How Does SQDCM Improve Workplace Safety?

1. Identifying Safety Hazards

SQDCM helps in recognising potential workplace hazards by tracking incidents, near misses, and unsafe conditions. By regularly updating safety metrics, businesses can take proactive measures to prevent accidents.

2. Encouraging a Safety Culture

By incorporating safety into daily reporting, SQDCM fosters a culture where employees prioritise safe practices. When safety is visibly monitored, workers become more aware and proactive in preventing risks.

3. Monitoring and Reducing Incidents

Tracking safety performance through SQDCM allows businesses to identify trends in workplace incidents. This data helps in implementing corrective actions, reducing workplace injuries, and ensuring compliance with safety regulations.

4. Improving Communication

Regular updates on safety issues keep teams informed about potential risks. This open communication helps employees report concerns more effectively and ensures that management addresses safety issues promptly.

5. Supporting Continuous Improvement

Safety performance is consistently monitored, allowing businesses to refine processes and introduce better protective measures. Over time, this leads to a safer and more efficient working environment.

Why Is Safety the First Component in SQDCM?

1. Protecting Employees and Workplace

Safety is the foundation of a productive workplace. Prioritising safety ensures that employees can perform their tasks without risk of injury, reducing workplace accidents and creating a secure environment.

2. Enhancing Productivity

A safe work environment leads to fewer disruptions caused by accidents or injuries. When employees feel secure, they can focus on their tasks more efficiently, leading to higher productivity and improved performance.

3. Compliance with Regulations

Workplace safety is governed by strict regulations. Making safety the first priority in SQDCM helps organisations comply with legal standards, avoiding penalties and ensuring a safe working environment for all employees.

4. Building a Safety Culture

When safety is placed first, it sets the tone for a workplace culture that values employee well-being. This encourages workers to follow safety protocols, report hazards, and take proactive measures to prevent accidents.

5. Supporting Continuous Improvement

By continuously monitoring safety performance, businesses can identify risks and implement preventive actions. This ongoing process reduces incidents and contributes to long-term operational success.

How Can SQDCM Help in Identifying Workplace Hazards?

1. Monitoring Safety Performance

SQDCM provides a structured approach to tracking safety performance in the workplace. By consistently measuring safety indicators, organisations can identify patterns and detect potential hazards before they cause accidents.

2. Encouraging Hazard Reporting

With a focus on safety, SQDCM encourages employees to report unsafe conditions or potential risks. This proactive approach allows management to address hazards quickly and prevent workplace injuries.

3. Visual Management for Risk Identification

SQDCM boards display key safety metrics, making it easier for teams to spot trends and identify high-risk areas. Regular updates on incidents, near misses, and safety observations help in maintaining awareness.

4. Supporting Workplace Inspections

Routine checks and inspections are part of the SQDCM process. By incorporating structured safety audits, businesses can systematically assess potential risks and implement corrective actions to improve workplace safety.

5. Promoting Employee Involvement

Employees play a key role in hazard identification. SQDCM fosters a culture where workers actively participate in safety discussions, share feedback, and contribute to solutions that make the workplace safer.

What Role Does Data Tracking Play in SQDCM Safety Management?

1. Identifying Safety Trends

Data tracking helps in identifying patterns related to workplace safety. By analysing recorded incidents, near misses, and safety violations, organisations can spot recurring issues and take corrective action before accidents occur.

2. Monitoring Safety Performance

With regular data collection, businesses can measure key safety indicators such as incident rates, hazard reports, and compliance levels. Tracking these metrics ensures continuous improvement in workplace safety standards.

3. Enhancing Risk Assessment

Accurate data helps in assessing potential risks in different workplace areas. By evaluating past incidents and hazard reports, businesses can prioritise safety measures and reduce the likelihood of future accidents.

4. Supporting Preventive Actions

Through data-driven insights, safety teams can implement preventive strategies. By tracking safety concerns over time, organisations can take proactive steps to mitigate risks and ensure a safer working environment.

5. Improving Accountability

Tracking safety-related data promotes accountability among employees and management. Regular monitoring of safety records encourages adherence to safety protocols and ensures that corrective actions are implemented effectively.

How Does SQDCM Encourage a Safety-First Culture in an Organisation?

