The Gemba Walk, originating from the Japanese word "Gemba" which translates to "the real place" or "where the action happens," is a management practice that emphasises firsthand observation of work processes in their actual environment. It's a fundamental concept in lean manufacturing and management philosophy, focusing on understanding and improving processes by engaging directly with the people involved and the work being done.

Gemba Walk involves leaders or managers going to the place where work is done, whether it's a factory floor, office space, hospital ward, or any other work environment. The purpose is to observe operations, ask questions, listen to concerns, and gain insights into how work is performed and how processes can be optimised for efficiency, quality, and safety.

Key Elements of a Gemba Walk:

Observation: During a Gemba Walk, leaders observe work processes, workflows, and interactions between employees and systems. They pay close attention to details such as workflow patterns, movement of materials, equipment usage, and employee behaviors. Observations are made without preconceived notions, allowing leaders to see the reality of operation.

Engagement: Gemba Walks are not passive activities. Leaders actively engage with frontline employees, supervisors, and other staff members to understand their perspectives, challenges, and ideas for improvement. By fostering open communication and collaboration, leaders create an environment where employees feel valued and empowered to contribute their insights.

Problem-Solving Gemba Walks serve as opportunities to identify problems or inefficiencies in work processes. Leaders use their observations and discussions with employees to identify root causes of issues and brainstorm potential solutions. By addressing problems at the source and involving frontline employees in problem-solving, organisations can implement more effective and sustainable solutions.

Continuous Improvement: The Gemba Walk is a cornerstone of the continuous improvement philosophy, known as Kaizen. Through regular Gemba Walks, leaders demonstrate their commitment to continuous improvement and encourage a culture of experimentation, learning, and adaptation. By seeking incremental improvements over time, organisations can drive significant gains in productivity, quality, and customer satisfaction.

Respect for People: A fundamental principle of the Gemba Walk is respect for people. Leaders show respect for frontline employees by actively listening to their concerns, involving them in decision-making processes, and recognising their contributions. This fosters trust, loyalty, and commitment among employees, leading to higher morale and better performance.

Gemba Walk Checklist

1. Observe the Work Environment: Is the workplace clean, organised, and safe? Are there any hazards or obstacles that need addressing?

2. Engage with Employees: Talk to employees about their work and any challenges they face. Are they experiencing any issues or frustrations?

3. Review Processes: Are work processes being followed? Is there any waste or inefficiency in the system? Look for opportunities to improve.

4. Identify Bottlenecks: Are there any bottlenecks or delays in the process? If so, where are they occurring, and what might be causing them?

5. Check Equipment and Tools: Are the tools and equipment being used effectively? Are there any maintenance issues or gaps in equipment functionality?

6. Review Standards and Documentation: Are all procedures, standards, and work instructions clearly documented and followed by the team?

7. Observe Team Collaboration: Are team members working well together? Are there any communication breakdowns or opportunities to improve teamwork?

8. Focus on Continuous Improvement: Look for opportunities to implement Kaizen (continuous improvement) practices and encourage feedback from employees on potential improvements.

9. Check for Customer Impact: Consider how the work being observed affects the customer. Are there any quality issues, delays, or inefficiencies that might impact the customer experience?

10. Record Observations and Actions: Take notes on what you observed and discuss potential improvements. Create an action plan for follow-up.

Benefits of Gemba Walks:

Better Understanding of Processes: Gemba Walks provide leaders with firsthand knowledge of how work is performed, allowing them to gain insights into process inefficiencies, bottlenecks, and waste.

Improved Communication: By engaging with frontline employees, leaders foster open communication and collaboration, breaking down silos and improving teamwork across departments.

Faster Problem Resolution: Gemba Walks help identify problems early and address them promptly, preventing issues from escalating and minimising disruptions to operations.

Empowered Employees: Involving employees in problem-solving and decision-making processes empowers them to take ownership of their work and contribute to continuous improvement initiatives.

Cultural Transformation Gemba Walks support the development of a culture of continuous improvement, where all employees are encouraged to identify problems, propose solutions, and strive for excellence in their work.

Gemba Walk is a powerful management practice that promotes understanding, collaboration, and continuous improvement within organisations. By going to the "gemba," leaders gain valuable insights into operations, engage with frontline employees, and drive positive changes that enhance efficiency, quality, and overall performance.

