In manufacturing and production environments, ensuring the maximum efficiency of equipment is essential for reducing costs, improving productivity, and maintaining competitiveness. Overall Equipment Effectiveness (OEE) is a key metric that measures the performance of manufacturing equipment. SAP provides a comprehensive suite of tools for OEE management, enabling businesses to track, analyze, and optimize the effectiveness of their equipment, identify bottlenecks, and make data-driven decisions to improve operations.

What is Overall Equipment Effectiveness (OEE)?

Overall Equipment Effectiveness (OEE) is a metric used to evaluate the efficiency of a manufacturing process by considering three key factors: availability, performance, and quality. The OEE score is a percentage that reflects the ratio of the ideal performance to the actual performance of equipment.

The OEE formula is as follows:

- Availability: Measures the percentage of time equipment is actually running compared to the total scheduled time.

- Performance: Measures the speed of equipment production compared to its maximum designed speed.

- Quality: Measures the percentage of good quality products produced compared to the total products produced.

The formula for calculating OEE is:

OEE = Availability × Performance × Quality

Key Benefits of SAP for OEE Management

Using SAP for OEE management offers several advantages for businesses looking to improve their equipment effectiveness. SAP integrates with existing manufacturing systems and provides a real-time, data-driven approach to OEE management. The key benefits include:

- Real-Time Monitoring: SAP allows businesses to track equipment performance in real-time, providing immediate visibility into machine uptime, production rates, and quality levels.

- Improved Decision-Making: With real-time data, managers can make informed decisions to optimize operations, reduce downtime, and improve throughput.