1. Prioritising Safety in Daily Operations

SQDCM places safety as the first focus area, ensuring that all workplace activities start with a strong commitment to preventing hazards. By making safety a core element of daily discussions, employees develop a habit of considering risks before taking action.

2. Promoting Awareness and Training

Regular safety briefings and training sessions are essential in reinforcing safety standards. SQDCM encourages ongoing learning by tracking incidents, reporting unsafe conditions, and ensuring employees understand the best practices for risk prevention.

3. Encouraging Proactive Hazard Reporting

Employees are more likely to report safety concerns when they see that management actively uses SQDCM boards to monitor and respond to issues. A structured system for tracking safety data ensures that hazards are addressed before they result in serious incidents.

4. Improving Accountability and Responsibility

By tracking safety performance alongside other key metrics, SQDCM holds teams and individuals accountable for maintaining safe work practices. When safety targets are regularly reviewed, employees feel responsible for creating a secure work environment.

5. Supporting Continuous Safety Improvements

With SQDCM, organisations can identify trends in safety performance and make informed decisions to enhance workplace conditions. Regular updates and corrective actions ensure that safety remains an ongoing priority, strengthening a culture of protection and care.

What Are the Key Safety Metrics Tracked in an SQDCM Board?

1. Number of Workplace Incidents

Tracking the total number of workplace incidents helps organisations identify patterns and areas that require immediate attention. This includes minor injuries, near misses, and more serious accidents.

2. Lost Time Injury (LTI)

LTIs measure the number of workdays lost due to injuries. Monitoring this metric helps assess the severity of incidents and the impact on workforce productivity.

3. Near Miss Reports

Near misses are situations where an accident was narrowly avoided. Regularly recording these helps organisations take preventive action before an actual injury occurs.

4. Hazard Identification and Corrections

This metric tracks reported hazards and the steps taken to correct them. Addressing hazards quickly reduces the risk of future incidents.

5. Safety Training and Compliance

Ensuring employees complete mandatory safety training is essential. This metric measures participation rates and helps identify gaps in training programs.

6. Personal Protective Equipment (PPE) Compliance

Monitoring PPE usage ensures that workers are following safety guidelines. Tracking compliance rates helps prevent injuries related to improper equipment use.

7. Safety Audits and Inspections

Regular audits assess workplace conditions and safety standards. Recording the results helps track improvements and highlight areas needing further action.

8. Emergency Preparedness Drills

Tracking the frequency and effectiveness of emergency drills ensures that employees are well-prepared for unexpected situations.

How Can SQDCM Boards Help Reduce Workplace Accidents?

1. Monitoring Safety Performance

SQDCM boards provide real-time visibility into safety metrics. By tracking incidents, near misses, and compliance rates, organisations can identify patterns and take preventive action.

2. Encouraging Hazard Reporting

These boards promote open communication about workplace hazards. Employees can report risks, allowing management to address them before they lead to accidents.

3. Tracking Safety Training

SQDCM boards ensure that all employees complete required safety training. Keeping track of participation helps prevent accidents caused by a lack of knowledge or awareness.

4. Reinforcing PPE Compliance

By displaying data on personal protective equipment (PPE) usage, these boards help ensure workers follow proper safety protocols, reducing injury risks.

5. Identifying High-Risk Areas

Regularly updating the board with accident reports helps identify high-risk areas. This allows teams to implement targeted improvements in workplace safety.

6. Promoting a Safety-First Culture

When safety metrics are visibly tracked, employees become more aware of risks and adopt safer work habits, leading to fewer accidents.

7. Supporting Continuous Improvement

By reviewing safety trends, organisations can refine policies, introduce better protective measures, and continuously improve workplace safety standards.

What Are the Benefits of Visual Management in Safety Monitoring?

1. Improves Hazard Awareness

Visual management makes safety information easy to understand. Clear signs, colour-coded indicators, and charts help employees quickly recognise hazards and follow safety protocols.

2. Enhances Real-Time Monitoring

With visual tools like SQDCM boards and dashboards, teams can monitor safety performance in real-time. Instant updates help identify risks and take immediate action.

3. Increases Employee Engagement

When safety data is displayed visually, employees are more likely to stay informed and actively participate in maintaining a safe workplace.

