Task TCard System

In project management and workflow organisation, Tcard systems are used to manage tasks visually. This method is often associated with Kanban, a scheduling system developed by Toyota for lean manufacturing. Each task is represented by a card, and these cards are moved through stages such as "To Do," "In Progress," and "Done" on a board. This visual representation helps teams understand the status of tasks at a glance, identify bottlenecks, and manage workflow more effectively.

Book Free Demo

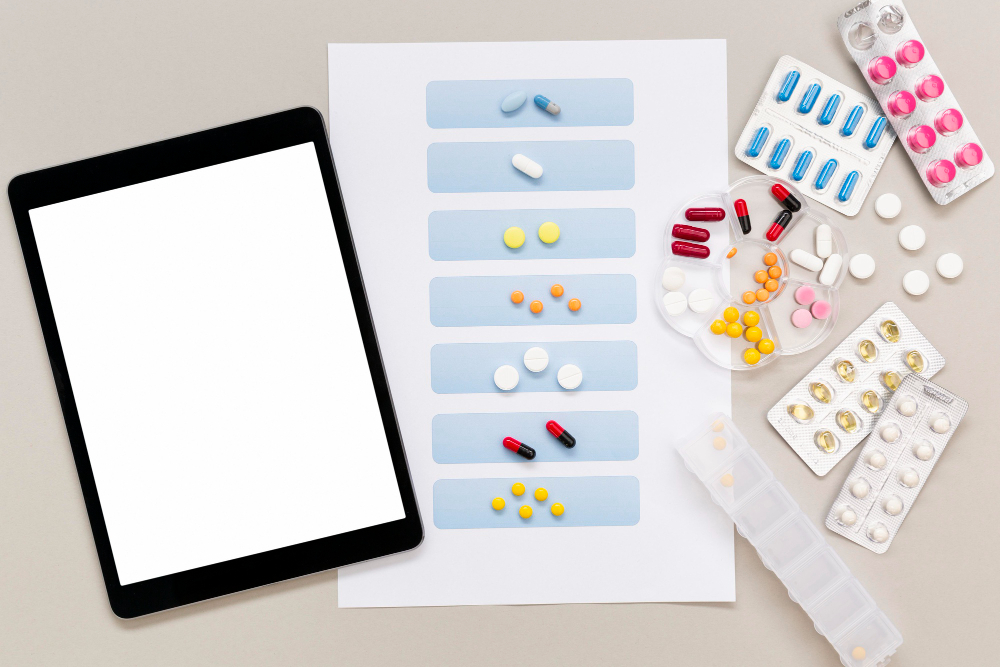

Healthcare TCard System

In healthcare, Tcard systems can be used to manage patient information and streamline processes. Health cards issued to patients can store medical history, insurance information, and appointment schedules. This system enhances the efficiency of healthcare delivery, reduces administrative burdens, and improves patient care by ensuring accurate and accessible medical records.

Book Free Demo

Manufacturing TCard System

A manufacturing Tcard System is a visual management tool used to organise, track, and prioritise tasks on the production floor. A board divided into sections (e.g., "To Do," "In Progress," "Completed") holds cards representing tasks or jobs. Workers move these cards across the board as tasks progress. This system enhances visibility, communication, and efficiency by providing real-time status updates and identifying bottlenecks. It is flexible, customisable, and helps reduce errors, improving overall workflow management.

Book Free Demo

Pharmaceuticals TCard System

A Pharmaceuticals TCard System is a visual management tool used in the pharmaceutical industry to organise, track, and prioritise tasks related to drug manufacturing, quality control, and regulatory compliance. It typically consists of a board divided into sections representing different stages of the pharmaceutical process, such as planning, manufacturing, quality control, and regulatory compliance. Cards are used to represent individual tasks or processes, with details like task descriptions, deadlines, responsible personnel, and current status. The system enhances visibility, improves communication and collaboration, increases efficiency, ensures regulatory compliance, and reduces errors by providing a structured approach to task management.

Book Free Demo

Scheduling TCard System

A scheduling Tcard system is a visual management tool used to organise and track schedules, tasks, and appointments. It typically consists of a board divided into sections representing different timeframes (e.g., days, weeks, months) or categories (e.g., work shifts, projects). Cards are used to represent individual tasks, appointments, or events, with details such as task descriptions, start and end times, assigned personnel, and any relevant notes. Users move cards across the board as tasks are scheduled, in progress, or completed, providing a visual representation of the schedule. This system enhances visibility, improves communication, and helps ensure that tasks are completed on time.