What Is a Gemba Walk? Understanding the Basics of This Lean Tool

A Gemba Walk is a key practice in lean manufacturing, where leaders or managers go to the "Gemba" – the place where work is done. The term "Gemba" is a Japanese word meaning "the real place," and in a business context, it refers to the shop floor or work area. The purpose of a Gemba Walk is to observe operations, engage with employees, and identify areas for improvement.

Why Is a Gemba Walk Important?

One of the main principles behind a Gemba Walk is that leaders gain a deeper understanding of processes by being physically present. Instead of relying on reports or second-hand information, they can see firsthand how work is being carried out. This allows them to identify inefficiencies, safety issues, or any obstacles that may be hindering performance.

How Does a Gemba Walk Work?

During a Gemba Walk, leaders observe processes in real time, ask questions, and interact with employees. It’s not just about finding problems, but also about listening to employees’ insights and feedback. These walks provide opportunities to foster a culture of continuous improvement and help drive operational efficiency. Importantly, a Gemba Walk is not a time for criticism but rather a chance to learn and improve together.

Benefits of a Gemba Walk

Gemba Walks build stronger relationships between management and staff, improve communication, and highlight areas for process improvements. They also encourage employee engagement and create a sense of ownership in the improvement process. By making these walks a regular practice, businesses can enhance productivity and create a more streamlined operation.

The Purpose of a Gemba Walk: Insights into Process Improvement

A Gemba Walk is a vital practice in continuous improvement, where managers and leaders go to the 'Gemba' – the location where work takes place. The goal of a Gemba Walk is to observe, understand, and engage with employees to identify areas for process improvement. By being physically present, leaders can gain a clearer understanding of the challenges and opportunities within their operations.

Key Purpose of a Gemba Walk

The primary purpose of a Gemba Walk is to allow leaders to see the reality of work in action. It provides an opportunity to spot inefficiencies, safety concerns, or process bottlenecks that may not be visible through reports or meetings. Observing the actual flow of work helps leaders make informed decisions on how to improve productivity and streamline operations.

Engaging with Employees

During a Gemba Walk, leaders engage with team members to gather valuable insights. This fosters a culture of open communication, where employees feel empowered to share their ideas for improvement. It also builds trust between managers and staff, creating a collaborative environment focused on problem-solving.

Impact on Process Improvement

By identifying areas for improvement directly on the shop floor, Gemba Walks play a crucial role in driving continuous improvement. They help uncover small issues before they become major problems, leading to increased efficiency, higher quality, and better overall performance. Regular Gemba Walks ensure that the business remains agile and responsive to changing conditions.

