What Is OEE Software and Why It Matters in Manufacturing

Understanding Overall Equipment Effectiveness

Overall Equipment Effectiveness (OEE) is a standard measure used in manufacturing to determine how efficiently production equipment operates. It evaluates three main factors: availability, performance, and quality. Availability measures the time equipment is ready to run compared to planned production time. Performance evaluates how fast the equipment produces compared to its ideal speed. Quality measures the proportion of good products produced without defects. OEE software automates the collection, calculation, and analysis of these metrics, giving managers and operators clear insight into equipment effectiveness.

The Importance of OEE on the Shop Floor

OEE Software is essential because it turns complex data into actionable insights. Manufacturers often face unplanned downtime, slow cycles, and quality issues, which can reduce productivity and increase costs. By providing real-time visibility into equipment performance, OEE software highlights areas that require attention. This allows teams to identify root causes of inefficiencies, schedule maintenance proactively, and track improvements over time.

Integration and Business Impact

Integrating OEE Software with broader business systems enhances its value. Performance data becomes more useful when connected with production planning, inventory management, and operational reporting. Decision-makers can see how shop floor performance affects overall business objectives such as cost reduction, delivery reliability, and quality improvement. This alignment ensures that production efforts support strategic priorities, making OEE software a vital tool for continuous improvement and operational excellence.

Setting Clear Objectives for OEE Implementation

Defining the Purpose of OEE

Before implementing OEE Software, organisations must define clear objectives. The main goal is to improve equipment efficiency, reduce downtime, and enhance product quality. Without specific objectives, OEE implementation can become unfocused and fail to deliver measurable improvements. Setting clear goals ensures that all teams understand the purpose of tracking OEE and can use the data effectively to drive improvements.

Aligning Objectives with Business Goals

OEE objectives should support broader business strategies. For example, reducing equipment downtime can improve delivery reliability, while enhancing production speed may lower operational costs. By aligning OEE targets with organisational goals, manufacturers ensure that daily activities on the shop floor contribute to overall business success. This connection helps operators see the value of their work beyond simple machine operation.

Creating Measurable and Realistic Targets

Objectives should be specific, measurable, achievable, relevant, and time-bound. For instance, a goal could be to improve machine availability by 10% over six months. Realistic targets encourage engagement and allow teams to track progress without becoming discouraged. Clear measurement criteria also make it easier to analyse performance trends and identify areas for improvement.

Establishing Ownership and Accountability

Well-defined objectives assign responsibility to operators, supervisors, and managers. Everyone understands their role in achieving OEE goals, fostering accountability and consistent improvement. When combined with transparent performance tracking, these objectives create a culture of continuous improvement, where teams work collaboratively to enhance equipment efficiency and production quality.

Assessing Current Equipment Performance and Data Readiness

Reviewing Existing Performance Levels

Before OEE Software implementation, it is essential to assess the current performance of all equipment. This involves reviewing machine uptime, production speed, and quality output. Understanding baseline performance provides a reference point for measuring improvement after OEE software is deployed. It also helps identify the most critical areas where improvements will have the greatest impact.

Evaluating Available Data

Manufacturers often have existing data from manual logs or digital systems. Evaluating this data is crucial to ensure it is accurate, complete, and consistent. Inconsistent or missing data can lead to incorrect conclusions and undermine the effectiveness of OEE software. This evaluation helps identify gaps and areas where additional data collection is necessary.

Assessing Data Readiness

Data readiness involves checking whether machines can provide the information required by OEE software. This may include verifying connectivity, sensors, and automation capabilities. Assessing readiness ensures that data will be reliable and accurate, providing a strong foundation for performance analysis and continuous improvement.

Preparing for Implementation

By thoroughly assessing equipment performance and data readiness, organisations can plan a smooth OEE implementation. This preparation allows teams to address potential issues in advance, streamline data collection, and set realistic targets. Ultimately, it increases the likelihood of achieving meaningful improvements and operational efficiency.

Identifying Critical Machines and Production Lines

Understanding Production Priorities

Not all equipment impacts production equally. Identifying critical machines is essential to focus OEE monitoring on assets that significantly affect output, quality, and delivery. Critical machines are often those that represent bottlenecks or high-value production lines, where inefficiencies have the greatest business impact.

