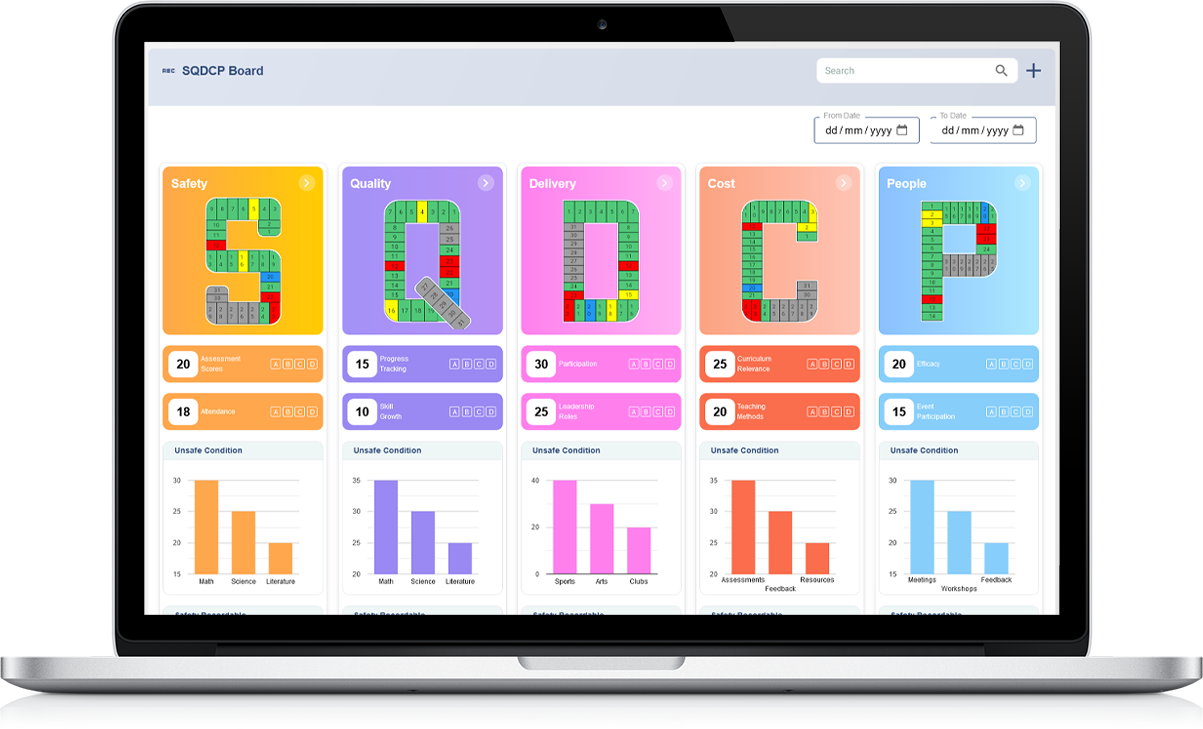

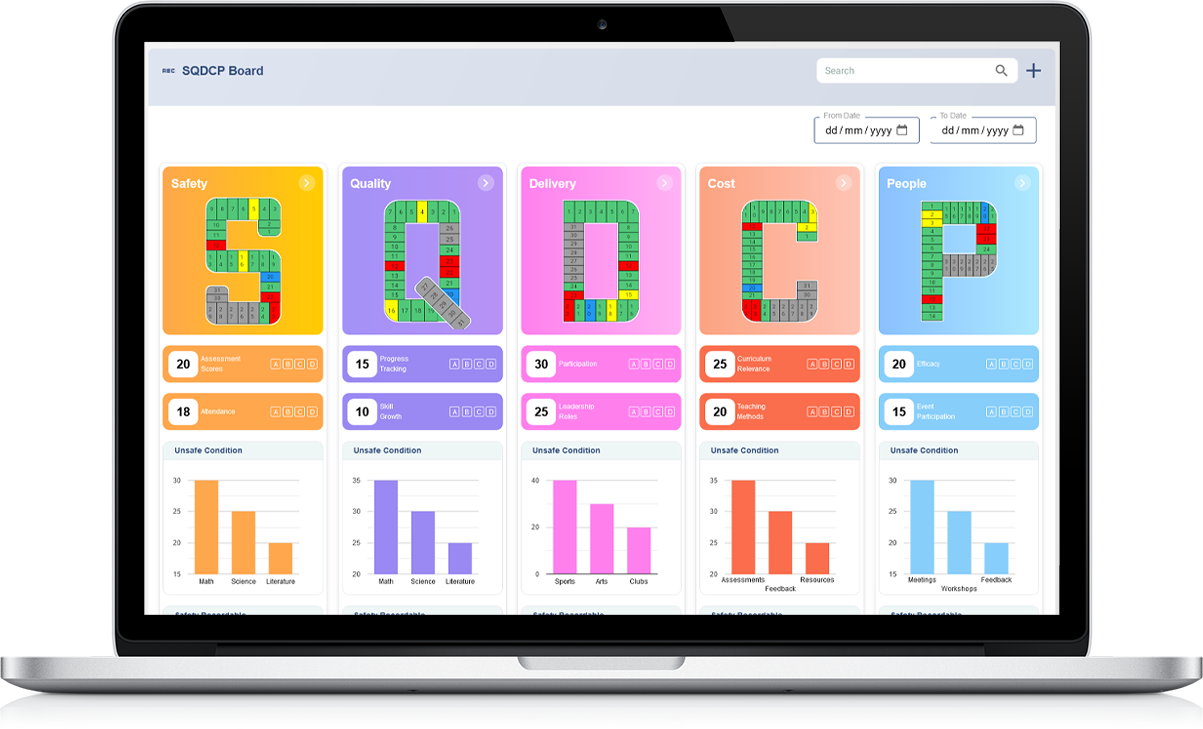

What is an SQDCP/SQCDP Board?