Book Free Demo

Textile TCard System

A textile Tcard system is a visual management tool used in the textile industry to organise and track the production process of textiles. It typically consists of a board divided into sections representing different stages of production, such as design, weaving, dyeing, and finishing. Cards are used to represent individual tasks or orders, with details such as order numbers, product specifications, deadlines, and assigned personnel. As tasks progress, the cards are moved across the board, providing a visual representation of the production workflow. This system helps streamline production, improve communication, and ensure that orders are completed on time and according to specifications.

Book Free Demo

Energy TCard System

An Energy Tcard system is a visual management tool used in the energy industry to monitor and optimise energy consumption, production, and distribution. It typically involves a board divided into sections representing different energy sources (e.g., solar, wind, hydro, fossil fuels) or aspects of energy management (e.g., production, distribution, consumption). Cards are used to represent key data points such as energy production levels, consumption patterns, maintenance schedules, and efficiency metrics. By visually organising this information, the Tcard system helps energy managers identify trends, track performance, and make informed decisions to improve energy efficiency and sustainability.

Book Free Demo

Automotive Industry TCard System

An Automotive Industry Tcard system is a visual management tool used to streamline production processes in automotive manufacturing. It typically involves a board divided into sections representing different stages of production, such as design, engineering, manufacturing, and quality control. Cards are used to represent individual tasks, components, or vehicles, with details such as part numbers, production schedules, quality standards, and assigned personnel. As tasks progress, cards are moved across the board, providing a visual representation of the production workflow. This system helps automotive manufacturers track progress, identify bottlenecks, and ensure that vehicles are produced efficiently and according to quality standards.

Book Free Demo

Food Industry TCard System

A Food Industry Tcard system is a visual management tool used in the food industry to organise and track various processes related to food production, quality control, and distribution. It typically consists of a board divided into sections representing different stages of the food production process, such as ingredient sourcing, food preparation, packaging, and shipping. Cards are used to represent individual tasks, orders, or batches, with details such as recipe specifications, production schedules, quality checks, and assigned personnel. As tasks progress, the cards are moved across the board, providing a visual representation of the production workflow. This system helps food manufacturers ensure food safety, quality, and regulatory compliance, while also improving efficiency and communication within the organisation.

Book Free Demo

Ship Industry TCard System

A Ship Industry Tcard system is a visual management tool used in the shipbuilding industry to organise and track the construction and maintenance of ships. It typically involves a board divided into sections representing different stages of ship construction, such as design, hull assembly, outfitting, and testing. Cards are used to represent individual tasks, components, or sections of the ship, with details such as part numbers, construction schedules, quality standards, and assigned personnel. As tasks progress, cards are moved across the board, providing a visual representation of the construction workflow. This system helps shipbuilders track progress, manage resources efficiently, and ensure that ships are constructed according to specifications and safety standards.

Book Free Demo

Construction TCard System

A Construction Tcard system is a visual management tool used in the construction industry to organise and track various aspects of construction projects. It typically consists of a board divided into sections representing different stages of the construction process, such as planning, foundation, framing, plumbing, electrical, finishing, and inspection. Cards are used to represent individual tasks, sub-contractors, materials, equipment, and inspections, with details such as task descriptions, deadlines, responsible personnel, and current status. As tasks progress, cards are moved across the board, providing a visual representation of the project's workflow. This system helps construction managers monitor progress, allocate resources effectively, and ensure that projects are completed on time and within budget.

