Lean Thinking is an approach that focuses on maximising customer value while minimising waste. It originated from the Toyota Production System and aims to optimise processes by eliminating inefficiencies, reducing costs, and improving quality. The key principles of Lean Thinking include continuous improvement, streamlining operations, and empowering employees to identify and solve problems. While it started in manufacturing, Lean Thinking can be applied across various industries, including services, healthcare, and software development, to enhance overall performance and better meet customer needs.

Core Principles of Lean Thinking

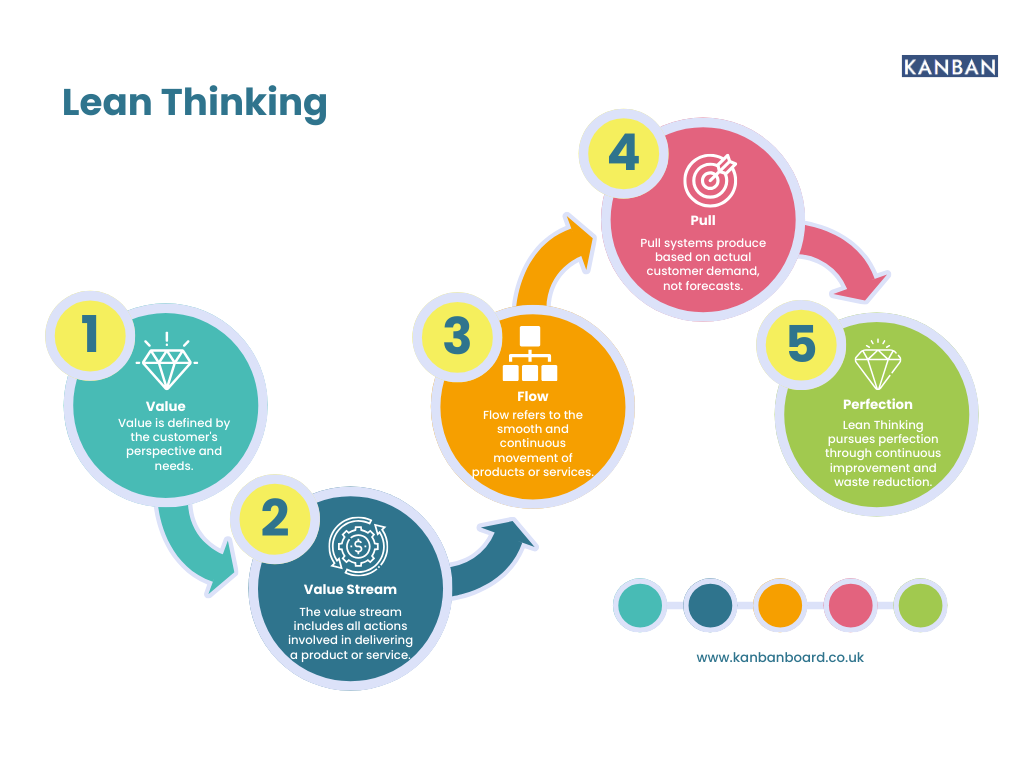

Lean Thinking is built on five fundamental principles that guide organisations toward achieving greater efficiency and value:

1. Value Definition

The first principle of Lean Thinking is understanding what constitutes value from the customer’s perspective. Value is defined as anything that the customer is willing to pay for, and it is crucial for organisations to distinguish between activities that directly add value and those that do not. By focusing on value-adding activities, businesses can prioritise the aspects of their operations that matter most to customers and eliminate unnecessary tasks.

2. Value Stream Mapping

Once value has been clearly defined, organisations must map out the entire process, or "value stream," involved in delivering that value to the customer. Value stream mapping identifies every step in the production or service delivery process and highlights areas where waste occurs. This visual representation helps teams understand where bottlenecks, redundancies, or inefficiencies are slowing down operations. The goal is to streamline the process by removing non-value-adding activities, thereby increasing overall efficiency.