Evaluating Equipment Impact

Assessing machine impact includes analysing downtime frequency, maintenance needs, and contribution to overall production. Machines that cause repeated stoppages or delays are high priority for OEE tracking. Similarly, equipment that produces products requiring high quality standards is critical to minimise defects.

Prioritising for Maximum Benefit

Focusing on critical machines first allows organisations to achieve visible improvements quickly. This phased approach ensures that resources are used effectively and that early successes can build confidence in OEE implementation. Non-critical machines can be added later once the methodology is established.

Linking to Strategic Goals

Identifying critical machines also helps align shop floor activities with broader business objectives. By targeting equipment that directly affects productivity, quality, and delivery, organisations can ensure that performance improvements contribute meaningfully to operational and financial outcomes.

Defining Availability, Performance, and Quality Metrics

Understanding Availability

Availability measures the proportion of scheduled production time that equipment is actually operating. It accounts for downtime caused by breakdowns, maintenance, or setup delays. Defining availability clearly ensures teams can monitor and reduce time lost to unplanned stops.

Measuring Performance

Performance evaluates the speed at which equipment operates compared to its designed maximum. It highlights losses caused by slow cycles, minor stops, or inefficiencies. Clear definitions help teams identify where improvements can increase throughput without compromising quality.

Tracking Quality

Quality measures the ratio of good products produced against total output. It captures defects, scrap, and rework, providing insights into process stability. Well-defined quality metrics allow operators to take corrective action promptly and maintain high standards.

Consistency and Standardisation

Defining OEE metrics consistently across all machines and lines ensures data is reliable and comparable. Standardised metrics help managers understand overall performance, identify trends, and drive targeted improvements in equipment efficiency and product quality.

Connecting Machines and Automating Data Collection

Limitations of Manual Data Collection

Manual data collection is time-consuming and prone to errors. Operators may miss events or record information inconsistently, leading to inaccurate insights. This inefficiency can reduce the effectiveness of OEE initiatives and delay improvements.

Benefits of Automated Data Collection

Automating data collection directly from machines ensures accuracy, consistency, and real-time availability. Sensors and software capture machine status, production counts, and quality metrics automatically, providing reliable information for analysis and decision-making.

Reducing Administrative Burden

By automating data capture, operators spend less time on paperwork and more time focusing on production and problem-solving. Supervisors gain immediate visibility into performance, enabling faster responses to issues and more efficient resource allocation.

Supporting Continuous Improvement

Accurate, real-time data forms the foundation for meaningful OEE insights. Organisations can identify recurring losses, prioritise corrective actions, and track the effectiveness of improvements. Automated data collection makes performance monitoring scalable and sustainable across the entire facility.

Integrating OEE Software with Existing ERP and MES Systems

Understanding the Integration Need

OEE software provides the most value when integrated with enterprise and manufacturing systems. ERP systems manage planning, inventory, and resources, while MES systems handle production execution. Connecting OEE data with these systems ensures alignment between planning, operations, and performance insights.

Linking Planning to Execution

Integration allows OEE metrics to be compared against planned schedules and targets. Managers can identify deviations, understand causes, and take timely corrective action. This connection ensures that shop floor performance is directly linked to business objectives, improving efficiency and reliability.

Reducing Errors and Improving Efficiency

Manual data transfers between systems often introduce errors and delays. Integration eliminates duplicate entry, ensures consistent reporting, and provides real-time visibility into performance. Teams can make informed decisions faster and with greater confidence.

Driving Strategic Decision-Making

With integrated OEE, ERP, and MES data, organisations gain a complete view of operations. Managers can evaluate the impact of equipment performance on production targets, costs, and delivery schedules. This holistic insight supports better planning, continuous improvement, and alignment with strategic goals.