Book Free Demo

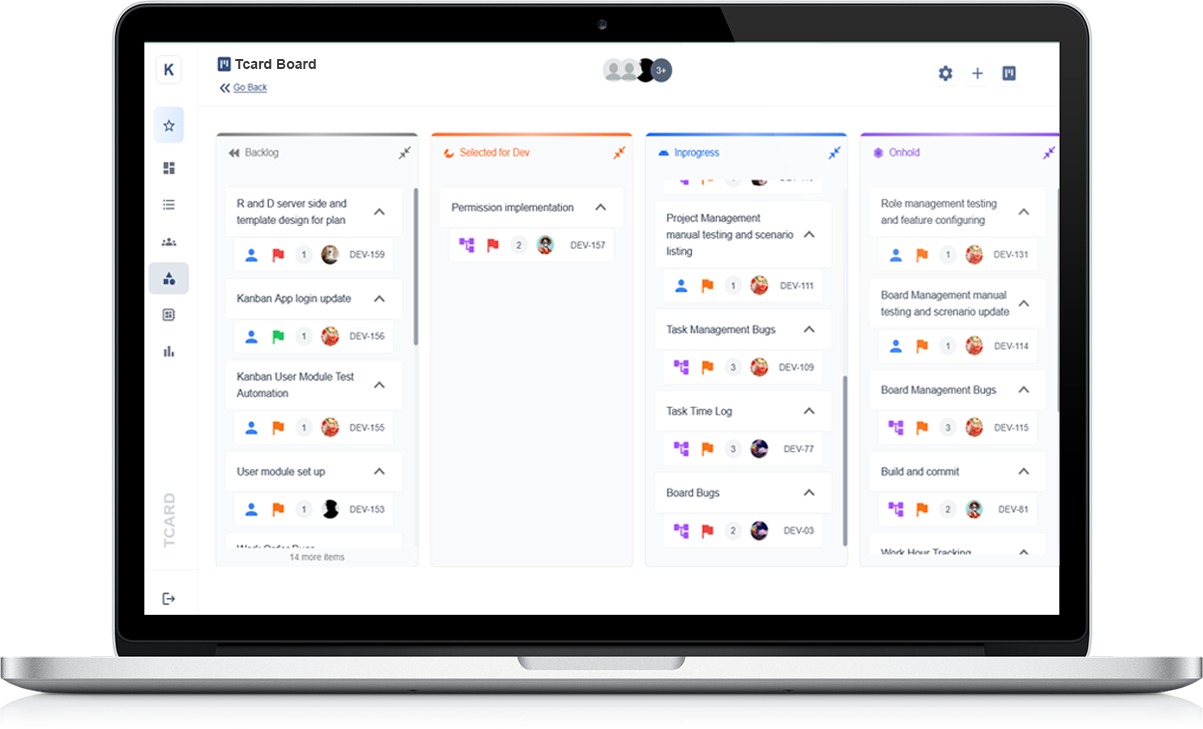

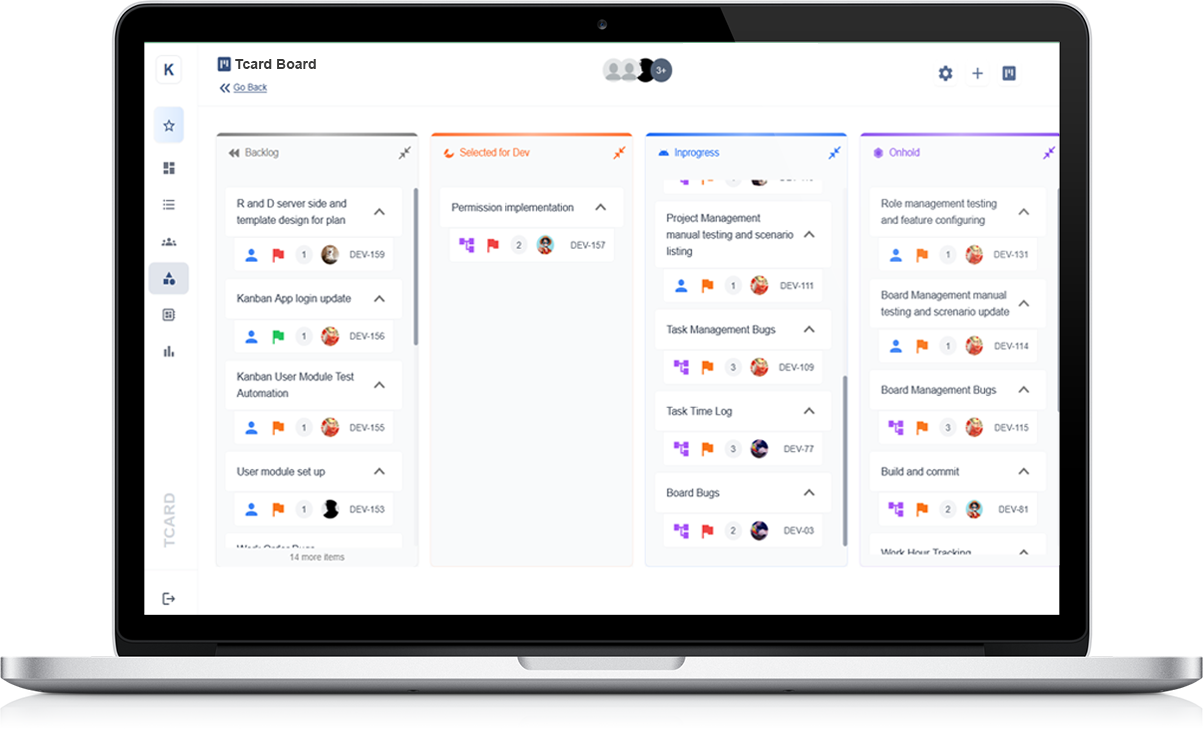

What is a TCard System?

A TCard system is a traditional project management tool used for visualising tasks, projects, or workflows. It consists of physical cards (T-Cards) that are inserted into slots on a board, allowing teams to track the status and progress of various activities. Each card typically represents a task or item and can be moved between different stages or columns on the board, such as "To Do," "In Progress," and "Completed."

How Does the TCard System Work?

The TCard system is a versatile and effective tool used for managing tasks, tracking assets, and improving operational efficiency. This system uses a simple, colour-coded card format to represent various tasks, assets, or pieces of equipment, making it easy to track and monitor progress in real-time. TCards can be used in physical or digital formats, depending on the specific needs of the business.

Easy-to-Understand Visual Tracking

The TCard system allows organisations to create visual boards that display tasks or assets on cards, often arranged by categories such as "To Do," "In Progress," and "Completed." Each card represents a specific task, asset, or job that needs attention. The use of colour coding ensures that the status and priority of tasks are instantly clear to all team members. For example, high-priority tasks might be marked in red, while lower-priority ones could be in blue or green.

Real-Time Updates and Collaboration

One of the key benefits of the TCard system is its ability to provide real-time updates. As work progresses or assets are moved, the cards are moved across the board to reflect the current status. This visual representation helps teams quickly identify bottlenecks, areas that require attention, and tasks that are falling behind. It fosters collaboration by keeping everyone informed and aligned on what needs to be done.

Customisable and Scalable

The TCard system is highly customisable, allowing businesses to tailor it to their specific needs. Whether it's for project management, inventory tracking, or maintenance scheduling, the system can be adjusted to suit any workflow. Additionally, it can scale with the growth of a business, making it a flexible and valuable tool for organisations of all sizes.

