What is an SQDCM Board?

Overview of SQDCM

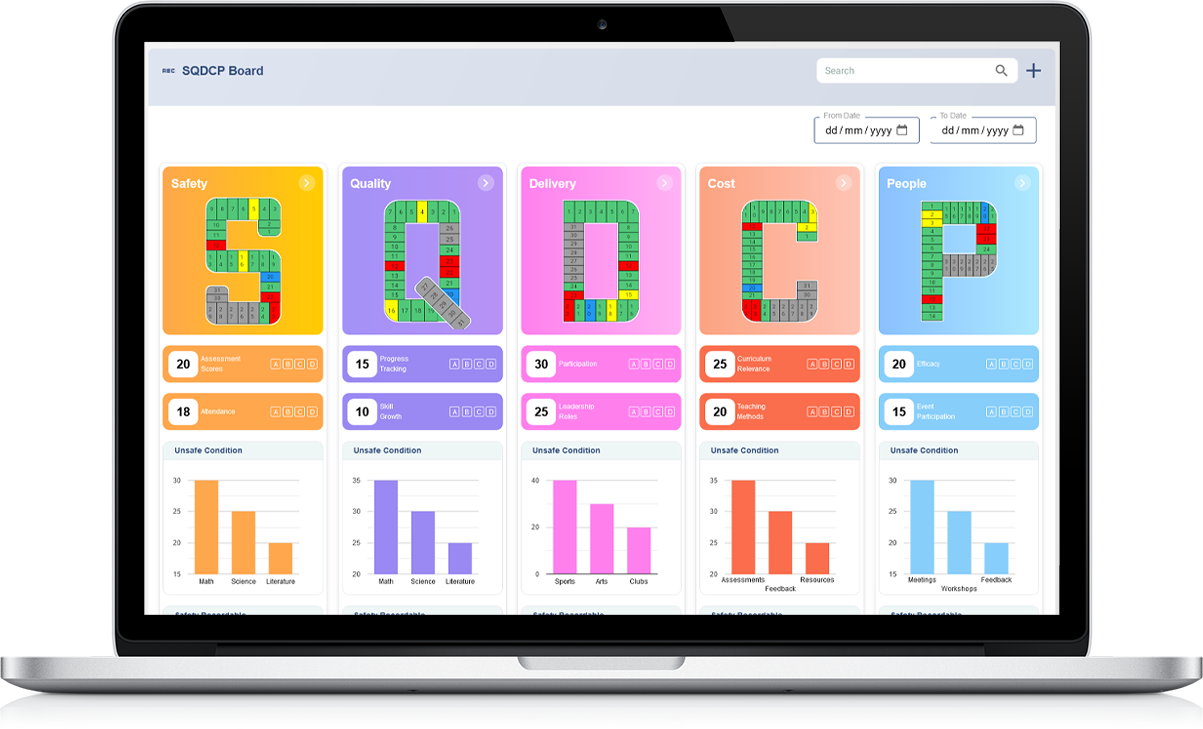

An SQDCM board is a visual management tool used to track key performance metrics in a structured way. It stands for Safety, Quality, Delivery, Cost, and Morale, helping teams focus on critical aspects of operations.

Purpose and Function

The board provides a clear snapshot of performance in these five areas, allowing teams to monitor progress, identify issues, and drive continuous improvements. Each category is visually represented to highlight trends and deviations.

Benefits in Workplace Management

By using an SQDCM board, organisations can improve communication, promote accountability, and enhance overall efficiency. It encourages teamwork and helps ensure that operational goals align with business objectives.

Why is an SQDCM Board Important?

Enhancing Workplace Efficiency

An SQDCM board is essential for improving workplace efficiency by providing a structured way to track key performance indicators. It helps teams monitor Safety, Quality, Delivery, Cost, and Morale, ensuring that all critical areas receive attention. By making performance visible, the board allows teams to address issues quickly and maintain smooth operations.

Encouraging Accountability

With clearly defined metrics, an SQDCM board promotes accountability at all levels. Team members can see how their work contributes to overall success, while managers can identify problem areas and take corrective action. This level of transparency leads to better decision-making and continuous improvement.

Supporting Continuous Improvement

Regular use of an SQDCM board helps organisations foster a culture of continuous improvement. By tracking trends over time, teams can pinpoint recurring issues and develop strategies to improve processes. The board also serves as a communication tool, ensuring that everyone stays informed and aligned with business goals.

