What is an SQDC Board?

An SQDC board is a visual management tool used in manufacturing and other process-oriented environments to track and display key performance indicators (KPIs) related to Safety, Quality, Delivery, and Cost. It provides a quick and visual overview of how a process is operating based on these four crucial criteria.

- Safety: Promoting a secure workplace by reducing risks and preventing incidents.

- Quality: Ensuring products and processes meet defined standards with minimal defects.

- Delivery: Achieving reliable, on-time delivery to meet customer expectations.

- Cost: Controlling operational expenses and improving cost-efficiency across processes.

Safety

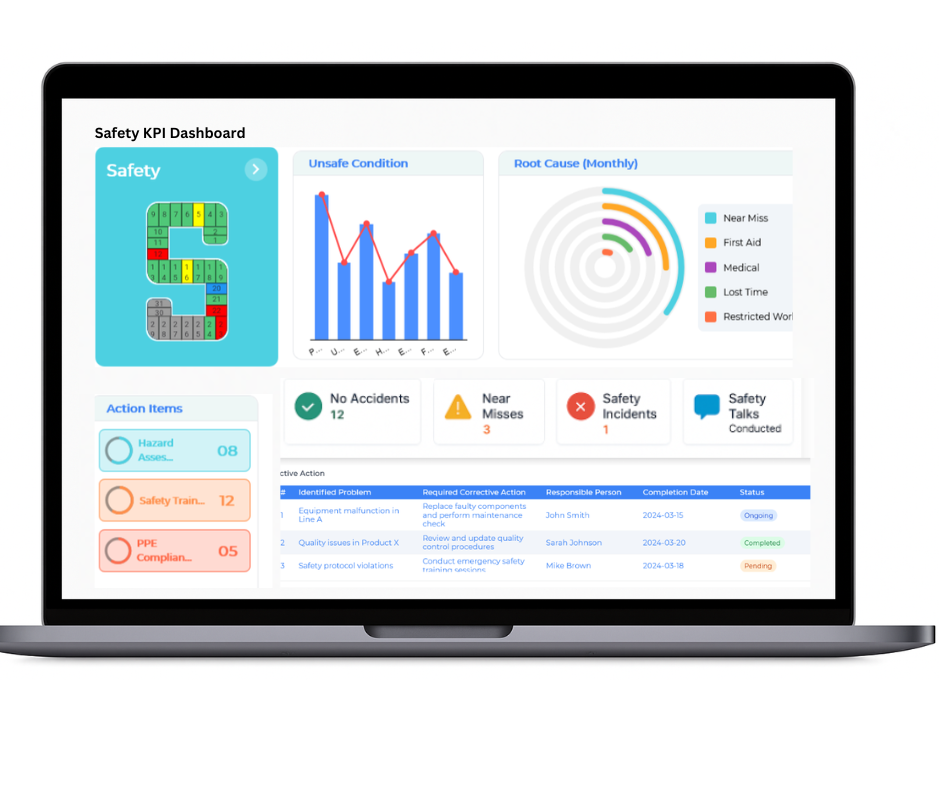

The Balanced Scorecard monitors on-site accidents and significant near-miss events to evaluate workplace safety. It offers valuable insights into current health and safety practices while highlighting key areas for improvement.

- Accidents Reported

- Near-Miss Events Logged

- Safety Incidents Recorded

- Safety Briefings Conducted

Quality

The Balanced Scorecard’s quality metrics enable organisations to assess defect levels in both incoming materials and in-house production, incorporating customer feedback. These indicators help ensure robust monitoring and effective management of quality assurance processes.

- Reported Workplace Accidents

- Failed Product Tests

- Rework and Corrections

- Non-Conformance Records

- Detected Product Defects

Delivery

The Balanced Scorecard evaluates every stage of the delivery process to ensure On Time In Full (OTIF) performance from suppliers through to end customers. It reviews warehouse efficiency and inventory movement, providing actionable insights to support strategic decisions by the management team.

