What Is OEE Software and Why Is It Crucial for Manufacturing?

Understanding OEE Software

OEE, or Overall Equipment Effectiveness, software is a tool used by manufacturers to measure and improve the efficiency of their production equipment. It provides a clear view of machine performance by tracking three key areas: availability, performance, and quality. By monitoring these factors, OEE software helps identify where production losses occur and enables managers to take targeted actions to optimise operations.

Tracking Availability, Performance, and Quality

Availability measures the actual operating time of equipment compared to scheduled time, highlighting downtime issues. Performance examines whether machines are running at optimal speed and identifies slow cycles or bottlenecks. Quality tracks the rate of defective products, ensuring production meets desired standards. Together, these metrics give a complete picture of equipment effectiveness.

Identifying Production Bottlenecks Quickly

With real-time data, OEE software allows manufacturers to spot inefficiencies and bottlenecks quickly. This helps prevent delays, reduce waste, and maintain consistent production flow. Managers can prioritise maintenance or process improvements where they are needed most.

Driving Continuous Improvement

OEE software supports data-driven decision-making, enabling teams to implement continuous improvement initiatives. By tracking trends and analysing performance over time, manufacturers can improve uptime, reduce defects, and enhance overall operational efficiency.

Enhancing Productivity and Reducing Costs

Ultimately, OEE software helps manufacturers boost productivity, lower operational costs, and ensure higher product quality. Its insights enable proactive management, leading to more reliable and efficient production processes.

Understanding Overall Equipment Effectiveness (OEE) Metrics

What OEE Measures

Overall Equipment Effectiveness (OEE) is a key performance metric used in manufacturing to assess how efficiently equipment is operating. It combines three critical aspects of production: availability, performance, and quality. By measuring these factors, OEE provides a clear understanding of how well machinery is being utilised and where improvements can be made.

Availability

Availability measures the proportion of scheduled production time that equipment is actually operational. It identifies downtime caused by maintenance, machine breakdowns, or changeovers. Tracking availability helps manufacturers minimise unexpected stoppages and plan maintenance proactively.

Performance

Performance evaluates whether machines are running at their optimal speed. It highlights slow cycles, minor stops, or inefficiencies in the production process. Understanding performance allows teams to address bottlenecks and improve throughput without compromising quality.

Quality

Quality measures the proportion of products that meet required standards without defects. High-quality output reduces rework, scrap, and customer complaints. Monitoring quality ensures that production processes consistently deliver products that meet expectations.

Using OEE Metrics for Improvement

By combining availability, performance, and quality into a single OEE score, manufacturers can pinpoint areas that need attention. Analysing these metrics over time helps drive continuous improvement, increase operational efficiency, and reduce costs. OEE provides actionable insights to enhance productivity and maximise the value of manufacturing resources.

How OEE Software Tracks Availability, Performance, and Quality

Monitoring Equipment Availability

OEE software helps manufacturers keep track of machine availability by recording both planned and unplanned downtime. It captures instances such as maintenance breaks, equipment failures, and changeovers, providing a clear picture of when machines are operational. By understanding these downtime events, manufacturers can identify recurring issues, optimise maintenance schedules, and ensure machines are available when needed, ultimately improving overall production efficiency.

Measuring Performance Efficiency

Performance tracking is a key feature of OEE software. It monitors the actual speed of machines compared to their ideal speed, identifying slow cycles or interruptions that reduce output. By analysing production rates and cycle times, manufacturers can detect bottlenecks, adjust workflows, and implement process improvements. This helps in maximising machine productivity and reducing the gap between potential and actual output.

Ensuring Product Quality

Quality monitoring within OEE software focuses on the number of good products produced versus defective ones. It records defects, rework, and scrap in real time, enabling manufacturers to quickly identify quality issues at their source. By tracking quality metrics, manufacturers can implement corrective measures, improve product standards, and reduce waste. This ensures that production not only meets quantity targets but also maintains high quality, contributing to customer satisfaction and cost efficiency.

By tracking availability, performance, and quality together, OEE software gives a complete view of production effectiveness, allowing manufacturers to make data-driven decisions, enhance operational efficiency, and minimise losses on the shop floor.

Identifying Production Bottlenecks Quickly Using OEE Tools

Understanding Bottlenecks in Manufacturing

Production bottlenecks occur when certain processes or machines slow down overall workflow, causing delays and inefficiencies. Identifying these constraints early is essential for maintaining smooth operations and meeting production targets. OEE tools provide detailed insights into equipment performance, allowing manufacturers to spot areas where output is being limited.

