A Kanban system is a visual workflow management method used to visualize work, maximize efficiency, and improve continuously. It originated from the Toyota Production System as a scheduling system for lean manufacturing and just-in-time manufacturing (JIT). Today, it’s widely used in software development and project management.

Kanban Principles

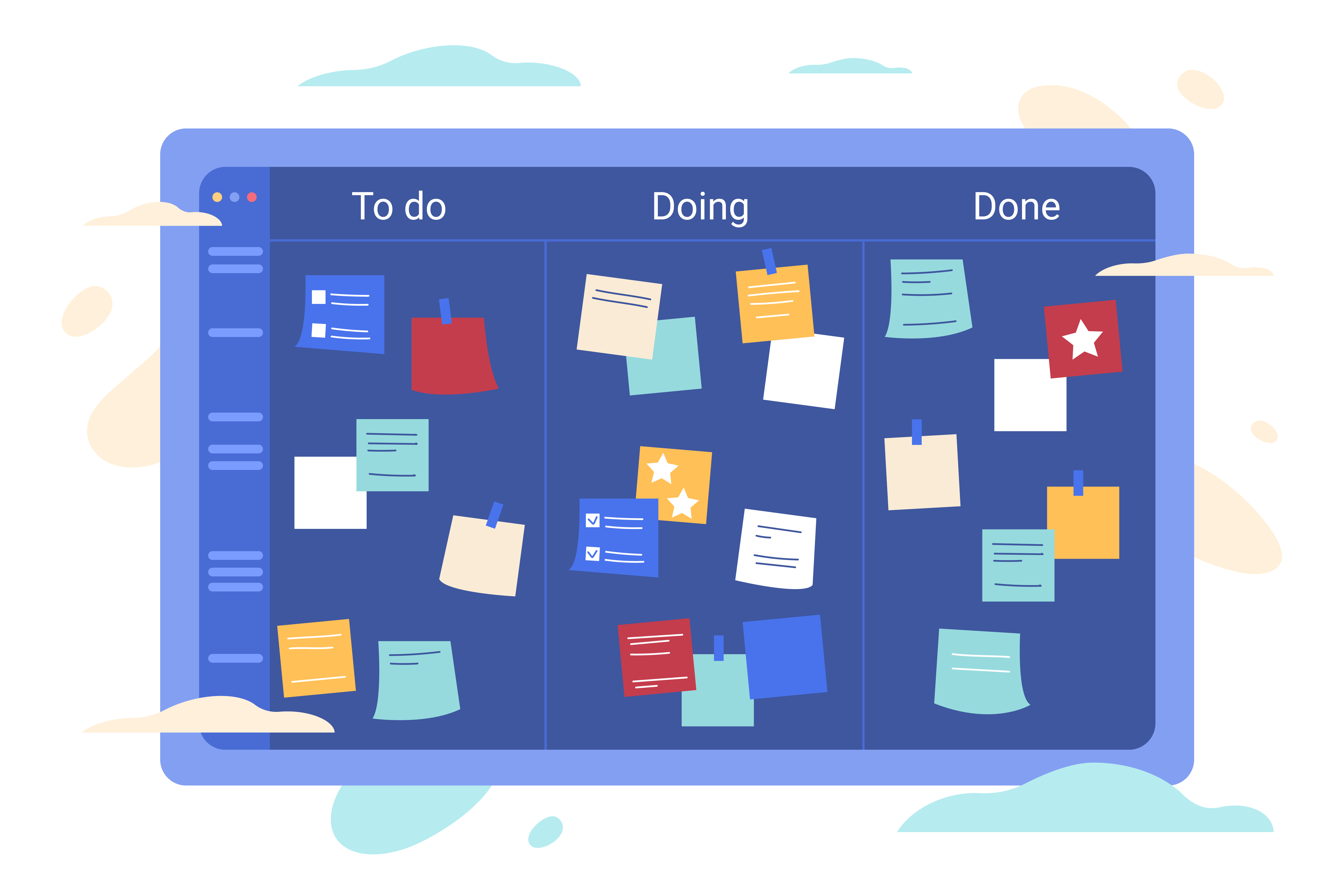

Visualize the Workflow: Use a Kanban board to visualize the flow of work. This can be physical (e.g., a whiteboard with sticky notes) or digital (e.g., software tools).

Limit Work in Progress (WIP): Set limits on the number of tasks in progress at each stage to prevent overloading and ensure a smooth flow of work.

Manage Flow: Monitor and optimize the workflow to ensure tasks move smoothly from start to completion.

Make Process Policies Explicit: Clearly define and communicate the rules and policies governing the workflow.

Implement Feedback Loops: Regularly review the process and progress to make improvements.

Improve Collaboratively, Evolve Experimentally: Continuously seek ways to improve the process with input from the team and through experimentation.

Components of a Kanban system

Kanban Board: The primary tool used to visualize the workflow. It typically consists of columns representing different stages of the workflow (e.g., To Do, In Progress, Done).

Cards: Represent individual tasks or work items. These are moved across the board as they progress through different stages.

Columns: Represent different stages of the workflow. Common columns include To Do, In Progress, and Done, but they can be customized to fit specific processes.

Swimlanes: Horizontal rows that help to organize and categorize work items, often used to separate different types of work or teams.

WIP Limits: Constraints set on the number of work items that can be in a specific column at one time to prevent bottlenecks.

Benefits of Using a Kanban system

Enhanced Visibility: Provides a clear view of the entire workflow, making it easier to identify bottlenecks and areas for improvement.

Increased Efficiency: By limiting WIP and managing flow, teams can work more efficiently and reduce waste.

Improved Collaboration: Facilitates better communication and collaboration among team members.

Flexibility: Can be easily adapted to fit different workflows and processes.

Continuous Improvement: Encourages regular review and improvement of processes.

FAQ: Kanban system

What is the Kanban system?

The Kanban system is a visual project management method that helps teams organize tasks and improve workflow efficiency. It uses boards and cards to represent tasks and their stages, promoting visibility and continuous improvement.

How does the Kanban system work?

Kanban works by visualizing tasks on a board divided into columns representing different stages (e.g., To Do, In Progress, Done). Tasks move through these stages, and the system limits work-in-progress to avoid overload, ensuring a smooth workflow.

What are the key principles of Kanban?

Kanban's core principles include visualizing tasks, limiting work-in-progress (WIP), managing flow, making processes explicit, and fostering continuous improvement.

What is a Kanban board?

A Kanban board is a tool used to visualize tasks. It is typically divided into columns representing various stages of a workflow. Cards (tasks) are moved across the board as they progress.

What are the benefits of using the Kanban system?

Kanban provides benefits such as improved task visualization, flexibility, efficient task management, reduced multitasking, and continuous delivery of tasks.

How is Kanban different from Scrum?

Kanban is more flexible and continuous, while Scrum works in time-boxed sprints with predefined roles. Kanban doesn't prescribe strict roles or deadlines, making it adaptable to changes.

Can Kanban be used in industries outside software development?

Yes, Kanban is widely applied in industries like manufacturing, healthcare, marketing, and logistics to improve task management and streamline processes.

What tools can I use to implement Kanban?

Physical Kanban boards or digital tools (e-Kanban systems) can be used. Digital tools offer features like real-time collaboration, task automation, and analytics to track workflows.

What is the work-in-progress (WIP) limit in Kanban?

A WIP limit is a cap on the number of tasks that can be in progress at any given time. It helps prevent overloading the team, ensuring focus and efficient task completion.