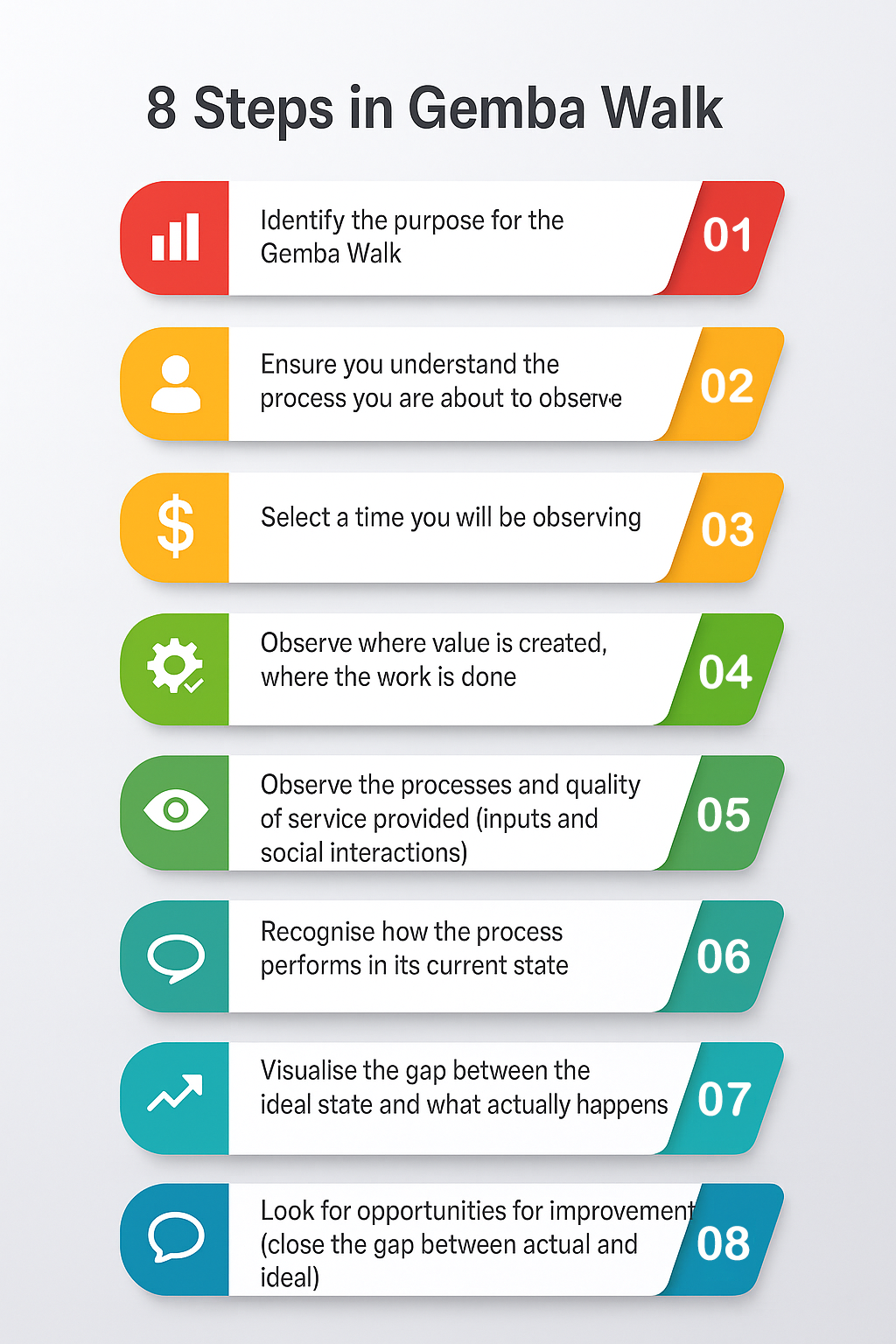

8 Steps in Gemba Walk

How Gemba Walks Drive Continuous Improvement in the Workplace

Gemba Walks are a fundamental part of the Lean methodology, enabling managers to directly observe work processes and engage with employees. By walking the Gemba, or "the real place," managers can identify inefficiencies and areas for improvement that may not be visible in reports or meetings. This hands-on approach plays a crucial role in driving continuous improvement in the workplace.

Identifying Issues at the Source

The primary benefit of a Gemba Walk is that it allows leaders to see firsthand how work is being performed. By being on the shop floor or in the workplace, managers can spot bottlenecks, delays, or safety concerns that might otherwise go unnoticed. This direct observation enables them to take immediate action to address issues, preventing them from escalating into larger problems.

Fostering Employee Engagement

Gemba Walks also promote a culture of communication and collaboration. During these walks, managers engage with team members, encouraging open discussions about challenges and potential improvements. This fosters an environment where employees feel valued, as their input is taken into account in the decision-making process. Engaged employees are more likely to contribute to continuous improvement efforts.

Driving Continuous Improvement

By regularly conducting Gemba Walks, managers can track progress, identify trends, and make informed decisions about process improvements. This ongoing cycle of observation, feedback, and action ensures that businesses remain agile and responsive, ultimately enhancing overall efficiency and performance. Gemba Walks are a powerful tool for driving continuous improvement and fostering a culture of excellence in the workplace.

The Role of Gemba Walks in Identifying Waste and Inefficiencies

Gemba Walks are a key tool in Lean management, offering a direct and effective approach to spotting waste and inefficiencies in the workplace. The term "Gemba" refers to the real place where work happens, and these walks involve managers or leaders observing operations firsthand. This active involvement is crucial for identifying problems that may not be apparent through reports or meetings.

Spotting Waste on the Shop Floor

During a Gemba Walk, leaders have the opportunity to observe processes as they unfold. They can identify forms of waste, such as waiting time, overproduction, unnecessary movement, and defects. By being on the frontlines, managers can spot areas where work is not flowing smoothly, uncovering issues that could otherwise remain hidden. This immediate visibility helps address inefficiencies before they impact productivity.

Improving Processes Through Direct Observation

Gemba Walks provide a unique opportunity for managers to interact with frontline employees and gain insights into the challenges they face. By observing the work in real-time, leaders can better understand the root causes of waste and inefficiencies. This hands-on approach is more effective than relying solely on data or reports, allowing managers to make more informed decisions about process improvements.