Real-Time Data for Faster Detection

OEE tools collect real-time data on machine availability, performance, and quality. By monitoring this information continuously, manufacturers can quickly detect slowdowns or stoppages that may indicate a bottleneck. Immediate alerts and visual dashboards help teams respond faster, reducing downtime and preventing minor issues from escalating into larger production problems.

Analysing Trends to Pinpoint Issues

Historical and trend analysis is another strength of OEE tools. By reviewing past performance data, manufacturers can identify recurring bottlenecks and understand their causes, such as equipment wear, staffing shortages, or process inefficiencies. This analysis enables proactive maintenance, resource reallocation, and process adjustments to prevent bottlenecks from affecting overall production flow.

Optimising Production for Maximum Efficiency

Once bottlenecks are identified, OEE tools provide actionable insights to optimise production. Adjusting machine schedules, balancing workloads, and improving process steps ensure that the entire production line operates efficiently. This leads to higher throughput, lower downtime, and better utilisation of resources, making manufacturing operations more productive and cost-effective.

Reducing Unplanned Downtime with Predictive Maintenance Insights

Understanding Unplanned Downtime

Unplanned downtime can significantly impact manufacturing productivity and increase operational costs. It occurs when machines stop unexpectedly due to failures or malfunctions, disrupting the production flow. Reducing these unexpected stoppages is crucial for maintaining efficiency, meeting delivery schedules, and minimising losses.

Role of Predictive Maintenance

Predictive maintenance uses data from equipment sensors and performance monitoring to anticipate potential failures before they happen. By analysing trends such as vibration levels, temperature fluctuations, and machine wear, manufacturers can predict when a component is likely to fail. This allows maintenance teams to take action proactively rather than reacting after a breakdown occurs.

Real-Time Monitoring for Early Detection

OEE and predictive maintenance tools provide real-time insights into machine health. Continuous monitoring enables early detection of anomalies that could lead to unplanned downtime. Alerts and notifications allow teams to schedule maintenance during planned breaks, reducing the impact on production and keeping machinery operating at optimal levels.

Benefits of Predictive Maintenance Insights

Using predictive maintenance insights helps manufacturers extend equipment life, improve reliability, and enhance overall efficiency. It reduces emergency repairs and replacement costs while increasing machine availability. By preventing unexpected stoppages, manufacturers can maintain consistent production schedules, reduce operational risks, and achieve better output quality.

Improving Machine Performance Through Real-Time Monitoring

Understanding Machine Performance

Efficient machine performance is essential for maintaining smooth manufacturing operations and maximising output. Poor performance can lead to delays, increased costs, and lower product quality. Monitoring machines effectively ensures that potential issues are detected early and performance standards are maintained consistently.

The Role of Real-Time Monitoring

Real-time monitoring collects continuous data on machine operations, including speed, cycle times, and operational status. This allows manufacturers to see exactly how equipment is performing at any given moment. By tracking performance metrics continuously, teams can quickly identify deviations from expected performance and take corrective action before problems escalate.

Detecting Issues Early

Real-time monitoring helps detect anomalies such as slow cycles, frequent stoppages, or abnormal vibrations. Early detection enables maintenance teams to address minor issues before they develop into major breakdowns. This proactive approach reduces unplanned downtime and keeps production lines running smoothly, ensuring that machines operate at peak efficiency.

Optimising Processes and Productivity

Data from real-time monitoring can be analysed to optimise machine performance further. Adjustments to workflows, machine settings, and resource allocation can be made based on performance insights. This not only enhances productivity but also improves product quality and extends the lifespan of machinery, contributing to cost savings and better overall operational efficiency.

How OEE Helps Minimise Defects and Scrap in Manufacturing

Understanding Defects and Scrap

Defects and scrap are major challenges in manufacturing, leading to wasted materials, increased costs, and reduced productivity. Defects refer to products that do not meet quality standards, while scrap is material that cannot be reused or reprocessed. Minimising both is crucial for improving efficiency and maintaining profitability.

The Role of OEE in Quality Management

OEE (Overall Equipment Effectiveness) provides a comprehensive view of machine performance, focusing on availability, performance, and quality. By tracking these key areas, OEE helps identify where defects and scrap are occurring. The data collected from OEE tools highlights inefficiencies in production processes, such as equipment malfunctions or poor-quality materials, allowing manufacturers to take corrective actions before issues escalate.

Identifying Root Causes of Defects

OEE software monitors production lines in real-time, capturing data that points to the root causes of defects. For example, it can reveal if defects are due to machine settings, incorrect tooling, or operator errors. By identifying these issues, manufacturers can make precise adjustments to the process, ensuring that defects are minimised and quality standards are consistently met.