Designing Dashboards for Real-Time Production Visibility

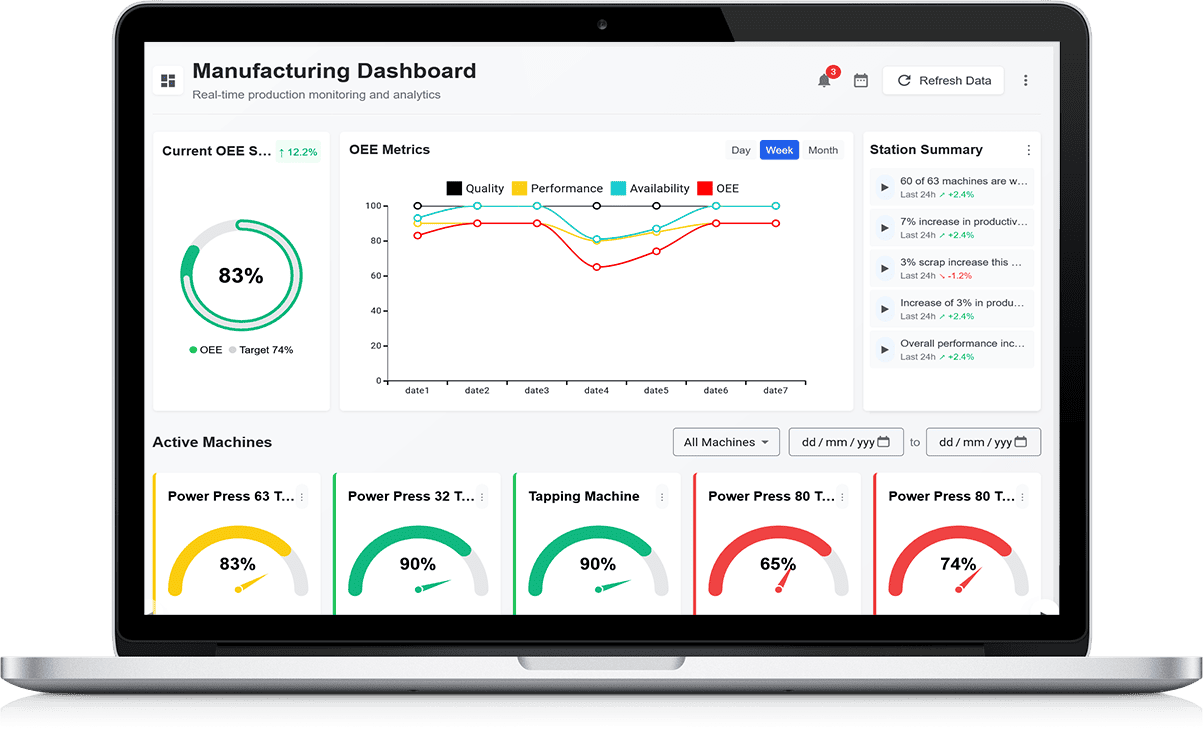

Making Production Data Easy to Understand

Dashboards are a critical tool for visualising production performance in real time. They convert complex manufacturing data into clear, actionable insights that everyone on the shop floor can understand. By presenting metrics visually, dashboards allow operators, supervisors, and managers to quickly grasp how equipment is performing, where bottlenecks are occurring, and which processes need attention. Well-designed dashboards avoid information overload by focusing on the most essential key performance indicators, such as availability, performance, and quality. This ensures that users can interpret data quickly without requiring technical expertise, which is especially important in fast-paced manufacturing environments.

Prioritising Relevant Metrics

Effective dashboards highlight the metrics that matter most to operational and business objectives. By showing trends and alerts for critical performance indicators, teams can focus on the areas that have the greatest impact on productivity and efficiency. Customisation options allow dashboards to reflect the priorities of different shifts, production lines, or departments, ensuring that every user sees information relevant to their role. When designed thoughtfully, dashboards also provide context, such as historical trends and targets, helping teams compare current performance against expectations and past results. This visual clarity fosters proactive problem-solving instead of reactive reporting.

Supporting Decision-Making and Continuous Improvement

Real-time dashboards enable faster decision-making because teams can respond immediately to production issues. They also support continuous improvement initiatives by tracking progress on corrective actions, efficiency gains, and quality improvements. With clear visuals and simple alerts, dashboards become a daily reference point for meetings and performance reviews, aligning shop floor activities with broader business goals. Overall, a well-designed dashboard ensures that production data is not just collected, but actively used to drive improvements, enhance visibility, and achieve operational excellence across the manufacturing plant.