How TCard Systems Improve Task Tracking and Workflow Management

The TCard system is a simple yet effective solution for improving task tracking and workflow management in any organisation. By using visual boards and colour-coded cards, businesses can easily manage tasks, track progress, and ensure that workflows run smoothly. This system provides clear visibility of work status, helping teams stay organised and focused on their objectives.

Visual Organisation and Simplified Tracking

TCard systems are known for their simplicity and visual nature. Each task or asset is represented by a card, which is placed on a board that is divided into columns or stages, such as "To Do," "In Progress," and "Completed." This structure allows teams to quickly assess the current status of various tasks at a glance. The use of colour coding further enhances clarity, as different colours can represent task priority or category, ensuring that important jobs are always visible.

Efficient Workflow Management

The TCard system streamlines workflow management by providing a central place for tracking tasks and assets. As tasks progress, cards are moved from one stage to another, allowing team members to easily follow the flow of work. This makes it easy to identify bottlenecks and areas requiring attention. The visual nature of the TCard system encourages better collaboration, as all team members can see the status of tasks and contribute to decision-making.

Improved Productivity and Accountability

With real-time updates and clear task visibility, the TCard system improves productivity by ensuring that nothing falls through the cracks. The system also encourages accountability, as each task is assigned to a specific team member and tracked throughout its lifecycle. This makes it easier to identify areas for improvement and helps teams stay on track to meet deadlines and objectives.

Top Benefits of Using a TCard System for Scheduling and Task Allocation

The TCard system is an effective and straightforward tool for scheduling and task allocation. With its visual and easy-to-use format, it offers a range of benefits that can significantly enhance organisational efficiency and productivity. From improving task management to ensuring better workflow, here are the top benefits of using a TCard system for scheduling and task allocation.