3. Flow Optimisation

The third principle of Lean Thinking is to ensure that value flows smoothly through the production or service delivery process. By eliminating obstacles and delays, businesses can create a continuous flow of work, reducing the time it takes to complete tasks and deliver products or services to customers. Flow optimisation often involves restructuring workflows, reducing batch sizes, and improving the coordination between different departments or teams.

4. Pull Systems

In contrast to traditional "push" systems, where work is completed based on forecasts or schedules, Lean Thinking advocates for a "pull" system, where work is initiated based on actual customer demand. This principle ensures that resources are only used when there is a real need for them, preventing overproduction and excess inventory. By aligning production with customer demand, organisations can respond more quickly to market changes and avoid the costs associated with unused or outdated products.

5. Pursuit of Perfection

Lean Thinking promotes a culture of continuous improvement, where perfection is always the goal, even though it may never be fully achieved. Organisations that adopt Lean Thinking commit to regularly reviewing and refining their processes, seeking out new opportunities for improvement. This principle fosters a mindset of constant learning, encouraging employees at all levels to contribute ideas for enhancing efficiency, quality, and customer satisfaction.

Types of Waste in Lean Thinking

A central focus of Lean Thinking is the elimination of waste, which is categorised into several types known as the "7 Wastes" (though some frameworks may include an eighth type of waste). These wastes represent any activity that consumes resources but does not add value to the customer:

1. Overproduction

Producing more than what is needed or producing it before it is needed, leading to excess inventory or storage costs.

2. Waiting

Delays in the production process, where workers or equipment are idle, waiting for the next task to begin.

3. Transportation

Unnecessary movement of materials or products between locations, increasing the risk of damage and adding no value.

4. Overprocessing

Performing more work or using more resources than necessary to meet customer requirements.

5. Inventory

Excess inventory that ties up resources and may lead to obsolescence, spoilage, or additional storage costs.

6. Motion

Unnecessary movement of people or equipment within a workspace, leading to inefficiencies and potential safety hazards.

7. Defects

Production of faulty or defective products that require rework, repairs, or replacement, leading to additional costs and time delays.

By systematically addressing these wastes, Lean Thinking helps organisations streamline operations and focus their efforts on activities that directly contribute to customer satisfaction.

Benefits of Lean Thinking

Adopting Lean Thinking provides numerous benefits for organisations looking to improve their operations and better serve their customers. Some of the key benefits include:

1. Increased Efficiency

Lean Thinking reduces waste and streamlines processes, allowing organisations to operate more efficiently and deliver products or services faster.

2. Cost Reduction

By eliminating non-value-adding activities, Lean Thinking reduces operating costs, such as excess inventory, transportation, and rework expenses.

3. Improved Quality

Lean Thinking emphasises continuous improvement, leading to better quality control, fewer defects, and higher customer satisfaction.

4. Greater Flexibility

Pull systems and flow optimisation enable organisations to respond more quickly to changes in customer demand or market conditions, improving their ability to adapt.

5. Employee Engagement

Lean Thinking encourages employee involvement in the improvement process, fostering a culture of innovation, collaboration, and empowerment.

Challenges in Implementing Lean Thinking

Despite its benefits, implementing Lean Thinking is not without its challenges. One of the primary obstacles is resistance to change. Employees who are accustomed to traditional ways of working may be hesitant to adopt new methods, especially if they fear job loss due to process automation or elimination of certain tasks. Additionally, organisations may struggle to sustain the continuous improvement mindset, as it requires ongoing effort and commitment from all levels of the business.

Another challenge is the difficulty in accurately identifying and eliminating waste. Some processes may appear essential but upon closer examination are redundant or inefficient. Proper training, leadership support, and effective communication are critical for overcoming these challenges and ensuring the successful implementation of Lean Thinking.