An SQDCP (or SQCDP) board is a visual management tool used in workplaces to track key performance indicators across five critical areas: Safety, Quality, Delivery, Cost, and People. This structured approach helps organisations monitor daily operations and drive continuous improvement.

Breaking Down the SQDCP Elements

Safety: Tracks incidents, near misses, and workplace hazards to ensure a safe environment.

Quality: Measures defects, rework, and compliance with standards to maintain product or service excellence.

Delivery: Monitors production schedules, lead times, and on-time performance.

Cost: Evaluates expenses, waste reduction, and resource efficiency.

People: Focuses on training, engagement, and workforce morale.

By using an SQDCP board, teams can quickly identify issues, implement corrective actions, and improve overall performance through real-time data tracking.

What is the primary purpose of an SQDCP board?

An SQDCP board is a structured visual tool used in workplaces to monitor key performance areas: Safety, Quality, Delivery, Cost, and People. Its primary purpose is to provide a clear and real-time overview of operational performance, allowing teams to identify issues quickly and take corrective actions.

Enhancing Visibility and Accountability

The board helps teams track daily progress, ensuring that each aspect of performance is continuously monitored. By displaying key metrics, it encourages accountability and promotes a culture of continuous improvement.

Facilitating Problem-Solving

By highlighting problem areas, the SQDCP board enables teams to address issues before they escalate. It supports decision-making by providing a visual representation of trends and operational challenges.

Driving Continuous Improvement

Regular updates on the board help organisations set improvement goals, track changes, and measure progress. This proactive approach enhances efficiency, reduces waste, and improves overall performance.

Overall, an SQDCP board ensures that teams remain focused on key priorities, leading to more effective and streamlined operations.

Can you provide an example of an SQCDP board?

An SQCDP board is a structured visual tool used to track key performance areas: Safety, Quality, Cost, Delivery, and People. It helps teams monitor daily operations and quickly identify areas needing improvement.

Example of an SQCDP Board Layout

A typical SQCDP board is divided into five sections:

- Safety (S): Records incidents, near misses, and safety measures.

- Quality (Q): Tracks defects, rework, and process issues.

- Cost (C): Monitors expenses, waste reduction, and efficiency.

- Delivery (D): Measures on-time performance and delays.

- People (P): Highlights training, attendance, and workforce engagement.

Usage in Daily Meetings

The board is updated regularly and used in team discussions to review performance, set targets, and resolve issues. By making key data visible, it helps drive continuous improvement in operations.

What are the different metrics used in visual management boards?

Visual management boards display key metrics to track performance, identify issues, and drive continuous improvement. These metrics vary based on industry needs but generally focus on essential operational areas.

Common Metrics in Visual Management Boards

- Safety: Tracks incidents, near misses, and safety compliance.

- Quality: Measures defects, errors, rework, and customer complaints.

- Cost: Monitors expenses, waste reduction, and financial efficiency.

- Delivery: Evaluates on-time performance, delays, and lead times.

- Productivity: Assesses output, efficiency, and target achievement.

- People: Displays workforce attendance, engagement, and training progress.

Benefits of Tracking Metrics

By visualising these metrics, teams can quickly identify trends, set goals, and take corrective actions. This approach enhances decision-making and promotes continuous improvement across operations.

Why is SQDC an essential aspect of operational management?

SQDC stands for Safety, Quality, Delivery, and Cost, which are critical factors in effective operational management. It provides a structured approach to monitoring and improving key performance areas within an organisation.

Importance of SQDC in Operations

- Safety: Ensures a secure working environment, reducing risks and accidents.

- Quality: Maintains high product and service standards to meet customer expectations.

- Delivery: Improves efficiency by ensuring timely production and service completion.

- Cost: Controls expenses, minimises waste, and optimises resource use.

How SQDC Enhances Performance

By tracking SQDC metrics, organisations can identify inefficiencies, implement improvements, and maintain operational excellence. This approach supports continuous improvement, strengthens teamwork, and drives long-term success.

What does SQDCPE stand for, and how is it used?

SQDCPE stands for Safety, Quality, Delivery, Cost, People, and Environment. It is a structured framework used in operational management to monitor key performance areas and drive continuous improvement.

Understanding SQDCPE Components

- Safety: Ensures a secure workplace by reducing risks and preventing accidents.

- Quality: Maintains product and service standards to meet customer expectations.

- Delivery: Focuses on efficiency to meet deadlines and production targets.

- Cost: Controls expenses and optimises resource usage.

- People: Emphasises employee engagement, training, and development.

- Environment: Promotes sustainability and reduces environmental impact.

How SQDCPE is Used

Organisations use SQDCPE as a visual management tool to track performance metrics daily. It helps teams identify issues, implement corrective actions, and improve overall efficiency. By focusing on these six key areas, businesses can ensure balanced and sustainable growth.

What is a Visual Management Board?

A Visual Management Board is a tool used to display key information about work processes, performance, and goals in a clear and organised way. It helps teams track progress, identify issues, and improve efficiency through real-time data visualisation.

Purpose of a Visual Management Board

The main purpose of a Visual Management Board is to enhance communication, transparency, and accountability within a team or organisation. By visually presenting important metrics, employees can quickly understand the current status of operations and make informed decisions.

Types of Visual Management Boards

- Performance Boards: Track key performance indicators (KPIs) such as quality, cost, and delivery.

- Task Boards: Display ongoing tasks, priorities, and progress updates.

- Problem-Solving Boards: Highlight issues and corrective actions taken to resolve them.

Benefits of Using a Visual Management Board

Using a Visual Management Board improves team collaboration, reduces errors, and increases efficiency. It ensures that employees stay aligned with organisational objectives while continuously improving processes for better results.