- Number of Late Deliveries

Cost

Cost objectives and metrics are essential for controlling expenses and maximising profitability. The Balanced Scorecard helps manage cost performance by analysing financial data, offering valuable insights to optimise cost control and support efficient decision-making.

- Cost Reduction

- Expense Control

- Operational Efficiency

- Budget Adherence

- Resource Allocation

SQDC Board for Shift Management

- Real-Time Tracking: Continuously monitors Safety, Quality, Delivery, Inventory, and Productivity metrics throughout every shift.

- Enhanced Safety Oversight: Records accidents, near-misses, and safety audits to maintain a safe working environment.

- Shift-Based Quality Control: Tracks defects, rework, and compliance with quality standards during production.

- Delivery Performance Monitoring: Measures production output, On Time In Full (OTIF) performance, and identifies delays in delivery.

- Inventory Control: Monitors stock levels, reduces waste, and ensures effective inventory turnover within each shift.

- Workforce & Productivity Evaluation: Assesses employee attendance, engagement, training progress, and team collaboration.

- Rapid Problem Resolution: Enables fast identification and resolution of operational or performance-related issues.

What Is an SQDC Board?

An SQDC board is a powerful visual management tool commonly used in operational settings to track and monitor key performance indicators across four critical areas: Safety, Quality, Delivery, and Cost. This board helps teams stay aligned, focused, and on track with their goals, ensuring that all aspects of their performance are optimised for better results.

Key Components of an SQDC Board

The SQDC board typically displays the following categories:

- Safety: Tracking safety incidents and ensuring a culture of safety is maintained at all times.

- Quality: Monitoring product or service quality to maintain standards and prevent defects.

- Delivery: Measuring how well the organisation is meeting its delivery targets and timelines.

- Cost: Tracking costs and identifying areas for cost optimisation to improve profitability.

How Does an SQDC Board Work?

The board provides a real-time, visual representation of performance, usually with colourful charts, graphs, or indicators. Team members update it regularly with the latest data, enabling everyone to quickly identify areas of concern or improvement. This visual approach enhances communication, encourages accountability, and drives continuous improvement within the organisation.

Why Use an SQDC Board?

By using an SQDC board, organisations can focus on their most important operational metrics, ensuring that all teams are working towards shared objectives. It fosters a proactive approach to problem-solving and supports effective decision-making, ultimately improving overall efficiency and productivity.

How Does an SQDC Board Work?

An SQDC board is a visual management tool that tracks performance across four essential areas: Safety, Quality, Delivery, and Cost. It helps teams stay aligned with organisational goals and provides real-time insights into operational performance. Here's how it works:

Real-Time Updates and Visual Representation

The SQDC board is typically displayed in a central location where everyone can easily view it. It is updated regularly with the latest performance data, often using colour-coded indicators, graphs, and charts. This makes it easy for teams to track progress and identify any issues that need attention. For example, safety incidents, quality control issues, or missed delivery deadlines can be highlighted in red to indicate areas needing immediate focus.

Fosters Collaboration and Accountability

Each of the four areas—Safety, Quality, Delivery, and Cost—has its own section on the board. Teams update the board with relevant data, and this fosters collaboration by keeping everyone informed. It encourages accountability, as team members can see where improvements are needed and work together to address challenges.

Driving Continuous Improvement

The SQDC board is not just a tool for tracking performance; it also drives continuous improvement. By monitoring these key metrics regularly, teams can identify trends, spot problems early, and implement solutions more efficiently. This visual approach makes it easier to communicate priorities and ensure that everyone is working towards the same objectives.

Why is the SQDC Board Important for Performance Management?

The SQDC board plays a crucial role in performance management by offering a structured approach to tracking key metrics that drive business success. It focuses on four critical areas: Safety, Quality, Delivery, and Cost. This enables organisations to monitor their performance in real-time, identify issues quickly, and take proactive measures to improve overall operations.

Visual Clarity for Better Decision-Making

The SQDC board provides a clear, visual representation of performance data, making it easier for teams to understand how they are performing against key targets. With easily identifiable trends and issues, leaders can make more informed decisions that are based on real-time data rather than assumptions or outdated reports.