What is Lean Thinking? An Overview of Its Principles and Benefits

Lean thinking is a business methodology focused on improving efficiency, reducing waste, and delivering greater value to customers. Rooted in the principles of continuous improvement, it aims to optimise processes and create more streamlined workflows. While it was originally developed for manufacturing, Lean thinking has since been adopted across various industries, from healthcare to service sectors, thanks to its proven effectiveness in driving operational excellence.

1. The Principles of Lean Thinking

At the core of Lean thinking are several key principles that guide its application:

- Value: Identify what adds value from the customer’s perspective and eliminate anything that does not.

- Value Stream: Map out all steps in the process and remove any that do not add value.

- Flow: Create smooth, uninterrupted flows of work, ensuring that processes are efficient and resources are used optimally.

- Pull: Implement a pull system, meaning that work is only done when it is needed, reducing unnecessary work and overproduction.

- Perfection: Continuously improve processes to achieve higher levels of efficiency and quality.

2. The Benefits of Lean Thinking

Adopting Lean thinking offers numerous benefits for businesses:

- Increased Efficiency: Lean thinking helps streamline processes, reducing wasted time and resources.

- Improved Quality: By focusing on continuous improvement, Lean helps eliminate defects and improve product or service quality.

- Cost Reduction: Reducing waste leads to lower costs, increasing profitability without sacrificing quality.

- Enhanced Customer Satisfaction: Lean thinking allows businesses to deliver more value to customers by improving lead times and product quality.

Lean thinking is a powerful approach to improving business operations. By focusing on efficiency, quality, and continuous improvement, organisations can reduce waste, lower costs, and deliver greater value to their customers.

How Lean Thinking Drives Operational Efficiency in Modern Businesses

Lean thinking is a powerful methodology that drives operational efficiency in modern businesses by focusing on continuous improvement and waste reduction. Originally developed for the manufacturing sector, Lean thinking has proven to be highly effective in various industries, from healthcare to retail. Its principles help businesses streamline processes, improve productivity, and deliver better value to customers while reducing costs.

1. Identifying and Eliminating Waste

One of the key concepts of Lean thinking is the identification and elimination of waste. In this context, waste refers to any activity or process that does not add value to the customer. By mapping out processes and examining each step, businesses can identify inefficiencies and remove non-value-added activities. This leads to faster operations, less inventory, and more efficient use of resources.

2. Improving Process Flow

Lean thinking encourages businesses to focus on improving the flow of work, ensuring that tasks and information move smoothly through the system. By reducing bottlenecks, unnecessary delays, and handoffs, organisations can create more efficient workflows. This leads to quicker turnaround times and higher productivity, helping businesses meet customer demand more effectively.

3. Continuous Improvement

Lean thinking promotes a culture of continuous improvement, where every employee is encouraged to identify areas for improvement and contribute to better processes. Regular reviews and feedback loops ensure that businesses are constantly evolving and adapting to changing market conditions, leading to sustained operational efficiency over time.

Lean thinking is essential for modern businesses seeking to improve their operational efficiency. By eliminating waste, improving process flow, and fostering continuous improvement, companies can enhance productivity, reduce costs, and increase customer satisfaction.

The Core Principles of Lean Thinking: Value, Flow, and Pull

Lean thinking is a methodology designed to optimise processes by focusing on eliminating waste and enhancing value for the customer. The core principles of Lean thinking—value, flow, and pull—serve as the foundation for creating more efficient and effective operations. By applying these principles, businesses can streamline their processes, improve productivity, and deliver better results.

1. Value

The first principle of Lean thinking is understanding and defining value from the customer's perspective. Value is any feature or service that meets customer needs and expectations. By identifying what truly adds value, businesses can focus their efforts on improving these aspects and eliminate activities or processes that do not contribute to customer satisfaction. This approach ensures resources are directed towards what matters most to the customer.