Boosting Employee Engagement

When employees see their contributions reflected on the SQDCM board, they feel more engaged and motivated. The board encourages collaboration by allowing teams to work together to solve problems and achieve performance targets, leading to a more productive and positive work environment.

How Does an SQDCM Board Work?

Providing a Clear Structure for Performance Monitoring

An SQDCM board works by visually displaying key performance metrics in five critical areas: Safety, Quality, Delivery, Cost, and Morale. It serves as a central communication tool, helping teams track progress, identify issues, and implement improvements. By maintaining real-time updates, the board ensures that workplace performance remains transparent and data-driven.

Daily Updates for Real-Time Insights

Teams update the SQDCM board daily to reflect the latest performance data. Each section of the board is dedicated to a specific metric:

- Safety: Tracks incidents, hazards, and compliance with safety protocols.

- Quality: Measures defects, rework, and adherence to standards.

- Delivery: Monitors deadlines, lead times, and production schedules.

- Cost: Evaluates waste reduction, budget adherence, and resource efficiency.

- Morale: Reflects employee engagement, attendance, and feedback.

By consistently updating these areas, teams gain an accurate overview of workplace performance and can quickly respond to any concerns.

Facilitating Team Discussions and Problem-Solving

The SQDCM board acts as a discussion tool during team meetings, particularly daily huddles. Employees and managers review the latest data, discuss ongoing challenges, and propose solutions. By using a visual format, the board simplifies complex information, making it easier to identify trends and areas needing improvement.

Driving Continuous Improvement

One of the key benefits of an SQDCM board is its role in continuous improvement. By monitoring data over time, teams can recognise recurring issues and implement long-term solutions. The board allows for structured problem-solving, ensuring that corrective actions are taken and progress is sustained.

Encouraging Accountability and Engagement

Because the board is visible to all team members, it fosters a culture of accountability. Employees take ownership of their tasks, knowing their contributions impact overall performance. It also promotes engagement, as employees can actively participate in identifying problems and suggesting improvements.

Customisation for Specific Needs

While the core elements of an SQDCM board remain consistent, organisations can customise it to align with specific goals and processes. Additional categories or metrics can be added to enhance relevance. Digital versions of the board can further improve efficiency by automating data collection and analysis.

What Type of Information is Displayed on an SQDCM Board?

Overview of the SQDCM Framework

An SQDCM board is designed to track and display key performance metrics across five critical areas: Safety, Quality, Delivery, Cost, and Morale. Each of these areas focuses on essential aspects of operational performance, helping teams monitor day-to-day activities, spot issues, and continuously improve processes.

1. Safety

The Safety section of the SQDCM board highlights workplace safety metrics. It typically includes data on:

- Number of accidents or incidents reported

- Safety compliance status

- Hazard identification and resolutions

- Preventative measures and safety initiatives

By tracking these figures, the board helps ensure a safe working environment and encourages proactive safety management.

2. Quality

The Quality section focuses on product or service quality, helping teams identify issues that affect the final output. Metrics displayed here can include:

- Defects per unit or defects found during inspections

- Quality control pass rates

- Rework or scrap rates

- Customer complaints or returns due to quality issues

This area allows teams to maintain consistent quality standards and take corrective action when necessary.

3. Delivery

Delivery metrics track the timeliness of production and services. This section typically displays:

- On-time delivery rates

- Lead times for orders or production processes

- Completion rates against scheduled goals

- Backlog or delays in delivery

Tracking delivery ensures that deadlines are met and helps identify any bottlenecks in the process.

4. Cost

The Cost section monitors the financial performance of operations, helping control budgets and reduce waste. Metrics in this section may include:

- Production cost per unit

- Energy consumption and resource usage

- Waste levels and material efficiency

- Cost savings from process improvements

By keeping a close eye on costs, the board encourages efficient resource usage and cost reduction strategies.

5. Morale

Morale is a critical factor for maintaining a motivated and engaged workforce. This section highlights:

- Employee engagement levels and satisfaction surveys

- Absenteeism rates

- Employee suggestions or feedback

- Team achievements or recognitions

Tracking morale helps identify potential issues affecting employee satisfaction and enables the implementation of strategies to boost motivation and performance.

Visual Representation and Daily Updates

Each of these sections on the SQDCM board is visually represented, often using graphs, charts, colour codes, or progress indicators, making it easy for teams to assess performance at a glance. Daily updates are crucial to keeping the information relevant and actionable, allowing quick responses to any emerging issues.

How Do SQDCM Boards Support Lean Manufacturing?

