What Is SQDCM and How Does It Drive Production Efficiency?

SQDCM is an acronym representing five key performance indicators in manufacturing and production environments: Safety, Quality, Delivery, Cost, and Morale. These factors play a critical role in driving production efficiency, ensuring that operations run smoothly, products meet quality standards, and costs are kept under control. By focusing on these five elements, businesses can improve both the effectiveness of their workforce and the overall performance of their production processes.

1. Safety

Safety is the foundation of any productive operation. By prioritising a safe work environment, businesses reduce the risk of accidents, injuries, and downtime. Fostering a culture of safety leads to fewer disruptions, less absenteeism, and a more focused workforce, which ultimately drives higher productivity.

2. Quality

Quality ensures that products meet the required standards, reducing the need for rework or returns. Focusing on quality helps eliminate defects, improve customer satisfaction, and reduce waste. By incorporating quality into every stage of production, businesses achieve consistent results and higher efficiency.

3. Delivery

Timely delivery of products is essential for meeting customer expectations and maintaining supply chain efficiency. By focusing on delivery performance, businesses can optimise production schedules, minimise delays, and ensure that customers receive their orders on time, which in turn boosts customer satisfaction and loyalty.

4. Cost

Controlling costs is crucial for maintaining profitability. By managing operational expenses, minimising waste, and improving resource utilisation, businesses can reduce production costs while maintaining high standards of quality and efficiency.

5. Morale

A motivated and engaged workforce is key to driving efficiency. When employees are satisfied and feel valued, they are more productive, committed to continuous improvement, and less likely to contribute to delays or mistakes. High morale promotes a positive work environment that fuels productivity.

SQDCM is a holistic approach to production efficiency. By focusing on safety, quality, delivery, cost, and morale, businesses can optimise their processes, enhance productivity, and stay competitive in a demanding market.