4. Reduces Human Errors

Simple visual cues such as warning labels, floor markings, and workflow diagrams help reduce mistakes that could lead to accidents.

5. Supports Compliance and Audits

Safety compliance is easier to track with visual tools. Auditors and managers can quickly assess whether safety measures are being followed.

6. Encourages Continuous Improvement

By visually displaying trends in accidents, near misses, and safety improvements, teams can identify areas for ongoing enhancement.

7. Simplifies Communication

Visual management eliminates confusion by presenting safety information in an accessible way. Employees of all experience levels can quickly grasp important safety details.

How Does SQDCM Support Compliance with Health and Safety Regulations?

1. Provides a Structured Safety Framework

The SQDCM system ensures that safety is prioritised by tracking incidents, hazards, and compliance measures. This structured approach helps organisations follow regulatory requirements effectively.

2. Monitors Safety Performance

By continuously tracking safety metrics, such as near-miss incidents and injury reports, SQDCM helps businesses identify risks and take corrective actions to stay compliant.

3. Enhances Documentation and Reporting

Health and safety regulations often require detailed records. SQDCM boards provide a clear way to document safety performance, making it easier to demonstrate compliance during inspections and audits.

4. Encourages Employee Involvement

Visual safety tracking keeps employees engaged and aware of compliance measures. Regular updates and safety meetings ensure that everyone understands and follows regulations.

5. Identifies and Reduces Risks

By highlighting safety concerns early, SQDCM helps prevent accidents and ensures that workplaces meet legal safety standards.

6. Supports Continuous Improvement

Tracking safety trends over time allows businesses to improve processes and adapt to changing regulations, ensuring long-term compliance.

7. Strengthens Accountability

With clear safety goals and real-time tracking, SQDCM ensures that teams take responsibility for maintaining a safe and compliant workplace.

How Can Organisations Use SQDCM to Conduct Safety Audits?

1. Establishing Clear Safety Criteria

SQDCM helps organisations define key safety metrics, such as incident rates, near-miss reports, and compliance with regulations. These criteria form the foundation of an effective safety audit.

2. Tracking Safety Incidents

Using the SQDCM board, teams can log workplace accidents, hazards, and unsafe behaviours. This data allows auditors to assess trends and identify areas requiring improvement.

3. Conducting Regular Inspections

Scheduled safety audits using SQDCM ensure that all safety protocols are being followed. By consistently reviewing safety performance, organisations can address potential risks before they escalate.

4. Engaging Employees in Safety Checks

Encouraging staff to report safety concerns and participate in inspections enhances workplace safety. SQDCM provides a transparent way to involve employees in the auditing process.

5. Identifying Root Causes of Safety Issues

By analysing trends in SQDCM safety data, organisations can determine the root causes of incidents and take corrective actions to prevent future occurrences.

6. Ensuring Compliance with Regulations

Safety audits supported by SQDCM help businesses verify that they meet industry safety standards and legal requirements, reducing the risk of non-compliance penalties.

7. Implementing Continuous Improvements

By regularly updating safety practices based on audit findings, organisations can create a safer work environment and improve overall compliance.

How Does Employee Engagement in SQDCM Improve Safety Awareness?

1. Encouraging Active Participation

When employees are actively involved in SQDCM processes, they become more aware of safety standards. Regular discussions and updates on safety help them understand potential risks and how to prevent accidents.

2. Promoting a Safety-First Mindset

Engagement in SQDCM ensures that employees prioritise safety in daily operations. By consistently tracking safety metrics and reporting hazards, teams develop a culture where safety is seen as a shared responsibility.

3. Increasing Hazard Identification

Employees who participate in SQDCM are more likely to identify and report workplace hazards. This proactive approach reduces the chances of incidents and helps organisations implement timely corrective actions.

4. Enhancing Communication and Feedback

Through regular SQDCM meetings and board updates, employees can openly discuss safety concerns. This improves communication between teams and management, ensuring that safety measures are effectively addressed.

5. Strengthening Accountability

When employees are involved in safety tracking, they take greater responsibility for their actions. This accountability encourages adherence to safety protocols, leading to a safer work environment.

6. Supporting Continuous Safety Improvements

Engaged employees contribute valuable insights for improving safety measures. Their feedback and experiences help refine safety strategies, ensuring ongoing improvements in workplace conditions.

