Kanban, a popular visual system used to manage workflows and inventory, plays a crucial role in improving operational efficiency. SAP S/4HANA, a next-generation enterprise resource planning (ERP) suite, incorporates Kanban functionality to enhance workflow and inventory management. By leveraging the Kanban functionality in SAP S/4HANA, organizations can streamline material flow, reduce waste, and ensure that production processes are optimized for efficiency.

1. What is Kanban?

Kanban is a Japanese word that translates to "visual signal" or "card." The Kanban system is a lean management method used to control the flow of materials in production processes. It ensures that production is closely aligned with demand, replenishing materials only when they are needed, thereby minimizing waste and preventing excess inventory. In manufacturing, Kanban helps teams signal when it's time to restock materials, promoting just-in-time production and reducing lead times.

Kanban uses visual cues, typically in the form of cards, to trigger actions such as the ordering of materials or the initiation of production steps. In SAP S/4HANA, the Kanban method is integrated into the Materials Management (MM) and Production Planning (PP) modules, where it helps automate inventory replenishment and streamline manufacturing operations.

2. Key Features of Kanban in SAP S/4HANA

SAP S/4HANA’s Kanban functionality is designed to provide businesses with a flexible, efficient, and automated solution to manage material flow. Some of the key features include:

- Kanban Containers: In SAP S/4HANA, materials are stored in containers, which can represent physical bins or logical storage locations. Each container holds a specific amount of material, and when the material reaches a low threshold, the system triggers a replenishment order to restock the container.

- Control Cycles: A control cycle in SAP S/4HANA defines how the Kanban system operates for each material. It includes parameters such as the minimum and maximum quantities for each container, the type of replenishment (production or procurement), and the associated work centers or suppliers.

- Kanban Cards: SAP uses digital Kanban cards to represent the visual signal in the system. When a container is empty or reaches the predetermined minimum level, the Kanban card is triggered, prompting the system to reorder materials or trigger production orders.

- Real-Time Monitoring: SAP S/4HANA enables real-time monitoring of Kanban containers, allowing users to track the status of materials, containers, and orders. The system provides up-to-date information on material availability, which helps prevent stockouts and ensures that production runs smoothly.