2. Flow

The second principle of Lean thinking is the creation of a smooth and uninterrupted flow of work. Processes should be organised to minimise delays, bottlenecks, and inefficiencies. By removing obstacles and reducing handoffs between tasks or departments, organisations can improve the speed and consistency of their workflows. This leads to faster turnaround times, increased productivity, and a more responsive organisation.

3. Pull

The third principle is the pull system, which ensures that work is done only when it is needed. Unlike a traditional push system, where work is completed in advance, a pull system initiates tasks based on customer demand or a specific trigger. This reduces overproduction, waste, and inventory costs, ensuring that resources are used efficiently and only when required.

By applying the core principles of Lean thinking—value, flow, and pull—businesses can optimise their operations, reduce waste, and deliver better value to customers.

How Lean Thinking Reduces Waste and Increases Profitability

Lean thinking is a proven approach that helps businesses reduce waste and enhance profitability by streamlining processes and focusing on value creation. By identifying inefficiencies and eliminating non-value-added activities, organisations can significantly cut costs and improve their overall performance. This methodology is widely applicable across industries, from manufacturing to services, and delivers measurable results.

1. Eliminating Waste

The primary goal of Lean thinking is to eliminate waste, which includes any activity that does not add value to the product or service. Lean identifies seven types of waste: overproduction, waiting, transport, extra processing, inventory, motion, and defects. By targeting these areas, businesses can reduce unnecessary expenses and optimise resource utilisation. For example, reducing overproduction helps avoid excess inventory and storage costs, while eliminating defects ensures fewer resources are spent on rework.

2. Streamlining Processes

Lean thinking emphasises process improvement and the creation of a smooth flow of work. By identifying and removing bottlenecks, businesses can speed up production and improve efficiency. This leads to quicker turnaround times, more consistent quality, and a better ability to meet customer demands. Streamlining processes also ensures that resources are used effectively, reducing the need for excess labour, materials, or equipment.

3. Increasing Profitability

By focusing on value creation and waste reduction, Lean thinking directly contributes to higher profitability. Reducing waste means lower operational costs, while improving process efficiency enhances productivity. The result is a more competitive organisation that can deliver quality products and services at a lower cost, increasing profit margins and ensuring long-term sustainability.

The Key Benefits of Implementing Lean Thinking in Your Organisation

Implementing Lean thinking within an organisation can transform operations by enhancing efficiency, reducing waste, and improving overall performance. This approach focuses on value creation, continuous improvement, and optimising processes to ensure businesses stay competitive and responsive to customer needs. Here are the key benefits of adopting Lean thinking in your organisation.

1. Improved Efficiency

Lean thinking prioritises process optimisation, which helps eliminate unnecessary steps, reduce bottlenecks, and streamline workflows. By ensuring that every task adds value, organisations can work more efficiently, completing tasks faster and with fewer resources. This results in higher productivity and reduced operational costs.

2. Cost Reduction

One of the most significant advantages of Lean thinking is its ability to reduce costs. By eliminating waste such as excess inventory, overproduction, and unnecessary movement, businesses can lower expenses and improve their bottom line. This not only helps cut costs but also ensures that resources are used more effectively.

3. Enhanced Customer Satisfaction

Lean thinking puts a strong focus on delivering value to customers. By streamlining processes and reducing lead times, organisations can provide higher-quality products or services faster and more reliably. This results in improved customer satisfaction, increased loyalty, and a stronger reputation in the market.

4. Continuous Improvement

Lean thinking fosters a culture of continuous improvement, where teams are encouraged to identify opportunities for enhancement. This ongoing focus on refining processes and solving problems leads to sustained growth and innovation, allowing businesses to adapt to changing market demands and stay ahead of the competition.

How Lean Thinking Improves Customer Value and Satisfaction

Lean thinking is centred around delivering maximum value to customers by reducing waste and improving processes. By focusing on what truly matters to the customer, businesses can enhance their products, services, and overall customer experience. Implementing Lean thinking can lead to significant improvements in customer value and satisfaction, making it a key strategy for success in today’s competitive marketplace.

