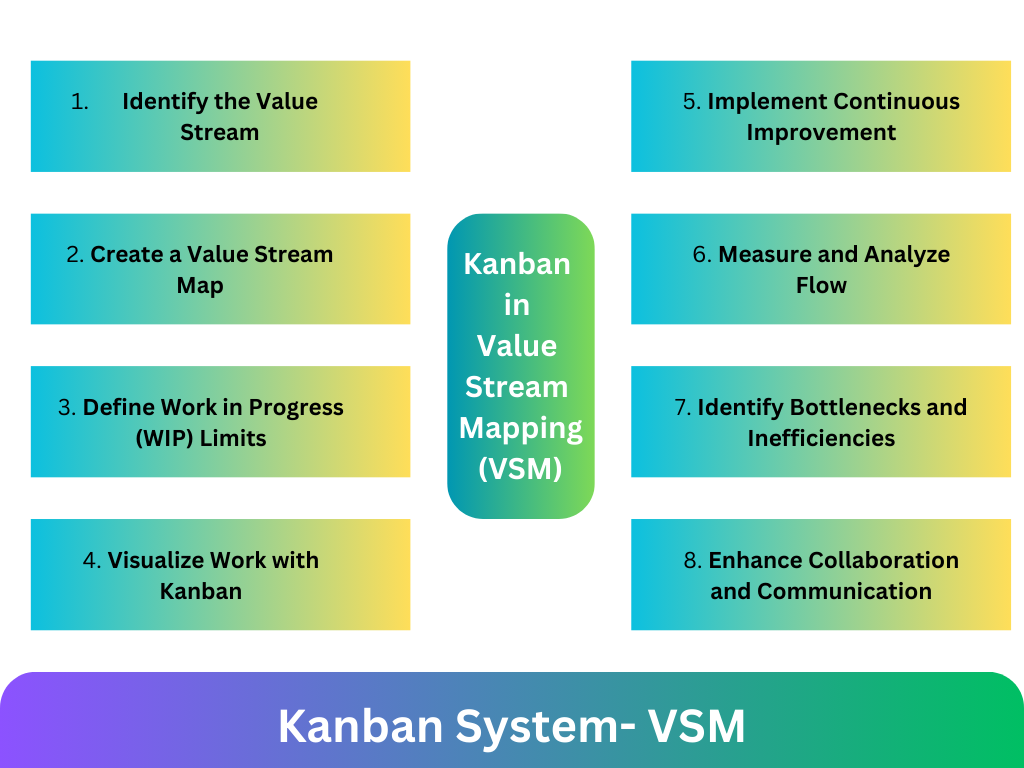

1. What is Kanban in Value Stream Mapping?

Kanban is a visual management tool used in Value Stream Mapping to visualize workflow, manage work-in-progress, and improve efficiency by identifying and eliminating bottlenecks.

2. What is Meant by Value Stream Mapping?

Value Stream Mapping (VSM) is a lean management method for analyzing and designing the flow of materials and information required to bring a product or service to a customer.

3. What are the Three Types of Value Stream Mapping (VSM)?

Current State Map: Depicts the existing process flow.

Future State Map: Illustrates the optimized process flow.

Ideal State Map: Represents the perfect, waste-free process.

4. Is Value Stream Mapping Lean or Six Sigma?

Value Stream Mapping is primarily a lean tool but can be integrated with Six Sigma for process improvement and waste reduction.

5. What are the Four Steps of Value Stream Mapping?

Identify the Product/Service: Define what you are mapping.

Map the Current State: Document the existing process.

Identify Opportunities for Improvement: Spot inefficiencies and waste.

Map the Future State: Design the optimized process flow.

6. What Are Value Stream Mapping Symbols?

Common VSM symbols include:

Process Box: Represents activities or steps.

Inventory Triangle: Indicates inventory or storage.

Arrow: Shows the direction of flow.

Data Box: Contains key performance metrics.

Supplier/Customer Icon: Represents external entities.

7. What is the Main Purpose of Value Stream Mapping?

The main purpose of Value Stream Mapping is to identify and eliminate waste, streamline processes, and improve the flow of materials and information to enhance overall efficiency.

8.How to Create a Value Stream Map Using a Kanban Board?

Identify the Value Stream: Define the process to be mapped.

Set Up the Kanban Board: Create columns for each step in the process.

Map Current Workflow: Place tasks/cards in appropriate columns.

Analyze and Optimize: Identify bottlenecks and adjust the workflow for improvement.

9. What are the 7 Lean Wastes?

Transport: Unnecessary movement of materials.

Inventory: Excess stock not being processed.

Motion: Unnecessary movement of people.

Waiting: Idle time waiting for the next step.

Overproduction: Producing more than needed.

Overprocessing: More work or higher quality than required.

Defects: Errors requiring rework or scrap.

10. What are the Limitations of VSM?

Time-Consuming: Can be complex and time-intensive to create.

Static Representation: May not capture real-time changes.

Complexity: Can be difficult to apply to highly complex processes.

Requires Cross-Functional Knowledge: Needs input from various departments.

11. What are the 5S of Lean?

Sort: Eliminate unnecessary items.

Set in Order: Organize remaining items.

Shine: Clean the workspace.

Standardize: Establish standards for processes.

Sustain: Maintain and review standards.

12. How VSM Works?

VSM works by visually mapping out the current state of a process, identifying waste and inefficiencies, and then designing a future state map that optimizes the flow and reduces waste.

13. What is the Principle of VSM?

The principle of VSM is to provide a clear visual representation of the entire process flow, enabling the identification and elimination of waste, leading to more efficient and effective processes.