Overall Equipment Effectiveness (OEE) is a critical metric for measuring manufacturing efficiency, ensuring that production processes operate at optimal levels. SAP OEE provides real-time insights into manufacturing operations, helping organizations identify bottlenecks, reduce downtime, and improve overall productivity. By integrating OEE with digital tools, manufacturers can gain a comprehensive view of equipment performance, streamline workflows, and drive continuous improvement.

Understanding Overall Equipment Effectiveness (OEE)

OEE is a key performance indicator that evaluates manufacturing productivity based on three primary factors:

- Availability: Measures the percentage of scheduled production time in which equipment is running.

- Performance: Assesses whether equipment is running at its optimal speed without slowdowns.

- Quality: Evaluates the number of defect-free units produced compared to total production.

The formula for calculating OEE is:

OEE = Availability × Performance × Quality

How SAP OEE Enhances Manufacturing Efficiency

SAP OEE integrates with enterprise systems to provide real-time insights into production processes. Key benefits include:

- Real-Time Monitoring: Captures live data from machines and sensors, providing a clear view of operational efficiency.

- Automated Data Collection: Reduces manual effort by pulling data directly from production lines and equipment.

- Downtime Analysis: Identifies the root causes of machine downtime and enables proactive maintenance strategies.

- Performance Benchmarking: Compares OEE metrics across different production lines, shifts, or facilities.

- Quality Management: Tracks defects and variations to improve product quality and reduce waste.

Key Features of SAP OEE

SAP OEE offers a range of features designed to optimize manufacturing performance:

- Customizable Dashboards: Provides real-time insights and analytics on production efficiency.

- Alerts and Notifications: Sends automated alerts when performance drops below predefined thresholds.

- Predictive Maintenance: Uses machine learning and historical data to predict equipment failures before they occur.

- Integration with IoT: Connects with industrial IoT devices for more accurate data collection and monitoring.

Implementing SAP OEE in Manufacturing

To successfully implement SAP OEE, manufacturers should follow these steps:

- Define Objectives: Establish clear goals for improving OEE, such as reducing downtime or increasing output.