Encourages Accountability and Ownership

By displaying individual performance metrics on the board, it fosters a culture of accountability. Team members and leaders alike can see the direct impact of their actions and efforts. This sense of ownership encourages everyone to actively participate in meeting objectives and resolving any issues that arise.

Promotes Continuous Improvement

The SQDC board is designed not only for tracking but also for improving performance. Regular reviews of key metrics allow teams to spot areas for improvement, address problems early, and take corrective actions. This continuous feedback loop is essential for driving ongoing improvements and achieving long-term operational excellence.

Can SQDC Boards Be Used in Industries Other Than Manufacturing?

Yes, SQDC boards are highly versatile and can be effectively used in various industries beyond manufacturing. While they were initially designed for tracking performance in manufacturing environments, their core principles of monitoring safety, quality, delivery, and cost are applicable to many other sectors.

Adaptable for Different Industries

For example, in the healthcare industry, SQDC boards can be used to monitor patient safety, the quality of care, delivery times for medical supplies, and overall costs of treatment. In retail, they can track product availability, customer satisfaction, on-time delivery, and expenses associated with stock management. These metrics help businesses in any sector streamline operations and improve overall efficiency.

Improving Service Delivery

In service-based industries, SQDC boards can also play a critical role in performance management. By tracking service quality, safety measures (such as customer security or data protection), delivery timelines, and cost control, organisations can ensure they are meeting customer expectations while staying within budget.

Encouraging Accountability and Continuous Improvement

By visualising key performance metrics, SQDC boards encourage accountability across teams, regardless of the industry. They promote continuous improvement by making it easy to identify areas that need attention and by providing a real-time snapshot of operations.

How Frequently Should an SQDC Board Be Updated?

Updating an SQDC board regularly is crucial for maintaining its effectiveness and ensuring real-time visibility of key performance indicators. The frequency of updates depends on the nature of the operations, but it is generally recommended to review the board daily or weekly.

Daily Updates for Dynamic Environments

In fast-paced environments, such as manufacturing or logistics, it’s ideal to update the SQDC board daily. This ensures that any issues related to safety, quality, delivery, or cost are immediately identified and addressed. Daily updates help teams stay focused on short-term goals, track progress, and make adjustments as needed to keep operations running smoothly.

Weekly Updates for More Stable Environments

In industries or departments with less fluctuating operations, such as administrative functions or certain service-based sectors, weekly updates may be sufficient. Weekly updates allow teams to review trends, assess the overall performance of the previous week, and implement necessary changes. This time frame is also beneficial for analysing long-term improvements and setting new priorities.

Real-Time Adjustments

Regardless of the update frequency, it’s essential that the information on the SQDC board reflects the most current data. Real-time adjustments help maintain clarity and drive the right actions. Consistent updates, whether daily or weekly, ensure that teams stay aligned, aware of any challenges, and proactive in making improvements.

What Are the Benefits of Using an SQDC Board?

Implementing an SQDC board in your organisation brings numerous advantages, making it an invaluable tool for driving continuous improvement and enhancing operational performance. The SQDC board focuses on four key areas: Safety, Quality, Delivery, and Cost, with the aim of providing real-time visibility, improving communication, and fostering accountability across teams.

Improved Visibility and Communication

An SQDC board offers clear, visual tracking of key performance indicators, making it easy for everyone to see how the organisation is performing. It helps identify problems early, allowing teams to address issues before they escalate. By displaying key metrics, such as safety incidents, quality defects, on-time delivery, and cost variations, the board provides a transparent overview of operational performance.

Enhanced Team Engagement and Accountability

Using an SQDC board encourages collaboration and accountability within teams. Employees become more engaged in tracking performance and understanding how their contributions affect overall results. This visibility empowers them to take ownership of their work and make improvements where needed.