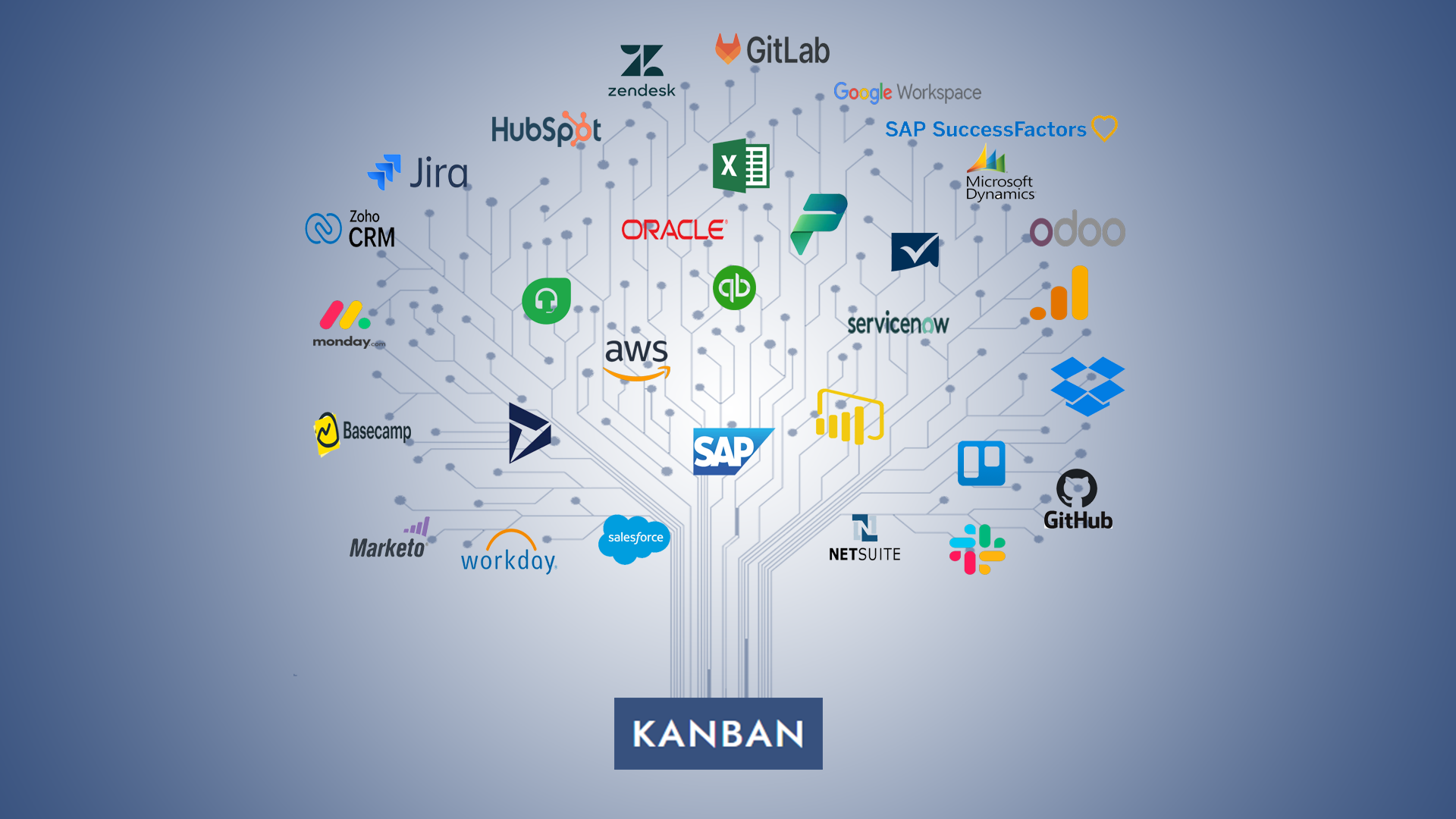

- Integration with Other Modules: Kanban in SAP S/4HANA is closely integrated with other modules, such as Materials Management (MM), Production Planning (PP), and Warehouse Management (WM). This integration ensures that material movements, replenishments, and production orders are efficiently managed within the ERP system.

3. Setting Up Kanban in SAP S/4HANA

To implement Kanban in SAP S/4HANA, businesses must configure various elements within the system to align with their specific production needs. The following are the key steps involved in setting up Kanban:

- Define Kanban Containers: The first step is to define the Kanban containers within the SAP system. This involves specifying the material type, container size, and capacity. Containers are associated with particular materials and locations within the production environment.

- Create Control Cycles: A control cycle defines the replenishment strategy for each material and container. In SAP S/4HANA, control cycles specify important parameters, such as the minimum and maximum stock levels, the replenishment method (whether to produce in-house or procure from suppliers), and the trigger conditions for Kanban cards.

- Assign Kanban to Materials: Once the control cycles are set, each material needs to be assigned to a Kanban container. SAP S/4HANA ensures that each material in the production line is correctly linked to its corresponding Kanban container, allowing automatic replenishment to occur when inventory levels fall below the defined threshold.

- Configure Replenishment Process: Businesses must decide whether they will replenish materials through in-house production or by purchasing from external suppliers. SAP S/4HANA supports both options, allowing companies to manage production orders or purchase orders automatically when a Kanban card is triggered.

- Set Up Monitoring and Reporting: SAP S/4HANA provides tools to track and report on the status of Kanban containers, replenishment cycles, and material flows. By configuring real-time monitoring and reporting tools, businesses can identify potential bottlenecks, track the efficiency of their Kanban system, and make data-driven decisions.

4. How Kanban Optimizes Workflow and Inventory Management in SAP S/4HANA

Kanban in SAP S/4HANA brings several benefits that optimize workflow and inventory management:

- Efficient Material Replenishment: With Kanban, the replenishment process is triggered only when necessary. SAP S/4HANA monitors inventory levels in real-time and automatically generates orders to restock materials when a container is empty or reaches the minimum threshold. This helps reduce excess inventory and ensures that materials are available exactly when needed, improving inventory turnover.

- Reduced Waste: By aligning production with actual demand, the Kanban system in SAP S/4HANA reduces the chances of overproduction or underproduction. This minimizes the risk of waste in the form of excess stock or production delays.

- Faster Production Lead Times: With a streamlined workflow, Kanban in SAP S/4HANA reduces production lead times. As the system automatically triggers replenishment and production orders, materials are always available for production, allowing the business to respond quickly to customer demands.

- Improved Coordination Across Departments: SAP S/4HANA’s integration with other modules such as Materials Management, Production Planning, and Warehouse Management ensures that the entire supply chain is optimized. The Kanban system helps synchronize the activities of procurement, production, and logistics, improving coordination between departments.

- Enhanced Visibility: Real-time monitoring of Kanban containers in SAP S/4HANA provides visibility into material levels, status of replenishment, and production progress. This transparency enables production planners and managers to identify potential issues early and make timely adjustments to avoid delays.

5. Benefits of Using Kanban in SAP S/4HANA

Implementing Kanban in SAP S/4HANA offers several advantages that contribute to operational excellence:

- Reduced Inventory Costs: By optimizing inventory levels, Kanban reduces the need for large stockpiles of materials, lowering storage and handling costs. Businesses can maintain leaner inventory while ensuring that production is not interrupted.

- Improved Productivity: The automated replenishment process frees up time for employees to focus on more value-added tasks. Kanban ensures that production runs smoothly without manual intervention, improving overall productivity.