Fostering a Culture of Continuous Improvement

By regularly conducting Gemba Walks, businesses can build a culture of continuous improvement. These walks not only help identify waste but also engage employees in the process of finding solutions. Employees feel empowered when their feedback is valued, leading to more proactive efforts to eliminate waste and optimise workflows. Ultimately, Gemba Walks drive efficiency and create a more productive work environment.

Gemba Walk vs Traditional Audits: What's the Difference?

Gemba Walks and traditional audits are both important tools used in businesses to identify areas for improvement. However, they differ in approach, focus, and the way they engage employees. Understanding these differences can help organisations choose the right method to enhance their operations.

Gemba Walk: A Hands-On Approach

A Gemba Walk involves managers or leaders physically visiting the workplace to observe operations in real-time. This allows them to see processes as they unfold, engage directly with employees, and identify issues such as inefficiencies, waste, or bottlenecks. The focus is on active participation and continuous improvement, with leaders gaining insights through direct observation. Gemba Walks foster a culture of open communication and collaboration between management and staff.

Traditional Audits: A Formal, Report-Based Process

Traditional audits, on the other hand, are typically more formal and data-driven. Auditors review records, policies, and procedures to assess compliance, performance, or financial accuracy. These audits are usually conducted periodically, with findings presented in a report format. While audits are useful for identifying discrepancies or compliance issues, they often lack the hands-on, real-time approach that Gemba Walks offer.

Key Differences

The main difference between Gemba Walks and traditional audits lies in the method of assessment. Gemba Walks focus on live, interactive observation, providing immediate insights into the current state of operations. Traditional audits are more retrospective and rely heavily on documented data and reports. While both are valuable, Gemba Walks offer a more dynamic and engaging way to address issues and drive continuous improvement.

How to Conduct a Successful Gemba Walk: A Step-by-Step Guide

A Gemba Walk is a crucial part of continuous improvement in lean management. It involves managers or team leaders visiting the shop floor to observe processes, engage with employees, and identify areas for improvement. To conduct a successful Gemba Walk, follow these simple steps.

Step 1: Prepare and Set Clear Objectives

Before starting the walk, define clear objectives. What are you looking to achieve? Are you focusing on improving efficiency, reducing waste, or identifying process bottlenecks? Setting specific goals ensures the walk stays focused and effective.

Step 2: Observe and Engage

During the walk, focus on observing how processes are being carried out. Engage with employees by asking open-ended questions and encouraging them to share insights. The goal is to understand their challenges and suggestions for improvement.

Step 3: Take Notes and Record Observations

While on the shop floor, take detailed notes on what you observe. Record any issues, inefficiencies, or areas where processes can be enhanced. This documentation will be valuable for future improvements and discussions with the team.

Step 4: Analyse and Follow Up

After the walk, review the notes and analyse the findings. Identify key action items and involve relevant team members to implement solutions. Follow up regularly to ensure that improvements are being made and sustained.

By following these steps, you can ensure your Gemba Walks are not only productive but also foster a culture of continuous improvement within your organisation.

The Benefits of Gemba Walks for Managers and Employees

Gemba Walks offer valuable benefits for both managers and employees, promoting a culture of continuous improvement in the workplace. By taking the time to visit the shop floor and observe processes first-hand, both managers and employees gain critical insights into operational performance.

For Managers: Improved Decision-Making

One of the primary benefits for managers is the ability to make informed decisions. By seeing processes in action, managers can identify inefficiencies, potential bottlenecks, and areas for improvement. This direct observation helps in making data-driven decisions rather than relying solely on reports or assumptions.

For Employees: Increased Engagement

Gemba Walks provide employees with an opportunity to interact with managers in a non-threatening environment. This engagement fosters open communication and makes employees feel valued. When employees feel heard and involved in the improvement process, they are more motivated and committed to achieving better results.

Strengthening Collaboration

Both managers and employees benefit from the improved collaboration that Gemba Walks foster. Managers gain a deeper understanding of the challenges faced by workers, while employees gain insight into management’s goals and priorities. This mutual understanding builds stronger teamwork and alignment across the organisation.

Gemba Walks are a powerful tool for improving both operational efficiency and workplace morale. When managers and employees work together, the result is a more engaged workforce and a more efficient organisation.