What Strategies Can Be Implemented Using SQDCM to Minimise Safety Risks?

1. Regular Safety Inspections

Conducting routine safety checks helps identify potential hazards before they lead to accidents. SQDCM boards track inspection results, ensuring timely corrective actions are taken.

2. Employee Training and Awareness

Providing regular training on safety procedures ensures employees understand workplace risks. Awareness sessions help reinforce best practices, reducing the likelihood of injuries.

3. Real-Time Incident Reporting

Encouraging employees to report hazards immediately allows for faster response and resolution. SQDCM boards help monitor trends and address recurring safety concerns effectively.

4. Personal Protective Equipment (PPE) Compliance

Ensuring all employees wear the required PPE minimises risks associated with hazardous tasks. SQDCM tracking ensures PPE usage remains consistent and enforced.

5. Continuous Safety Monitoring

Using SQDCM boards to display safety metrics helps teams monitor performance. Visibility of safety trends promotes proactive risk management and necessary improvements.

6. Root Cause Analysis for Accidents

Investigating incidents using SQDCM helps identify underlying causes. Addressing root causes rather than symptoms prevents similar accidents from happening in the future.

7. Leadership Involvement in Safety

Strong management commitment to SQDCM ensures safety remains a top priority. Regular discussions on safety performance encourage a culture of responsibility and improvement.

How Does SQDCM Contribute to Continuous Safety Improvement?

1. Tracking Safety Performance

SQDCM boards provide real-time visibility into safety metrics, allowing teams to monitor incidents, near misses, and compliance issues. Regular tracking helps identify patterns and areas for improvement.

2. Encouraging Proactive Risk Management

By consistently reviewing safety performance, organisations can take preventive action rather than reacting to incidents. This reduces workplace hazards and ensures a safer environment for employees.

3. Promoting Employee Involvement

Employees play a key role in safety improvement when they are encouraged to report risks and participate in discussions. SQDCM boards provide a structured way for workers to engage in safety initiatives.

4. Standardising Safety Procedures

Clear and consistent safety procedures help maintain a high level of workplace safety. SQDCM ensures that best practices are documented and followed across all teams.

5. Continuous Monitoring and Audits

Regular safety audits supported by SQDCM allow for ongoing assessment of safety measures. Monitoring progress ensures that improvements are sustained over time.

6. Root Cause Analysis for Safety Incidents

When accidents or near misses occur, SQDCM facilitates thorough investigations to identify root causes. Addressing these issues prevents similar incidents from happening again.

7. Enhancing Communication and Awareness

Displaying safety metrics on SQDCM boards keeps safety a visible priority. Increased awareness leads to better decision-making and a stronger safety culture within the organisation.