Reducing Scrap with Better Resource Utilisation

Through performance analysis, OEE helps optimise machine utilisation, reducing the likelihood of scrap. By monitoring cycle times, throughput, and material usage, manufacturers can ensure that resources are used efficiently. This proactive approach to process optimisation not only reduces material waste but also improves product quality and maximises the use of available resources.

Boosting Operational Efficiency Across Shifts and Lines

Understanding Operational Efficiency

Operational efficiency is crucial in manufacturing to ensure that production lines run smoothly and resources are used effectively. Inefficiencies can lead to increased costs, delays, and reduced output. Improving efficiency across shifts and lines ensures consistent performance, higher productivity, and better overall results.

Monitoring Performance Across Shifts

Tracking performance across different shifts helps identify variations in output and productivity. Real-time monitoring tools allow managers to compare performance metrics, detect inconsistencies, and address issues quickly. This ensures that each shift operates at optimal levels, reducing downtime and maintaining consistent quality throughout production.

Optimising Workflow Across Production Lines

Efficient workflow management across multiple production lines is essential for maximising output. By analysing data from each line, manufacturers can identify bottlenecks, resource constraints, or underperforming equipment. Adjustments can then be made to balance workloads, streamline processes, and improve coordination between lines, ensuring smoother operations and reduced delays.

Using Data to Drive Continuous Improvement

Collecting and analysing performance data enables manufacturers to implement continuous improvement strategies. Insights from production metrics help in planning preventive maintenance, training staff, and improving machine utilisation. By addressing issues proactively and optimising processes, operational efficiency is boosted across all shifts and lines, leading to higher productivity, reduced costs, and better utilisation of resources.

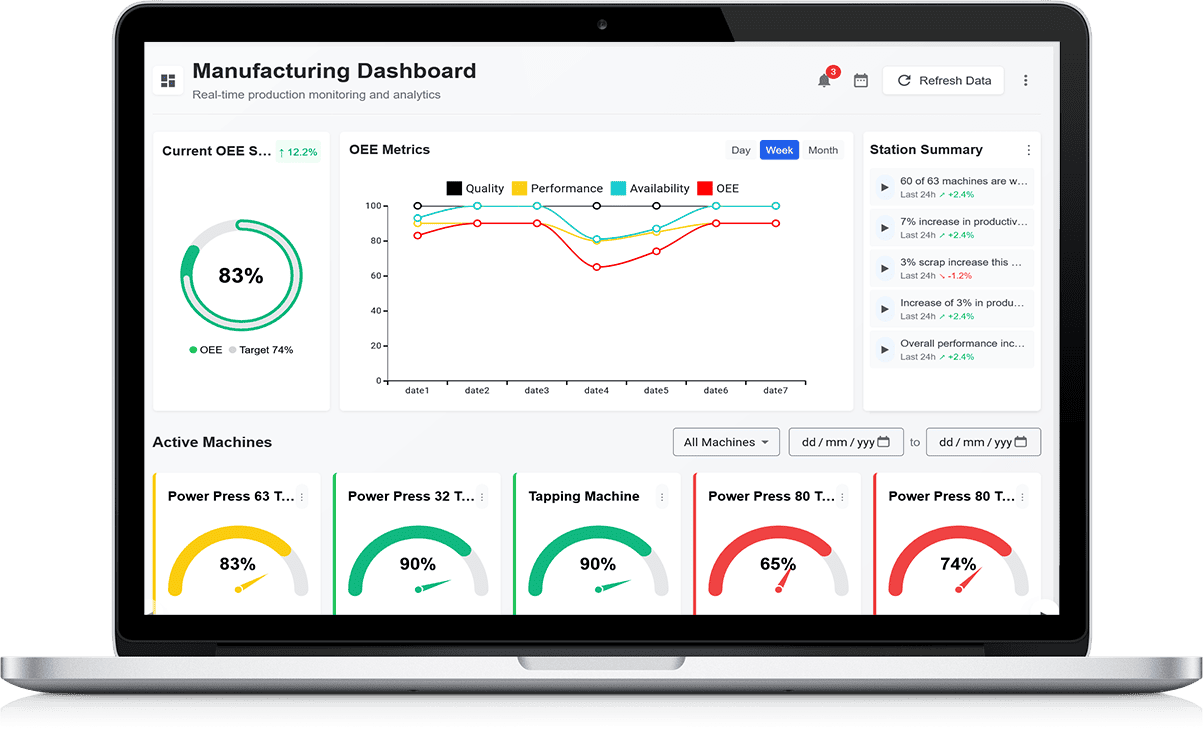

Using OEE Dashboards to Make Data-Driven Decisions

Understanding OEE Dashboards

OEE dashboards provide a clear and visual representation of manufacturing performance, combining key metrics such as availability, performance, and quality. These dashboards allow managers to quickly understand how equipment and processes are performing, helping them make informed decisions that improve overall efficiency.