Training Operators and Supervisors for Successful Adoption

Building Knowledge and Confidence

Training operators and supervisors is essential for successful OEE adoption. Without a clear understanding of what OEE measures and why it is important, teams may resist using the system effectively. Structured training helps users understand how availability, performance, and quality metrics relate to their daily work and overall business objectives. Practical sessions allow operators to practice using the system, interpret data, and make informed decisions based on real-time insights. This hands-on approach builds confidence and reduces the likelihood of errors, ensuring that teams are comfortable with the tools before full-scale implementation.

Connecting OEE to Daily Responsibilities

Training should demonstrate how individual actions directly impact OEE results. Operators who understand how machine downtime, cycle speed, and defect rates affect overall performance are more likely to take ownership of outcomes. Supervisors can use training to learn how to interpret dashboard data, guide their teams, and identify areas for improvement. By connecting OEE metrics to daily responsibilities, the software becomes more than a reporting tool; it becomes a mechanism for continuous improvement and operational accountability.

Encouraging Long-Term Adoption and Improvement

Ongoing education is also crucial. Refresher courses and coaching sessions help maintain engagement, reinforce best practices, and adapt to changes in production processes. By embedding OEE knowledge into regular routines, organisations can create a culture of continuous learning, ensuring that operators and supervisors remain proactive in improving performance. Ultimately, effective training transforms OEE software from a monitoring tool into a strategic driver of operational efficiency, quality, and business success.

Using OEE Data to Identify Losses and Bottlenecks

Understanding Production Losses

OEE data provides a structured view of where manufacturing performance is being lost. By breaking down production into availability, performance, and quality categories, organisations can pinpoint whether downtime, slow cycles, or defects are affecting output. This data-driven approach replaces guesswork with clear insights, helping teams identify specific areas that need improvement. Losses can be equipment-related, process-driven, or operator-dependent, and accurate data allows management to determine the root cause of each issue.

Spotting Bottlenecks and Constraints

OEE reporting helps reveal bottlenecks in production flow. By monitoring cycle times, equipment utilisation, and throughput, teams can see where capacity is being limited. Identifying these constraints allows for targeted interventions, such as reallocating resources, adjusting schedules, or introducing process improvements. Early detection of bottlenecks reduces the risk of delays and ensures smoother production operations, which in turn improves delivery reliability and overall productivity.

Enabling Prioritised Improvement Efforts

With detailed OEE data, organisations can prioritise improvement initiatives based on the scale of impact. High-impact areas can be addressed first, ensuring that time and resources are invested where they will generate the greatest gains. This structured approach drives more effective problem-solving and helps teams measure the results of implemented changes. By using data to guide decisions, organisations foster a culture of accountability, operational excellence, and continuous improvement across all production lines.

Implementing Corrective Actions Based on OEE Insights

Translating Data into Action

Collecting OEE data is only valuable if it leads to meaningful corrective actions. Organisations must analyse insights to identify underlying issues that cause downtime, reduced speed, or defects. Once root causes are determined, specific interventions can be designed, such as maintenance adjustments, process changes, or operator training. This ensures that improvements address the true source of inefficiencies rather than symptoms, leading to sustainable performance gains.

Prioritising and Planning Improvements

Not all issues have the same impact on production. OEE data allows teams to prioritise corrective actions based on the potential effect on output, quality, and cost. Planning interventions strategically ensures that resources are allocated effectively and that improvements yield measurable results. Documenting the corrective actions and assigning responsibilities also supports accountability and ensures follow-through across shifts and departments.

Monitoring Outcomes and Sustaining Gains

After implementing corrective actions, OEE should continue to be monitored to evaluate effectiveness. Tracking trends over time confirms whether improvements have resolved issues and highlights any areas that require further attention. Continuous monitoring also supports a culture of ongoing learning, where teams regularly assess performance and make iterative improvements. By embedding corrective actions into operational routines, organisations can achieve lasting enhancements in productivity, quality, and overall operational efficiency.

Embedding OEE into Daily Management and Review Meetings

Making OEE Part of Daily Routines

Integrating OEE into daily management ensures that performance is consistently reviewed and understood. Daily meetings provide a structured forum for discussing production results, identifying issues, and coordinating corrective actions. By making OEE metrics a standard part of these discussions, organisations create accountability and maintain focus on operational priorities throughout the day.

Using Data to Guide Conversations

OEE dashboards offer real-time data that supports factual, rather than subjective, discussions. Teams can identify trends, review variances, and highlight areas needing immediate attention. This clarity reduces misunderstandings, accelerates decision-making, and ensures that improvement efforts are evidence-based.