Integrating Gemba Walks with Kaizen for Ongoing Improvement

Integrating Gemba Walks with Kaizen is a powerful strategy for driving continuous improvement in any organisation. Gemba Walks, where managers observe work processes directly on the shop floor, complement Kaizen's philosophy of small, incremental improvements by offering real-time insights into daily operations.

What is Kaizen?

Kaizen is a Japanese term meaning "continuous improvement" and focuses on making small, sustainable changes that add up over time. It involves everyone in the organisation, from top management to front-line employees, working together to enhance processes, reduce waste, and increase efficiency.

How Gemba Walks Support Kaizen

Gemba Walks provide a direct link between Kaizen’s theoretical principles and practical application. By actively observing processes, managers can identify areas that need improvement, which can then be addressed through Kaizen’s small-step approach. This integration ensures that the improvements are grounded in reality and based on actual challenges faced by workers.

Benefits of the Integration

The combination of Gemba Walks and Kaizen helps organisations maintain a continuous improvement cycle. Gemba Walks provide the data and insights, while Kaizen offers the structured methodology for making improvements. Together, they foster a culture of collaboration, where employees are encouraged to participate in the problem-solving process, leading to higher engagement and better results.

Integrating Gemba Walks with Kaizen creates a dynamic feedback loop that supports ongoing operational improvements, driving efficiency and fostering a culture of continuous learning and development.

How Gemba Walks Foster a Culture of Open Communication and Engagement

Gemba Walks play a significant role in creating a culture of open communication and employee engagement within an organisation. By encouraging managers and leaders to spend time on the shop floor, Gemba Walks promote direct, meaningful conversations with employees about their daily challenges and successes.

Building Trust through Direct Interaction

One of the core principles of a Gemba Walk is that leaders go to the actual place where work is happening, the "Gemba." This allows them to engage with employees face-to-face, listen to their concerns, and provide support. This direct interaction helps build trust, as employees feel valued and understood, leading to a stronger sense of involvement and ownership in the process of improvement.

Encouraging Open Dialogue

During a Gemba Walk, leaders ask open-ended questions and actively listen to feedback, which creates an environment where employees are encouraged to speak up. This fosters transparency and an open line of communication across all levels of the organisation. Employees are more likely to share insights, ideas, and concerns when they feel heard and supported.

Promoting Engagement and Collaboration

When employees are actively engaged in conversations about process improvements, they become more invested in the outcomes. Gemba Walks create opportunities for collaboration between management and staff, reinforcing a culture where everyone is working together towards common goals. This collaborative approach enhances problem-solving, boosts morale, and improves overall performance.

In summary, Gemba Walks are a valuable tool in fostering a culture of open communication and engagement, where trust, transparency, and collaboration thrive, driving continuous improvement and stronger team dynamics.

Using Gemba Walks to Boost Employee Morale and Ownership

Gemba Walks are an effective way to enhance employee morale and foster a sense of ownership within a team. By engaging with employees on the shop floor, managers and leaders can show genuine interest in their work, making them feel more valued and motivated.

Enhancing Employee Engagement

When managers conduct Gemba Walks, they are actively participating in the daily activities of employees, showing that their contributions are important. This visible presence helps to bridge the gap between management and staff, creating a stronger sense of teamwork. Employees who feel acknowledged are more likely to be motivated and committed to their work, which significantly boosts morale.

Building Ownership Through Involvement

One of the key benefits of Gemba Walks is the opportunity for employees to voice their opinions and ideas. During these walks, leaders can ask questions, listen to feedback, and encourage employees to share their thoughts on improving processes. This involvement gives employees a sense of ownership in the company's success and a greater responsibility for their own work.

Encouraging Recognition and Positive Reinforcement

Gemba Walks also provide an excellent opportunity for managers to offer positive feedback and recognition for good work. Recognising employees' efforts not only boosts their confidence but also encourages them to take pride in their work. When employees feel appreciated, they are more likely to take initiative and contribute to improvements.

In summary, Gemba Walks play a crucial role in boosting employee morale and ownership, promoting a positive work environment where employees feel valued, engaged, and empowered to make a difference.

Real-World Examples of Gemba Walks in Manufacturing and Service Industries

Gemba Walks are a powerful tool used across various industries to drive improvements. By engaging directly with the workplace, both managers and employees gain valuable insights into operational challenges and opportunities. Let’s explore real-world examples in both manufacturing and service industries.