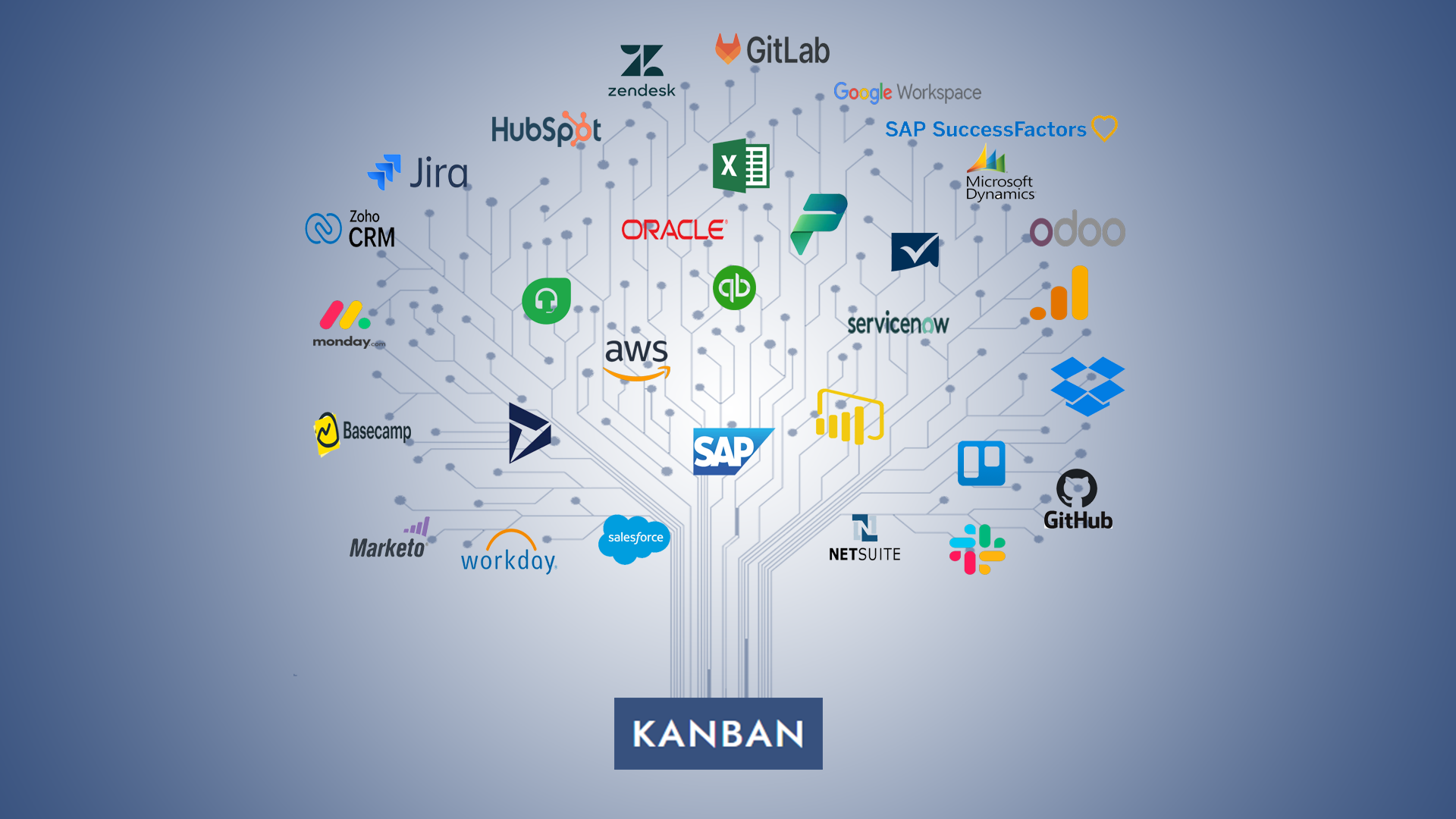

- Integrate with Existing Systems: Ensure that SAP OEE seamlessly connects with ERP, MES, and IoT platforms.

- Configure Performance Metrics: Set up key parameters for availability, performance, and quality tracking.

- Train Teams: Provide hands-on training for operators and managers to maximize the benefits of real-time insights.

- Monitor and Optimize: Continuously analyze OEE data to identify improvement opportunities and adjust strategies.

SAP OEE: Maximising Manufacturing Efficiency with Real-Time Insights

What is SAP OEE?

SAP OEE (Overall Equipment Effectiveness) is a solution designed to monitor and improve manufacturing efficiency by analyzing real-time performance data from machines and production lines.

How does SAP OEE help improve manufacturing efficiency?

It helps by identifying inefficiencies, tracking machine downtime, and providing real-time insights that enable proactive decision-making to enhance productivity.

What are the key components of SAP OEE?

The key components include availability tracking, performance analysis, quality measurement, and real-time reporting dashboards.

How does SAP OEE calculate Overall Equipment Effectiveness?

OEE is calculated using three factors: availability (machine uptime), performance (speed efficiency), and quality (defect rate). The formula is OEE = Availability × Performance × Quality.

What real-time insights does SAP OEE provide?

It provides insights on machine performance, downtime causes, production speed, quality trends, and overall plant efficiency.

How does SAP OEE help identify production bottlenecks?

By analyzing machine performance and downtime trends, SAP OEE highlights slow or problematic areas in the production process that need attention.

Can SAP OEE integrate with existing manufacturing systems?

Yes, SAP OEE can be integrated with existing MES, ERP, and IoT-based systems to provide a unified view of production data.

How does SAP OEE track machine performance?

It tracks performance by continuously collecting data on runtime, speed, energy consumption, and error rates from machines.

What role does SAP OEE play in predictive maintenance?

SAP OEE helps predict maintenance needs by analyzing historical machine data and detecting early signs of wear or failure.

How does SAP OEE support lean manufacturing principles?

It supports lean manufacturing by reducing waste, optimizing machine usage, and improving production flow based on real-time data.

What are the benefits of real-time data monitoring in SAP OEE?

Real-time data monitoring allows for quick decision-making, immediate issue resolution, and improved overall equipment efficiency.

How can SAP OEE help reduce production downtime?

By identifying and addressing the root causes of downtime, SAP OEE helps maintain continuous production and minimize disruptions.

What industries benefit the most from SAP OEE?

Industries such as manufacturing, automotive, pharmaceuticals, food processing, and logistics benefit from improved production efficiency using SAP OEE.

How does SAP OEE contribute to quality management?

It ensures quality by tracking defect rates, analyzing trends, and alerting teams to potential issues before they impact production.

What reporting and analytics features does SAP OEE offer?

SAP OEE offers dashboards, KPI tracking, historical analysis, and customizable reports to monitor efficiency and drive continuous improvement.