Enhancing Alignment Across Teams

Sharing OEE insights across operations, quality, and management teams ensures everyone is aligned on objectives and outcomes. Cross-functional visibility fosters collaboration, reduces silos, and helps teams work towards shared goals. Consistently reviewing performance also reinforces the connection between shop floor actions and broader business objectives.

Driving Continuous Focus on Improvement

Regular discussion of OEE results encourages teams to identify opportunities for improvement proactively. It promotes a culture of continuous learning, where operational efficiency, product quality, and reliability are constantly evaluated and enhanced.

Supporting Continuous Improvement and Lean Manufacturing

Identifying Waste Through Data

OEE highlights inefficiencies in production processes, such as unplanned downtime, slow cycles, or defective output. By analysing this data, organisations can identify and eliminate waste in line with lean manufacturing principles. Continuous monitoring allows for regular assessment and timely interventions, ensuring that production remains efficient and cost-effective.

Encouraging Incremental Improvements

OEE supports small, consistent improvements rather than large, disruptive changes. Teams can test changes, monitor their effect on availability, performance, and quality, and iterate based on results. This incremental approach reduces risk and ensures that improvements are sustainable over time.

Engaging Teams in Improvement Activities

When employees can see the impact of their actions on OEE metrics, they are more engaged in identifying and solving problems. Participation in improvement activities fosters ownership and accountability, creating a culture of proactive performance management. Supervisors can guide teams using dashboards and data to drive results effectively.

Embedding Discipline in Daily Operations

Consistent use of OEE for monitoring and reporting reinforces operational discipline. Teams develop routines around data collection, analysis, and problem-solving, which contributes to long-term process stability and higher performance standards across the plant.

Measuring ROI and Performance Gains from OEE Software

Linking Operational Improvements to Business Value

OEE software provides a clear link between operational performance and financial results. By tracking improvements in availability, performance, and quality, organisations can quantify the impact on output, production costs, and delivery reliability. This direct correlation helps justify investments in software and process improvements.

Evaluating Tangible and Intangible Benefits

ROI measurement goes beyond numbers. While cost reductions and productivity gains are tangible, improved decision-making, data accuracy, and team engagement are equally important. Organisations that track both tangible and intangible benefits gain a complete understanding of the software's contribution to business success.

Using Baseline Data for Comparison

Establishing baseline performance metrics prior to OEE implementation allows organisations to measure improvements effectively. Comparing pre-implementation and post-implementation performance provides evidence of efficiency gains, highlighting areas where corrective actions have succeeded and identifying further opportunities for improvement.

Supporting Future Investment Decisions

Reliable ROI data informs strategic decisions, such as expanding OEE usage to additional plants or integrating with other digital systems. By demonstrating clear returns and performance benefits, organisations can confidently plan for growth and continued optimisation of manufacturing operations.

Scaling OEE Across Plants and Preparing for Smart Manufacturing

Standardising Metrics Across Locations

To scale OEE effectively, organisations must implement standardised metrics and reporting formats across multiple plants. Consistency ensures that performance comparisons are meaningful and that best practices can be shared efficiently. Standardisation also simplifies training, reporting, and decision-making, creating a cohesive operational approach across all facilities.

Maintaining Visibility During Expansion

Scalable OEE solutions ensure that managers can maintain real-time visibility of production performance, even as operations grow. By connecting multiple plants through integrated dashboards, leadership teams can monitor trends, identify issues quickly, and make informed strategic decisions without losing control over operations.

Enabling Data-Driven Manufacturing Strategies

Consistent OEE data across plants forms the foundation for advanced analytics and predictive insights. Organisations can identify patterns, optimise scheduling, and allocate resources more effectively. Data-driven strategies support higher efficiency, better quality, and improved responsiveness to market demands, preparing plants for a more intelligent manufacturing approach.

Preparing for Smart and Connected Manufacturing

OEE provides a strong foundation for smart manufacturing initiatives, including IoT-enabled monitoring, predictive maintenance, and automated decision-making. By scaling OEE across facilities, organisations can move towards fully connected operations, leveraging real-time insights to drive continuous improvement and maintain competitiveness in an increasingly digital manufacturing landscape.