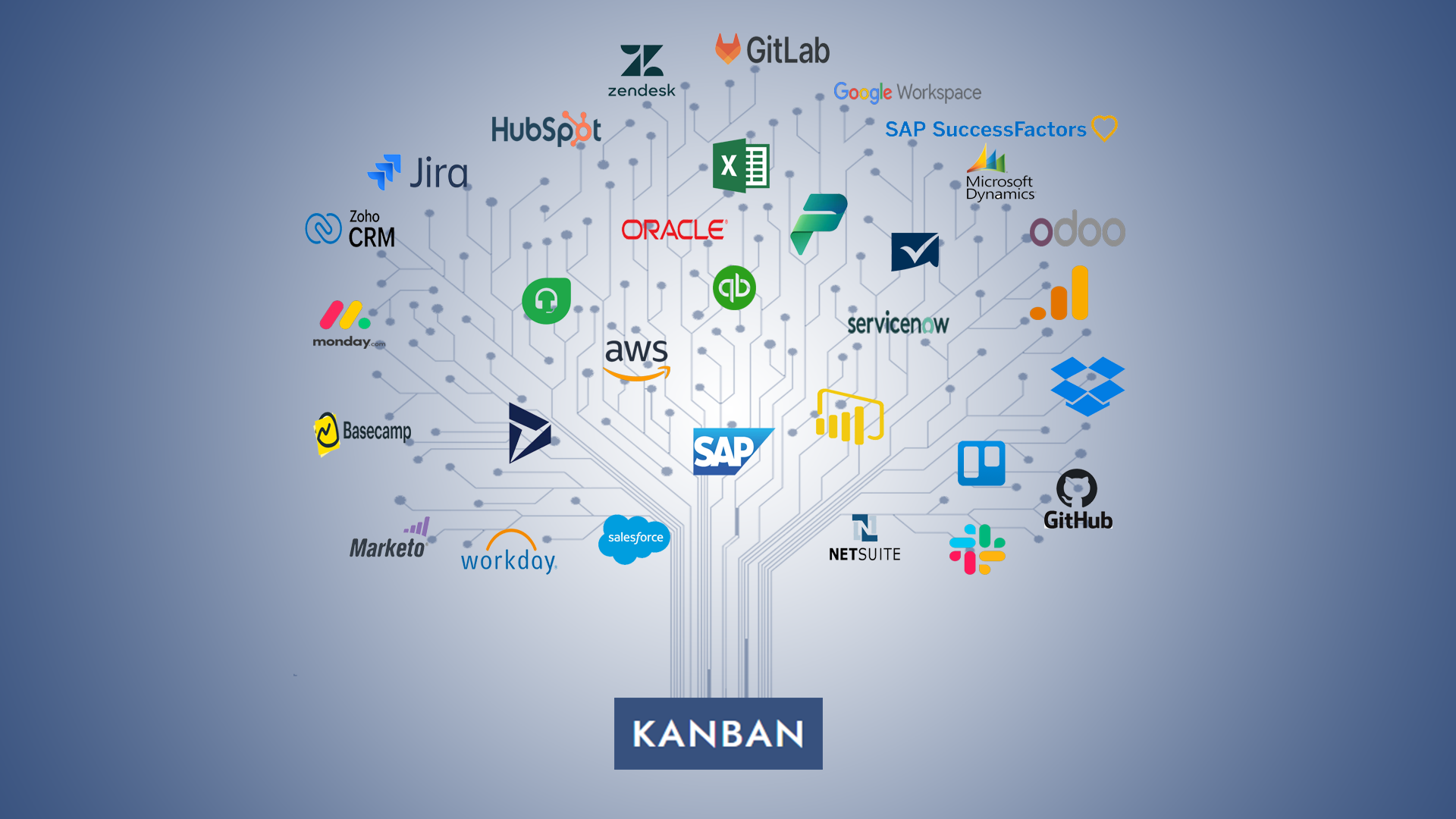

- Seamless Integration: SAP can integrate with other enterprise resource planning (ERP) systems, allowing for seamless data flow across various departments such as production, maintenance, and inventory management.

- Predictive Maintenance: By analyzing historical data, SAP helps predict potential equipment failures, enabling proactive maintenance and reducing unplanned downtime.

- Continuous Improvement: SAP's analytics tools help identify areas for improvement in equipment utilization, highlighting inefficiencies and opportunities to enhance OEE.

Key SAP Modules for OEE Management

SAP offers a range of modules and functionalities to effectively manage OEE. These tools help organizations monitor, analyze, and optimize equipment performance.

1. SAP Manufacturing Execution (SAP ME)

SAP Manufacturing Execution is a powerful tool that integrates shop floor operations with enterprise systems, allowing for seamless data collection and analysis of equipment performance. SAP ME provides the following capabilities for OEE management:

- Real-time tracking of equipment availability, performance, and quality.

- Integration with machine sensors and production lines to capture data automatically.

- Monitoring of equipment utilization to identify bottlenecks and optimize production schedules.

2. SAP Plant Maintenance (SAP PM)

SAP Plant Maintenance helps manage the maintenance of manufacturing equipment, ensuring its reliability and minimizing downtime. This module is critical for maintaining high OEE scores by improving equipment availability through proactive maintenance strategies:

- Scheduling preventive and predictive maintenance to avoid unexpected breakdowns.

- Tracking maintenance costs and downtime to optimize asset performance.

- Integrating maintenance data with production schedules to minimize disruptions.

3. SAP S/4HANA Manufacturing

SAP S/4HANA Manufacturing is a next-generation suite that supports production processes and enables real-time insights into manufacturing performance. For OEE management, SAP S/4HANA provides:

- Advanced analytics to monitor and assess equipment performance continuously.

- Integration with Internet of Things (IoT) devices for real-time data collection from machinery.

- Dashboards and visualizations to track KPIs such as OEE, uptime, and downtime.

How to Implement OEE Management with SAP

Implementing OEE management with SAP involves several steps to ensure the system is integrated, data is accurately collected, and processes are optimized. The following steps provide a framework for successful implementation:

Step 1: Define OEE Metrics

Begin by defining the OEE metrics that are most important to your organization. This includes determining which machines or production lines to monitor, setting up KPIs for availability, performance, and quality, and identifying any relevant targets or thresholds for optimal performance.

Step 2: Integrate SAP Modules

Integrate relevant SAP modules, such as SAP ME, SAP PM, and SAP S/4HANA Manufacturing, into your existing manufacturing and maintenance processes. This ensures that all data flows seamlessly between systems and that key performance indicators (KPIs) are tracked consistently.

Step 3: Install Data Collection Systems

Install sensors and data collection systems on machines and equipment to automatically gather real-time data related to equipment performance, downtime, and quality. This data will feed into SAP systems for real-time analysis and reporting.

Step 4: Set Up Dashboards and Reporting

Create dashboards and reports to visualize OEE data. Use SAP’s reporting tools to track equipment performance, identify areas for improvement, and share insights with relevant stakeholders.

Step 5: Monitor and Optimize

Once the system is live, continuously monitor equipment performance and identify areas of inefficiency. Use SAP’s analytics tools to pinpoint issues and implement corrective actions such as adjusting maintenance schedules or addressing production bottlenecks.