Overview of Lean Manufacturing

Lean manufacturing focuses on minimising waste while maximising productivity. It aims to improve efficiency by streamlining processes, reducing costs, and enhancing overall operational performance. SQDCM boards play a significant role in supporting these objectives by providing clear visual tracking of key performance indicators (KPIs) across five crucial areas: Safety, Quality, Delivery, Cost, and Morale.

Continuous Improvement and Waste Reduction

By displaying real-time data on an SQDCM board, teams can immediately spot areas of concern, enabling quick corrective actions. This visual feedback fosters continuous improvement, which is a core principle of lean. For example, if quality issues or delays are identified, teams can implement solutions to eliminate root causes, reducing defects and non-value-adding activities.

Visual Management for Efficiency

SQDCM boards help to simplify communication and decision-making by providing clear and concise visual information. This promotes better coordination and faster responses, crucial for lean processes. Employees at all levels can track performance, identify bottlenecks, and make adjustments, ensuring that production flows smoothly without interruptions.

Supporting Lean Culture

Incorporating SQDCM boards into daily operations encourages a lean culture, where all team members are engaged in monitoring and improving processes. By regularly reviewing these metrics, organisations can maintain a focus on waste reduction, cost control, and overall efficiency, which are key tenets of lean manufacturing.

What Are the Advantages of Digital SQDCM Boards?

Real-Time Data Access

One of the primary advantages of digital SQDCM boards is the ability to access real-time data. Unlike traditional physical boards, digital versions allow for instant updates across multiple locations, providing employees and managers with up-to-date information. This ensures that any issues, whether related to safety, quality, delivery, cost, or morale, can be addressed promptly without delay, improving decision-making processes.

Enhanced Collaboration

Digital SQDCM boards enable enhanced collaboration by allowing multiple teams to view and interact with the same data simultaneously. Whether in the office, on the shop floor, or working remotely, team members can easily share insights, identify problems, and contribute to solutions. This fosters better communication and a more collaborative approach to continuous improvement.

Customisation and Flexibility

Digital SQDCM boards offer a high level of customisation, allowing businesses to tailor the display of key performance indicators (KPIs) to their specific needs. Organisations can add or modify data fields, adjust layouts, and integrate the board with other software systems, such as Enterprise Resource Planning (ERP) or Manufacturing Execution Systems (MES). This flexibility ensures the board is aligned with company goals and processes.

Data Analytics and Reporting

Digital SQDCM boards can automatically generate data analytics and reports, providing valuable insights into performance trends over time. These reports help identify recurring issues, track improvement initiatives, and support data-driven decision-making. Automated reporting reduces the manual effort needed for performance analysis, saving time and enhancing operational efficiency.

Improved Visual Management

With dynamic and interactive visuals, digital SQDCM boards improve the visibility of performance metrics. Colour coding, graphs, and visual indicators make it easier for employees to understand key information quickly, helping to boost productivity and address issues as soon as they arise.

How Can SQDCM Boards Be Customised for Different Industries?

Tailoring Metrics to Industry Needs

SQDCM boards can be highly customised to suit the specific requirements of different industries. Each industry faces unique challenges, and the key performance indicators (KPIs) displayed on the board should reflect those needs. For example, in manufacturing, the focus might be on production efficiency, defect rates, and downtime, while in healthcare, the emphasis might be on patient safety, wait times, and service quality. By aligning the displayed metrics with the industry's priorities, companies can track and manage what matters most to their operations.

Industry-Specific Visuals

The visual elements of an SQDCM board can also be adapted to meet industry demands. For instance, in the automotive sector, a production line might be shown with detailed performance data at each stage, while in retail, a digital SQDCM board might display stock levels, sales performance, and customer satisfaction metrics. By using industry-relevant visuals, businesses can make it easier for employees to interpret data at a glance, fostering quicker decision-making and more efficient operations.

Integration with Industry-Specific Software

Another key aspect of customisation is the integration of SQDCM boards with industry-specific software. Whether it’s linking with a manufacturing execution system (MES) in manufacturing or a point-of-sale system in retail, integrating the SQDCM board with existing systems ensures that the displayed data is accurate and up-to-date. This seamless integration supports better process monitoring and decision-making across all levels of the organisation.

Adaptation for Different Workflows

The structure of the SQDCM board can also be modified to suit the workflow of a particular industry. In sectors such as construction, the board might focus on project milestones and deadlines, while in healthcare, it could highlight patient throughput and resource allocation. Customising the board’s layout and content ensures that it reflects the specific operational flow of each industry, making it more relevant and effective for daily management and improvement initiatives.