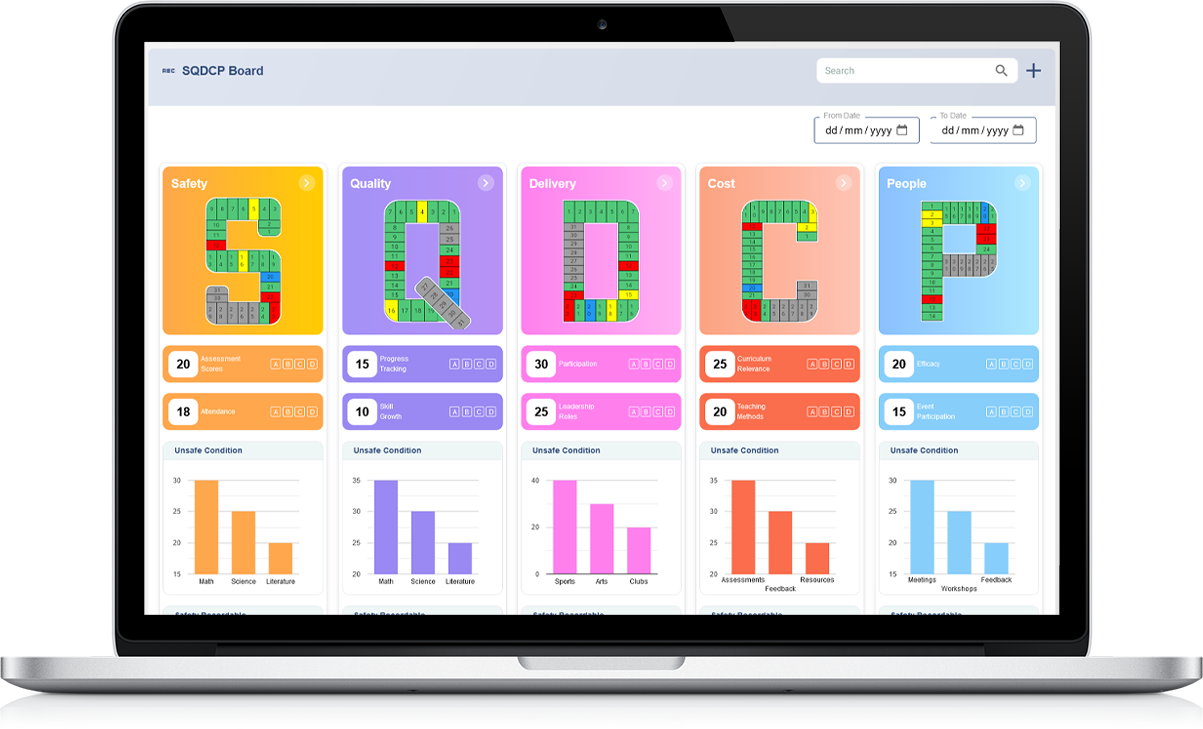

The Power of a Production Dashboard in Daily SQDCM Monitoring

A production dashboard is a powerful tool for monitoring and managing the key performance indicators of SQDCM: Safety, Quality, Delivery, Cost, and Morale. By displaying real-time data on a single, easy-to-read screen, a production dashboard empowers managers and teams to make informed decisions, track performance, and drive improvements across the entire production process. With the integration of SQDCM metrics, a dashboard provides a comprehensive view of daily operations, ensuring that production goals are consistently met.

1. Real-Time Monitoring of Safety

A production dashboard allows for immediate tracking of safety metrics, such as accident reports, near misses, and compliance with safety protocols. This enables management to identify potential hazards quickly and take action to mitigate risks, ensuring a safer working environment. Prioritising safety reduces downtime and promotes a culture of safety within the workplace.

2. Quality Control at a Glance

By tracking quality metrics such as defect rates, rework, and inspection results, a production dashboard helps identify areas where processes can be improved. Real-time visibility into quality performance allows teams to address issues promptly, reducing waste and ensuring consistent product quality.

3. Monitoring Delivery and Performance

Delivery metrics, such as on-time performance and production throughput, are displayed on the dashboard to ensure that production schedules are met. By monitoring these metrics in real-time, managers can take immediate action to address any delays or bottlenecks, ensuring that deadlines are consistently met and customer satisfaction is maintained.

4. Cost Control and Efficiency

The dashboard provides insight into cost-related metrics, such as labour costs, material usage, and energy consumption. By tracking these costs, businesses can identify inefficiencies and implement cost-saving measures, helping to maintain profitability without compromising quality or safety.

5. Enhancing Employee Morale

Employee morale is directly impacted by transparent communication and visible recognition of achievements. A production dashboard can highlight team successes, celebrate improvements in performance, and identify areas where additional support is needed, fostering a more engaged and motivated workforce.

A production dashboard is an essential tool for monitoring and optimising SQDCM performance. By providing real-time data on safety, quality, delivery, cost, and morale, it enables businesses to drive continuous improvement, enhance operational efficiency, and achieve production goals.

How to Use a Production Dashboard to Track SQDCM Metrics in Real-Time

A production dashboard is a valuable tool for tracking SQDCM metrics—Safety, Quality, Delivery, Cost, and Morale— in real-time. With instant visibility into these key performance indicators (KPIs), businesses can ensure smooth operations, identify issues promptly, and make data-driven decisions. Here’s how to effectively use a production dashboard to monitor these essential metrics:

1. Real-Time Safety Monitoring

A production dashboard allows you to track safety incidents, near misses, and compliance with safety protocols in real-time. By displaying safety-related metrics, it helps teams stay vigilant, respond to hazards immediately, and prevent accidents that could disrupt operations.

2. Quality Performance Tracking

Track quality-related metrics such as defect rates, rejection percentages, and rework times. A dashboard provides real-time insights into quality control, enabling managers to spot trends, identify potential problems, and implement corrective actions quickly. This reduces waste and ensures high-quality output.

3. Monitoring Delivery and On-Time Performance

Delivery metrics, such as on-time production rates and order fulfilment, are displayed on the dashboard for easy tracking. This real-time data helps managers stay on top of production schedules, ensuring that targets are met and customer orders are delivered on time, boosting satisfaction and trust.

4. Cost Control and Efficiency Insights

Track operational costs, including labour, materials, and overheads, with the dashboard’s real-time updates. By monitoring these metrics, you can quickly spot inefficiencies and adjust processes to reduce costs while maintaining quality standards.

5. Tracking Employee Morale

Employee morale can be tracked using the dashboard by monitoring engagement levels, performance feedback, and satisfaction metrics. Recognising achievements and addressing concerns in real-time helps maintain a motivated workforce, which directly contributes to productivity and overall performance.

A production dashboard is an indispensable tool for tracking SQDCM metrics in real-time. By providing instant visibility into safety, quality, delivery, cost, and morale, it enables businesses to make timely, informed decisions and drive continuous improvement across their production processes.