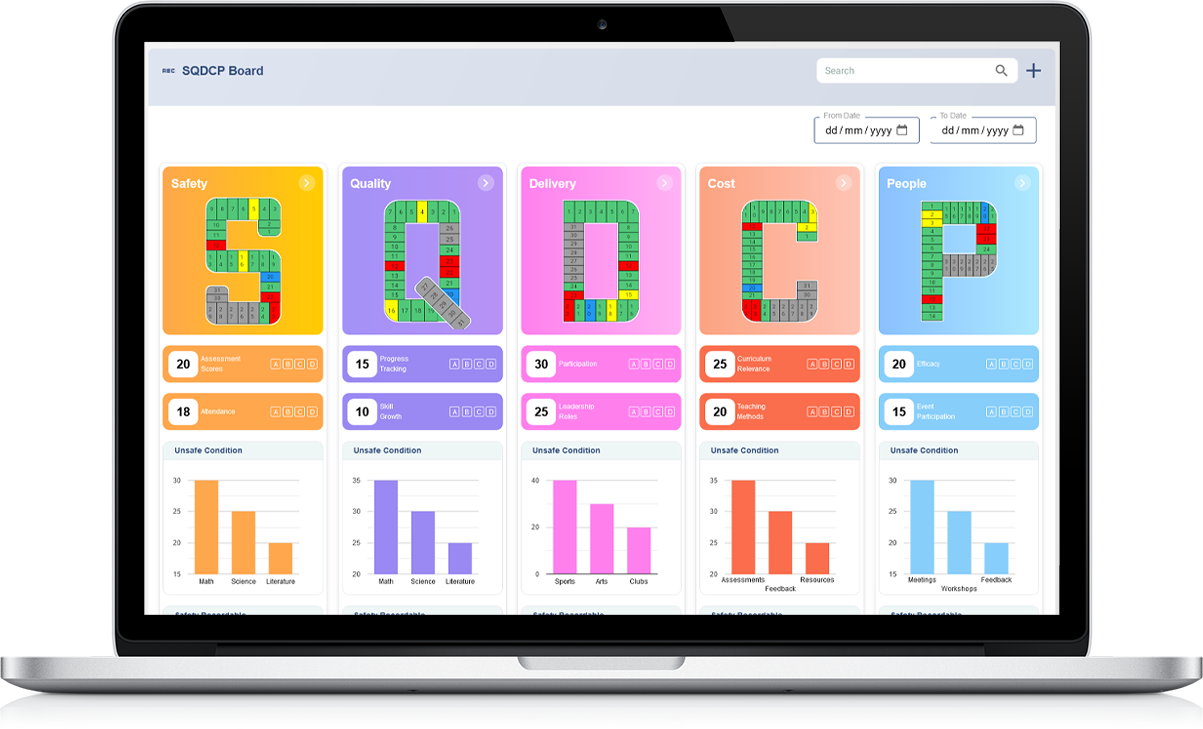

Can Digital SQDCM Boards Enhance Safety Tracking and Reporting?

1. Real-Time Safety Data Collection

Digital SQDCM boards allow organisations to capture and update safety data in real time. This ensures that incidents, near misses, and compliance checks are recorded without delay, improving response times.

2. Automated Safety Alerts

With digital tracking, automated alerts can notify teams of potential risks or safety violations. This proactive approach helps prevent accidents before they occur.

3. Centralised Safety Reporting

Digital SQDCM boards store all safety-related information in one place, making it easy to generate reports and analyse trends. This improves decision-making and ensures compliance with safety standards.

4. Improved Data Accuracy

Manual data entry can lead to errors, but digital boards reduce inaccuracies by automating record-keeping. Consistent and precise data ensures better safety analysis.

5. Customisable Safety Metrics

Organisations can tailor digital SQDCM boards to track specific safety indicators, such as injury rates, hazard reports, and compliance checks. This flexibility enhances workplace safety monitoring.

6. Enhanced Visibility and Transparency

Digital boards provide clear, real-time visibility into safety performance. Employees and managers can access up-to-date information, promoting accountability and continuous improvement.

7. Integration with Other Safety Systems

Digital SQDCM boards can integrate with other workplace safety tools, streamlining data collection and reporting. This leads to a more efficient and effective safety management process.

What Industries Benefit Most from Using SQDCM for Safety Management?

1. Manufacturing

Manufacturing industries use SQDCM to monitor workplace hazards, machine safety, and employee compliance. It helps track incidents, enforce safety protocols, and reduce risks in production environments.

2. Construction

Construction sites involve high-risk tasks. SQDCM ensures regular safety inspections, tracks incidents, and improves hazard awareness, leading to a safer work environment.

3. Healthcare

Hospitals and medical facilities rely on SQDCM for infection control, patient safety, and staff compliance with health regulations. It helps monitor hygiene practices and reduce workplace injuries.

4. Transportation and Logistics

In transportation, SQDCM supports vehicle safety checks, accident reporting, and driver compliance. It enhances road safety and ensures regulatory adherence.

5. Oil and Gas

The oil and gas sector faces high safety risks. SQDCM tracks equipment maintenance, worker safety, and emergency response readiness, reducing the likelihood of incidents.

6. Warehousing and Distribution

Warehouses use SQDCM to manage forklift safety, proper material handling, and emergency preparedness. It helps prevent accidents and ensures a safe working environment.

7. Food Processing

Food production industries use SQDCM to maintain hygiene, monitor equipment safety, and prevent contamination, ensuring both employee and consumer safety.

8. Utilities and Energy

Utility companies use SQDCM to monitor electrical safety, emergency preparedness, and employee compliance, reducing hazards in power plants and energy facilities.