Enhanced Visual Organisation

One of the key benefits of a TCard system is its visual nature. Tasks are represented by colourful cards placed on boards, which are typically divided into stages like "To Do," "In Progress," and "Completed." This allows teams to quickly see the status of tasks at a glance, ensuring that everyone is on the same page. The clear visual structure simplifies the scheduling process, making it easy to prioritise and allocate tasks effectively.

Streamlined Task Allocation

TCard systems make task allocation easier by providing a centralised platform where tasks can be assigned to specific team members. Each card contains important information such as deadlines, priority levels, and the person responsible, which makes it straightforward for managers to delegate work. This helps prevent overloading team members and ensures that each task is completed on time.

Improved Communication and Collaboration

The visual and collaborative nature of TCard systems improves communication within teams. As tasks progress, cards are moved across stages, allowing everyone to stay informed about task status. This real-time update fosters better teamwork and reduces the chances of miscommunication, ensuring smoother task management and efficient collaboration.

Increased Accountability and Productivity

By assigning tasks clearly and tracking their progress in real time, the TCard system increases accountability. Team members know exactly what they need to do and by when, which improves productivity. Managers can also easily identify potential delays and address issues promptly, keeping the workflow uninterrupted and on track.

Why Choose TCard Systems Over Traditional Task Management Tools?

Task management is crucial for any business to stay organised and efficient. While traditional tools like spreadsheets or paper-based systems have their uses, TCard systems offer several advantages that make them a superior choice for task management. Here’s why TCard systems stand out over more traditional task management tools.

Visual Clarity and Simplicity

One of the key advantages of TCard systems is their visual format. With tasks represented by cards on boards, it’s easy to see the status of tasks at a glance. Unlike spreadsheets or written logs, TCards give an immediate visual overview, making it clear which tasks are pending, in progress, or completed. This simplicity leads to less confusion and faster decision-making.

Real-Time Collaboration and Updates

TCard systems promote real-time updates and collaboration. As tasks progress, cards are moved across columns to show their status, which can be instantly viewed by all team members. This level of visibility is difficult to achieve with traditional task management tools, which often require manual updates and are prone to errors.

Customisation for Flexibility

Unlike rigid spreadsheets or paper systems, TCard systems are highly customisable. You can set up columns, colour-code tasks, and create categories that best fit your team’s needs. This flexibility allows the system to grow and adapt with your organisation, something that traditional task management tools often struggle with.

Better Task Tracking and Accountability

With TCard systems, each task is clearly assigned, making it easy to track progress and hold team members accountable. The system’s transparency ensures that nothing is overlooked, while traditional tools often require additional effort to monitor individual progress.

In conclusion, TCard systems offer a streamlined, visual, and collaborative approach to task management that traditional methods simply can’t match. Their ease of use, real-time updates, and adaptability make them an excellent choice for modern businesses looking to improve efficiency and productivity.

How TCard Systems Simplify Task Prioritisation and Organisation

Effective task prioritisation and organisation are essential for any business to stay on top of their goals. TCard systems make this process much easier by offering a visual and intuitive way to manage tasks. Here's how TCard systems simplify task prioritisation and organisation:

Visual Overview for Quick Decision-Making

One of the key benefits of TCard systems is their visual format. Tasks are displayed on cards that can be moved across columns to show their current status. This makes it easy to quickly see which tasks need attention and which are on track. The simple visual layout helps teams prioritise work by quickly identifying urgent or overdue tasks, ensuring nothing gets missed.

Customisable Categories and Prioritisation

TCard systems allow for flexible categorisation of tasks. Tasks can be organised based on priority, deadlines, or project phases, allowing teams to tailor the system to their specific needs. Colour-coded cards and labels can be used to indicate high, medium, or low-priority tasks, which helps teams focus on what matters most. This customisation ensures that the workflow remains organised and efficient, with clear distinctions between tasks that need immediate attention and those that can wait.

Streamlined Workflow Management

By setting up columns for different stages of progress, such as "To Do," "In Progress," and "Completed," TCard systems provide a simple yet effective way to track tasks through their lifecycle. This keeps tasks organised and helps teams stay on track with their priorities. It’s easier to spot potential bottlenecks or delays in the workflow, making it possible to take action before issues escalate.

Overall, TCard systems simplify task prioritisation and organisation by offering a clear, visual way to manage workloads. The customisation options and streamlined workflow ensure that teams can focus on what’s most important, improving efficiency and productivity.