How Do SQDCM Boards Promote Continuous Improvement?

Real-Time Performance Tracking

SQDCM boards play a crucial role in promoting continuous improvement by providing real-time performance tracking. By displaying key metrics like safety, quality, delivery, cost, and morale (SQDCM), these boards make it easy for teams to assess their current performance. With constant monitoring, any issues or deviations from set targets are immediately visible, allowing for quick action. This transparency helps teams identify areas that need attention, fostering a proactive approach to problem-solving and process optimisation.

Data-Driven Decision Making

The visual nature of SQDCM boards ensures that data is not only accessible but also easy to understand. By presenting performance data in a clear and concise format, teams can make informed decisions based on real-time information. This data-driven approach encourages a culture of continuous improvement, as employees and managers are empowered to make adjustments and improvements to processes based on concrete evidence rather than assumptions.

Encouraging Collaboration and Accountability

SQDCM boards also promote collaboration and accountability, which are essential for continuous improvement. With key metrics visible to everyone in the workplace, team members are more likely to engage in discussions about performance and share ideas for improvement. The boards also encourage accountability by showing individual and team progress toward goals, motivating everyone to take ownership of their work and contribute to ongoing improvement efforts.

Driving Long-Term Growth

By consistently using SQDCM boards to monitor performance and track improvements, organisations can foster a culture of continuous improvement. Over time, small, incremental improvements lead to significant long-term gains, both in efficiency and quality. This continuous cycle of reflection, action, and improvement drives sustained growth and helps businesses stay competitive in a rapidly changing marketplace.

How Do SQDCM Boards Enhance Team Collaboration?

Visualisation of Key Metrics

SQDCM boards enhance team collaboration by providing a clear visual representation of key metrics like safety, quality, delivery, cost, and morale. By making these metrics visible to all team members, everyone has access to the same information, which fosters transparency. This shared understanding ensures that all team members are aligned in their goals and objectives, promoting a sense of collective responsibility for achieving targets and driving improvements.

Encouraging Open Communication

The visibility of performance data on SQDCM boards encourages open communication among team members. When metrics are displayed, teams can have informed discussions on progress, challenges, and areas for improvement. This collaborative approach helps identify problems early and promotes brainstorming for solutions, ensuring that everyone’s input is valued. It also reduces silos, as different departments or functions can collaborate more effectively, knowing exactly what’s happening in other areas.

Fostering Accountability

With performance metrics displayed in real time, SQDCM boards help foster accountability. Teams are motivated to track their progress and ensure they meet targets, knowing that their performance is visible to everyone. This sense of shared accountability not only drives better individual performance but also strengthens team spirit, as everyone works towards common objectives.

Supporting Continuous Improvement

By making performance data readily accessible and easy to understand, SQDCM boards support continuous improvement efforts. Teams can collaborate on identifying issues, tracking progress, and suggesting improvements. The ongoing dialogue about performance helps teams stay focused on improvement and adapt quickly to changes, which is essential for long-term success in dynamic work environments.

What Are the Best Practices for Using an SQDCM Board Effectively?

Keep Information Clear and Relevant

To use an SQDCM board effectively, it is important to ensure that the information displayed is clear and relevant to the team. Use simple and straightforward language to communicate key metrics like safety, quality, delivery, cost, and morale. Avoid cluttering the board with unnecessary details that could distract from the main objectives. Focus on what truly matters for your team’s success and make sure the data is updated regularly to reflect the most current performance.

Ensure Consistent Updates

Regularly updating the SQDCM board is crucial for its success. Team members should take responsibility for updating the metrics, ensuring that everyone has access to real-time data. This helps identify trends, problems, and successes as they happen, allowing teams to react quickly and make informed decisions. Establish a routine for reviewing and updating the board, whether it’s daily, weekly, or after key meetings.

Encourage Team Involvement

For an SQDCM board to be truly effective, all team members should be involved in the process. Encourage open discussions about the metrics displayed on the board, where everyone can provide insights or suggest improvements. This fosters a sense of ownership and accountability across the team, driving a collective effort toward meeting goals.

Use the Board for Problem-Solving

Don’t just use the SQDCM board to track progress; use it as a tool for problem-solving. When issues are identified, the team should gather around the board to discuss potential solutions and assign action items. This encourages collaboration and ensures that the team is proactive in addressing challenges.