Focus on Continuous Improvement

The SQDC board promotes a culture of continuous improvement by regularly monitoring critical metrics and setting clear goals. It serves as a daily reminder to focus on safety, quality, delivery, and cost management, which leads to better decision-making, problem-solving, and overall operational excellence.

In summary, an SQDC board drives improvement through visibility, engagement, and a strong focus on performance, making it an essential tool for any organisation looking to enhance efficiency and foster a culture of continuous improvement.

How Does the Safety Section of the SQDC Board Function?

The Safety section of an SQDC board plays a critical role in fostering a safe working environment by monitoring and addressing safety-related issues in real-time. It helps organisations prioritise safety, reduce workplace accidents, and promote a culture of well-being for all employees. This section typically displays key safety metrics, such as accident rates, near misses, safety audits, and other important indicators.

Tracking Safety Metrics

By displaying safety metrics clearly, the Safety section provides a visual representation of the current safety performance. This could include metrics like the number of workplace incidents, injuries, or safety compliance rates. This real-time data helps teams identify areas for improvement and take immediate action to prevent accidents. It encourages everyone in the organisation to stay alert and proactive about safety.

Promoting Accountability

The Safety section ensures that safety is not just a managerial concern but a shared responsibility across all levels of the organisation. It holds employees accountable for reporting hazards, following safety protocols, and addressing unsafe practices. The visibility of safety metrics motivates individuals and teams to uphold safety standards, helping to reduce risk and improve overall workplace safety.

Facilitating Continuous Improvement

With the Safety section on the SQDC board, organisations can continuously track improvements or setbacks in their safety performance. By identifying trends and patterns, teams can make informed decisions to implement corrective actions, enhancing safety measures and reducing incidents over time. This creates a dynamic feedback loop that supports ongoing safety improvements.

What Does the Quality Section of the SQDC Board Measure?

The Quality section of an SQDC board is designed to track and improve the overall quality performance of an organisation’s processes, products, or services. By visually presenting key quality metrics, this section ensures that quality is a continuous focus, driving improvements and meeting customer expectations. The main purpose is to monitor the standards of output and identify areas for improvement.

Monitoring Product and Service Quality

The Quality section measures various quality-related metrics, including defect rates, rework levels, customer complaints, and product returns. These metrics help to highlight any gaps in the production or service processes and allow teams to respond quickly to issues. For example, a rise in product defects or an increase in customer complaints can trigger immediate corrective actions to prevent further issues.

Ensuring Compliance with Standards

Another crucial aspect the Quality section tracks is the adherence to internal and external quality standards. This includes compliance with industry regulations, company-specific quality benchmarks, and customer requirements. By keeping track of these standards, organisations can maintain consistency and reliability in their offerings, helping to build customer trust and loyalty.

Driving Continuous Improvement

With real-time data, the Quality section of the SQDC board helps identify patterns or recurring issues that may need attention. This insight drives continuous improvement initiatives by allowing teams to evaluate root causes and implement preventive measures. Whether it's streamlining production processes or refining customer service practices, the Quality section supports ongoing efforts to enhance overall performance and deliver higher-quality results.

What Does the Delivery Section of the SQDC Board Track?

The Delivery section of the SQDC board plays a vital role in ensuring that an organisation meets its delivery targets and customer expectations. This section focuses on tracking key performance indicators (KPIs) related to the timeliness and reliability of product or service delivery. By visualising these metrics, it helps teams stay on track and addresses any delivery-related challenges promptly.

Tracking On-Time Deliveries

The main focus of the Delivery section is the on-time delivery rate. This measures the percentage of orders or services that are completed and delivered to customers by the promised date. A high on-time delivery rate indicates efficient operations and satisfied customers, while delays can highlight issues that need to be addressed, such as production bottlenecks or supply chain disruptions.

Identifying Delivery Delays

In addition to monitoring on-time deliveries, this section tracks any delays that occur. It provides insight into the reasons behind late deliveries, such as unexpected breakdowns, staffing shortages, or supply chain issues. By identifying these root causes, teams can take proactive measures to prevent future delays and improve overall delivery performance.

