Distributor management software (DMS) is a specialized tool that helps businesses effectively manage their relationships with distributors, streamline operations, and enhance the efficiency of their distribution channels. This software is particularly valuable for manufacturers, wholesalers, and companies that rely on a network of distributors to reach their customers. Here’s a detailed exploration of distributor management software, covering its features, benefits, challenges, and market trends.

Key Features of Distributor Management Software

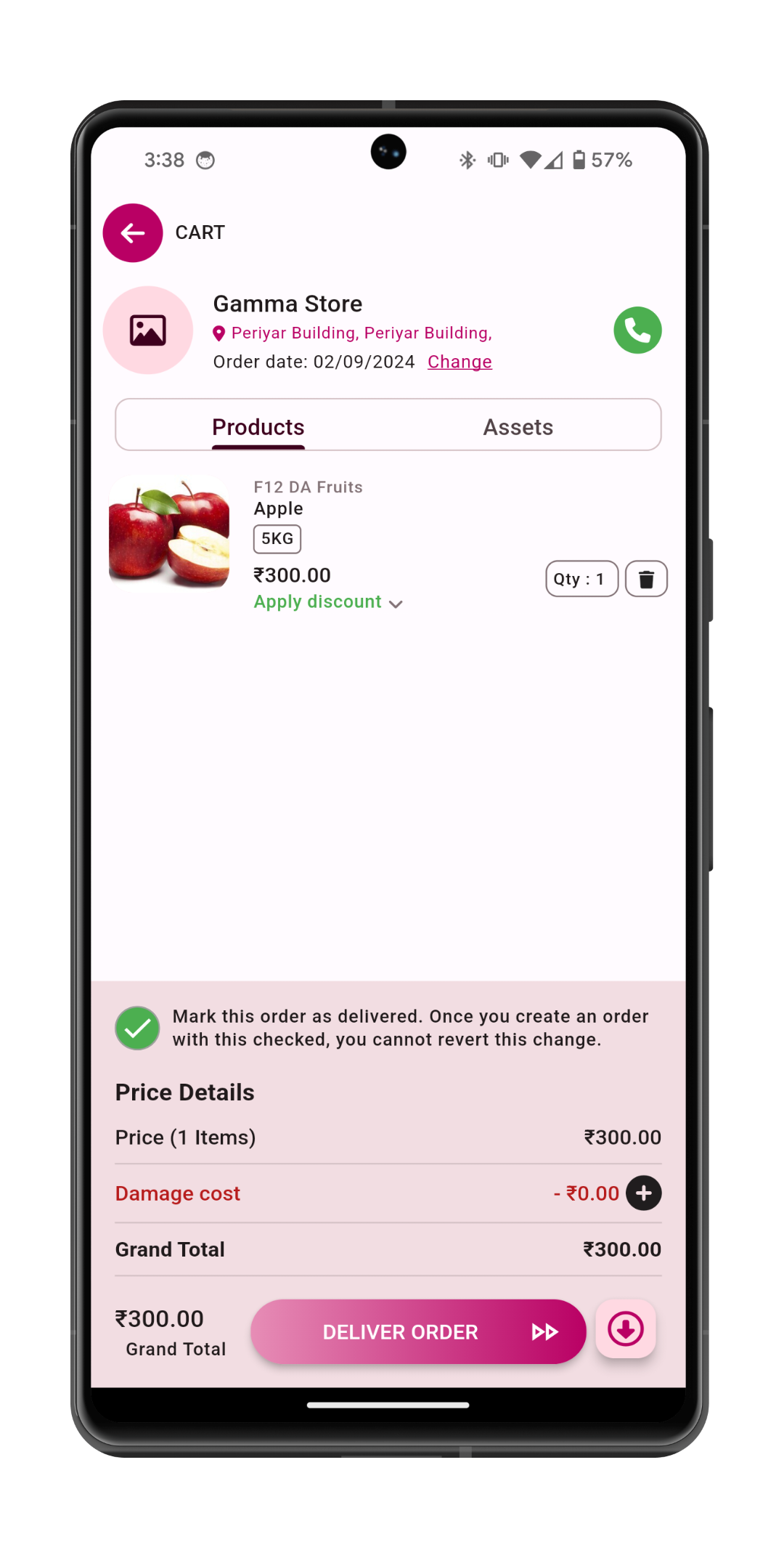

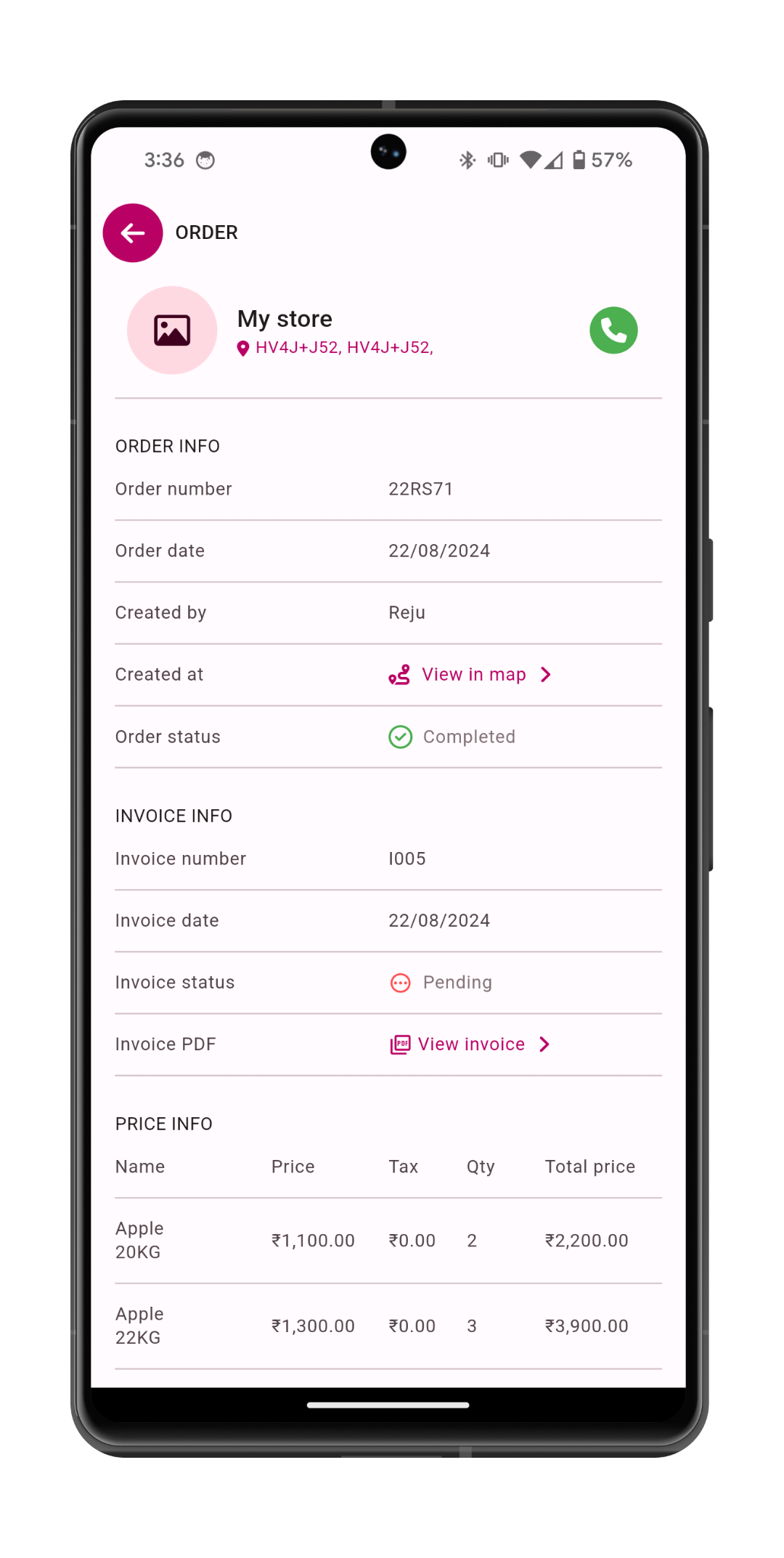

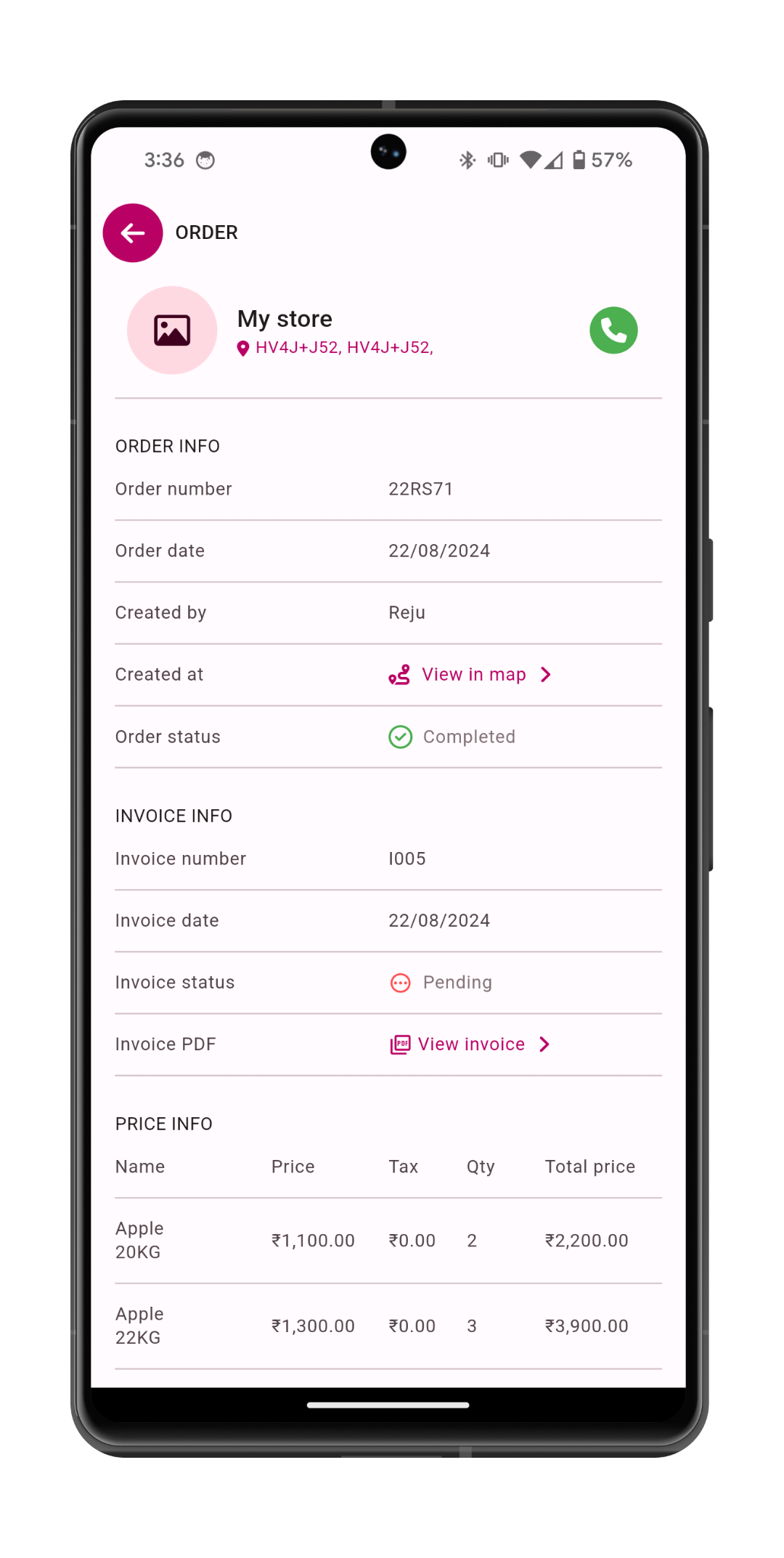

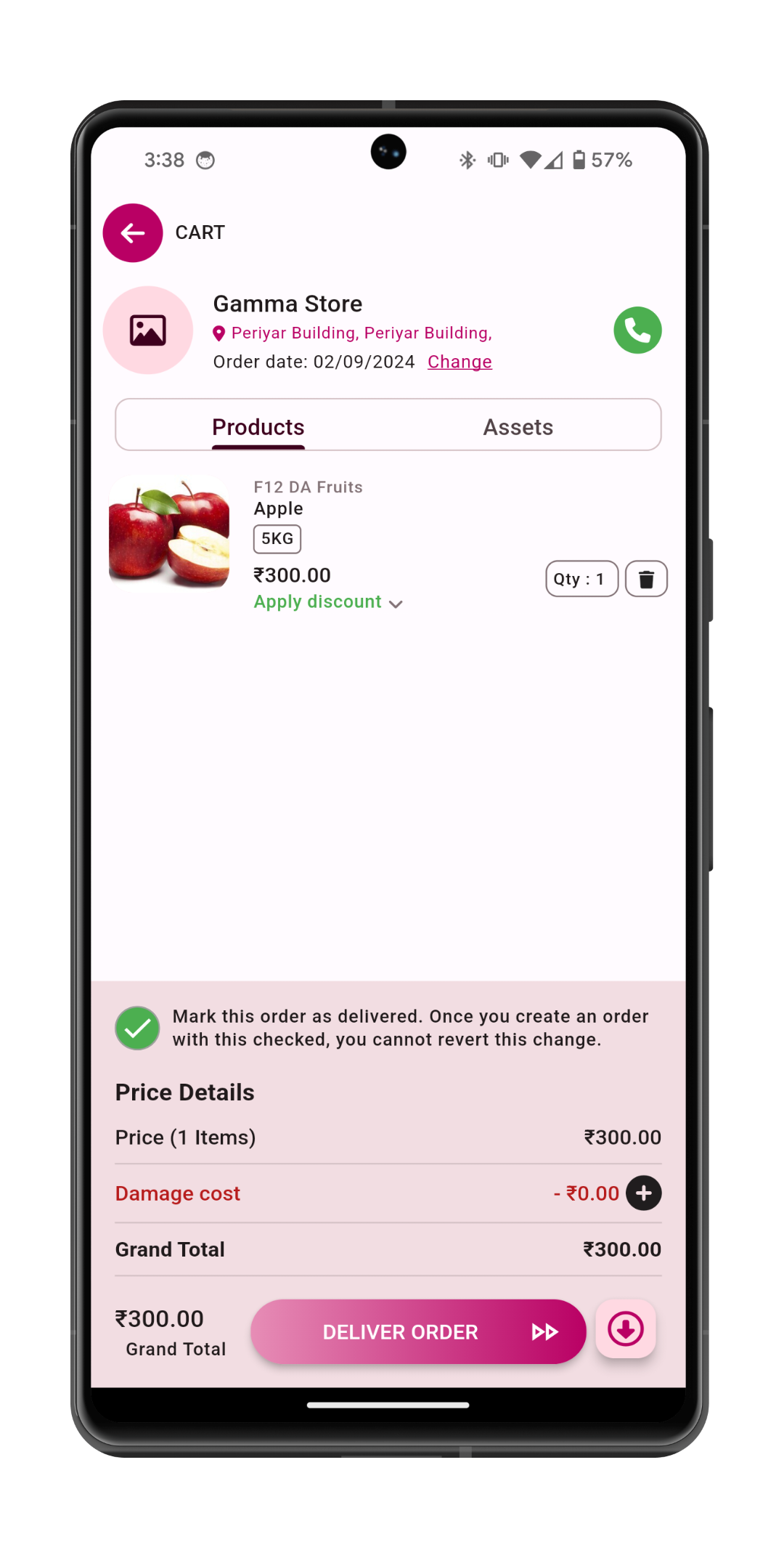

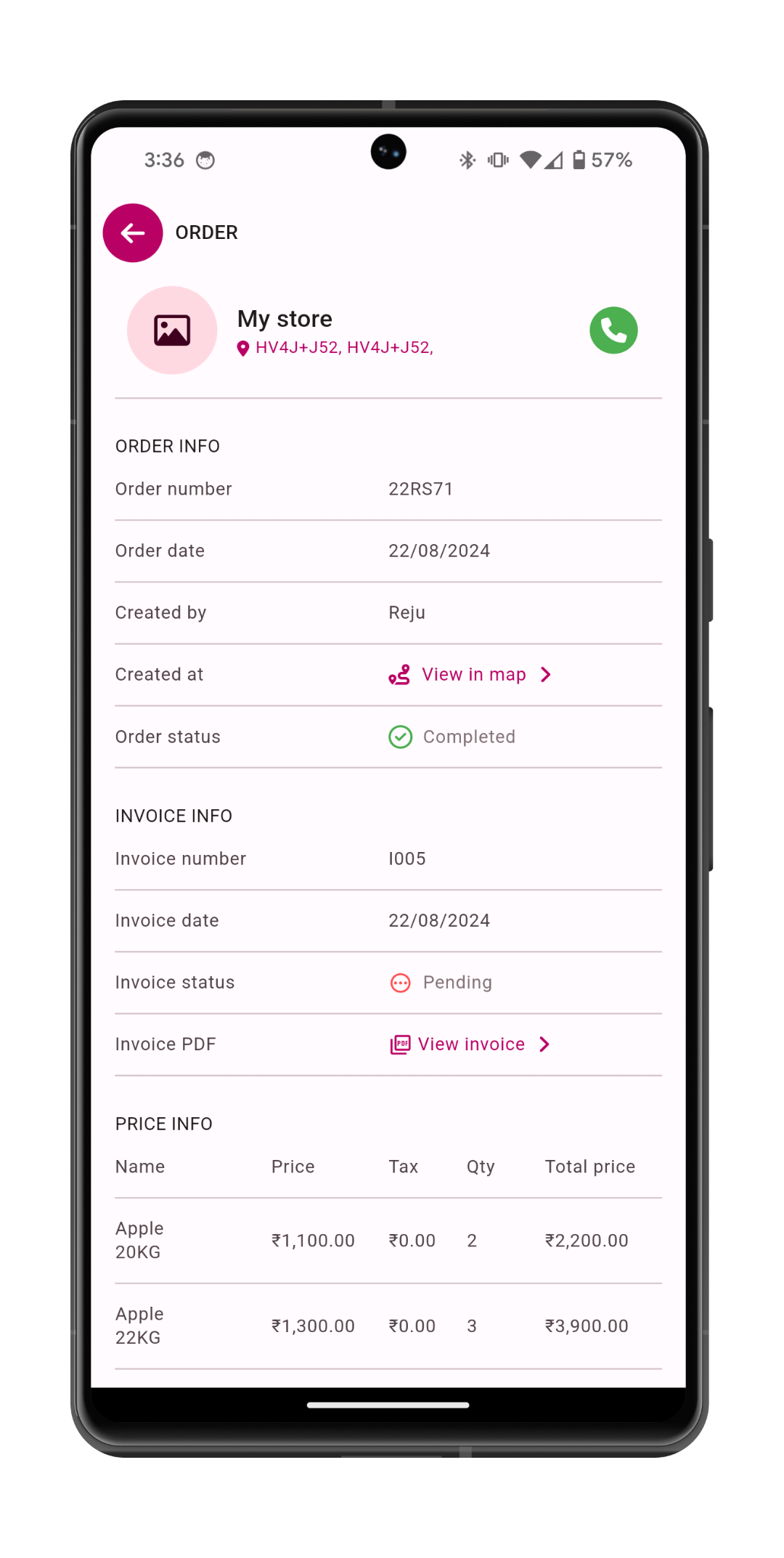

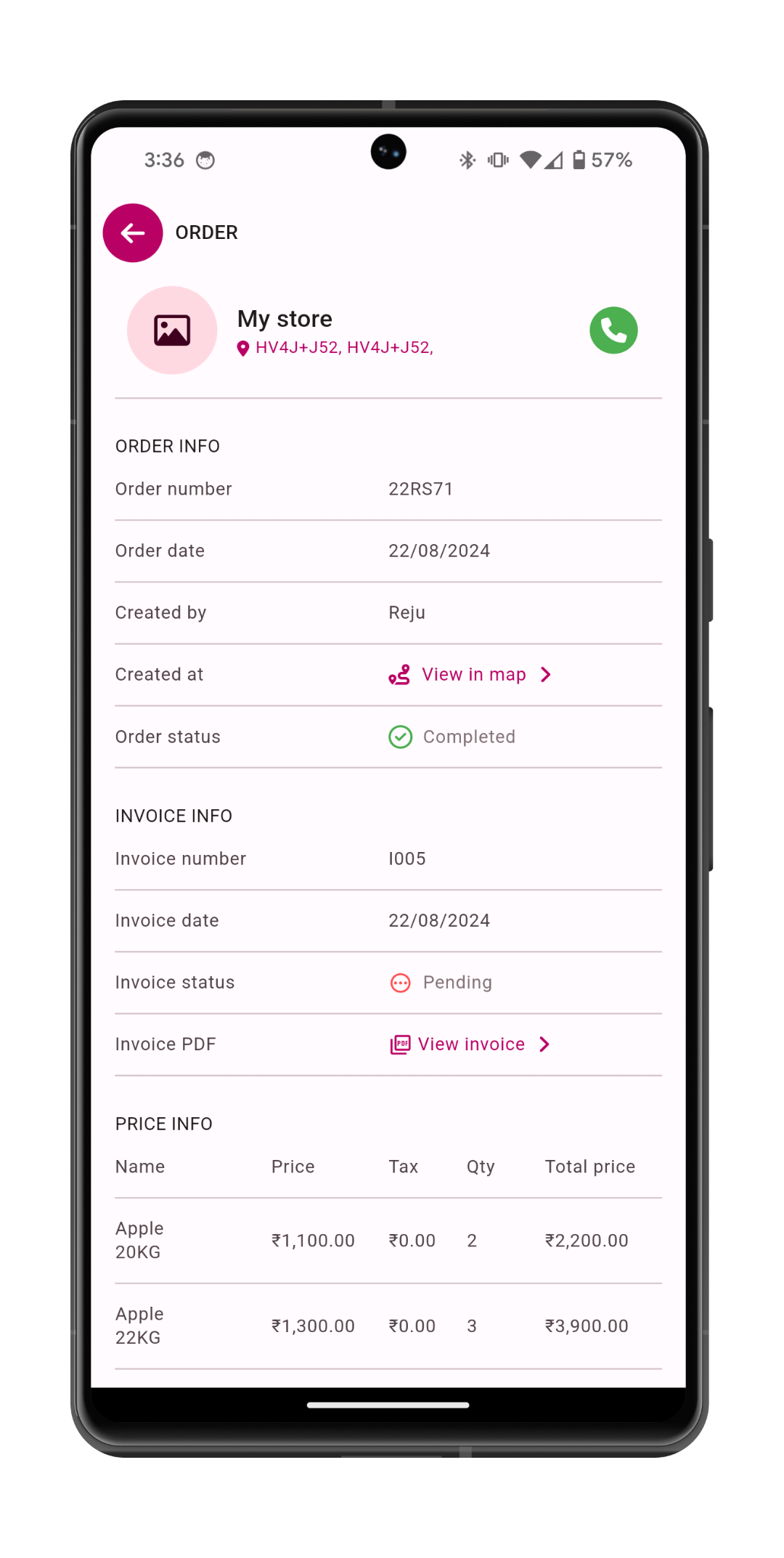

1. Order Management:

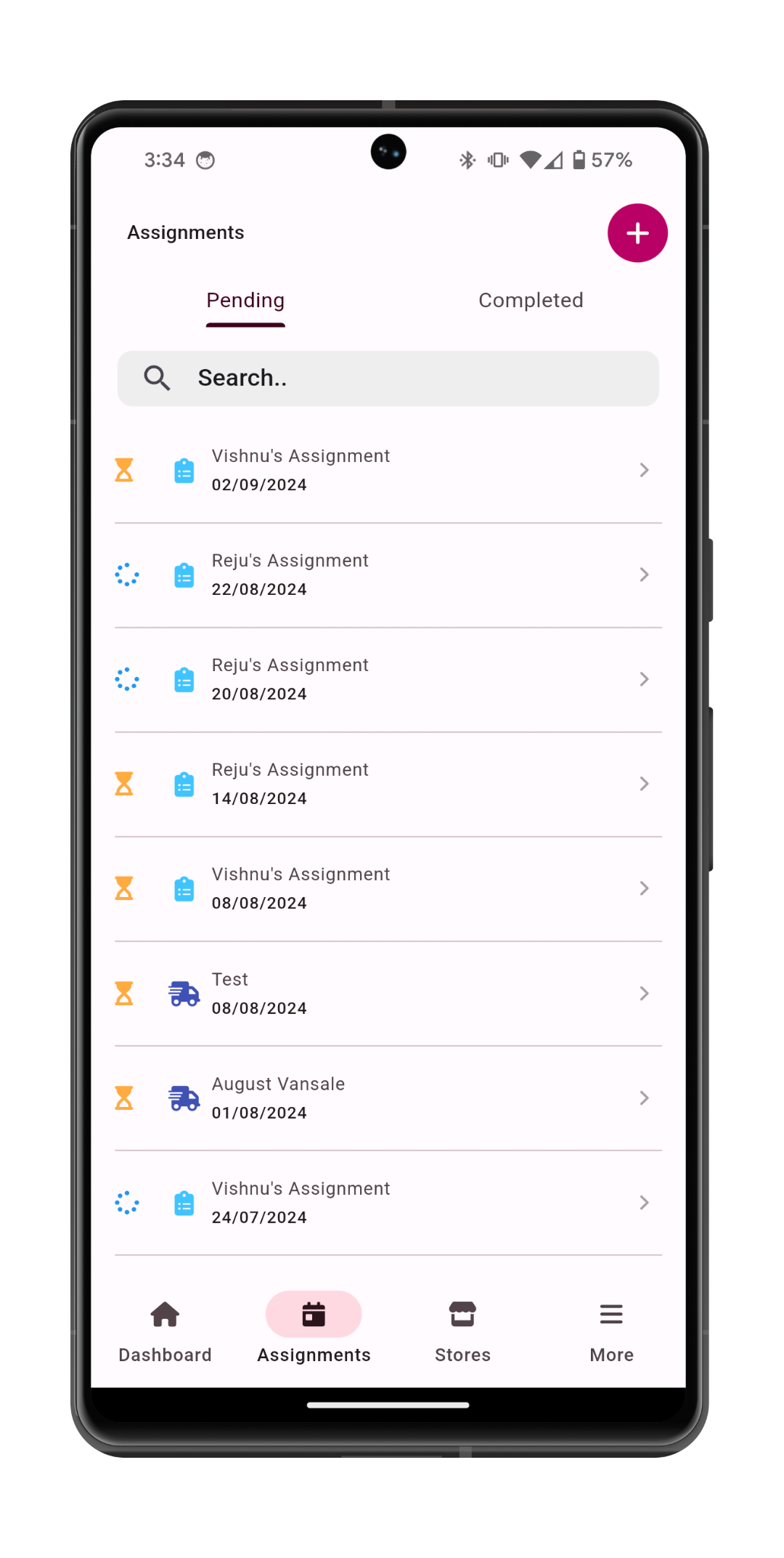

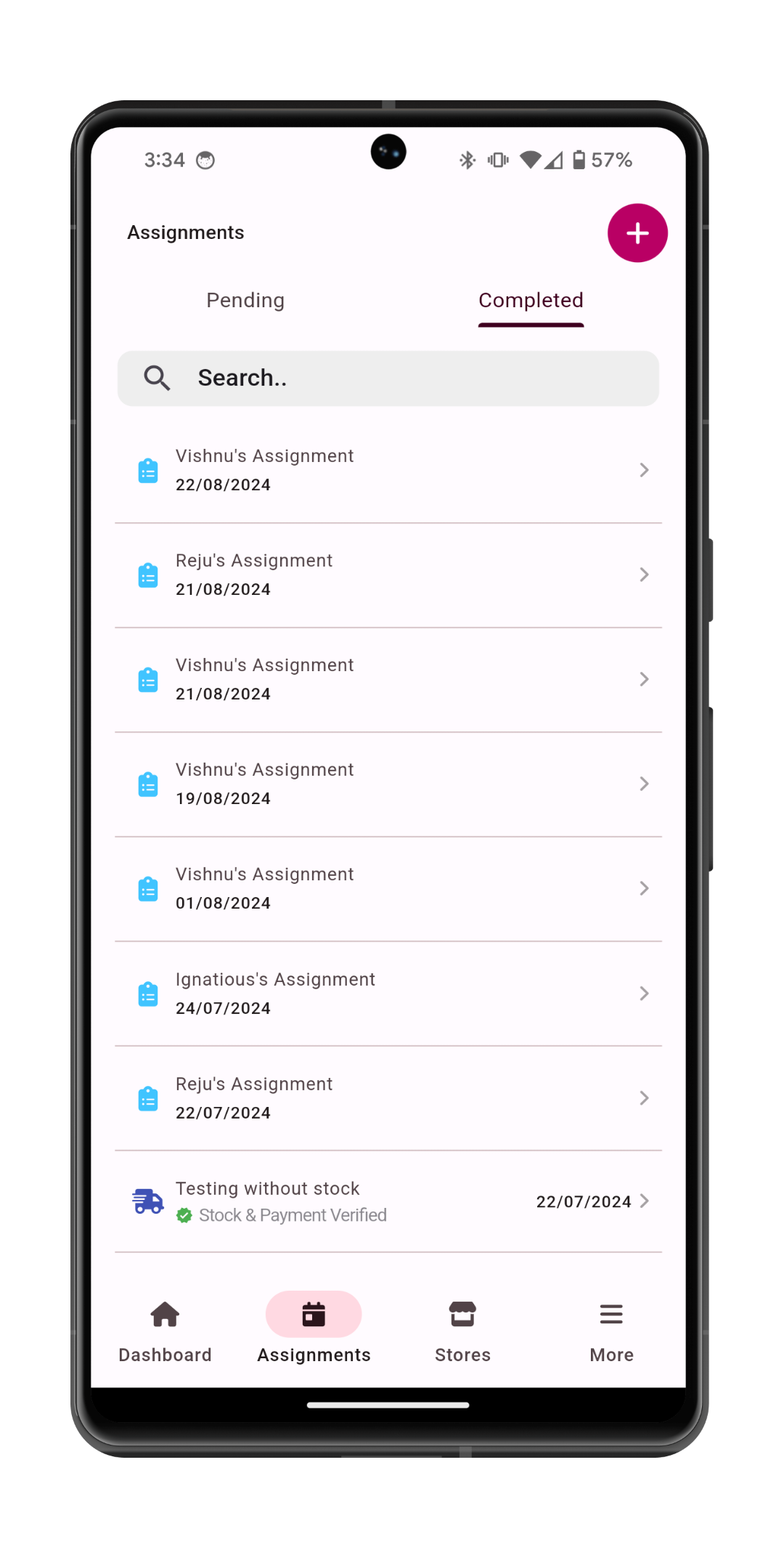

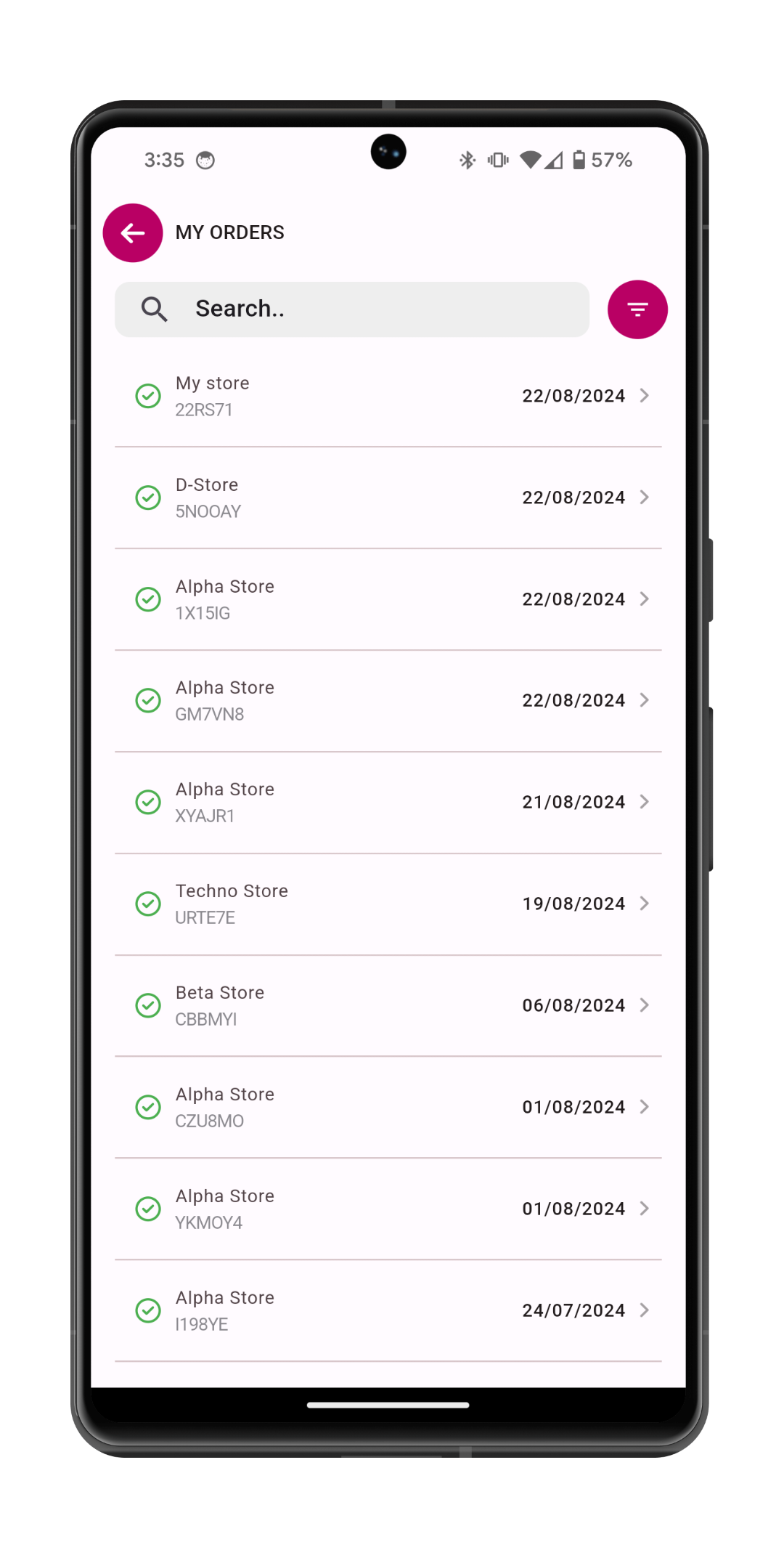

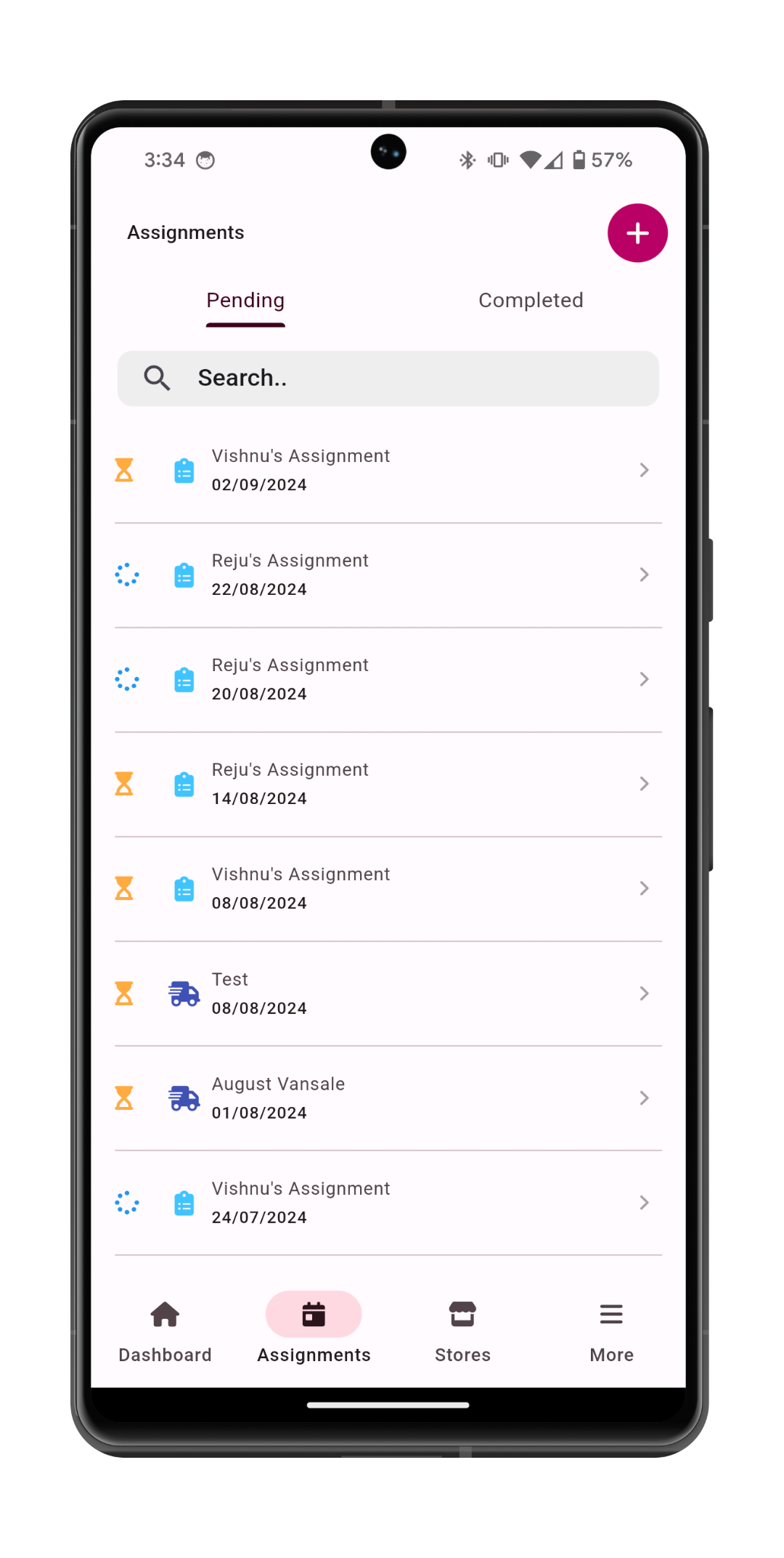

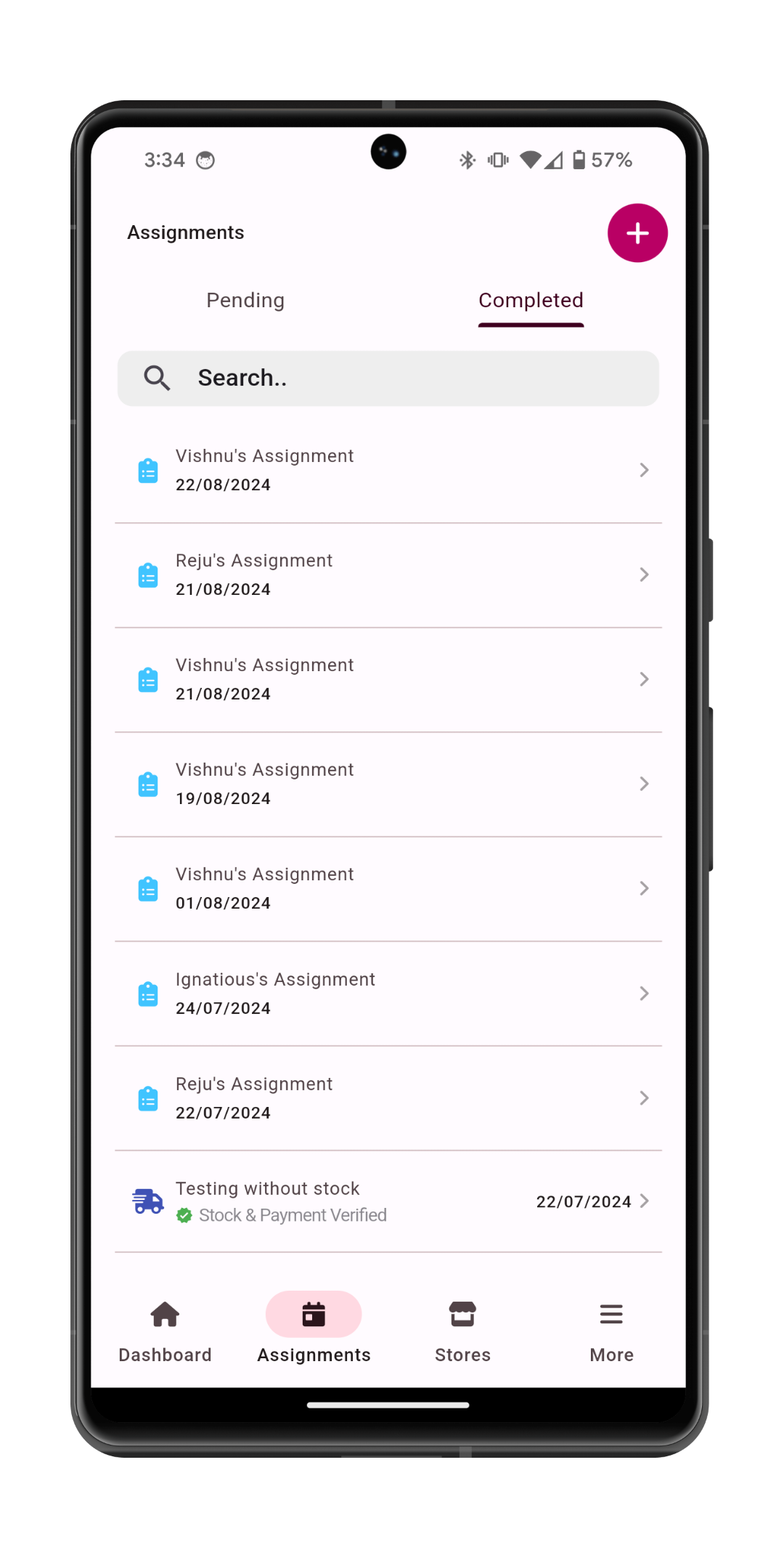

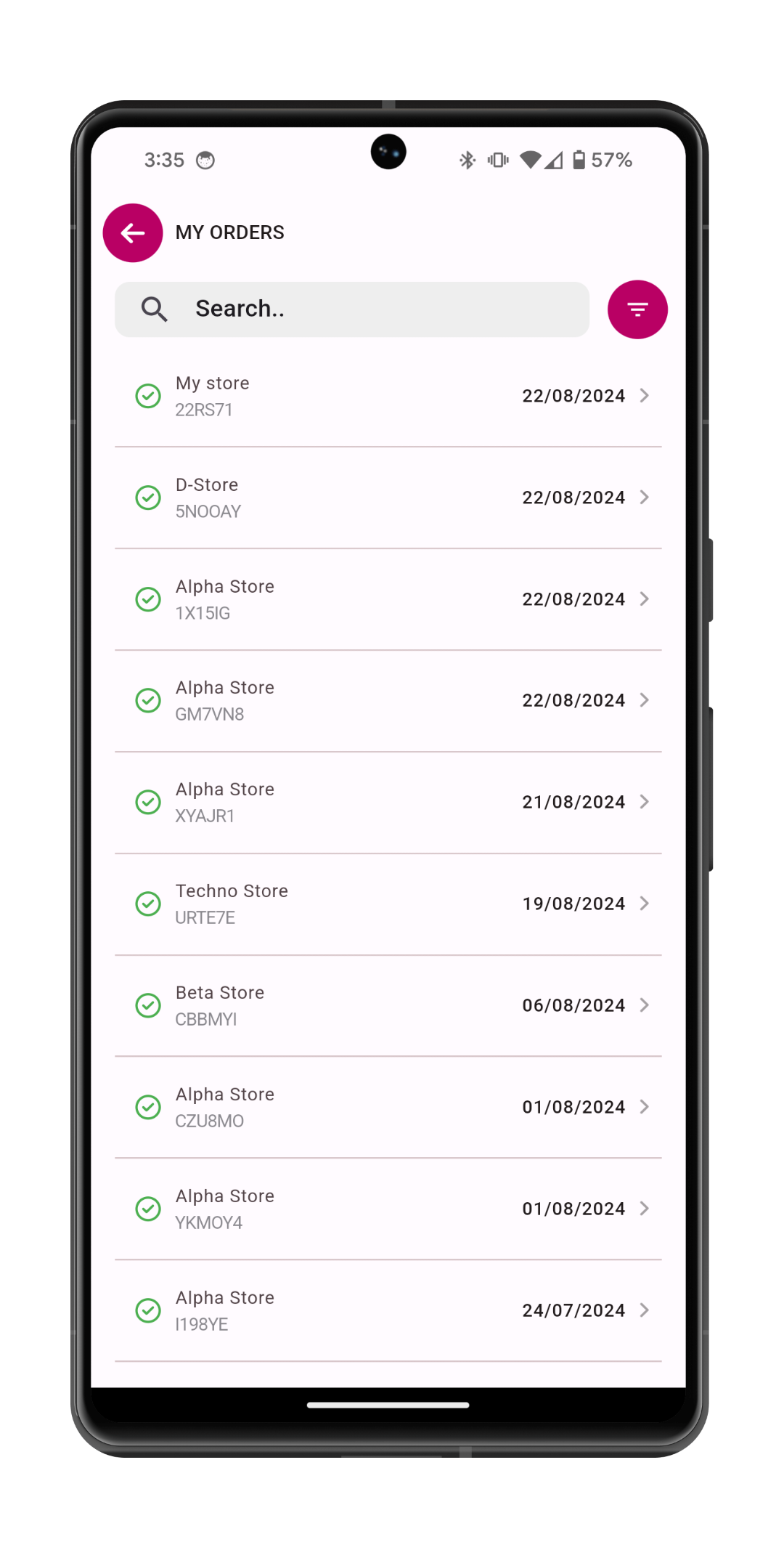

DMS automates the order processing workflow, allowing businesses to manage orders from receipt through fulfillment. This includes tracking order status, processing returns, and managing backorders.

Real-time visibility into order status helps businesses respond quickly to customer inquiries and maintain a high level of service.