1. Faster Delivery Times

Lean thinking focuses on optimising processes to eliminate unnecessary delays and bottlenecks. By streamlining workflows, businesses can reduce lead times and deliver products or services to customers more quickly. Faster delivery times not only improve customer satisfaction but also give companies a competitive edge in the market.

2. Consistent Quality

Lean thinking emphasises continuous improvement and quality control, which ensures that products and services meet or exceed customer expectations. By removing defects and reducing variability in processes, businesses can consistently deliver high-quality results. This builds trust and loyalty with customers, who value reliability and consistency.

3. Cost-Effective Solutions

Reducing waste in Lean thinking translates into cost savings, which can be passed on to customers. By eliminating non-value-added activities, businesses can lower their costs, offering competitive prices while maintaining product or service quality. Cost-effective solutions are highly valued by customers, driving higher satisfaction and retention rates.

4. Focus on Customer Needs

Lean thinking places a strong emphasis on understanding and meeting customer needs. By gathering feedback and continuously improving processes based on customer input, businesses can ensure that they are always aligned with customer expectations. This customer-centric approach enhances satisfaction and strengthens customer relationships.

Lean Thinking vs Traditional Management: What Sets It Apart?

When comparing Lean thinking to traditional management approaches, the key differences lie in their focus, efficiency, and adaptability. Lean thinking is a modern, customer-focused methodology aimed at maximising value while reducing waste. In contrast, traditional management often follows a more rigid, process-oriented structure. Understanding these differences is crucial for organisations aiming to improve efficiency and competitiveness in today’s fast-paced business environment.

1. Focus on Value

Lean thinking prioritises customer value and strives to deliver the highest quality at the lowest cost by eliminating waste. Traditional management tends to focus more on maintaining control and following established processes. Lean thinking encourages continuous improvement and value creation, while traditional methods may place greater emphasis on meeting specific targets or maintaining existing processes.

2. Efficiency and Waste Reduction

One of the hallmarks of Lean thinking is its commitment to eliminating waste in all forms—whether it’s time, materials, or resources. Lean encourages the streamlining of processes to ensure every step adds value. Traditional management systems, however, may not focus as heavily on waste reduction and can sometimes accept inefficiencies as part of the process.

3. Flexibility and Adaptability

Lean thinking promotes flexibility and adaptability, allowing businesses to respond quickly to customer demands or changing market conditions. Traditional management, on the other hand, often relies on rigid structures and standardised procedures that can hinder rapid adjustments and innovation.

4. Employee Involvement

Lean thinking emphasises a culture of continuous improvement, where employees at all levels are encouraged to suggest improvements and identify areas of waste. Traditional management may focus more on top-down decision-making, with less input from front-line employees. This greater involvement in Lean thinking leads to a more empowered and engaged workforce.

The Role of Continuous Improvement in Lean Thinking

Continuous improvement is at the heart of Lean thinking, driving businesses to constantly refine processes, reduce waste, and enhance value. Unlike traditional management approaches that may focus solely on short-term goals or efficiency, Lean thinking is built on the principle of ongoing development. This relentless focus on improvement ensures that organisations stay competitive, innovative, and aligned with customer needs.

1. Identifying Areas for Improvement

Continuous improvement begins with a deep understanding of existing processes. By regularly evaluating workflows, teams can identify inefficiencies, bottlenecks, or areas where value can be increased. This proactive approach helps businesses stay ahead of problems and make adjustments before they impact performance or customer satisfaction.

2. Employee Engagement and Empowerment

In Lean thinking, continuous improvement is not just the responsibility of management; it involves employees at all levels. By empowering team members to suggest improvements and make decisions, businesses foster a culture of innovation and accountability. This collective effort helps organisations tap into the insights and expertise of those closest to the work, resulting in more effective solutions.