The Role of TCard Systems in Enhancing Team Collaboration

In any organisation, effective collaboration is key to achieving goals and driving success. TCard systems play a crucial role in enhancing team collaboration by providing a clear and shared view of tasks, progress, and priorities. Here's how TCard systems help teams work better together:

Clear Visual Communication

TCard systems offer a visual representation of tasks, making it easy for everyone to see what needs to be done, who is responsible, and the current status of each task. This clarity helps team members stay aligned and ensures everyone knows what is happening at a glance. Whether working on a large project or a daily task, having this transparency improves communication and reduces misunderstandings.

Real-Time Updates and Feedback

With TCard systems, team members can update the status of their tasks in real-time. This allows everyone to stay informed of changes or progress without waiting for formal updates. If there are issues or roadblocks, they can be flagged immediately, enabling the team to collaborate on solutions. This real-time communication helps keep projects moving forward smoothly.

Centralised Task Management

TCard systems centralise task management, ensuring that everyone is working from the same list of priorities. Tasks are grouped into stages such as "To Do," "In Progress," and "Completed," allowing team members to see where they can support each other and where collaboration is needed. This shared platform encourages a more coordinated and cooperative approach to problem-solving and decision-making.

Overall, TCard systems foster collaboration by providing a shared, transparent, and dynamic environment for teams to work together more effectively, leading to better results and increased productivity.

Streamlining Your Workflows: TCard Systems for Better Productivity

In today's fast-paced work environment, productivity is key to success. TCard systems provide an effective way to streamline workflows, ensuring tasks are organised and progress is easily tracked. By visually managing work processes, TCard systems help eliminate inefficiencies and enhance productivity across various industries.

Visual Task Management

TCard systems use a clear, visual layout that helps teams quickly understand the status of all tasks. By categorising tasks into stages such as "To Do," "In Progress," and "Completed," team members can easily track progress and focus on the tasks that need attention. This visual structure makes prioritising work easier, ensuring that no task is overlooked or delayed.

Improved Collaboration and Communication

With a TCard system, all team members have access to the same real-time data, which improves communication and collaboration. As tasks move through different stages, team members can see updates instantly, reducing the need for constant meetings or emails. This shared knowledge leads to quicker decision-making and a more cohesive team effort.

Better Resource Allocation

By tracking the workload and progress of each task, TCard systems help managers allocate resources more effectively. They can identify bottlenecks or tasks that are falling behind schedule and adjust priorities accordingly. This efficient allocation of time and resources ensures that work flows smoothly, leading to higher productivity and less downtime.

Overall, TCard systems simplify workflows, boost collaboration, and help businesses maximise productivity by providing an intuitive, transparent task management system.

How to Set Up a TCard System for Your Business

Setting up a TCard system for your business is a straightforward process that can bring significant improvements to your task management and workflow. With its simple, visual interface, the TCard system is designed to help businesses stay organised and ensure smooth operations. Here’s how to get started:

Step 1: Define Your Workflow Stages

The first step in setting up a TCard system is to define the stages of your workflow. These could include categories like “To Do,” “In Progress,” and “Completed,” or more specific stages depending on your business needs. Clearly defining these stages will make it easy to track the progress of each task and ensure that work is organised.

Step 2: Create Your TCards

Once the workflow stages are established, start creating TCards for each task. Each TCard should include key information such as task name, deadline, priority level, and the person responsible for completing the task. This will help your team stay on top of their responsibilities and avoid confusion about who is doing what.

Step 3: Assign Tasks and Track Progress

Place the TCards in the appropriate stage of the workflow and assign tasks to team members. As work progresses, move the TCards through the stages to reflect their current status. This will give everyone a clear visual representation of the work being done and what needs attention.

Step 4: Regularly Review and Update

To maintain efficiency, regularly review the TCard system to make sure everything is up to date. This helps ensure that no task is forgotten and that priorities are adjusted as needed.

By setting up a TCard system, you can streamline operations, boost productivity, and ensure better communication within your team.

The Flexibility of TCard Systems: Tailoring to Your Team’s Needs

TCard systems offer unparalleled flexibility, making them an excellent solution for teams across various industries. The adaptable nature of TCards means you can easily tailor the system to fit your specific workflow, ensuring it meets your team's unique needs. Here’s how TCard systems can be customised for your team:

Customisable Workflow Stages

One of the greatest advantages of TCard systems is the ability to design your workflow stages. Whether you need basic categories like “To Do,” “In Progress,” and “Completed,” or more complex stages to reflect your processes, TCard boards allow for easy customisation. This ensures that every team, from project management to maintenance, can align their tasks with the most relevant workflow stages.