Gemba Walks in Manufacturing

In manufacturing, Gemba Walks are commonly used to assess production lines, identify bottlenecks, and improve workflow. For example, a car manufacturer uses Gemba Walks to observe assembly line processes, speak with workers, and identify areas where efficiency can be improved. During a walk, managers may notice that certain parts are being assembled slower than others. By discussing this with the workers, they may discover that additional training or better tools are needed to enhance productivity. These walks lead to faster production times and reduced waste.

Gemba Walks in Service Industries

In service industries, Gemba Walks help managers identify areas for improvement in customer service and operational processes. For instance, a hotel manager might conduct a Gemba Walk by observing the front desk operations. They may notice that customers are waiting too long to check in. By discussing the issue with the staff, they can implement process changes such as optimising staff shifts or automating check-in systems, leading to faster service and improved customer satisfaction.

Overall, Gemba Walks provide organisations in both manufacturing and service industries with valuable real-time insights, fostering continuous improvement and better operational outcomes.

The Role of Gemba Walks in Lean Transformation

Gemba Walks play a vital role in supporting lean transformation by helping organisations identify waste, improve processes, and engage employees in continuous improvement. The term "Gemba" translates to "the real place," which refers to the location where value is created – whether it's the factory floor, customer service area, or office space. Through these walks, managers and leaders gain firsthand insights into daily operations, making it easier to pinpoint inefficiencies and areas for improvement.

Identifying and Reducing Waste

In a lean transformation, the main goal is to eliminate waste. Gemba Walks allow leaders to observe work in real time, helping them identify activities that do not add value to the customer. For example, unnecessary steps in a production process or delays due to poor communication can be spotted during these walks. Once identified, solutions can be put in place to streamline operations and reduce waste, leading to a more efficient workflow.

Empowering Employees and Encouraging Collaboration

Gemba Walks also encourage collaboration between management and employees. By engaging with workers on the shop floor, managers can build trust and gather valuable feedback. Employees feel empowered when they know their input is valued, which fosters a culture of continuous improvement. This collaboration is essential for driving successful lean transformation and sustaining improvements over time.

In summary, Gemba Walks are a powerful tool for lean transformation, helping organisations identify waste, empower employees, and continuously improve operations.

Tips for Effectively Using Gemba Walks in Remote or Hybrid Work Environments

Gemba Walks are essential for continuous improvement in any work environment, but they can be challenging to implement in remote or hybrid settings. These environments require adaptation, but with the right approach, Gemba Walks can still provide valuable insights into operations and employee engagement. Here are some tips for effectively using Gemba Walks in these modern work settings.

Leverage Technology for Virtual Gemba Walks

In remote or hybrid work environments, technology plays a crucial role. Use video calls, screen-sharing tools, and real-time collaboration platforms to conduct virtual Gemba Walks. Leaders can observe employees at their workstations, review workflows, and discuss issues or improvements, just as they would in a traditional face-to-face walk.

Maintain Regular Check-Ins

Consistency is key when conducting Gemba Walks remotely. Schedule regular check-ins with teams to monitor their progress and discuss challenges. These walks should be a part of the routine, ensuring continuous feedback loops and sustained improvement efforts.

Foster Open Communication and Feedback

Remote Gemba Walks should prioritise open communication. Encourage employees to share feedback, raise concerns, and propose improvements. Virtual platforms like team messaging apps or collaborative documents can facilitate this exchange, ensuring that every team member’s voice is heard.

Adapting Gemba Walks to remote or hybrid work settings requires the use of technology and a focus on clear, consistent communication. These steps help ensure that the spirit of lean improvement continues, even when working remotely.

How Gemba Walks Support Problem-Solving and Root Cause Analysis

Gemba Walks are a powerful tool in lean management, helping to identify and solve problems at their source. By engaging directly with the workplace and observing processes firsthand, managers and leaders gain valuable insights that support problem-solving and root cause analysis. Here's how Gemba Walks contribute to these critical tasks.

Observing Problems in Real-Time

During a Gemba Walk, leaders observe operations in real-time, allowing them to witness issues as they occur. This direct engagement helps identify areas where problems might be emerging, whether it’s inefficiencies in a process, safety concerns, or quality issues. Being on the shop floor provides an unfiltered view that helps leaders understand the context of the problem.

Facilitating Root Cause Analysis

One of the main benefits of Gemba Walks is their role in root cause analysis. Instead of jumping to conclusions or relying on reports, Gemba Walks allow leaders to ask the right questions and explore the underlying causes of problems. By engaging with employees and observing workflows, they can trace issues back to their origin and develop effective solutions.