Boosting Productivity with SQDCM: A Step-by-Step Guide to Using Dashboards

Implementing SQDCM (Safety, Quality, Delivery, Cost, and Morale) metrics into your daily operations is a powerful way to boost productivity. Using a dashboard to track these key performance indicators (KPIs) ensures real-time insights, helping you optimise processes and improve overall performance. Here’s a step-by-step guide to using dashboards for boosting productivity:

1. Set Clear SQDCM Goals

Start by setting specific, measurable goals for each of the five SQDCM metrics. Define targets for safety, quality, delivery, cost, and morale that align with your overall production objectives. This step ensures that your team knows exactly what they need to achieve.

2. Customise Your Dashboard

Customise your dashboard to reflect the most important SQDCM metrics for your operations. For instance, include real-time updates on safety incidents, defect rates, production efficiency, and costs. The dashboard should display key data clearly and concisely for easy monitoring.

3. Monitor Safety First

Track safety incidents and near-misses in real-time. A high focus on safety helps prevent accidents, reduce downtime, and ensure workers' well-being, leading to higher productivity in the long term.

4. Track Quality and Delivery

Monitor quality control and delivery performance directly on the dashboard. Keep an eye on defect rates and on-time deliveries to prevent issues before they affect your production targets. Real-time tracking helps ensure the quality of your output remains consistent.

5. Control Costs and Boost Morale

Use the dashboard to monitor operational costs and efficiency. Track metrics such as labour and material expenses to make informed decisions. At the same time, keep track of employee morale by monitoring engagement levels and feedback, ensuring a motivated team.

In conclusion, dashboards are an effective tool for tracking SQDCM metrics. By setting clear goals, customising your dashboard, and monitoring key performance areas, you can significantly boost productivity and drive continuous improvement across your operations.

The Importance of Daily Monitoring for SQDCM Metrics in Manufacturing

In manufacturing, maintaining high levels of productivity and efficiency is crucial for long-term success. One of the best ways to achieve this is by monitoring SQDCM (Safety, Quality, Delivery, Cost, and Morale) metrics daily. Daily tracking ensures that your operations stay on course and helps you identify issues before they become major problems. Here’s why daily monitoring of SQDCM metrics is essential:

1. Ensures Ongoing Safety

Safety is the top priority in any manufacturing facility. By monitoring safety metrics daily, you can quickly identify and address hazards or safety breaches. This proactive approach helps prevent accidents, reduces downtime, and ensures a safer work environment for employees.

2. Maintains Consistent Quality

Daily tracking of quality metrics helps ensure that products meet the required standards. By identifying quality issues in real-time, you can reduce defects, improve product consistency, and minimise the risk of product recalls. It also enables your team to address minor issues before they escalate into costly problems.

3. Improves Delivery Timeliness

Monitoring delivery performance every day allows you to track production timelines and delivery schedules. By addressing delays quickly, you can improve on-time delivery rates and maintain customer satisfaction, which directly impacts your brand's reputation and profitability.

4. Controls Costs Effectively

Keeping a close eye on cost-related metrics such as labour and material expenses ensures that you stay within budget. Daily monitoring helps you spot areas of inefficiency and take corrective actions to control operational costs, leading to better profit margins.

5. Boosts Employee Morale

Finally, daily monitoring of employee morale helps you identify any concerns or dissatisfaction early. By addressing issues quickly, you can maintain a motivated workforce, which is vital for productivity and employee retention.

Daily monitoring of SQDCM metrics in manufacturing is essential for maintaining operational efficiency. It helps identify potential issues before they grow, ensures continuous improvement, and supports a safe, high-quality, and cost-effective production environment.

How a Production Dashboard Helps You Stay on Top of Quality, Safety, and Delivery

In a fast-paced production environment, staying on top of key metrics such as quality, safety, and delivery is crucial for maintaining operational efficiency. A production dashboard offers a real-time, visual tool to track these critical factors, ensuring that your team can make quick, data-driven decisions. Here’s how a production dashboard can help manage these important areas:

1. Enhancing Quality Control

A production dashboard provides instant insights into quality metrics, allowing you to monitor product defects, rework rates, and overall product standards. By tracking quality in real-time, you can quickly identify issues and address them before they impact large batches. This proactive approach ensures that your products meet the highest standards and reduces waste caused by poor-quality items.

2. Improving Safety Monitoring

Safety is a top priority in any production facility, and a production dashboard can help ensure compliance with safety protocols. By displaying safety-related metrics, such as accident rates, near misses, and safety audits, it enables managers to spot trends and take preventive action. Daily updates on safety performance help reduce risks and promote a culture of safety among employees.