Adapt and Improve the Board

As team goals and processes evolve, the SQDCM board should also adapt. Review the board periodically to ensure that it still serves the team’s needs. Make adjustments to metrics, layout, or content as necessary to ensure it remains a helpful and effective tool for continuous improvement.

How Can SQDCM Boards Be Used in Production Environments?

Visualising Key Metrics

SQDCM boards are highly effective tools for visualising important metrics in production environments. They provide a clear overview of key performance indicators (KPIs) such as safety, quality, delivery, cost, and morale. By displaying these metrics in a central location, team members can quickly assess production performance and identify areas that need attention. This real-time visibility helps teams stay focused on their objectives and make informed decisions.

Driving Continuous Improvement

In production environments, SQDCM boards support continuous improvement initiatives by tracking progress and highlighting areas for optimisation. For example, if there are consistent delays in delivery, teams can use the board to investigate and address the root cause. The regular review of these metrics promotes problem-solving and encourages action to improve processes and outcomes, making it easier to identify and resolve bottlenecks.

Fostering Team Collaboration

SQDCM boards enhance collaboration among production teams by providing a common platform for communication. Teams can gather around the board to discuss performance, share insights, and propose solutions to challenges. This fosters a culture of teamwork and accountability, as everyone is aligned with the same goals and priorities. It also encourages employees to take ownership of their roles in driving improvements.

Improving Operational Efficiency

By highlighting issues such as quality defects, equipment breakdowns, or safety concerns, SQDCM boards help teams address problems swiftly, improving overall efficiency. Continuous monitoring and visual tracking of KPIs enable production environments to optimise processes, reduce waste, and enhance output quality, contributing to a more streamlined operation.

How Do SQDCM Boards Contribute to Cost Reduction?

Identifying Waste and Inefficiencies

SQDCM boards are effective tools for identifying areas of waste and inefficiencies in production environments. By visualising key metrics like quality, delivery, and cost, teams can quickly spot areas where resources are being used inefficiently. For example, high defect rates or delays in delivery can lead to unnecessary costs. By addressing these issues, organisations can reduce waste, optimise resources, and cut operational expenses.

Improving Process Efficiency

The real-time tracking of performance on SQDCM boards enables teams to pinpoint bottlenecks and inefficiencies within their processes. By continuously monitoring key performance indicators (KPIs), organisations can make data-driven decisions to streamline production workflows. This improvement in process efficiency can directly lead to cost savings by reducing downtime, lowering waste, and enhancing throughput.

Encouraging Preventative Maintenance

SQDCM boards also play a significant role in cost reduction through better maintenance practices. By tracking equipment performance and highlighting potential issues, these boards encourage preventative maintenance. Timely maintenance of machinery helps avoid costly breakdowns and repairs, reducing unplanned downtime and the associated costs. This proactive approach helps maintain smooth operations while lowering long-term maintenance expenses.

Optimising Resource Allocation

By providing a clear overview of team performance and resource utilisation, SQDCM boards allow managers to allocate resources more effectively. This helps prevent overuse or underuse of resources, ensuring that they are deployed where they are needed most. Optimal resource allocation reduces unnecessary costs and ensures that production targets are met efficiently and within budget.

Common Mistakes to Avoid When Implementing SQDCM Boards

1. Overcomplicating the Board

One of the most common mistakes when implementing SQDCM boards is overcomplicating the design. While it’s important to track key performance metrics, adding too many indicators can make the board overwhelming and difficult to read. To ensure effectiveness, it’s crucial to focus on the most critical metrics related to safety, quality, delivery, cost, and morale (SQDCM). A simple and focused approach will make the board easier to use and understand for everyone involved.

2. Lack of Regular Updates

Another mistake is not updating the SQDCM board regularly. These boards are only effective when they reflect real-time data. If information is not updated frequently, the board becomes obsolete and loses its value as a communication tool. Regular updates are essential to monitor performance, spot issues early, and make timely adjustments. Consistency in updating the board ensures the team stays aligned with goals and objectives.

3. Ignoring Team Input

Implementing an SQDCM board without considering team input can hinder its success. The board should be a collaborative tool that involves everyone in the process. Teams should have the opportunity to suggest metrics and discuss how the board can best serve their needs. Ignoring input from those directly involved in the work may lead to a lack of engagement and reduced effectiveness of the SQDCM board.