Real-Time Insights for Quick Action

OEE dashboards display real-time data from production lines, enabling managers to detect issues as they occur. Immediate visibility into machine stoppages, slow cycles, or quality problems allows teams to respond quickly and reduce downtime. This proactive approach ensures that small issues do not escalate into major disruptions.

Analysing Trends and Patterns

Beyond real-time monitoring, OEE dashboards help track historical performance and identify trends over time. Analysing patterns in machine behaviour, defect rates, and production output enables manufacturers to uncover recurring problems and areas for improvement. This insight is crucial for implementing long-term solutions and optimising processes.

Supporting Data-Driven Decisions

With clear visualisation and detailed metrics, OEE dashboards empower managers to make decisions based on accurate data rather than assumptions. This includes planning maintenance schedules, adjusting workflows, or reallocating resources to improve efficiency. By leveraging data-driven insights, manufacturers can enhance productivity, reduce waste, and maintain high-quality standards across their operations.

Integrating OEE Software with ERP and Production Systems

Understanding System Integration

Integrating OEE software with ERP and production systems allows manufacturers to unify their operations, creating a seamless flow of data across departments. This integration ensures that information about machine performance, production schedules, and resource utilisation is accessible in one place, improving visibility and decision-making.

Enhancing Data Accuracy

When OEE software is connected to ERP systems, data from production lines is automatically synchronised with inventory, maintenance, and planning modules. This reduces manual entry errors and ensures that all departments work with accurate, up-to-date information. Accurate data supports better planning, forecasting, and resource allocation.

Optimising Production Planning

Integrated systems provide a holistic view of manufacturing operations, allowing managers to align production schedules with machine performance and capacity. By combining insights from OEE metrics with ERP planning tools, manufacturers can optimise workflows, prevent bottlenecks, and balance workloads across multiple lines or shifts, improving overall efficiency.

Driving Continuous Improvement

Integration also supports continuous improvement initiatives. By analysing combined data from OEE and ERP systems, manufacturers can identify trends, monitor KPIs, and implement process enhancements. This proactive approach helps reduce downtime, minimise defects and scrap, and maximise utilisation of equipment and resources, contributing to higher productivity and cost efficiency.

Setting Targets and Monitoring Progress for Continuous Improvement

Importance of Setting Targets

Setting clear targets is essential for driving continuous improvement in manufacturing. Targets provide measurable goals for productivity, quality, and efficiency, helping teams understand what needs to be achieved. Well-defined targets motivate employees, align efforts across departments, and establish a benchmark for evaluating performance over time.

Tracking Progress Effectively

Monitoring progress towards targets allows manufacturers to identify gaps and take corrective actions promptly. Using real-time data from machines and production lines, teams can track key metrics such as output rates, defect levels, and downtime. This visibility ensures that issues are addressed quickly, keeping operations on track and supporting consistent performance improvement.

Using Metrics to Drive Improvement

Data-driven insights are vital for continuous improvement. By analysing trends and performance metrics, manufacturers can pinpoint inefficiencies, recurring problems, or areas with potential for optimisation. This information helps in making informed decisions, adjusting workflows, and implementing targeted solutions to enhance overall productivity and quality.

Encouraging a Culture of Continuous Improvement

Setting targets and monitoring progress also fosters a culture of accountability and continuous learning. Teams are encouraged to take ownership of their performance, identify opportunities for enhancement, and adopt best practices. Over time, this approach leads to higher operational efficiency, reduced waste, and improved product quality, ensuring that manufacturing processes continually evolve and improve.

Tracking OEE Trends Over Time to Optimise Processes

Understanding OEE Trends

Tracking OEE (Overall Equipment Effectiveness) trends over time provides manufacturers with valuable insights into equipment performance, production efficiency, and quality levels. By observing patterns and changes, teams can identify areas where improvements are needed and ensure that operations remain efficient and reliable.

Collecting and Analysing Data

OEE tracking involves collecting data on machine availability, performance, and product quality consistently over time. Analysing this data allows manufacturers to detect recurring issues, seasonal variations, or gradual declines in performance. This information helps pinpoint the root causes of inefficiencies, enabling more effective decision-making and targeted interventions.