What are the primary uses of Visual Boards?

Visual Boards are essential tools used to display key information in an organised and easy-to-understand format. They help teams track progress, manage tasks, and improve overall efficiency by providing clear visibility into work processes and performance.

Tracking Performance

One of the main uses of Visual Boards is to monitor performance by displaying key metrics. These can include quality, productivity, safety, and delivery timelines. Teams can quickly identify trends and take action to improve results.

Improving Communication

Visual Boards enhance communication by providing a shared platform where team members can see updates in real-time. They reduce the need for frequent meetings and emails, ensuring everyone stays informed.

Managing Tasks and Workflow

By outlining tasks and responsibilities, Visual Boards help teams organise work efficiently. They show what needs to be done, who is responsible, and deadlines, reducing confusion and delays.

Identifying Issues and Improvements

Visual Boards help teams spot problems early by making deviations from expected performance clear. This allows for quick corrective actions and continuous improvement.

Enhancing Accountability

Since information is visible to everyone, team members take ownership of their responsibilities, leading to better accountability and engagement.

What are some examples of daily lean visual management boards?

Daily lean visual management boards help teams organise, track, and improve work processes. These boards provide a clear visual representation of key activities, making it easier to identify issues and drive continuous improvement.

Production Board

A production board displays daily targets, actual performance, and any deviations. It helps teams track output, identify bottlenecks, and take corrective actions to meet goals.

Safety Board

A safety board highlights workplace safety incidents, hazard reports, and preventive measures. It ensures that safety remains a priority and encourages a culture of awareness.

Quality Board

This board focuses on quality metrics such as defects, errors, and customer feedback. It helps teams track and resolve quality-related issues promptly.

Task Management Board

Task boards display ongoing, completed, and pending tasks. They improve team coordination and ensure that daily activities are completed efficiently.

Continuous Improvement Board

This board collects improvement suggestions, tracks implementation progress, and measures results. It promotes a culture of innovation and problem-solving.

By using these boards, teams can visualise progress, improve collaboration, and enhance efficiency in daily operations.

How do continuous improvement visual boards support process enhancements?

Continuous improvement visual boards play a crucial role in enhancing processes by providing a clear and organised way to track progress, identify inefficiencies, and encourage collaboration. These boards create transparency, making it easier for teams to focus on problem-solving and process optimisation.

Real-Time Performance Tracking

Visual boards display key performance indicators, helping teams monitor progress and detect issues early. This real-time tracking ensures that corrective actions can be taken promptly.

Identifying Process Bottlenecks

By visualising workflows, teams can quickly spot bottlenecks or inefficiencies in the process. This allows for timely interventions to improve productivity and reduce delays.

Encouraging Team Collaboration

Continuous improvement boards foster teamwork by providing a shared space for discussing challenges and solutions. Employees can actively participate in problem-solving, leading to better engagement and innovation.

Driving Accountability

With tasks, responsibilities, and deadlines clearly displayed, visual boards help teams stay accountable. This ensures that improvement initiatives are implemented effectively.

By making process improvements visible, continuous improvement boards help organisations streamline operations, enhance efficiency, and promote a culture of ongoing development.

What is the role of 5S boards in workplace organisation?

5S boards play a vital role in workplace organisation by visually guiding teams in maintaining a clean, structured, and efficient work environment. They support the principles of 5S—Sort, Set in Order, Shine, Standardise, and Sustain—helping businesses improve productivity and safety.

Enhancing Workplace Efficiency

5S boards display clear instructions, checklists, and visual cues that help employees follow organised workflows. This reduces wasted time searching for tools or materials and ensures that everything is in its proper place.

Improving Safety

By promoting cleanliness and organisation, 5S boards help minimise hazards such as clutter, misplaced tools, and spills. A well-maintained workspace reduces the risk of accidents and enhances overall safety.

Encouraging Standardisation

5S boards help establish consistent procedures across teams, ensuring that best practices are followed. Standardised workflows lead to higher efficiency and fewer errors.

Supporting Continuous Improvement

These boards create a culture of responsibility and continuous improvement by visually tracking progress and encouraging employee participation in maintaining workplace organisation.

By implementing 5S boards, businesses can achieve a structured, efficient, and safer work environment, leading to improved performance and productivity.

How do visual performance boards enhance efficiency?

Visual performance boards play a crucial role in improving efficiency by providing clear and real-time information about key performance indicators, tasks, and goals. These boards help teams stay organised, reduce delays, and ensure smooth workflow management.

Improving Communication

Visual boards present essential data in an easy-to-understand format, ensuring that all team members have access to the same information. This reduces misunderstandings and improves overall coordination.

Enhancing Accountability

By displaying tasks, deadlines, and responsibilities, visual performance boards make it easier for employees to track their progress. This fosters accountability and encourages timely task completion.

Identifying Bottlenecks

Real-time updates on performance help teams quickly identify inefficiencies, delays, or process bottlenecks. Addressing these issues promptly leads to smoother operations and better resource allocation.

Supporting Continuous Improvement

Regular updates on visual boards allow teams to analyse trends, measure performance, and implement necessary improvements. This contributes to ongoing efficiency gains and operational excellence.

By using visual performance boards, organisations can streamline workflows, enhance communication, and achieve greater efficiency in daily operations.

What is the relationship between visual management and Kanban boards?

Understanding Visual Management

Visual management is a method used to improve workplace efficiency by making information clear and accessible. It relies on visual signals, such as charts, boards, and colour-coded indicators, to communicate real-time progress and priorities.

The Role of Kanban Boards

Kanban boards are a practical tool within visual management. They display tasks in different stages, such as "To Do," "In Progress," and "Completed." This approach helps teams track workflow, manage workloads, and maintain productivity.

