoT Sensors

- Connects with IoT-enabled machines to capture real-time operational data.

- Ensures accurate and continuous monitoring of critical components.

5. Data-Driven Decision-Making

- Provides actionable insights to optimise maintenance schedules.

- Helps reduce repair costs by addressing issues before they escalate.

6. Increased Equipment Lifespan

- Prevents excessive wear and tear by maintaining optimal operating conditions.

- Ensures machines function efficiently for a longer duration.

7. Reduced Downtime and Production Delays

- Minimises unexpected equipment failures that disrupt production.

- Enhances overall manufacturing efficiency and reliability.

8. Cloud Accessibility for Remote Monitoring

- Allows maintenance teams to track equipment health from any location.

- Supports agile decision-making through cloud-based dashboards.

What kind of data does Cloud-Based OEE Software collect?

Cloud-based OEE (Overall Equipment Effectiveness) software collects data on equipment availability, performance speed, quality output, production rates, downtime reasons, and maintenance schedules to help manufacturers improve efficiency and productivity.

Is Cloud-Based OEE Software easy to implement and use?

Yes, Cloud-Based OEE software is typically user-friendly with simple interfaces and easy integration with existing manufacturing systems. Implementation is often quick and seamless.

How can Cloud-Based OEE Software help in continuous improvement for manufacturing?

Cloud-Based Overall Equipment Effectiveness (OEE) software plays a vital role in driving continuous improvement in manufacturing by providing real-time insights, automating performance tracking, and enabling data-driven decision-making.

1. Real-Time Performance Monitoring

- Continuously tracks machine uptime, downtime, and efficiency.

- Provides live dashboards for instant visibility into key performance metrics.

2. Data-Driven Decision-Making

- Uses historical and real-time data to identify inefficiencies.

- Helps teams make informed decisions to improve productivity.

3. Root Cause Analysis & Problem Solving

- Identifies the root causes of machine failures and production bottlenecks.

- Provides actionable insights to prevent recurring issues.

4. Predictive Maintenance

- Utilises AI and analytics to predict equipment failures.

- Reduces unplanned downtime by scheduling proactive maintenance.

5. Continuous Performance Optimisation

- Provides trend analysis to monitor long-term process improvements.

- Helps manufacturers implement lean and Six Sigma strategies.

6. Customisable Dashboards & Reports

- Allows users to focus on specific KPIs relevant to their roles.

- Generates detailed reports to support continuous improvement initiatives.

7. Seamless Collaboration Across Teams

- Enables real-time data sharing between production, maintenance, and management.

- Improves communication and accountability in manufacturing operations.

8. Cloud Accessibility & Remote Monitoring

- Allows managers to track performance data from any location.

- Supports agile decision-making by providing instant access to insights.