Step 6: Review and Improve

OEE management is an ongoing process. Regularly review performance reports and use insights from SAP tools to improve processes and increase equipment effectiveness. Apply lean manufacturing principles to eliminate waste, reduce downtime, and continuously improve OEE scores.

Challenges in OEE Management and How SAP Helps Overcome Them

OEE management presents several challenges, such as data collection issues, inaccurate performance tracking, and difficulty in identifying inefficiencies. SAP helps overcome these challenges in the following ways:

- Automated Data Collection: SAP’s integration with sensors and IoT devices ensures that accurate data is collected automatically, eliminating manual errors and inconsistencies.

- Real-Time Analytics: SAP provides real-time performance insights, enabling businesses to identify and address problems immediately.

- Proactive Maintenance: With SAP’s predictive maintenance features, businesses can predict and prevent equipment failures before they occur, reducing downtime and improving OEE.

SAP Overall Equipment Effectiveness Management

What is SAP Overall Equipment Effectiveness (OEE) Management?

SAP OEE Management is a comprehensive tool that helps businesses measure and optimize equipment performance in manufacturing environments. It tracks key factors like equipment availability, performance efficiency, and product quality to maximize operational efficiency.

How does SAP OEE Management improve manufacturing efficiency?

SAP OEE Management enhances efficiency by providing real-time data on equipment performance, identifying bottlenecks, minimizing downtime, and facilitating informed decision-making to improve overall production output.

What are the key metrics tracked by SAP OEE Management?

Key metrics tracked include availability, performance, and quality, all of which contribute to calculating the overall effectiveness of equipment in the manufacturing process.

How does SAP OEE software calculate availability, performance, and quality?

SAP OEE software calculates these metrics based on real-time data from equipment. Availability is based on uptime versus scheduled production time, performance measures actual output versus expected output, and quality compares the number of good units produced to total units produced.

Can SAP OEE Management integrate with existing manufacturing systems?

Yes, SAP OEE Management integrates seamlessly with existing manufacturing execution systems (MES), enterprise resource planning (ERP) systems, and other data sources to ensure a unified approach to equipment management.

How does SAP OEE management help reduce downtime in manufacturing?

By providing real-time visibility into equipment performance, SAP OEE management helps identify potential issues before they cause significant downtime, allowing for proactive maintenance and faster response to disruptions.

What are the benefits of real-time monitoring in SAP OEE Management?

Real-time monitoring helps managers track equipment performance as it happens, enabling quicker adjustments, minimizing delays, and optimizing production efficiency throughout the manufacturing process.

Can SAP OEE Management be customized for different manufacturing processes?

Yes, SAP OEE Management can be tailored to meet the unique needs of different manufacturing processes, with customizable dashboards, reporting, and KPI tracking relevant to each specific production line or facility.

How does SAP OEE software track equipment failure rates?

SAP OEE software tracks failure rates by collecting data on unplanned downtimes, equipment failures, and maintenance issues, then uses this data to calculate equipment reliability and predict future failures.

Does SAP OEE Management provide predictive analytics for equipment maintenance?

Yes, SAP OEE Management utilizes predictive analytics to anticipate equipment failures before they occur, allowing for scheduled maintenance and reducing the likelihood of unplanned downtime.

How does SAP OEE software handle data collection from equipment?

SAP OEE software collects data directly from machines and sensors through IoT integrations or manually entered data, ensuring accurate and up-to-date tracking of equipment performance metrics.

Can SAP OEE Management improve overall equipment utilization?

Yes, by providing detailed insights into equipment performance, SAP OEE Management helps manufacturers identify underperforming assets, optimize utilization, and improve overall equipment effectiveness.

What is the role of SAP OEE in lean manufacturing processes?

SAP OEE plays a key role in lean manufacturing by identifying areas of waste, tracking inefficiencies, and providing insights that help streamline processes and reduce unnecessary downtime or idle time.

How does SAP OEE software help with continuous improvement initiatives?

SAP OEE provides data-driven insights that guide continuous improvement initiatives by identifying trends, pinpointing inefficiencies, and suggesting actionable improvements for equipment and operations.

What are the security measures in SAP OEE Management software?

SAP OEE Management ensures data security through robust encryption, access control policies, and compliance with international standards for data protection and privacy.