Enhancing Efficiency and Transparency

By integrating Kanban boards into visual management, organisations gain better visibility into their processes. Teams can quickly identify delays, reduce bottlenecks, and improve task flow. This results in smoother operations and higher efficiency.

Supporting Continuous Improvement

Kanban boards allow teams to monitor progress, adjust priorities, and refine workflows. This aligns with visual management principles, ensuring continuous improvement and operational excellence.

In conclusion, Kanban boards are a key component of visual management, helping teams stay organised, efficient, and focused on achieving their goals.

How do digital Obeya boards contribute to visual management?

Enhancing Collaboration and Communication

Digital Obeya boards provide a centralised platform where teams can share critical information in real time. By displaying key performance indicators, project status, and goals, they ensure alignment across departments and improve communication.

Improving Decision-Making

With real-time data updates and visual analytics, digital Obeya boards support faster and more informed decision-making. Teams can quickly identify issues, track progress, and adjust strategies based on current insights.

Boosting Transparency and Accountability

These boards make objectives, responsibilities, and timelines visible to all team members. This transparency enhances accountability, ensuring that everyone understands their role and contributions toward achieving business goals.

Supporting Continuous Improvement

By visually representing workflows, challenges, and performance trends, digital Obeya boards help organisations identify areas for improvement. Teams can analyse past performance, implement changes, and drive ongoing process enhancements.

In summary, digital Obeya boards play a crucial role in visual management by promoting clarity, collaboration, and efficiency within organisations.

What are SQDIP boards, and how do they differ from SQDCP boards?

Understanding SQDIP Boards

SQDIP stands for Safety, Quality, Delivery, Inventory, and Productivity. SQDIP boards are visual management tools used to track key performance metrics in a structured way. They help teams monitor daily operations, identify problems, and ensure continuous improvement.

How SQDIP Boards Work

Each category on an SQDIP board represents a critical aspect of performance. Safety focuses on workplace incidents, Quality monitors defects, Delivery tracks on-time completion, Inventory manages stock levels, and Productivity measures efficiency. The board is regularly updated to reflect current conditions.

Difference Between SQDIP and SQDCP Boards

SQDCP boards, which stand for Safety, Quality, Delivery, Cost, and People, are similar in function but emphasise cost management and workforce engagement instead of inventory control and productivity. While SQDIP focuses more on operational efficiency and stock levels, SQDCP balances cost control and employee involvement.

Choosing the Right Board

Organisations select SQDIP or SQDCP boards based on their priorities. Manufacturing firms may prefer SQDIP for inventory tracking, while service industries might use SQDCP to focus on cost and workforce management.

Both boards support visual management by improving transparency, efficiency, and decision-making in daily operations.

What is the Kaizen Board, and how does it drive continuous improvement?

Understanding the Kaizen Board

A Kaizen Board is a visual tool used to track continuous improvement initiatives in a workplace. It helps teams identify, document, and implement small, incremental changes that enhance efficiency and productivity. The board provides a structured way to visualise problems, solutions, and progress.

How the Kaizen Board Works

The board is typically divided into columns representing different stages of improvement, such as Idea, In Progress, Review, and Completed. Team members contribute ideas for improvements, which are then discussed, assigned, and tracked until completion. This approach encourages participation and accountability.

Driving Continuous Improvement

The Kaizen Board supports a culture of continuous improvement by making problem-solving visible and structured. It encourages employees at all levels to suggest and implement changes that enhance quality, reduce waste, and streamline workflows. Regular updates ensure ongoing progress and alignment with organisational goals.

Benefits of Using a Kaizen Board

By using a Kaizen Board, organisations improve collaboration, increase efficiency, and foster innovation. It enables teams to systematically address challenges, measure results, and maintain a cycle of continuous improvement for long-term success.

What are the advantages of using digital SQDCP boards over traditional physical boards?

Improved Accessibility and Real-Time Updates

Digital SQDCP boards provide instant access to data from any location, allowing teams to monitor performance remotely. Unlike physical boards, digital versions update in real-time, ensuring accurate and current information.

Enhanced Data Analysis and Reporting

With digital boards, organisations can collect, analyse, and visualise data more effectively. Automated reports and trend analysis help teams identify patterns and make informed decisions to improve safety, quality, delivery, cost, and productivity.

Better Collaboration and Communication

Teams across different locations can collaborate seamlessly using digital SQDCP boards. Cloud-based platforms enable multiple users to update information simultaneously, ensuring transparency and alignment with business goals.

Increased Efficiency and Sustainability

Digital boards eliminate the need for manual updates and paper-based tracking, reducing administrative tasks and supporting environmental sustainability. Automated alerts and notifications ensure that issues are addressed promptly.

Customisation and Scalability

Unlike traditional boards, digital versions can be customised to fit specific operational needs. They can scale with business growth, integrating with other management systems for a streamlined workflow.

How can SQCDP boards enhance visual management in a production environment?

Providing Clear Performance Metrics

SQCDP boards help track key performance areas such as Safety, Quality, Cost, Delivery, and Productivity. By displaying real-time data, they allow teams to identify issues quickly and take corrective action.

Improving Transparency and Accountability

These boards make performance information visible to all team members, promoting accountability. Employees can see progress, understand their roles, and work together to achieve common goals.

Supporting Continuous Improvement

Regular updates on SQCDP boards highlight areas that need improvement. Teams can analyse trends, implement corrective measures, and enhance processes to boost efficiency and effectiveness.

Enhancing Communication and Collaboration

By displaying essential data in a structured format, SQCDP boards facilitate better communication among teams. They encourage discussions during daily meetings and support problem-solving efforts.

Enabling Quick Decision-Making

With real-time data available, managers can make informed decisions faster. SQCDP boards help in identifying trends, reducing downtime, and ensuring smooth production operations.