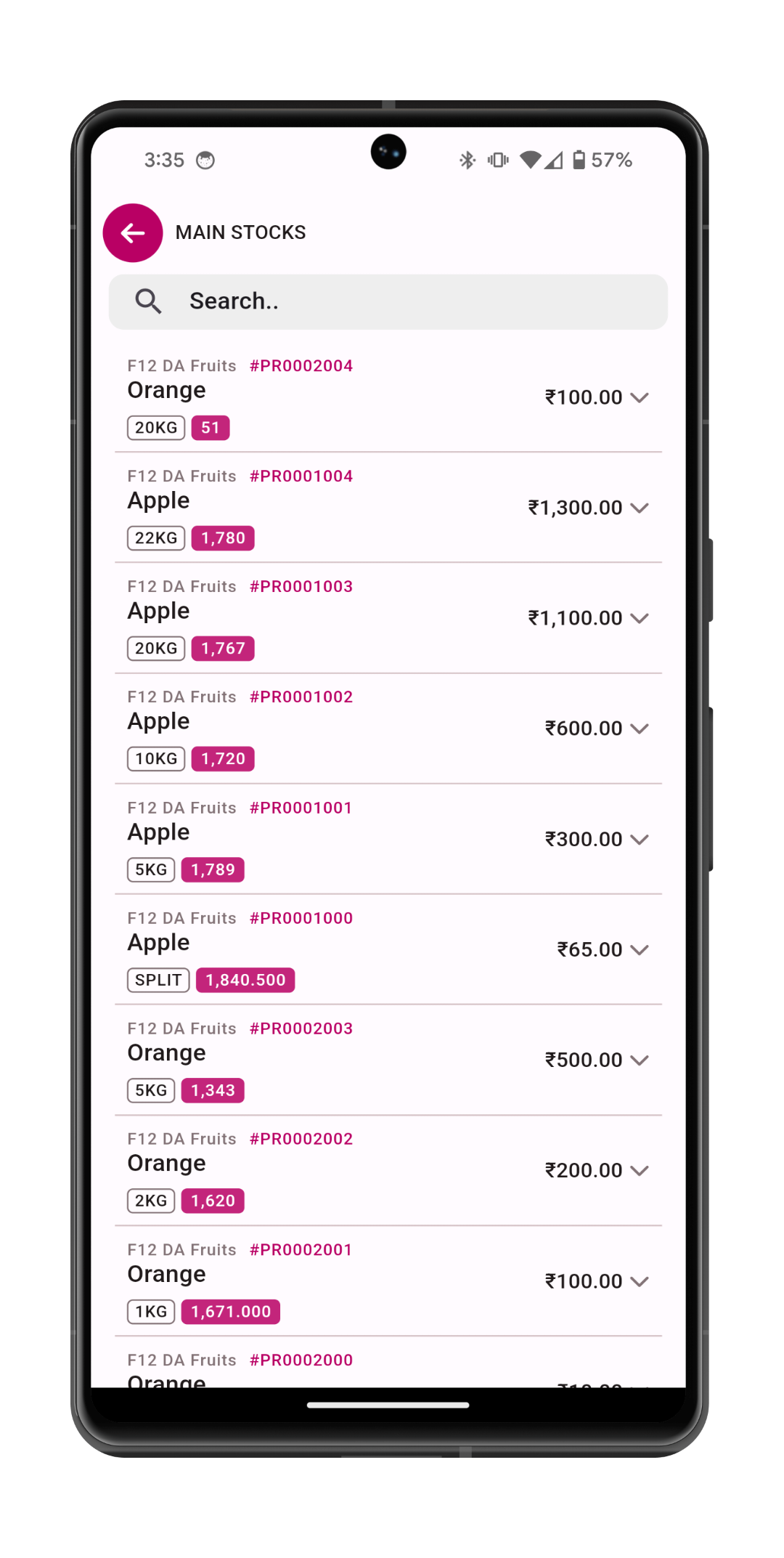

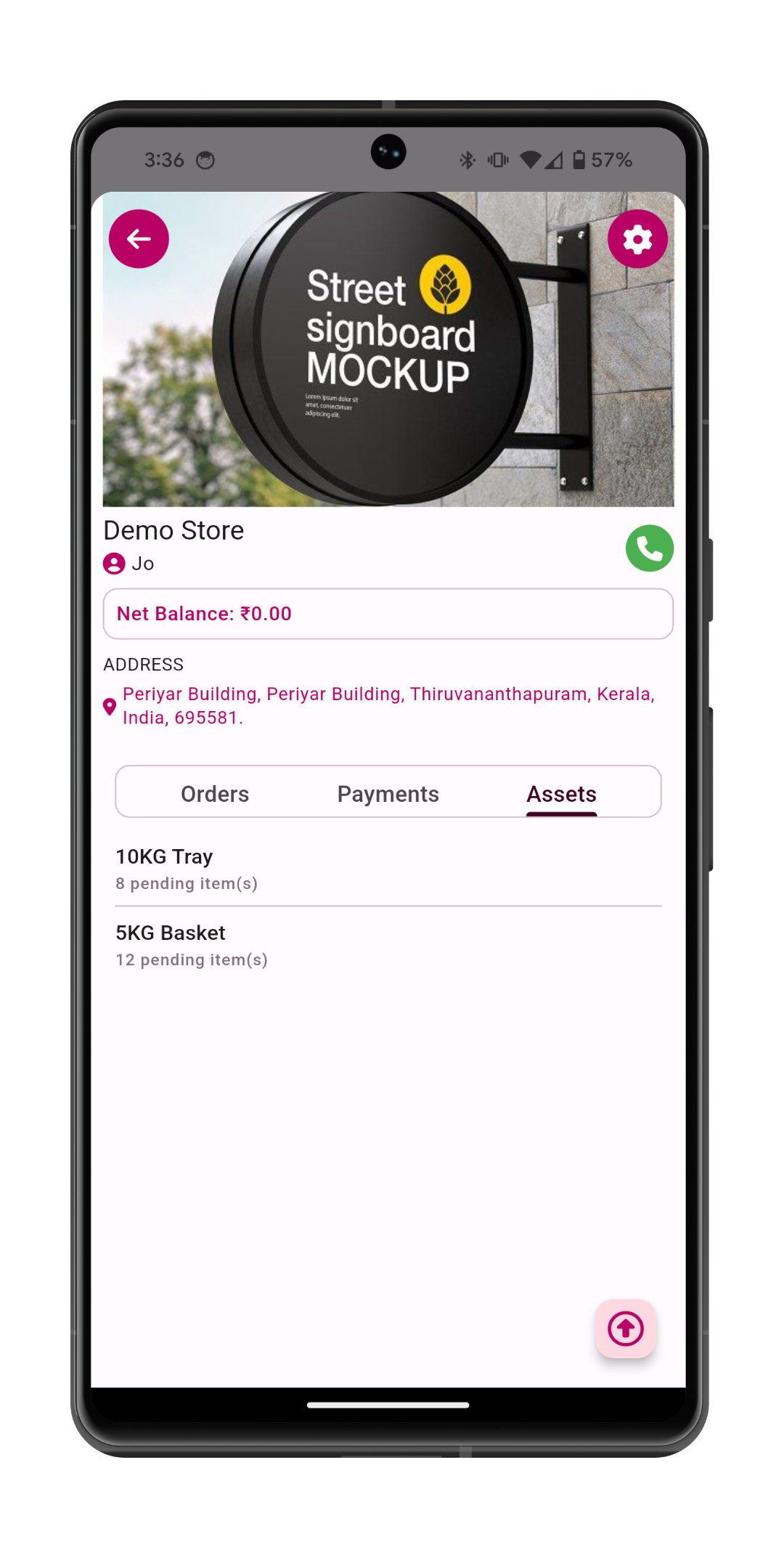

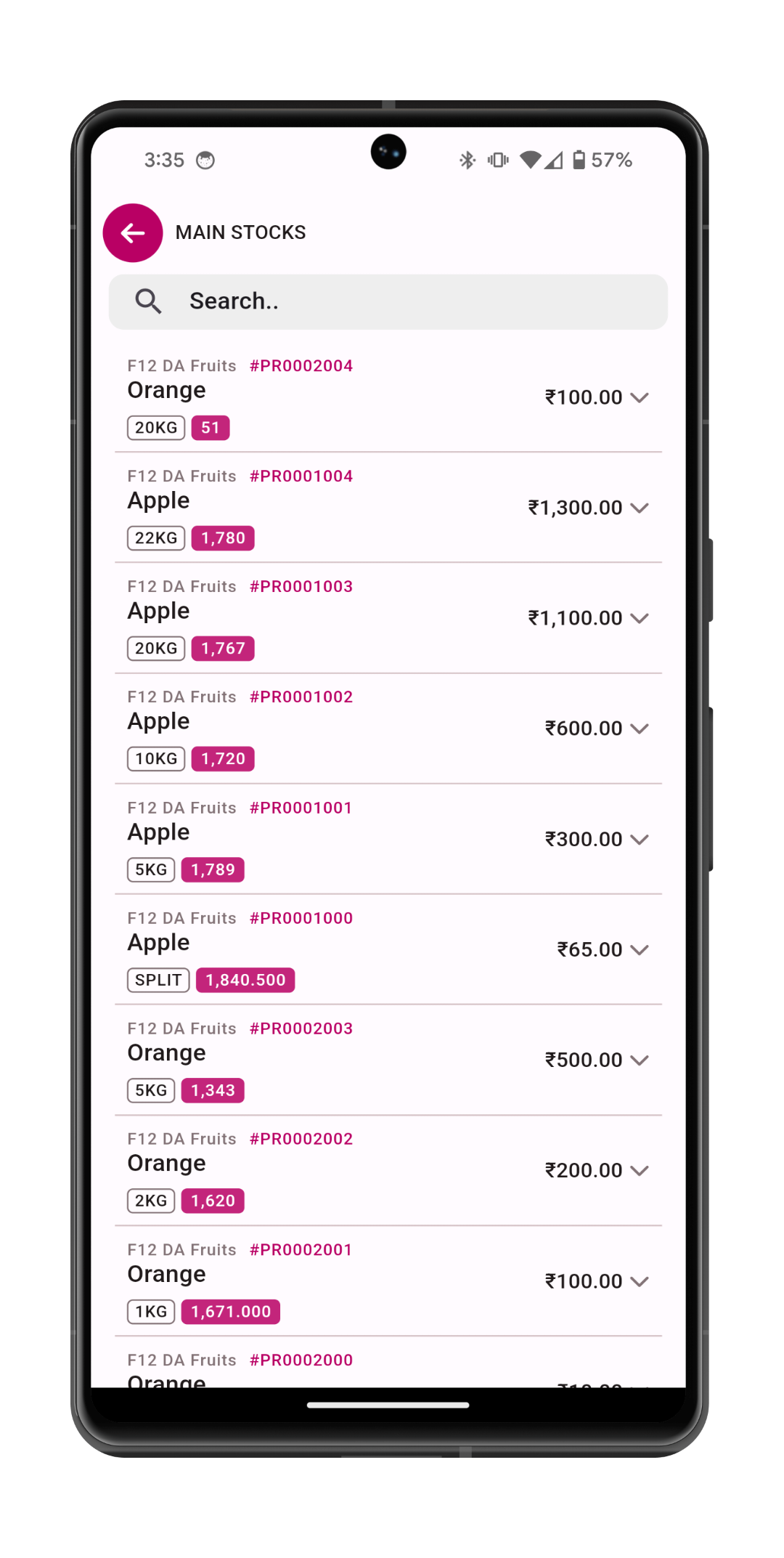

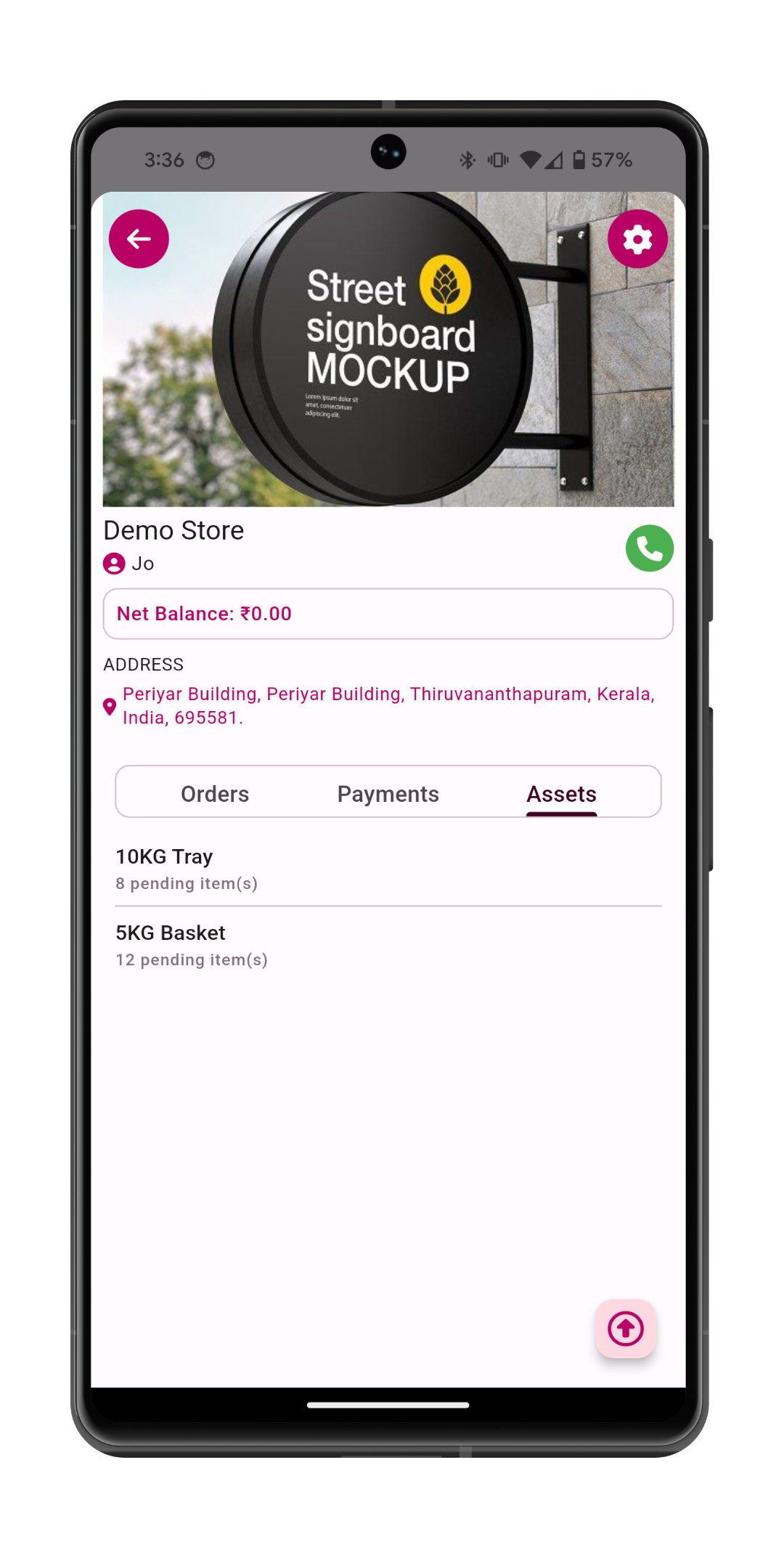

2. Inventory Management:

DMS offers tools for monitoring inventory levels across multiple locations, ensuring that stock is readily available to meet customer demand.