- Higher Flexibility: Kanban in SAP S/4HANA allows businesses to be more responsive to changes in demand. The system can quickly adjust to fluctuations in production requirements, helping businesses manage varying levels of production efficiently.

- Better Supplier Management: Kanban can be integrated with suppliers to trigger automatic purchase orders when material levels reach the predefined thresholds. This ensures timely delivery and strengthens supplier relationships.

- Enhanced Decision-Making: With the availability of real-time data on material flow, replenishment status, and production performance, decision-makers can take timely actions to address potential issues and optimize production processes.

Kanban in SAP S/4HANA: Optimising Workflow and Inventory Management

What is Kanban in SAP S/4HANA?

Kanban in SAP S/4HANA is an inventory management method that uses visual signals, such as cards or bins, to trigger material replenishment when inventory levels drop below a certain threshold. It helps in optimizing production flow and reducing excess stock by triggering timely replenishment actions.

How does Kanban work in SAP S/4HANA?

Kanban in SAP S/4HANA works by monitoring inventory levels and using a pull-based system. When stock levels reach a minimum, Kanban signals are generated to trigger the replenishment of materials or goods, ensuring the right materials are available at the right time for production without overstocking.

What are the advantages of using Kanban in SAP S/4HANA?

Kanban in SAP S/4HANA improves material availability, reduces inventory costs, enhances production efficiency, and helps in maintaining just-in-time (JIT) inventory practices. It simplifies supply chain management by automating replenishment and providing real-time inventory tracking.

How does Kanban help in managing inventory in SAP S/4HANA?

Kanban optimizes inventory management by automatically adjusting stock levels based on demand. It reduces the risk of stockouts and overstocking by triggering replenishment only when necessary, helping to keep inventory at optimal levels and improving overall material flow efficiency.

What are the key features of Kanban in SAP S/4HANA?

Key features of Kanban in SAP S/4HANA include visual signals for replenishment, real-time inventory tracking, automated material procurement, integration with production processes, and customizable control parameters for different Kanban scenarios (e.g., containers, storage locations, and product types).

How do I set up Kanban in SAP S/4HANA?

To set up Kanban in SAP S/4HANA, you need to define the Kanban control cycle, set up material master data, assign Kanban containers, and configure the relevant system parameters. You can also integrate it with the procurement and production processes to automate replenishment actions.

Can I use Kanban for both procurement and production in SAP S/4HANA?

Yes, Kanban can be used for both procurement and production processes in SAP S/4HANA. For procurement, it triggers automatic orders for raw materials, and for production, it ensures that materials are available for manufacturing when required, based on the production schedule.

How does SAP S/4HANA track Kanban signals?

SAP S/4HANA tracks Kanban signals by monitoring the status of Kanban containers. When a container's stock reaches the minimum predefined level, the system generates a replenishment signal and updates the inventory accordingly. This triggers an automatic action, such as a purchase order or production request.

How does Kanban in SAP S/4HANA support just-in-time (JIT) processes?

Kanban in SAP S/4HANA supports JIT by ensuring that materials are delivered and available precisely when needed for production, reducing inventory holding costs. It minimizes waste and delays, maintaining a continuous flow of production with no excess stock and timely material availability.

Can SAP S/4HANA automate Kanban replenishment?

Yes, SAP S/4HANA can automate Kanban replenishment by triggering purchase orders or production orders based on predefined thresholds. The system automatically updates stock levels and initiates procurement or production activities as soon as a Kanban signal is received.

What types of Kanban containers can I use in SAP S/4HANA?

SAP S/4HANA supports different types of Kanban containers, including physical bins, digital signals, and virtual containers. These containers can be customized to hold various quantities of materials, and each container type is linked to a specific inventory or production process.

How does SAP S/4HANA integrate Kanban with other inventory management processes?

SAP S/4HANA integrates Kanban with other inventory management processes by syncing with stock management, procurement, and production planning modules. It allows seamless updates between the Kanban system and the overall supply chain, enabling a unified view of material requirements and inventory levels.

What are the challenges when implementing Kanban in SAP S/4HANA?

Challenges include configuring the system correctly, aligning Kanban signals with production schedules, maintaining accurate inventory records, and overcoming resistance to process changes. These can be mitigated through proper training, system integration, and continuous monitoring of Kanban performance.

Can Kanban in SAP S/4HANA be used for both raw materials and finished goods?

Yes, Kanban in SAP S/4HANA can be applied to both raw materials and finished goods. For raw materials, it ensures that the necessary materials are available for production, and for finished goods, it helps in the distribution process to ensure timely delivery to customers or sales channels.

How do I optimize Kanban processes in SAP S/4HANA?

Optimization can be achieved by reviewing Kanban performance data, fine-tuning control parameters, minimizing bottlenecks, and automating replenishment processes. Regular monitoring and adjustments to the Kanban control cycle based on demand fluctuations can help maintain efficiency and reduce operational costs.