Can the 1-3-10 rule be applied to SQDCP boards for process control and deviation tracking?

Understanding the 1-3-10 Rule

The 1-3-10 rule is a structured approach for problem resolution, ensuring quick response times at different levels. It focuses on resolving issues within 1, 3, or 10 minutes, depending on severity and complexity.

Applying the Rule to SQDCP Boards

SQDCP boards track Safety, Quality, Delivery, Cost, and Productivity. Integrating the 1-3-10 rule into these boards enhances process control by setting clear timeframes for addressing deviations.

Fast Response to Issues

Minor deviations can be addressed within 1 minute by frontline workers. More complex problems requiring team collaboration can be handled within 3 minutes. If an issue needs managerial intervention, it is escalated and resolved within 10 minutes.

Enhancing Visual Management

SQDCP boards highlight real-time performance data, making it easier to identify and track deviations. The 1-3-10 rule ensures that responses are immediate and structured, reducing downtime and improving efficiency.

Driving Continuous Improvement

By applying the 1-3-10 rule, teams can maintain process stability and prevent recurring issues. This structured approach promotes accountability, faster decision-making, and a proactive problem-solving culture.

What are the key benefits of implementing visual management boards in manufacturing?

Improved Communication

Visual management boards provide a clear and structured way to communicate key production metrics, progress, and potential issues. They help align teams by ensuring that everyone has access to the same information in real time.

Increased Efficiency

By displaying live data on performance, delays, and targets, these boards help teams quickly identify areas that need attention. This reduces time spent on reporting and allows for faster decision-making.

Enhanced Problem-Solving

Visual boards highlight deviations in processes, making it easier to spot and address problems before they escalate. Teams can take corrective actions promptly, preventing disruptions in the workflow.

Better Accountability

With responsibilities clearly displayed, employees can see their roles in meeting production goals. This visibility encourages ownership of tasks, improving overall performance and team engagement.

Supports Continuous Improvement

Visual boards allow teams to track trends over time, helping identify opportunities for process optimisation. Regular updates and reviews encourage a culture of continuous improvement.

Boosts Workplace Organisation

By structuring information in a visual format, these boards contribute to a more organised and efficient workplace. Teams can access essential data quickly, reducing confusion and enhancing workflow.

How do SQDCP boards support the daily huddle process?

Structured Communication

SQDCP boards provide a clear structure for daily huddles, ensuring that discussions stay focused on key performance areas. Teams can quickly review critical metrics such as safety, quality, delivery, cost, and productivity.

Real-Time Performance Tracking

By displaying up-to-date performance data, SQDCP boards help teams assess progress against targets. This visibility allows for immediate recognition of achievements and identification of areas that need improvement.

Faster Problem-Solving

The boards highlight deviations from expected performance, making it easier to address issues during daily meetings. Teams can collaborate on solutions and assign responsibilities for corrective actions.

Encourages Team Engagement

Daily huddles with SQDCP boards create an open environment where team members can contribute insights and share feedback. This participation helps build accountability and fosters a culture of continuous improvement.

Improved Decision-Making

Leaders and team members can make informed decisions based on real-time data displayed on the board. This ensures that actions taken during the huddle are relevant and directly address current challenges.

Consistency in Operations

Using SQDCP boards in daily meetings ensures that key performance areas are reviewed consistently. This helps maintain operational stability and promotes a proactive approach to workplace efficiency.

In what ways can SQCDP boards help identify and address process bottlenecks?

Real-Time Performance Monitoring

SQCDP boards display key performance indicators related to safety, quality, cost, delivery, and productivity. By reviewing these metrics daily, teams can quickly spot delays or inefficiencies affecting workflow.

Visualising Process Weaknesses

By tracking performance trends over time, SQCDP boards help identify recurring bottlenecks. If a particular area consistently falls short, it signals a deeper issue that needs further analysis.

Highlighting Resource Constraints

When productivity is low or delays occur, SQCDP boards reveal if resource shortages—such as labour, materials, or equipment—are causing bottlenecks. Addressing these issues promptly can improve efficiency.

Enabling Quick Problem-Solving

With data presented in an accessible format, teams can collaborate effectively to find solutions. By discussing issues during daily meetings, employees can propose immediate corrective actions to remove barriers.

Supporting Continuous Improvement

SQCDP boards provide historical data that helps teams analyse long-term patterns. This supports process improvements by ensuring that past bottlenecks are resolved and do not reoccur.

Improving Communication

By making performance and process issues visible, SQCDP boards encourage open discussions. This ensures that both frontline workers and management work together to eliminate inefficiencies.

What role do SQDCP boards play in tracking and optimizing productivity?

Monitoring Key Performance Areas

SQDCP boards help track essential performance metrics, including safety, quality, delivery, cost, and productivity. By displaying real-time data, they provide a clear overview of operational efficiency.

Identifying Performance Gaps

By reviewing daily updates on the board, teams can quickly identify deviations from expected performance. This helps highlight areas where productivity is slowing down or where improvements are needed.

Driving Continuous Improvement

With clear data insights, teams can make informed decisions to optimize workflows. Regular review of SQDCP boards encourages problem-solving and continuous improvements in productivity.

Enhancing Team Collaboration

These boards promote open discussions among employees and management. By visualizing performance trends, teams can work together to implement corrective actions and boost overall efficiency.

Supporting Strategic Decision-Making

SQDCP boards provide valuable data that helps leadership assess long-term productivity trends. This ensures resources are allocated effectively to maintain consistent operational performance.

How can SQDCP boards be leveraged to foster continuous improvement?

Providing Real-Time Performance Insights

SQDCP boards display key operational metrics, allowing teams to track safety, quality, delivery, cost, and productivity in real time. This visibility helps identify trends and areas for improvement.