3. Streamlining Delivery Timelines

Meeting delivery deadlines is crucial for maintaining customer satisfaction and meeting business targets. A production dashboard allows you to track delivery performance in real-time, helping you stay informed about production progress and potential delays. This visibility enables you to make quick adjustments to stay on track and meet delivery goals consistently.

A production dashboard serves as an invaluable tool for monitoring quality, safety, and delivery. By offering real-time insights, it empowers teams to take swift action, reduce risks, and improve overall operational performance, ultimately boosting productivity and customer satisfaction.

Using SQDCM Data to Identify Performance Gaps and Improve Production

Monitoring and improving production efficiency is key to any manufacturing operation. By using SQDCM (Safety, Quality, Delivery, Cost, and Morale) data, businesses can pinpoint performance gaps and make informed decisions to enhance production outcomes. Here’s how SQDCM data helps identify these gaps and drive improvements:

1. Spotting Safety Concerns

Safety is the first pillar of SQDCM, and identifying safety gaps is essential for a productive environment. By tracking safety data such as accidents, near misses, and compliance with safety protocols, production managers can spot trends that may indicate unsafe practices. This data enables proactive measures to address hazards and ensure a safer working environment, ultimately reducing downtime caused by accidents.

2. Enhancing Quality Control

Quality issues can significantly impact production efficiency. SQDCM data related to product defects, rework rates, and process deviations helps to highlight areas where quality is slipping. By identifying these issues early, teams can adjust processes, conduct additional training, or invest in better equipment to reduce defects and improve product quality, ultimately increasing production output.

3. Improving Delivery Performance

Timely delivery is crucial for customer satisfaction. Delivery data from the SQDCM model allows managers to monitor production schedules and identify delays. By analysing delivery performance, you can adjust workflows, optimise production schedules, and improve resource allocation to ensure on-time deliveries and enhance customer satisfaction.

4. Managing Costs Effectively

Cost efficiency is a vital part of production success. Using SQDCM data to track operational costs helps identify areas where resources are being wasted. Whether through overproduction, inefficient machinery, or labour costs, recognising these inefficiencies helps teams take corrective actions to optimise costs and improve profitability.

SQDCM data provides valuable insights into safety, quality, delivery, cost, and morale. By regularly tracking and analysing these metrics, manufacturers can identify performance gaps, implement improvements, and drive production efficiency across the board.

Maximise Operational Efficiency by Monitoring SQDCM on a Single Dashboard

In today’s fast-paced manufacturing environment, optimising operational efficiency is essential for maintaining competitiveness. Monitoring key metrics through a single dashboard can significantly enhance productivity and decision-making. By consolidating SQDCM (Safety, Quality, Delivery, Cost, and Morale) metrics on one dashboard, managers can gain a clear, real-time overview of operations and identify areas for improvement quickly.

1. Centralised Data for Quick Insights

Having all SQDCM data on a single dashboard enables managers to track key performance indicators (KPIs) in one place. This centralised approach saves time, allowing for faster decision-making. With a quick glance, you can see safety issues, quality concerns, delivery performance, cost overruns, and employee morale levels, ensuring that nothing is overlooked. It empowers teams to respond to problems before they escalate, keeping operations running smoothly.

2. Proactive Problem Identification

Real-time monitoring of SQDCM metrics helps identify bottlenecks or inefficiencies as they arise. For example, if safety incidents are rising, the dashboard will highlight this trend immediately, prompting swift action to rectify the issue. Similarly, quality problems can be spotted early, allowing for timely adjustments to prevent defects and minimise downtime.

3. Improved Resource Allocation

By using a dashboard to track delivery performance and cost data, managers can make more informed decisions about resource allocation. This data-driven approach ensures that labour, materials, and equipment are being used efficiently, reducing waste and improving overall productivity.

4. Enhanced Team Morale

Monitoring employee morale through the SQDCM framework is essential for creating a positive work environment. By identifying any signs of low morale, managers can address concerns, promote engagement, and foster a more motivated and productive workforce.

Monitoring SQDCM on a single dashboard enables manufacturers to maximise operational efficiency, reduce risks, and improve performance across all key areas. It provides valuable insights that drive smarter decision-making and continuous improvement.

How to Leverage SQDCM Data for Smarter Decision-Making in Production

In the fast-moving world of production, making informed decisions is crucial to achieving operational excellence. Leveraging SQDCM (Safety, Quality, Delivery, Cost, and Morale) data enables managers to gain deep insights into every aspect of their production process, leading to smarter, more strategic decisions. By analysing these metrics, businesses can improve efficiency, reduce costs, and enhance overall performance.