Adaptable Task Categories

Each task card in the TCard system can be customised with different fields like priority, deadlines, assigned team members, or specific project tags. This flexibility helps you organise tasks in a way that makes sense for your team, making it easier to track progress, set priorities, and identify bottlenecks.

Scalable for Growth

As your team or business grows, your TCard system can scale accordingly. You can add new categories, stages, or even integrate new team members without disrupting the overall structure. The ability to easily scale and adapt the system to evolving needs makes TCards a long-term solution for efficient task management.

The flexibility of TCard systems empowers teams to stay organised, maintain clear communication, and boost productivity, regardless of the size or complexity of their projects.

Integrating TCard Systems with Other Project Management Tools

Integrating TCard systems with other project management tools can enhance your workflow and improve overall team efficiency. TCards offer a visual, flexible approach to task tracking, and combining them with digital tools can create a seamless experience for managing your projects. Here’s how integrating TCard systems with other tools can benefit your business:

Centralised Task Management

By integrating TCard systems with tools like calendars, communication platforms, or project management software, you can centralise all your tasks in one place. This means that all team members can access up-to-date information, collaborate more easily, and track progress across different systems without duplicating efforts. It creates a unified space for task management, reducing confusion and improving productivity.

Enhanced Visibility and Reporting

When combined with data analytics or reporting tools, TCards can provide enhanced visibility into your team’s performance. By automatically synchronising data from other tools, you can generate real-time reports, identify trends, and make informed decisions faster. This integration allows for clearer tracking of key performance indicators (KPIs) and a more effective overview of your project timelines.

Streamlined Workflow Automation

Integrating TCard systems with workflow automation tools can streamline repetitive tasks. For instance, you can automate task assignments, notifications, and status updates, allowing your team to focus on high-value work. This integration saves time and ensures that nothing falls through the cracks.

Overall, integrating TCard systems with other project management tools can help you manage tasks more efficiently, increase collaboration, and drive better results for your projects.

Case Study: How Businesses Are Succeeding with TCard Task Management

Businesses of all sizes are increasingly turning to TCard task management systems to streamline their operations, improve task visibility, and enhance team collaboration. Below is a look at how one company successfully implemented TCard systems to optimise their workflow and achieve greater efficiency.

Improved Task Tracking and Communication

A manufacturing company found that their traditional task management system was inefficient and disorganised. By implementing TCard boards, they were able to visually track tasks in real-time. The cards were colour-coded to indicate priority levels and task stages, allowing the team to easily identify what needed immediate attention. This clarity in task status helped improve communication between departments and reduced delays caused by miscommunication.

Increased Productivity and Accountability

The integration of TCard systems also allowed the company to assign specific tasks to individual team members, making each person accountable for their part of the project. With clear visual cues on progress, employees were more motivated and could easily track their performance. As a result, the company saw a marked increase in productivity and task completion rates.

Scalable and Customisable for Growth

As the business expanded, the TCard system proved to be highly adaptable. The software allowed for easy customisation of boards to accommodate new departments and projects. Whether managing routine maintenance or complex projects, TCard task management remained flexible and scalable to support the company’s growth.

This case study highlights how businesses can use TCard systems to enhance task management, boost productivity, and support organisational growth.

Improving Task Transparency and Accountability with TCard Systems

TCard systems are a powerful tool for enhancing task transparency and accountability in any organisation. By visually managing tasks on a clear and organised board, TCard systems help ensure that everyone knows exactly what needs to be done, who is responsible, and when it needs to be completed.

Clear Visibility of Tasks

One of the main advantages of using TCard systems is the ability to visualise all tasks in real-time. Each task is represented by a card, which can be colour-coded based on priority or progress. This provides teams with a straightforward, at-a-glance overview of all ongoing tasks, ensuring that nothing is overlooked and that deadlines are clearly visible. The visibility encourages employees to stay focused and prioritise effectively.

Increased Accountability

With TCard systems, assigning tasks is made simple and clear. Each task card can be linked to an individual or a team, making it easy to track who is responsible for each piece of work. This fosters a culture of accountability, as team members can clearly see their responsibilities and the expectations for completion. Furthermore, the progress of tasks can be updated regularly, ensuring that managers and teams are kept in the loop.