Encouraging Data-Driven Decision-Making

By analysing performance data on the board, teams can make informed decisions to enhance efficiency. Regular updates ensure that problem areas are addressed quickly, leading to continuous process improvements.

Promoting a Culture of Accountability

When performance metrics are clearly displayed, employees take ownership of their tasks. This transparency encourages proactive problem-solving and engagement in improvement initiatives.

Supporting Root Cause Analysis

SQDCP boards help teams investigate underlying issues affecting performance. By tracking recurring problems, organisations can implement long-term solutions to prevent future inefficiencies.

Facilitating Continuous Communication

These boards serve as a central platform for discussions during daily meetings. Regular reviews ensure that improvement strategies are consistently monitored and refined for better operational success.

How can SQCDP boards be customized to fit specific departmental or process needs?

Aligning Metrics with Department Goals

Each department has unique objectives, and SQCDP boards can be adapted to reflect key performance indicators relevant to their processes. Customising metrics ensures meaningful tracking and improvement.

Modifying Data Categories

While SQCDP stands for safety, quality, cost, delivery, and productivity, additional categories such as efficiency, waste reduction, or team performance can be added based on specific requirements.

Adjusting Visual Layout

The board’s layout can be redesigned to fit departmental needs, such as using colour-coded sections, graphs, or priority indicators. This makes data easier to interpret and act upon.

Integrating Digital Tools

For enhanced tracking and automation, digital SQCDP boards can be implemented. These allow real-time updates, remote access, and automated data collection, improving efficiency.

Encouraging Team Collaboration

Departments can personalise the board to include team discussions, improvement suggestions, or issue tracking sections. This fosters engagement and continuous improvement.

What impact do SQDCP boards have on waste reduction and process management?

Enhancing Visibility of Waste

SQDCP boards provide a clear and structured way to track key performance areas, making it easier to identify waste in processes. By continuously monitoring safety, quality, delivery, cost, and productivity, inefficiencies become more apparent.

Encouraging Proactive Problem-Solving

Real-time data tracking on SQDCP boards helps teams detect deviations early, allowing them to take corrective actions before waste accumulates. This proactive approach improves overall process efficiency.

Improving Process Standardisation

By visualising performance trends, teams can standardise best practices that minimise waste. Consistently reviewing SQDCP data leads to more effective workflows and reduced variability in production.

Driving Continuous Improvement

Regular use of SQDCP boards promotes a culture of continuous improvement by encouraging staff to suggest process enhancements. Tracking these improvements ensures long-term waste reduction.

Supporting Lean Management Principles

By focusing on eliminating inefficiencies and optimising resources, SQDCP boards align with lean methodologies. This results in better resource allocation and a reduction in unnecessary costs.

What strategies ensure the effective utilization of SQDCP boards in dynamic workplaces?

Ensuring Real-Time Data Updates

To maximise the impact of SQDCP boards, it is essential to update them regularly with real-time data. This keeps all team members informed about current performance trends and areas needing improvement.

Encouraging Team Collaboration

Involving employees in reviewing and updating the board fosters engagement and accountability. Daily discussions around the board help teams align their actions with organisational goals.

Integrating SQDCP with Problem-Solving

Using SQDCP boards to track recurring issues ensures that teams can focus on root cause analysis. Implementing corrective actions based on board insights leads to sustainable process improvements.

Customising for Workplace Needs

Each workplace has unique requirements, so adapting SQDCP boards to reflect key priorities ensures relevance. Adjusting metrics based on department-specific goals enhances their effectiveness.

Providing Clear Visual Indicators

Using colour-coded sections and simple charts improves clarity, making it easier to identify trends at a glance. This allows for quicker decision-making and better response times to emerging challenges.

What are some best practices for designing efficient SQDCP boards?

Keep the Layout Clear and Organised

An effective SQDCP board should have a well-structured layout with clearly defined sections for each key metric. Using a grid format ensures easy readability and quick access to important data.

Use Colour Coding for Better Visibility

Applying colour codes to different performance indicators helps highlight critical issues. Green can indicate targets met, yellow for areas needing attention, and red for urgent issues.

Ensure Real-Time Data Updates

Regular updates keep the board accurate and useful. Assigning responsibility for updates ensures data is always current, allowing teams to make informed decisions.

Align Metrics with Organisational Goals

Each section of the board should reflect key performance areas relevant to business objectives. This alignment ensures the board provides actionable insights that drive improvements.

Encourage Team Engagement

Making the board interactive and involving employees in discussions enhances engagement. Daily reviews help teams stay aligned and focused on continuous improvement.

Use Simple and Concise Information

Avoid overcrowding the board with excessive details. Using clear headings, simple charts, and brief notes ensures quick understanding and efficient decision-making.

How can SQDCP boards be integrated with lean tools like Kanban or 5S?

Aligning SQDCP with Kanban for Workflow Efficiency

Integrating SQDCP boards with Kanban helps visualise workflow and identify process gaps. While SQDCP tracks key performance indicators, Kanban ensures smooth task progression by managing work-in-progress limits and reducing bottlenecks.

Using 5S Principles for Organised SQDCP Boards

Applying 5S principles enhances the effectiveness of SQDCP boards by ensuring they are well-structured and easy to use. Standardising board layouts and maintaining cleanliness help teams access and update data efficiently.

Driving Continuous Improvement Through Lean Integration

By combining SQDCP with Kanban or 5S, teams can identify issues, track performance trends, and implement corrective actions systematically. This integration promotes waste reduction and sustained process improvements.

Enhancing Visual Management with Unified Lean Tools

Incorporating lean tools into SQDCP boards strengthens visual management. Clear status indicators, task flow tracking, and organised workspaces improve communication, decision-making, and overall efficiency in workplace operations.