Collaboration and Continuous Improvement

Gemba Walks encourage collaboration between managers and frontline workers. This open dialogue fosters a culture of continuous improvement, as employees feel empowered to contribute their insights. By working together, teams can identify improvements that address root causes and prevent recurring issues.

Gemba Walks are an essential tool for problem-solving and root cause analysis. By observing processes firsthand and engaging employees, leaders can uncover deeper insights, leading to more effective solutions and a stronger commitment to continuous improvement.

Measuring the Impact of Gemba Walks on Business Performance and Outcomes

Gemba Walks play a significant role in improving business performance and achieving positive outcomes. By providing leaders with direct insight into daily operations, these walks help identify inefficiencies, foster better communication, and drive continuous improvement. But how can businesses effectively measure the impact of Gemba Walks on their overall performance?

Tracking Operational Improvements

The primary benefit of Gemba Walks is their ability to uncover areas of inefficiency within workflows. By actively engaging with employees and observing processes firsthand, leaders can identify bottlenecks, delays, and other inefficiencies that may not be apparent through reports alone. Measuring improvements in cycle time, productivity, or reduction in waste after implementing changes can offer tangible evidence of the walk’s impact.

Enhancing Employee Engagement and Morale

Another measurable outcome of Gemba Walks is increased employee engagement. When leaders take the time to understand workers' challenges and provide feedback, employees feel more valued and involved in problem-solving. This can lead to higher morale, improved teamwork, and increased productivity. Surveys or feedback from employees before and after Gemba Walks can be a helpful way to assess this effect.

Improved Decision-Making

Gemba Walks provide leaders with valuable, real-time information that aids in decision-making. By being directly involved in daily operations, managers can make informed decisions about process improvements, resource allocation, and prioritisation. Tracking the number of successful initiatives launched following a Gemba Walk can help gauge its impact on business outcomes.

Measuring the impact of Gemba Walks involves looking at both operational improvements and employee engagement. By consistently tracking key performance indicators, businesses can assess the long-term benefits of this lean management tool and make adjustments to maximise its effectiveness.

What are the 4 Steps to a Gemba Walk?

A Gemba Walk is a key practice in lean management that helps leaders identify issues, engage with employees, and drive continuous improvement. It involves going to the "Gemba" (the real place) where work happens, observing operations, and interacting with the team. To make the most of a Gemba Walk, it’s important to follow a structured approach. Here are the four essential steps:

1. Plan the Walk

Before heading to the floor, it’s crucial to plan your Gemba Walk. Define the purpose of the walk, whether it’s to observe a specific process, identify inefficiencies, or engage with employees about a challenge. Setting clear objectives helps to focus your attention and ensures the walk is productive.

2. Observe and Listen

Once on the shop floor or workspace, observe the processes in action. Pay attention to the flow of work, employee interactions, and any potential issues. Listening is equally important—ask questions and encourage employees to share their thoughts and challenges. This helps you gain insight into the root causes of problems.

3. Analyse and Ask Questions

During the walk, it’s essential to analyse what you see and ask probing questions to understand the "why" behind observed issues. This will help identify areas of improvement. Make sure you engage with employees to gather their perspectives on how processes can be enhanced.

4. Follow Up and Implement Changes

The final step is to follow up after the walk. Review your findings, discuss them with the team, and prioritise action items. Implement changes based on the observations and feedback. Keep employees informed of progress and continue to make regular Gemba Walks a part of the continuous improvement cycle.

By following these four steps, a Gemba Walk can provide valuable insights into operations and help foster a culture of continuous improvement within the organisation.

What are the 5S in Gemba Walk?

The 5S methodology is an essential tool in the Gemba Walk, aimed at creating a clean, organised, and efficient workspace. The 5S process helps identify waste, improve productivity, and promote a safer work environment. By incorporating the 5S principles into Gemba Walks, managers and leaders can identify areas for improvement and drive operational excellence. The 5S stands for Sort, Set in Order, Shine, Standardise, and Sustain.

1. Sort (Seiri)

Sorting involves removing unnecessary items from the workspace. During a Gemba Walk, observe if there are tools, equipment, or materials that are not needed for the current process. Removing these items can reduce clutter, increase space, and make operations more efficient.