1. Track Performance Across Key Areas

Each element of SQDCM represents a critical area of production. Safety metrics allow businesses to monitor and address potential hazards, ensuring a safe working environment. Quality data highlights areas where defects occur, enabling targeted improvements. Delivery metrics help teams stay on schedule and meet customer expectations. Cost data aids in identifying areas for financial optimisation, while morale data ensures a motivated workforce. By regularly reviewing these metrics, decision-makers can make adjustments to improve performance across the board.

2. Identify Trends and Patterns

SQDCM data helps uncover trends that might not be immediately obvious. For example, a sudden increase in safety incidents or quality defects could indicate underlying issues in the production line or employee training. By recognising these patterns early, managers can take corrective action before problems escalate, saving both time and money.

3. Drive Continuous Improvement

Using SQDCM data as a benchmark for continuous improvement helps businesses optimise their processes. By setting performance goals for each metric and tracking progress over time, production teams can achieve better results. Regular analysis ensures that operations remain aligned with business objectives, fostering ongoing efficiency and growth.

Leveraging SQDCM data empowers managers to make more informed, data-driven decisions. By focusing on key metrics, identifying trends, and continuously improving processes, businesses can drive greater efficiency, improve product quality, and reduce operational costs.

Customising Your Production Dashboard for SQDCM to Meet Specific Needs

Every production facility operates differently, which means a one-size-fits-all dashboard won’t always deliver the best results. Customising your production dashboard to suit your specific SQDCM (Safety, Quality, Delivery, Cost, Morale) requirements ensures your team has the most relevant and actionable insights at their fingertips. Tailoring your dashboard helps you monitor what matters most and make quicker, smarter decisions.

1. Focus on Priority Metrics

Not all production challenges are the same. Some teams may need to concentrate on improving safety, while others might be focused on meeting tight delivery timelines. Custom dashboards allow you to highlight the SQDCM pillars most relevant to your goals. You can display these metrics front and centre, making it easier to track progress and take immediate action when needed.

2. Adjust for Workflow and Department Needs

Each department may have different responsibilities and performance indicators. With a flexible dashboard, you can assign different views to different teams. For example, the maintenance team might focus more on cost and downtime, while the quality team can track defect rates. Custom views ensure each group sees the data that matters most to their role.

3. Visualise Data in a Way That Works Best

Customisation isn’t just about what data you see – it’s also about how you see it. Whether it’s graphs, charts, or simple tables, your dashboard should present data clearly and in a way your team can understand and use easily. Effective visuals support faster decision-making and keep everyone aligned.

By customising your SQDCM dashboard, you enhance visibility, empower teams, and make your operations more responsive to real-time production needs.

Why Real-Time SQDCM Monitoring Leads to Better Production Outcomes

In today’s fast-paced manufacturing environment, having access to real-time data is essential for staying ahead. Real-time SQDCM monitoring (Safety, Quality, Delivery, Cost, Morale) allows production teams to track performance instantly, spot issues as they arise, and take quick corrective actions. This approach leads to improved efficiency, reduced delays, and stronger overall outcomes across the entire facility.

1. Quick Response to Issues

When a safety concern or quality error happens on the shop floor, real-time monitoring ensures it’s flagged immediately. This helps teams act fast before small problems become major disruptions. Instant alerts reduce waste, prevent delays, and support a safer workplace environment.

2. Improved Decision-Making

With live data at your fingertips, managers and team leaders can make more accurate decisions. Whether adjusting schedules, reallocating resources, or shifting priorities, up-to-date SQDCM metrics provide the insight needed to react effectively and confidently in any situation.

3. Higher Accountability and Engagement

When staff can see real-time performance, they become more engaged with targets. Everyone knows where the team stands and what needs attention. This transparency fosters a culture of responsibility and continuous improvement, driving long-term success.

By implementing real-time SQDCM monitoring, production teams gain the visibility and control needed to improve daily performance, reduce waste, and ensure consistent delivery on targets. It transforms reactive operations into proactive, agile ones.

How Production Dashboards Help You Maintain Consistency in Quality and Delivery

In a busy production setting, consistency in quality and on-time delivery is vital. A well-designed production dashboard gives teams the visibility they need to manage work more effectively. By showing live updates on key metrics, dashboards help ensure every product meets quality standards and gets delivered as promised.

1. Real-Time Monitoring for Better Control

Dashboards display real-time data, allowing teams to spot issues quickly. If a delay or defect occurs, it can be seen and acted on immediately. This level of control helps reduce the risk of errors and keeps production running smoothly from start to finish.