3. Incremental Progress for Long-Term Success

Lean thinking embraces small, incremental improvements rather than large, disruptive changes. This approach reduces risk and allows businesses to implement changes gradually, making it easier to measure results and adjust as necessary. Over time, these continuous improvements add up, leading to significant gains in efficiency, quality, and customer satisfaction.

4. Adapting to Changing Market Conditions

Continuous improvement also enables organisations to remain flexible and responsive to changing market conditions. By continuously evaluating processes and seeking better ways to meet customer demands, businesses can adapt quickly to new challenges and opportunities, ensuring long-term success.

Lean Thinking in Manufacturing: How to Streamline Your Processes

Lean thinking in manufacturing focuses on improving efficiency by eliminating waste and optimising processes. By adopting Lean principles, manufacturers can reduce costs, improve product quality, and increase overall productivity. The goal is to create value for the customer while minimising the resources used, making it an essential approach for businesses seeking continuous improvement.

1. Identifying and Eliminating Waste

In Lean manufacturing, the first step is identifying and eliminating the seven types of waste: overproduction, waiting time, unnecessary transport, excess inventory, unnecessary motion, defects, and overprocessing. By recognising these inefficiencies, manufacturers can streamline operations, reduce costs, and improve lead times.

2. Implementing Just-in-Time (JIT) Production

Just-in-Time production is a key Lean strategy that focuses on producing goods only when they are needed, in the exact quantities required. This reduces excess inventory, optimises space, and lowers the risk of overproduction. By aligning production with customer demand, manufacturers can improve efficiency and reduce waste.

3. Standardising Work Processes

Standardising work processes ensures consistency and reliability in production. Lean thinking encourages creating clear procedures that can be followed by all employees, helping to eliminate variability and improve product quality. This also makes it easier to identify areas for improvement and implement changes effectively.

4. Continuous Improvement and Employee Involvement

Lean manufacturing fosters a culture of continuous improvement (Kaizen), where employees are encouraged to contribute ideas and take ownership of process improvements. By involving all team members in problem-solving, organisations can unlock creative solutions and drive incremental improvements that lead to long-term success.

How Lean Thinking Promotes a Culture of Efficiency and Innovation

Lean thinking is not only about reducing waste but also about fostering a culture that prioritises efficiency and encourages continuous innovation. By focusing on value creation and process improvement, Lean thinking enables organisations to drive long-term success through smarter ways of working and a commitment to continuous improvement.

1. Encouraging Efficiency at Every Level

One of the key principles of Lean thinking is eliminating waste in all its forms. By engaging employees at all levels in identifying inefficiencies, organisations can streamline processes, reduce unnecessary costs, and increase productivity. This approach helps businesses deliver value faster and more effectively, while maintaining a focus on customer satisfaction.

2. Driving Innovation Through Problem-Solving

Lean thinking encourages a culture where employees are not just following orders but actively solving problems. With tools like root cause analysis and the PDCA (Plan-Do-Check-Act) cycle, organisations can identify areas for improvement and find innovative solutions. This constant focus on problem-solving drives innovation, ensuring that companies stay competitive in a rapidly changing market.

3. Continuous Improvement with Kaizen

The concept of Kaizen, or continuous improvement, is at the heart of Lean thinking. It involves making small, incremental changes that add up over time, leading to significant improvements in efficiency and innovation. By empowering teams to suggest and implement improvements regularly, Lean thinking creates a dynamic environment where innovation is not a one-time event, but a continual process.

4. Empowering Employees

Lean thinking gives employees the tools and responsibility to make decisions about their work processes. This empowerment leads to greater engagement, a sense of ownership, and an eagerness to contribute innovative ideas. When employees feel valued, they are more likely to suggest improvements and embrace new ways of working, ultimately benefiting the entire organisation.

Real-World Examples of Lean Thinking in Action

Lean thinking is a powerful approach that has been successfully implemented across various industries. Its focus on efficiency, waste reduction, and continuous improvement has helped many businesses streamline their operations and achieve significant gains in performance. Here are some real-world examples of how Lean thinking is applied in action.