How do SQDCP boards enable real-time monitoring of key performance metrics?

Providing Instant Visibility of Key Metrics

SQDCP boards offer a structured way to track key performance indicators, such as safety, quality, delivery, cost, and productivity. By updating the board regularly, teams gain real-time insights into operational performance.

Enhancing Decision-Making with Live Data

With continuous updates, SQDCP boards provide accurate and up-to-date information. This allows teams to identify trends, address issues quickly, and make data-driven decisions to improve processes.

Supporting Proactive Problem-Solving

Real-time monitoring helps teams detect deviations from targets early. By addressing concerns immediately, businesses can prevent delays, reduce defects, and maintain smooth workflow operations.

Improving Team Collaboration and Accountability

Regular interaction with SQDCP boards promotes transparency and accountability. Teams can clearly see responsibilities, track progress, and work together to maintain high performance standards.

How can SQDCP boards help align teams with organizational goals?

Establishing Clear Performance Expectations

SQDCP boards provide a structured way to display key metrics related to safety, quality, delivery, cost, and productivity. By regularly updating these metrics, teams understand what is expected and how their work contributes to overall objectives.

Encouraging Accountability and Ownership

With real-time visibility of performance indicators, team members can take ownership of their responsibilities. Tracking progress and identifying issues early helps ensure that everyone remains aligned with business goals.

Enhancing Communication and Collaboration

Regular engagement with SQDCP boards fosters teamwork by keeping all employees informed. Clear visual data encourages discussions, problem-solving, and a shared focus on continuous improvement.

Supporting Continuous Improvement Initiatives

By identifying trends and potential challenges, SQDCP boards enable teams to proactively make improvements. This ensures that daily actions align with long-term company goals and strategies.

What are common mistakes to avoid when implementing SQDCP boards?

Overloading the Board with Excessive Data

One common mistake is including too much information, making the board cluttered and difficult to read. Keeping it simple and focusing on key metrics ensures that the board remains effective.

Failing to Update the Board Regularly

Inconsistent updates can lead to outdated or incorrect information, reducing the board’s effectiveness. Assigning responsibility for updates ensures that data remains current and actionable.

Lack of Team Engagement

If team members are not involved in maintaining and using the board, it becomes ineffective. Encouraging participation and making it a part of daily routines fosters ownership and accountability.

Ignoring Identified Issues

Tracking performance without addressing recurring problems defeats the purpose of the board. Establishing clear action plans for improvement helps drive continuous progress.

Not Aligning with Organizational Goals

If the board’s metrics do not reflect business objectives, its impact will be limited. Ensuring alignment with company goals enhances the board’s value in driving performance.

How can SQDCP boards facilitate cross-functional collaboration and problem-solving?

Providing a Centralized Communication Platform

SQDCP boards create a shared space where teams from different departments can track performance and identify issues in real time. This transparency helps align objectives and fosters teamwork.

Encouraging Data-Driven Discussions

By displaying key performance indicators, the board ensures that problem-solving efforts are based on actual data rather than assumptions. Teams can use this information to analyse trends and develop effective solutions.

Enhancing Accountability Across Departments

Cross-functional teams can clearly see how their performance impacts overall operations. Assigning responsibilities on the board ensures that tasks and corrective actions are followed up efficiently.

Supporting Quick Decision-Making

Real-time updates enable teams to make informed decisions without delays. By reviewing the board regularly, managers and employees can address issues before they escalate.

Driving a Culture of Continuous Improvement

SQDCP boards encourage open discussions, leading to collaborative problem-solving. Teams work together to refine processes, eliminate inefficiencies, and enhance overall productivity.

How do SQDCP boards help in identifying and resolving workplace safety concerns?

Providing Real-Time Visibility of Safety Issues

SQDCP boards display key safety metrics, making it easy to track incidents, near misses, and hazards. By monitoring trends, teams can proactively address potential risks before they lead to accidents.

Encouraging Employee Participation

Workers can report safety concerns directly on the board, ensuring that issues are documented and addressed promptly. This involvement helps create a culture where safety is a shared responsibility.

Facilitating Root Cause Analysis

When safety incidents occur, SQDCP boards help teams analyse their causes by visualising patterns and identifying problem areas. This structured approach supports long-term corrective actions.

Ensuring Accountability and Follow-Up

By assigning responsibility for resolving safety issues, the board ensures that corrective actions are tracked and completed. Regular updates keep management and employees informed about progress.

Driving Continuous Safety Improvements

Regular reviews of SQDCP boards help identify recurring safety concerns, allowing organisations to implement training, process adjustments, or new safety measures to prevent future incidents.

How do SQDCP boards promote employee engagement and participation?

Encouraging Transparent Communication

SQDCP boards provide a clear and visual representation of key performance areas, making it easier for employees to understand progress, challenges, and expectations. This transparency fosters a sense of involvement.

Empowering Employees to Contribute

By allowing workers to provide updates, raise concerns, and suggest improvements, SQDCP boards give employees a voice in operational decisions. This involvement increases motivation and accountability.

Recognising Employee Efforts

Displaying performance achievements and improvements on the board highlights individual and team contributions. Recognising efforts in real-time boosts morale and encourages continued participation.

Driving Team Collaboration

Daily meetings around SQDCP boards bring teams together to discuss performance, share ideas, and resolve issues. This collaborative approach strengthens teamwork and collective problem-solving.

Supporting a Culture of Continuous Improvement

Regular interaction with the board reinforces a proactive mindset. Employees can see how their feedback leads to positive changes, reinforcing engagement and encouraging continuous participation in process improvements.

In what ways do SQDCP boards support lean manufacturing principles?

Enhancing Visual Management

SQDCP boards provide a clear, structured display of key performance indicators, making it easy to monitor operations in real time. This visibility helps teams quickly identify areas that need attention.