2. Tracking Performance Against Set Targets

With a dashboard, teams can track progress against daily, weekly, or monthly goals. Quality and delivery targets are clearly visible, so everyone knows how the team is performing. This constant awareness helps teams stay focused and aligned with production goals.

3. Supporting Continuous Improvement

Production dashboards also store historical data, which is useful for identifying trends and areas for improvement. By reviewing past performance, managers can find patterns and make changes that boost quality and delivery consistency over time.

Overall, production dashboards offer a simple yet powerful way to maintain high standards in quality and delivery. They give your team the tools to act quickly, stay on track, and deliver results with confidence.

How SQDCM Metrics Can Help You Identify Root Causes of Production Issues

Understanding the root cause of production issues is key to maintaining a smooth and efficient operation. SQDCM metrics—focused on Safety, Quality, Delivery, Cost, and Morale—offer a structured way to monitor performance and uncover the real reasons behind recurring problems. By analysing these key areas, teams can take informed actions that lead to lasting improvements.

1. Pinpointing Specific Areas of Concern

Each SQDCM category highlights different aspects of your operation. If there are repeated quality concerns, for example, looking into the Quality metric may reveal patterns such as process errors or material defects. Likewise, frequent delivery delays may show up in the Delivery section, helping teams focus on scheduling or supply chain issues.

2. Linking Metrics to Root Causes

By tracking these metrics regularly, it becomes easier to connect outcomes to behaviours or events. For example, low morale scores might be linked to higher error rates or safety incidents. This insight allows managers to explore deeper reasons, such as training gaps or workload issues, rather than treating only the symptoms.

3. Driving Targeted Improvements

Once the root causes are clear, targeted actions can be taken to resolve them. SQDCM provides both visibility and accountability, so improvements can be tracked and measured over time. This approach leads to more sustainable changes and fewer repeat problems.

Using SQDCM metrics to identify root causes gives teams the clarity they need to fix issues effectively and maintain high performance in production.

The Role of a Production Dashboard in Facilitating Continuous Improvement

A production dashboard plays a vital role in driving continuous improvement across any manufacturing or operational environment. By providing real-time visibility into key performance indicators, teams can make informed decisions, identify trends, and take proactive steps to improve processes on a regular basis.

1. Clear and Centralised Performance Tracking

With a production dashboard, all essential data is displayed in one easy-to-read place. This includes metrics related to quality, output, safety, efficiency, and more. Having this information in a single view allows teams to quickly assess whether they are meeting daily targets or if there are issues that need attention.

2. Identifying Patterns and Areas for Improvement

Over time, dashboards help reveal performance trends. Repeated issues, such as downtime, missed deadlines, or quality concerns, can be spotted early. Teams can then investigate the root causes and apply changes before the problems grow larger. This proactive approach is the foundation of continuous improvement.

3. Supporting Team Engagement and Accountability

Production dashboards also keep everyone aligned. When all departments can see progress in real-time, it encourages collaboration and ownership. Staff are more likely to contribute improvement ideas and stay motivated when they understand how their work directly impacts overall performance.

In summary, a well-designed production dashboard empowers teams to stay focused, act quickly, and continuously refine operations—leading to better results over time.

Integrating SQDCM Metrics into Your Daily Workflow for Maximum Production Gains

Incorporating SQDCM (Safety, Quality, Delivery, Cost, and Morale) metrics into your daily workflow helps maintain focus on key production goals and promotes long-term improvements. These core metrics provide structure, consistency, and visibility across departments, driving better performance every day.

1. Making SQDCM a Routine Practice

Start by introducing short daily checks or team huddles where SQDCM performance is reviewed. Use a visual board or dashboard to show the current status of each metric. Keeping this process quick and focused ensures teams stay informed without disrupting workflow.

2. Encouraging Cross-Department Accountability

By linking SQDCM metrics to each department's responsibilities, everyone understands their role in overall success. For instance, safety performance can be tracked by incidents or near-misses, while delivery may focus on on-time completion rates. Assigning ownership ensures accountability and action when targets aren't met.

3. Tracking Progress and Adjusting Actions

Daily reviews of SQDCM metrics allow for immediate feedback and response. If quality drops or delivery delays occur, teams can discuss causes and implement quick fixes. Over time, these small daily changes lead to major production gains without needing large-scale overhauls.

By embedding SQDCM into your everyday routine, you create a culture of transparency, teamwork, and continuous improvement—key ingredients for long-term operational success.