2. Set in Order (Seiton)

Set in Order is about organising the workspace so that tools and materials are easy to find and use. During the Gemba Walk, look for areas where items are not properly organised. A well-organised space leads to quicker access to tools, reducing downtime and improving productivity.

3. Shine (Seiso)

Shining refers to cleaning the workspace regularly to maintain a tidy and safe environment. In a Gemba Walk, check for cleanliness and areas that may require maintenance or repairs. A clean workspace not only boosts morale but also helps to prevent accidents and maintain equipment efficiency.

4. Standardise (Seiketsu)

Standardising involves creating procedures and practices that maintain the improvements made in the first three S’s. During a Gemba Walk, ensure that cleaning, organisation, and sorting practices are consistently followed by employees. Standardising these practices creates uniformity and reduces variation.

5. Sustain (Shitsuke)

Sustaining means ensuring that the improvements made are maintained long-term. In a Gemba Walk, assess whether the workplace consistently follows the 5S principles. Managers should encourage employees to keep up with these practices and make 5S part of their daily routine for ongoing improvements.

By integrating the 5S methodology into Gemba Walks, organisations can create a more efficient, productive, and safer work environment, all contributing to long-term success and continuous improvement.

What are the 5 Gs of Gemba?

The 5 Gs of Gemba are key principles that guide leaders and managers during a Gemba Walk to gain deeper insights into operations and foster continuous improvement. The 5 Gs are simple yet powerful concepts that help ensure effective observations, problem-solving, and decision-making. These principles are: Gemba, Genjitsu, Gensoku, Gemba Walk, and Genba.

1. Gemba (The Real Place)

Gemba, the Japanese term for "the real place," refers to the actual location where work is happening. In the context of a Gemba Walk, it is the place where value is created—whether it's the shop floor, a factory, or any area where the core activities of a business take place. The idea is to observe and engage directly in the environment where processes are being executed.

2. Genjitsu (The Facts)

Genjitsu focuses on observing and collecting facts in the Gemba. During a Gemba Walk, it's crucial to rely on data and real-time observations rather than assumptions. This ensures that decisions are based on accurate information and reflect the true status of operations, leading to better problem-solving and process improvements.

3. Gensoku (Principles or Rules)

Gensoku refers to the fundamental principles or rules that guide work processes. These are the standards that help ensure consistency, efficiency, and quality. During a Gemba Walk, it is important to assess whether these principles are being followed and whether any improvements or adjustments are necessary to align operations with best practices.

4. Gemba Walk (The Act of Observing)

The Gemba Walk itself is the act of physically going to the site of operations to observe, listen, and engage with employees. It involves asking questions, gathering feedback, and understanding challenges directly from those involved in the work process. This enables leaders to identify issues, uncover opportunities for improvement, and make informed decisions.

5. Genba (The Actual Condition)

Genba refers to the actual conditions present on the ground. It is about seeing things as they truly are, not as they are imagined. This principle encourages leaders to be present, observe real-world challenges, and identify any obstacles that hinder productivity or quality. Understanding the actual conditions helps pinpoint areas that need attention and improvement.

By understanding and applying the 5 Gs of Gemba, organisations can improve communication, enhance operational efficiency, and ensure sustainable improvements in their processes.

Gemba walk template

Gemba Walk Template: Continuous Improvement

Date: ___________________

Leader/Observer: ___________________

Area/Department: ___________________

1.Purpose & Objective

What is the focus of today's Gemba walk?

- Safety

- Quality

- Delivery

- Cost

- Morale

- Process Improvement

- Other: ___________________________

2.Observe the Process

| Question | Observations |

|---|---|

| What is the standard process? | |

| Is the process being followed? | |

| Are there visual controls in place? | |

| Are materials/tools easily accessible? | |

| Are there any bottlenecks or waste (Muda)? | |

| Any signs of motion, waiting, or overprocessing? |

3.Engage with the Team

| Question | Notes |

|---|---|

| What challenges are team members facing? | |

| Do they have suggestions for improvements? | |

| Are they aware of the purpose behind the process? | |

| Are they empowered to solve problems? |

4.Performance Metrics

| Metric | Target | Actual | Notes |

|---|---|---|---|

| Safety | |||

| Quality | |||

| Productivity | |||

| Downtime | |||

| Other: __________ |

5.Opportunities for Improvement

| Area | Improvement Idea | Owner | Target Date |

|---|---|---|---|

6.Follow-Up Actions

| Action Item | Responsible | Due Date | Status |

|---|---|---|---|