1. Manufacturing Sector: Reducing Lead Time

In manufacturing, Lean thinking is commonly used to reduce lead time and improve production efficiency. By analysing and optimising each step of the production process, companies can eliminate bottlenecks, reduce downtime, and increase output. A typical example involves streamlining the assembly line by organising workstations more efficiently and minimising unnecessary movements. This leads to quicker production cycles, lower costs, and improved customer satisfaction.

2. Healthcare: Improving Patient Flow

In healthcare, Lean thinking has been used to enhance patient care by improving patient flow and reducing wait times. Hospitals have implemented Lean principles to optimise scheduling, streamline patient intake processes, and reduce delays in care delivery. By analysing the entire patient journey, healthcare providers can identify inefficiencies and implement solutions that lead to faster, more effective treatments without compromising quality.

3. Retail: Enhancing Inventory Management

Retailers have applied Lean thinking to better manage inventory, reduce overstocking, and ensure products are available when customers need them. By using just-in-time inventory systems and streamlining the supply chain, retailers can reduce costs associated with storage and stockouts. This approach allows them to respond more flexibly to changing demand while maintaining a smooth and efficient operation.

These examples show that Lean thinking, when applied properly, can lead to improved efficiency, lower costs, and higher customer satisfaction across different sectors.

How to Implement Lean Thinking in Your Organisation

Implementing Lean thinking in your organisation can significantly enhance efficiency and reduce waste. This approach involves systematically analysing processes, eliminating inefficiencies, and focusing on delivering value to customers. Here’s how you can get started with Lean thinking in your organisation.

1. Identify Value

The first step in implementing Lean thinking is to define what value means for your customers. Understand their needs and ensure that every process or action within your organisation contributes to delivering this value. By focusing on value, you can align your efforts towards activities that truly matter, improving customer satisfaction and outcomes.

2. Map the Value Stream

Mapping the value stream involves identifying all the steps involved in producing a product or service, from start to finish. This helps you visualise where waste exists and where improvements can be made. Look for areas where time, resources, or effort are wasted, such as unnecessary waiting times, excess inventory, or redundant steps in a process.

3. Eliminate Waste

Lean thinking revolves around reducing waste. Once you’ve identified inefficiencies in your processes, work on eliminating them. Waste can take many forms, including overproduction, waiting times, unnecessary motion, and defects. Streamlining these areas helps reduce costs and speeds up delivery times, enhancing overall efficiency.

4. Foster a Culture of Continuous Improvement

Lean thinking is an ongoing journey. Encourage a culture of continuous improvement by empowering employees to identify problems and suggest solutions. Regularly review processes and look for ways to optimise them. This helps your organisation stay agile and responsive to customer needs, maintaining a competitive edge.

By following these steps, you can successfully implement Lean thinking in your organisation, driving operational efficiency, reducing waste, and enhancing customer satisfaction.

Measuring Success with Lean Thinking: Key Performance Indicators (KPIs)

To successfully implement Lean thinking, it's crucial to measure the impact of your efforts. Key Performance Indicators (KPIs) are essential tools that help track progress, identify areas for improvement, and ensure that your organisation is aligned with its Lean goals. Here's how you can use KPIs to measure success with Lean thinking.

1. Efficiency Metrics

Efficiency is at the heart of Lean thinking. Key metrics such as cycle time, lead time, and throughput help you understand how efficiently your processes are running. By tracking these, you can identify bottlenecks and streamline operations to reduce delays, ensuring faster delivery and higher customer satisfaction.

2. Waste Reduction

One of the primary goals of Lean thinking is to eliminate waste. KPIs such as defect rates, rework time, and waste levels provide insights into how effectively your organisation is reducing inefficiencies. Tracking waste helps you pinpoint areas for improvement and measure the success of your waste-reduction initiatives.