Ensuring Consistency and Reliability

Reliability is another critical aspect of the Delivery section. It tracks consistency in meeting delivery deadlines over time, helping to ensure that customers can trust the organisation’s ability to deliver as promised. This consistency not only boosts customer satisfaction but also builds long-term loyalty and trust in the organisation's services or products.

How Does the Cost Section of the SQDC Board Function?

The Cost section of the SQDC board is a crucial component for managing and optimising operational costs. By tracking financial performance, this section helps organisations identify inefficiencies and control spending, ultimately driving profitability and improving financial health. It offers a clear view of cost-related metrics, enabling informed decision-making and the ability to take corrective actions when needed.

Monitoring Cost Performance

At its core, the Cost section focuses on monitoring key cost indicators, such as production costs, labour costs, material expenses, and overheads. By regularly reviewing these figures, teams can quickly spot areas where costs are exceeding expectations or budget limits. This allows management to act swiftly to identify and rectify the cause, ensuring that operations stay within financial targets.

Identifying Cost Reduction Opportunities

The Cost section also highlights opportunities for cost reduction. For instance, if material waste or excessive overtime is driving up costs, this can be pinpointed and addressed. Teams can implement process improvements, optimise resource allocation, or renegotiate supplier contracts to achieve cost savings without compromising quality or delivery.

Driving Cost Efficiency

By keeping a close eye on cost metrics, the SQDC board encourages a culture of cost-consciousness. Employees and managers alike are motivated to find ways to work more efficiently, reduce waste, and improve processes. This not only helps control costs but also contributes to overall organisational growth and competitiveness in the market.

What Tools Can Be Used with an SQDC Board?

Using the right tools alongside an SQDC board can greatly enhance its effectiveness and streamline operations. These tools help in tracking, analysing, and improving the key metrics of Safety, Quality, Delivery, Cost, and Leadership. By combining traditional methods with digital solutions, organisations can optimise their performance and achieve continuous improvement.

Digital Dashboards and Software

Digital dashboards and software tools are increasingly popular for SQDC boards. These platforms allow real-time data to be updated automatically, providing instant insights into performance metrics. With visual representations such as graphs, charts, and heat maps, teams can quickly assess progress, identify issues, and make data-driven decisions. Digital tools also enable easier collaboration across departments, especially in remote or multi-location teams.

Kanban Systems

Kanban boards are another valuable tool that can complement the SQDC board. By providing a visual representation of task flow, Kanban systems help teams manage workloads, reduce bottlenecks, and improve efficiency. Kanban’s simplicity and flexibility make it an ideal tool for tracking tasks related to safety, quality control, and cost management.

Root Cause Analysis Tools

To identify and address underlying issues in performance, organisations can use root cause analysis tools such as the Fishbone Diagram (Ishikawa) or the 5 Whys. These tools help teams drill down to the core problems affecting safety, quality, or cost and take corrective action more effectively.

Spreadsheets and Reporting Tools

Spreadsheets and reporting tools are useful for tracking data over time. They allow teams to input and analyse performance trends, providing a historical view that aids in forecasting and planning. Spreadsheets can also be used to generate reports that summarise SQDC data for stakeholders and decision-makers.

How Does the SQDC Board Drive Continuous Improvement?

The SQDC board is a powerful tool for driving continuous improvement within organisations by providing a clear, visual representation of key performance indicators (KPIs) across four critical areas: Safety, Quality, Delivery, and Cost. By consistently monitoring and updating these areas, teams can identify trends, address challenges, and work towards achieving operational excellence.

Promoting Accountability and Transparency

One of the primary ways the SQDC board drives improvement is through increased accountability. By visually tracking the progress of each metric, team members can easily see where performance is excelling or lacking. This transparency encourages ownership, with each team member taking responsibility for their contributions to the overall goals, leading to a culture of continuous improvement.