Streamlined Communication

Since TCard systems facilitate real-time updates, communication between team members becomes smoother and more efficient. Updates on task progress can be made instantly, allowing teams to address potential issues before they become problems. This seamless communication helps to avoid bottlenecks and ensures tasks stay on track.

Overall, TCard systems are an excellent way to improve transparency and accountability, leading to better team coordination and enhanced productivity.

How TCard Systems Help Managers Track Progress and Meet Deadlines

TCard systems are an invaluable tool for managers looking to track progress and ensure deadlines are met. By providing a visual representation of tasks, TCard systems make it easier for managers to monitor work and stay on top of project timelines.

Visual Task Management

One of the main advantages of TCard systems is their visual approach to task management. Each task is represented by a card, which can be moved across different columns to reflect its current status, such as "To Do," "In Progress," or "Completed." This makes it simple for managers to quickly assess the status of each task and ensure nothing is falling behind schedule.

Real-Time Updates

TCard systems allow for real-time updates, meaning that any changes to task progress can be immediately reflected on the board. This feature ensures that managers are always up to date with the latest information, making it easier to identify potential delays or issues. With this visibility, managers can take proactive steps to keep tasks on track and address any challenges promptly.

Deadline Tracking

By integrating deadlines into each task card, TCard systems make it clear when a task is due. Managers can quickly see which tasks are nearing their deadline and prioritise them accordingly. The visual nature of TCard systems also makes it easier to spot potential bottlenecks and adjust resources or timelines to prevent delays.

Overall, TCard systems provide managers with the tools needed to effectively track progress, stay organised, and meet deadlines, helping ensure that projects run smoothly and on time.

Using TCard Systems for Better Resource Allocation and Planning

Effective resource allocation and planning are essential for optimising productivity and ensuring that tasks are completed efficiently. TCard systems offer a straightforward and visual approach that helps businesses manage resources more effectively.

Clear Visual Representation

One of the key benefits of using TCard systems is their visual layout. Tasks, resources, and deadlines are displayed on cards, making it easy to see at a glance which resources are available, assigned, or overloaded. This visual representation allows managers to assess the situation quickly and make informed decisions about how to allocate resources most effectively.

Optimising Task Assignment

TCard systems help with assigning tasks to the right individuals based on their current workload and expertise. By tracking who is working on what, managers can ensure that tasks are distributed fairly and that no one is overburdened. This leads to better planning and helps to prevent delays caused by overworked team members.

Improved Planning and Forecasting

By providing a clear overview of tasks and resource allocation, TCard systems assist in long-term planning. Managers can identify trends and potential challenges, making it easier to forecast future resource needs. With this insight, businesses can plan ahead and ensure that the necessary resources are in place when needed.

Overall, TCard systems enhance resource allocation and planning by providing clear visibility, improving task assignment, and offering valuable insights for future planning. This leads to more efficient use of resources and better overall project management.

The Future of Task Management: Why TCard Systems Are Here to Stay

In today’s fast-paced work environment, efficient task management is more crucial than ever. TCard systems provide a simple yet effective solution for businesses of all sizes to manage tasks, track progress, and streamline workflows. As organisations continue to prioritise efficiency and collaboration, TCard systems are poised to play a significant role in the future of task management.

Adaptability and Ease of Use

One of the primary reasons TCard systems are here to stay is their adaptability. These systems can be tailored to meet the specific needs of any team, making them highly versatile. Whether it's managing daily tasks, tracking project milestones, or coordinating team efforts, TCard systems offer a flexible solution that works for a wide range of industries and departments.

Visual and Intuitive Interface

Another key feature driving the success of TCard systems is their visual and intuitive nature. Users can quickly view tasks, deadlines, and progress, making it easier to prioritise and allocate resources. The straightforward layout reduces complexity, enabling teams to stay focused and organised without getting bogged down by unnecessary processes.

Increased Collaboration and Accountability

TCard systems also promote collaboration by providing a central platform for teams to manage and update tasks. This transparency boosts accountability and keeps everyone on the same page, which is vital for achieving long-term success in any organisation.

With their adaptability, visual appeal, and focus on collaboration, TCard systems are not just a trend – they’re the future of task management, here to stay for the long term.