4. Inconsistent or Poor Communication

If the information displayed on the board is not communicated clearly or consistently, it can lead to confusion. Poor communication may cause misunderstandings about targets, deadlines, or process changes. Clear, consistent messaging is key to ensuring everyone on the team is on the same page and can act on the information presented on the board.

5. Failing to Link the Board to Action

Lastly, using the SQDCM board solely as a tracking tool without linking it to actionable steps is a common mistake. The purpose of the board is not just to display data, but to drive continuous improvement. Teams should be encouraged to use the board to identify issues, take corrective actions, and monitor progress over time. Without clear action steps, the SQDCM board loses its potential to impact performance positively.

How SQDCM Boards Improve Employee Engagement

1. Encourages Active Participation

SQDCM boards are designed to be highly visual and interactive, which encourages employees to actively engage with them. By displaying key performance metrics related to safety, quality, delivery, cost, and morale, employees can easily see how their individual efforts contribute to the broader goals of the organisation. This visibility creates a sense of ownership and accountability, motivating employees to take an active role in achieving targets and improving performance.

2. Provides Clear Communication

Effective communication is crucial for employee engagement, and SQDCM boards help foster this by providing a centralised platform where important information is clearly displayed. Employees can quickly review performance metrics, recognise areas for improvement, and align their actions with organisational objectives. This transparency reduces uncertainty, keeps everyone informed, and ensures that employees know exactly where the focus is at any given time.

3. Fosters a Collaborative Environment

SQDCM boards promote teamwork by encouraging discussions and problem-solving. As teams regularly review the board during meetings or huddles, they can identify issues, share insights, and collaborate on solutions. This sense of collaboration strengthens relationships among colleagues and enhances a team-oriented culture. Engaged employees feel more connected to their colleagues and are motivated to work together to achieve common goals.

4. Recognises and Celebrates Achievements

Using SQDCM boards allows for regular recognition of achievements. When targets are met or exceeded, it’s easy to celebrate successes, big or small. Recognition of individual and team contributions fosters a positive work environment and encourages employees to continue striving for excellence. Regular feedback and acknowledgement contribute significantly to overall job satisfaction and morale.

5. Drives Continuous Improvement

SQDCM boards are not just about tracking data, but also about driving continuous improvement. When employees are given the tools and support to identify problems and implement solutions, they feel empowered. This continuous improvement mindset increases engagement as employees are encouraged to contribute ideas and actively participate in refining processes, which leads to a greater sense of accomplishment and personal growth.

How SQDCM Boards Can Be Integrated with Other Lean Tools

1. Integration with Kanban

SQDCM boards can be effectively integrated with the Kanban system, a Lean tool used for visualising work, maximising efficiency, and ensuring smooth workflows. By aligning SQDCM boards with Kanban, teams can visually track their progress on tasks in real-time. For instance, tasks that are tracked on the SQDCM board, such as quality, safety, or delivery, can be placed in specific stages (To Do, In Progress, Completed) on the Kanban board. This integration ensures that employees are constantly aware of the status of different tasks and can quickly identify and address bottlenecks or delays in the process.

2. Integration with 5S

5S is a Lean methodology designed to improve workplace organisation, reduce waste, and enhance productivity. When combined with SQDCM boards, 5S principles can be reflected on the board to monitor and track workplace cleanliness, orderliness, and standardisation. For example, an SQDCM board could include specific metrics to track the 5S stages (Sort, Set in Order, Shine, Standardise, Sustain) in real-time. This integration helps teams visually monitor their progress in maintaining a clean, organised workspace, fostering better employee engagement and promoting a culture of continuous improvement.

3. Integration with Value Stream Mapping

Value Stream Mapping (VSM) is another Lean tool used to analyse and design the flow of materials and information. By incorporating the insights from Value Stream Mapping into SQDCM boards, teams can track key performance indicators (KPIs) that directly relate to value stream performance. For example, SQDCM boards can include metrics related to lead times, cycle times, or inventory levels, giving employees a visual representation of how their work contributes to the overall value stream. This integration helps teams identify inefficiencies, reduce waste, and continuously improve processes in alignment with Lean principles.

4. Integration with Root Cause Analysis (RCA)

Root Cause Analysis is a problem-solving technique used to identify the underlying causes of issues. By linking SQDCM boards to Root Cause Analysis, teams can track issues identified during daily huddles or performance reviews and trace them back to their source. This allows for a more targeted approach to resolving problems, reducing the recurrence of similar issues in the future. Using the SQDCM board to document RCA findings encourages a culture of problem-solving and continuous improvement across all levels of the organisation.