Identifying Opportunities for Process Optimisation

By monitoring trends, manufacturers can identify bottlenecks, underperforming equipment, or processes that require improvement. This insight allows teams to make adjustments such as balancing workloads, refining workflows, or scheduling preventative maintenance. Optimising processes based on OEE trends ensures smoother production and maximises output without compromising quality.

Supporting Continuous Improvement

Tracking OEE trends is key to fostering a culture of continuous improvement. Regular analysis encourages proactive problem-solving and helps implement long-term solutions rather than temporary fixes. By using trend data to guide decisions, manufacturers can enhance productivity, reduce downtime, and improve overall operational efficiency, leading to more consistent performance and better utilisation of resources.

Encouraging Accountability with Transparent Equipment Performance Data

The Importance of Accountability in Manufacturing

Accountability is a critical factor in ensuring consistent performance and high-quality output in manufacturing operations. When teams understand their responsibilities and the impact of their actions on production, they are more likely to adhere to best practices and maintain high standards.

Using Transparent Equipment Data

Providing transparent data on equipment performance helps foster accountability among employees and management. Real-time monitoring and reporting of machine availability, performance, and quality make it clear how individual contributions affect overall production. This visibility ensures that everyone is aware of their role in achieving operational goals.

Identifying Areas for Improvement

Transparent performance data allows teams to see where issues such as downtime, slow cycles, or defects occur. By highlighting these areas, employees can take ownership of their tasks and work proactively to resolve problems. Managers can also use this data to provide targeted support, training, or process adjustments, ensuring continuous improvement across the production line.

Driving a Culture of Responsibility

Sharing equipment performance metrics openly encourages a culture of responsibility and collaboration. Teams are motivated to meet targets, reduce errors, and optimise machine utilisation. This approach not only improves productivity and quality but also builds trust and engagement among staff, leading to a more efficient and accountable manufacturing environment.

How OEE Software Supports Lean Manufacturing Principles

Understanding Lean Manufacturing

Lean manufacturing focuses on maximising value while minimising waste in production processes. The goal is to create efficient, streamlined operations that deliver high-quality products with minimal delays or excess resources. Achieving these objectives requires clear visibility into machine performance and process efficiency.

Role of OEE in Lean Practices

OEE software plays a key role in supporting lean manufacturing by tracking equipment effectiveness across availability, performance, and quality. By providing real-time insights, OEE tools help manufacturers identify waste in the form of downtime, slow cycles, or defective products. This visibility allows teams to take immediate action to improve efficiency and reduce non-value-added activities.

Eliminating Waste and Improving Productivity

With OEE software, manufacturers can pinpoint the root causes of inefficiencies and implement corrective measures. By addressing bottlenecks, optimising machine utilisation, and reducing defects, teams can eliminate unnecessary waste and enhance productivity. Continuous monitoring ensures that improvements are sustained over time and processes remain lean.

Supporting Continuous Improvement

OEE software also promotes a culture of continuous improvement, a core principle of lean manufacturing. By analysing trends and performance metrics, teams can make data-driven decisions to refine workflows, enhance machine performance, and improve overall operational efficiency. This proactive approach ensures that production remains optimised and lean principles are consistently applied throughout the manufacturing process.

Case Studies: Real-World Examples of Efficiency Gains Using OEE Tools

Improving Machine Availability

In one manufacturing facility, OEE tools were used to monitor machine uptime and identify frequent unplanned stoppages. By analysing the data, the maintenance team implemented preventive measures and optimised schedules. This led to a significant increase in machine availability, reducing downtime and improving overall production output.

Enhancing Production Performance

Another case involved a production line experiencing slow cycle times and inconsistent throughput. OEE monitoring highlighted specific machines and processes that were underperforming. Adjustments were made to workflows, machine settings, and staffing allocation, resulting in faster production cycles and higher efficiency across the line.

Reducing Defects and Scrap

In a separate example, a factory used OEE tools to track quality metrics and identify the sources of defects and scrap. By pinpointing problematic equipment and processes, corrective actions were taken to improve product quality. This reduced waste, lowered production costs, and enhanced customer satisfaction by delivering more consistent products.

Driving Continuous Improvement

These real-world applications of OEE tools demonstrate their value in promoting continuous improvement. By providing actionable insights into equipment performance, production efficiency, and quality, manufacturers can make informed decisions that lead to measurable efficiency gains. OEE tools help create a proactive approach to optimising operations, ensuring sustainable improvements over time.