3. Customer Satisfaction

Customer satisfaction is a critical KPI that reflects the success of Lean thinking. By measuring customer feedback, Net Promoter Score (NPS), and delivery performance, you can gauge how well your organisation is meeting customer expectations. A higher level of satisfaction often indicates that Lean practices are creating value and improving service delivery.

4. Employee Engagement

Engaged employees are key to the success of Lean thinking. KPIs such as employee involvement in continuous improvement initiatives, training completion rates, and employee satisfaction scores provide insight into how well Lean principles are embedded in your culture. A motivated workforce drives sustainable Lean results.

By tracking these KPIs, organisations can assess the effectiveness of their Lean efforts, ensuring continuous improvement and alignment with business objectives.

Overcoming Common Challenges When Adopting Lean Thinking

Implementing Lean thinking can significantly improve your organisation's efficiency, but it often comes with challenges. By understanding these challenges and proactively addressing them, you can ensure a smoother adoption and greater success in the long term.

1. Resistance to Change

One of the most common challenges when adopting Lean thinking is resistance from employees. People often fear change or feel that Lean practices may disrupt their work. To overcome this, it is essential to foster a culture of continuous improvement and involve employees in the process. Providing training and communicating the benefits of Lean thinking can help reduce resistance and encourage buy-in.

2. Lack of Clear Leadership

For Lean thinking to be successful, strong leadership is essential. Without clear guidance and commitment from senior management, Lean initiatives may lose momentum. It's important for leaders to be visibly involved, set clear goals, and champion Lean principles to ensure alignment across all levels of the organisation.

3. Inadequate Training

Lean thinking requires a shift in mindset, and adequate training is crucial to its success. Organisations may struggle if employees do not fully understand the Lean principles or how to apply them. To address this, invest in comprehensive training programmes that equip your team with the skills needed to implement Lean practices effectively.

4. Failing to Measure Success

Another challenge is the failure to track and measure the success of Lean initiatives. Without proper metrics, it can be difficult to determine whether Lean thinking is delivering the desired results. Establish clear KPIs to monitor progress and make adjustments where necessary.

By addressing these challenges head-on, your organisation can successfully adopt Lean thinking and realise its benefits in terms of efficiency, waste reduction, and continuous improvement.

Training Your Team in Lean Thinking: Skills and Techniques You Need

Training your team in Lean thinking is essential for successfully implementing its principles and achieving operational efficiency. It involves equipping employees with the right skills and techniques to identify waste, improve processes, and enhance value for customers.

1. Understanding Lean Principles

The first step in training is to ensure that your team understands the core principles of Lean thinking. These include the elimination of waste, continuous improvement, and delivering value to the customer. It is important to provide a comprehensive overview of Lean concepts such as value streams, the 5S method, and Kaizen. This foundational knowledge will help your team embrace Lean thinking and apply it effectively in their daily tasks.

2. Problem-Solving Techniques

Lean thinking focuses on solving problems at the root cause rather than just addressing symptoms. Training should include problem-solving techniques such as the “5 Whys” and Fishbone diagram (Ishikawa), which encourage teams to dig deeper into issues and identify long-term solutions. Empowering employees with these tools will help them continuously improve processes and drive efficiency.

3. Encouraging a Culture of Continuous Improvement

A key element of Lean thinking is fostering a culture of continuous improvement. Encourage your team to think critically, question the status quo, and always look for ways to improve. Training should include methods for identifying and eliminating waste, such as value stream mapping and standard work practices, ensuring that improvements are sustainable over time.

4. Collaboration and Communication

Lean thinking thrives in collaborative environments. It’s important to train your team on effective communication, team dynamics, and the importance of working together to achieve common goals. Techniques such as daily stand-up meetings and visual management can support collaboration and transparency across departments.

Investing in Lean training for your team is essential for maximising the benefits of Lean thinking, driving operational efficiency, and ensuring continuous improvement in your organisation.