Reducing Waste

By tracking quality, delivery, and productivity, SQDCP boards help identify inefficiencies such as defects, delays, and resource wastage. This aligns with lean manufacturing’s focus on waste reduction.

Driving Continuous Improvement

Regular updates on the board encourage teams to analyse trends, address root causes of issues, and implement improvements. This supports lean principles of ongoing optimisation.

Encouraging Team Collaboration

Daily reviews of SQDCP boards promote teamwork by enabling open discussions on performance. This collaborative approach fosters shared responsibility for process improvements.

Standardising Processes

The structured format of SQDCP boards helps establish consistent tracking methods, ensuring that processes remain standardised while allowing for adjustments based on real-time data.

How does SQDCP contribute to cost control and cost reduction strategies?

Minimising Defects and Rework

By tracking quality metrics, SQDCP helps identify defects early, reducing the need for rework or scrapping materials. This prevents unnecessary costs related to production errors.

Improving Operational Efficiency

Monitoring safety, quality, delivery, cost, and productivity ensures that resources are used efficiently. By addressing inefficiencies, organisations can lower expenses related to delays and wasted materials.

Reducing Downtime

Identifying trends in equipment failures or process disruptions allows teams to take preventive action. This minimises downtime costs and ensures smooth operations.

Enhancing Workforce Productivity

By setting clear performance goals, SQDCP helps optimise labour efforts, ensuring that tasks are completed efficiently. This reduces overtime costs and improves overall workforce management.

Optimising Inventory Management

By tracking delivery performance, SQDCP helps prevent overproduction and excess inventory, which can tie up capital. Efficient stock control reduces storage and holding costs.

What key elements of SQDCP help optimize delivery operations?

Monitoring Delivery Performance

SQDCP tracks on-time delivery rates, helping teams identify delays and implement corrective actions. This ensures that customer expectations are met efficiently.

Streamlining Workflow Processes

By continuously assessing workflow efficiency, SQDCP helps eliminate bottlenecks that slow down deliveries. This results in a smoother and faster supply chain.

Enhancing Communication and Coordination

Regular monitoring of key metrics fosters collaboration between teams. Clear visibility into progress and potential issues improves decision-making and response times.

Reducing Errors and Rework

Quality control measures within SQDCP minimise defects and order inaccuracies. This reduces the need for returns or rework, improving overall delivery efficiency.

Optimising Resource Allocation

By analysing performance data, SQDCP helps optimise workforce and equipment usage. Proper resource management reduces delays and ensures smooth operations.

How does SQDCP aid in the implementation of quality control measures?

Tracking Quality Performance

SQDCP provides a structured approach to monitoring quality metrics. By tracking defects, errors, and deviations, teams can quickly identify problem areas and take corrective action.

Standardising Quality Procedures

Consistent use of SQDCP ensures that quality standards are clearly defined and followed. This helps maintain uniform production processes and reduces variability in output.

Enhancing Root Cause Analysis

SQDCP supports continuous improvement by helping teams analyse quality issues. By investigating trends and recurring problems, businesses can implement long-term solutions to improve product consistency.

Improving Team Accountability

By visualising quality performance, SQDCP fosters responsibility among employees. Teams can monitor their contributions to quality control and work collaboratively to enhance overall performance.

Minimising Defects and Waste

With a focus on quality control, SQDCP reduces the likelihood of defective products. This leads to fewer recalls, less waste, and improved customer satisfaction.

How can SQDCP boards enhance Gemba walks and process evaluations?

Providing Real-Time Data

SQDCP boards display real-time metrics, allowing teams to assess performance during Gemba walks. This helps identify issues quickly and enables immediate corrective actions.

Highlighting Process Inefficiencies

By tracking key performance indicators, SQDCP boards make it easier to spot bottlenecks and inefficiencies. Teams can use this information to refine workflows and improve productivity.

Encouraging Team Engagement

With visual data available, employees can actively participate in process evaluations. SQDCP boards promote collaboration and empower teams to suggest improvements.

Supporting Root Cause Analysis

Gemba walks focus on observing processes in action. SQDCP boards enhance this by offering historical data, helping teams investigate trends and identify root causes of recurring issues.

Strengthening Continuous Improvement

Regularly reviewing SQDCP boards during Gemba walks fosters a culture of continuous improvement. It ensures that corrective actions are tracked and implemented effectively.

SQDCP Board Template

SQDCP Board Template: Continuous Improvement

Department / Line: ___________________

Team Leader: ___________________

Date: ___________________

Safety

| Metric | Target | Actual | Status | Action Taken |

|---|---|---|---|---|

| Incident-Free Days | 30 | 27 | Safety briefing conducted | |

| PPE Compliance (%) | 100% | 95% | Retraining scheduled |

Quality

| Metric | Target | Actual | Status | Action Taken |

|---|---|---|---|---|

| Defect Rate (%) | ≤2% | 2.5% | Root cause analysis started | |

| First Pass Yield (%) | ≥98% | 96% | Operator training reinforced |

Delivery

| Metric | Target | Actual | Status | Action Taken |

|---|---|---|---|---|

| On-Time Delivery (%) | ≥95% | 92% | Reviewed bottleneck processes | |

| Production Plan Adherence (%) | ≥98% | 99% |

Cost

| Metric | Target | Actual | Status | Action Taken |

|---|---|---|---|---|

| Scrap Cost (per day) | ≤ $500 | $600 | Implemented defect control check | |

| Overtime Hours | ≤ 10 | 8 |

People

| Metric | Target | Actual | Status | Action Taken |

|---|---|---|---|---|

| Training Completion (%) | 100% | 100% | ||

| Suggestions Submitted | ≥2/week | 1 | Motivation session planned |