Real-Time Problem Solving

The real-time nature of an SQDC board allows teams to address issues quickly. If a problem is detected in safety, quality, delivery, or cost, immediate actions can be taken to resolve it. This proactive approach ensures that problems don’t fester and allows teams to continuously refine processes to improve performance.

Fostering Collaboration and Communication

The SQDC board also fosters collaboration by providing a centralised space where teams can discuss challenges, share solutions, and celebrate successes. Regular meetings and updates encourage open communication, leading to collective problem-solving and continuous improvement across departments.

In summary, the SQDC board is an essential tool for driving continuous improvement by enhancing accountability, enabling real-time problem-solving, and promoting collaboration within teams.

Can Digital SQDC Boards Improve Performance Tracking?

Digital SQDC boards are revolutionising the way organisations track and manage their performance. By transitioning from traditional physical boards to digital platforms, companies can unlock numerous advantages that enhance tracking and decision-making processes. These digital boards are designed to simplify data management, offering real-time updates and improved accessibility.

Real-Time Data Access

One of the key benefits of digital SQDC boards is the ability to access real-time data from any location. Whether you’re on the shop floor, in the office, or working remotely, team members can monitor progress and identify issues instantly. This instant access ensures that any problems, such as delays or quality issues, are addressed before they escalate, helping to maintain operational efficiency.

Better Collaboration and Communication

Digital SQDC boards improve team collaboration by allowing multiple users to view and update the board simultaneously. This fosters a more communicative environment, where team members can easily share updates, discuss challenges, and adjust strategies. Centralising data in one digital platform also reduces the risk of miscommunication, ensuring everyone is aligned on performance goals.

Automated Reporting and Analysis

Unlike manual boards, digital systems can automate reporting and analysis. With built-in tools for tracking performance, teams can easily generate reports, identify trends, and make data-driven decisions. This level of automation saves time, reduces errors, and provides a clearer overview of performance over time.

What Are Best Practices for Using an SQDC Board Effectively?

Using an SQDC board effectively is key to improving operational efficiency and driving continuous improvement. By following best practices, organisations can ensure that the board becomes a valuable tool for monitoring performance and achieving strategic goals. Here are some top practices to get the most out of your SQDC board.

1. Regularly Update the Board

To maintain an accurate reflection of your operations, it's essential to update the SQDC board regularly. Daily or weekly updates help track progress in real-time, identify any issues early, and ensure all team members are on the same page. Make it a habit to review and refresh the data consistently.

2. Engage the Entire Team

For an SQDC board to be effective, it must involve the entire team. Encourage everyone to actively participate by adding data, reviewing performance, and discussing potential solutions. This fosters a culture of collaboration and accountability, leading to better decision-making and problem-solving.

3. Use Clear Visuals

Clarity is crucial when setting up an SQDC board. Use easy-to-understand visuals, such as colour-coded charts and graphs, to represent the data. This makes it quicker for team members to grasp important information at a glance, helping them make informed decisions without getting bogged down in complex details.

4. Focus on Continuous Improvement

Ensure that the SQDC board is used not just for tracking, but for driving continuous improvement. Set aside time to analyse trends, identify recurring issues, and take corrective actions. Encourage a mindset of constant evaluation and improvement to achieve long-term operational excellence.

By following these best practices, organisations can maximise the effectiveness of their SQDC boards, enhancing team collaboration, streamlining operations, and driving continuous improvement.

Benefits of the SQDC Board

- Visual Management: The SQDC board provides a visual representation of key performance indicators, making it easy for teams to track progress and identify areas for improvement.

- Transparency: By displaying key metrics on a visible board, the SQDC board promotes transparency and accountability within an organisation.

- Continuous Improvement: The SQDC board encourages a culture of continuous improvement by providing a framework for monitoring and optimising processes.

- Employee Engagement: By tracking metrics related to employee morale, the SQDC board helps organisations identify factors that affect employee satisfaction and engagement.

- Operational Efficiency: By monitoring metrics related to safety, quality, delivery, and cost, the SQDC board helps organisations identify and eliminate waste, streamline processes, and improve overall operational efficiency.