Features often include inventory forecasting, automated replenishment alerts, and tracking of product shelf life, which is crucial for perishable goods.

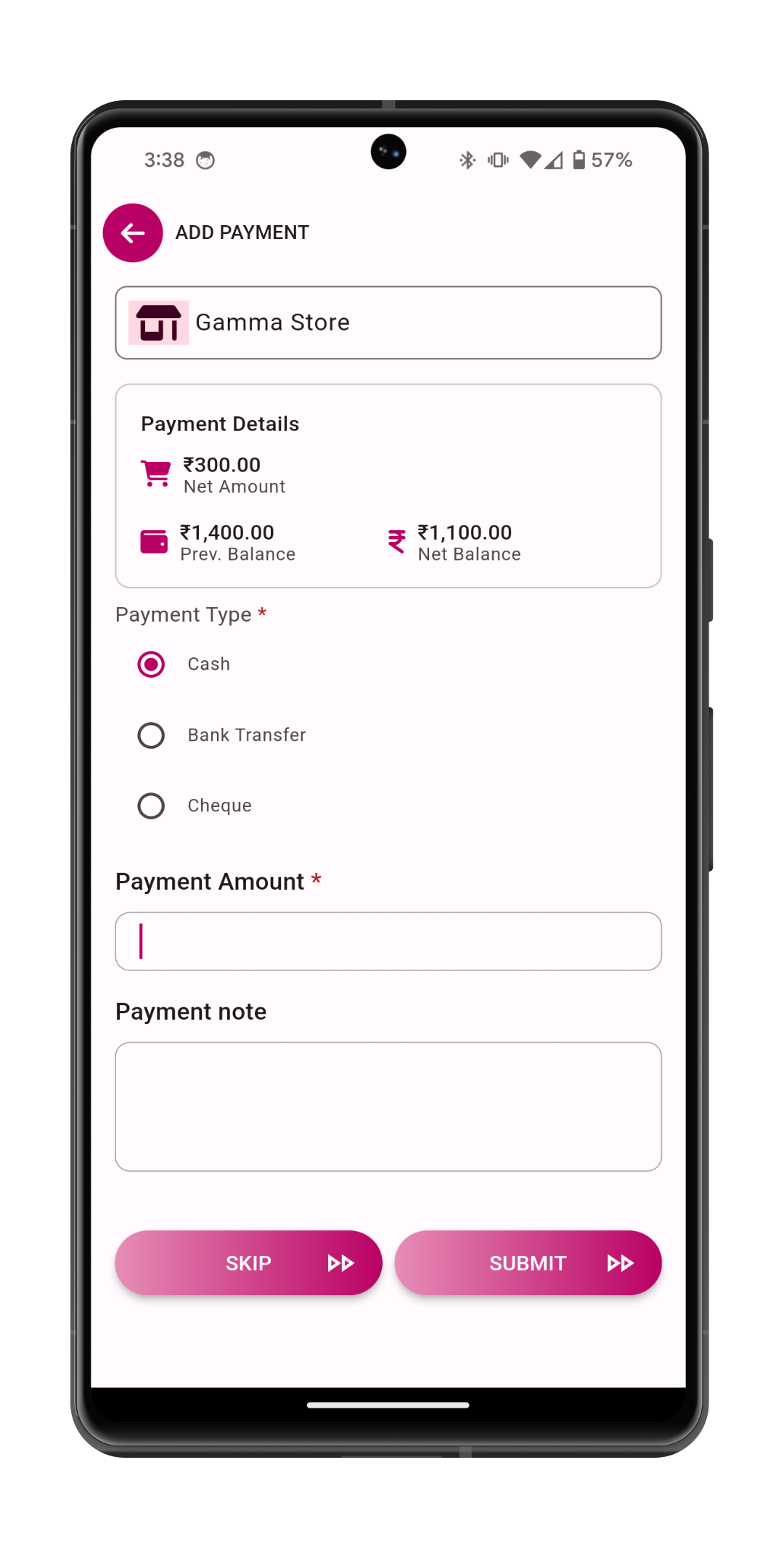

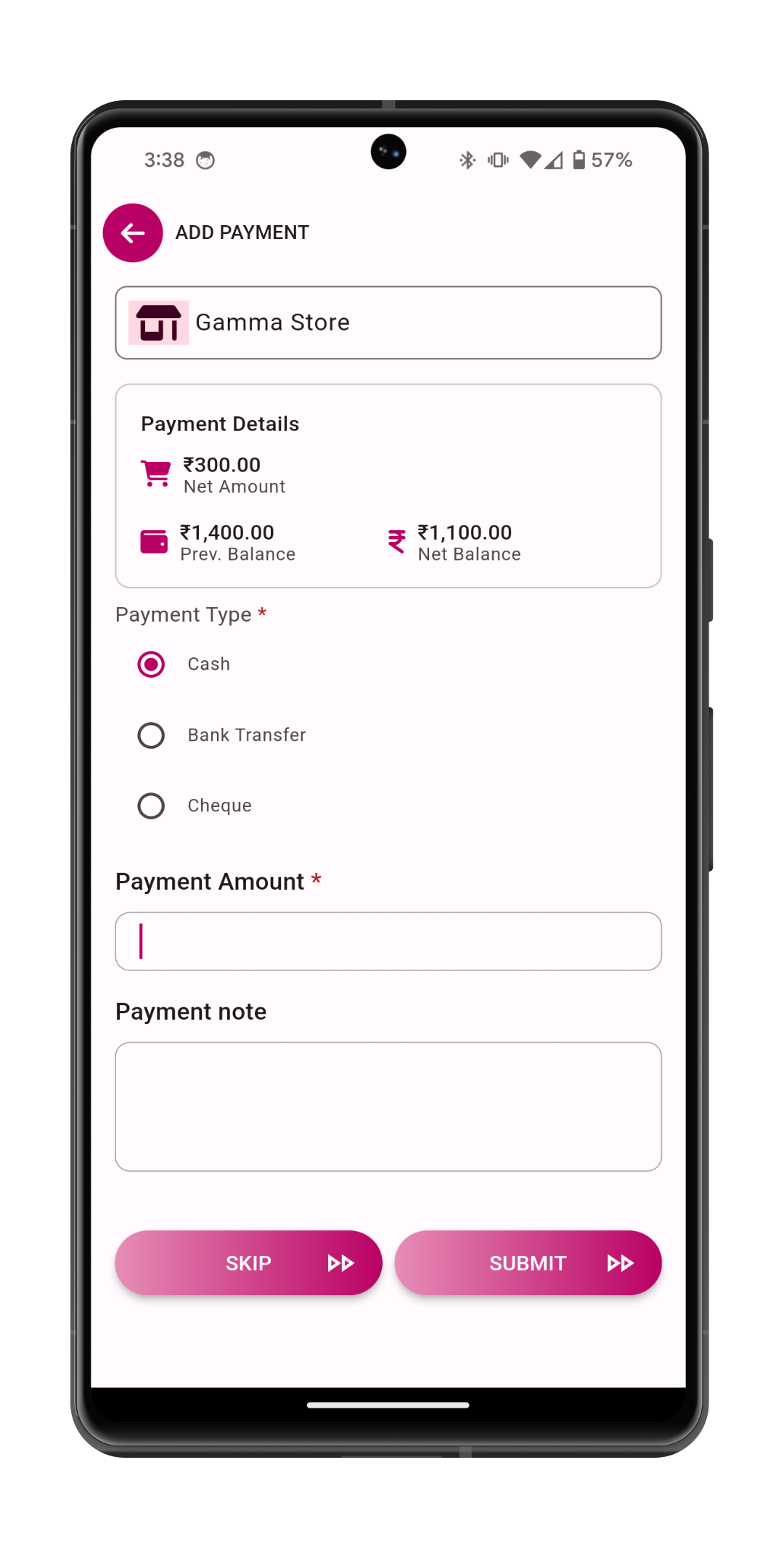

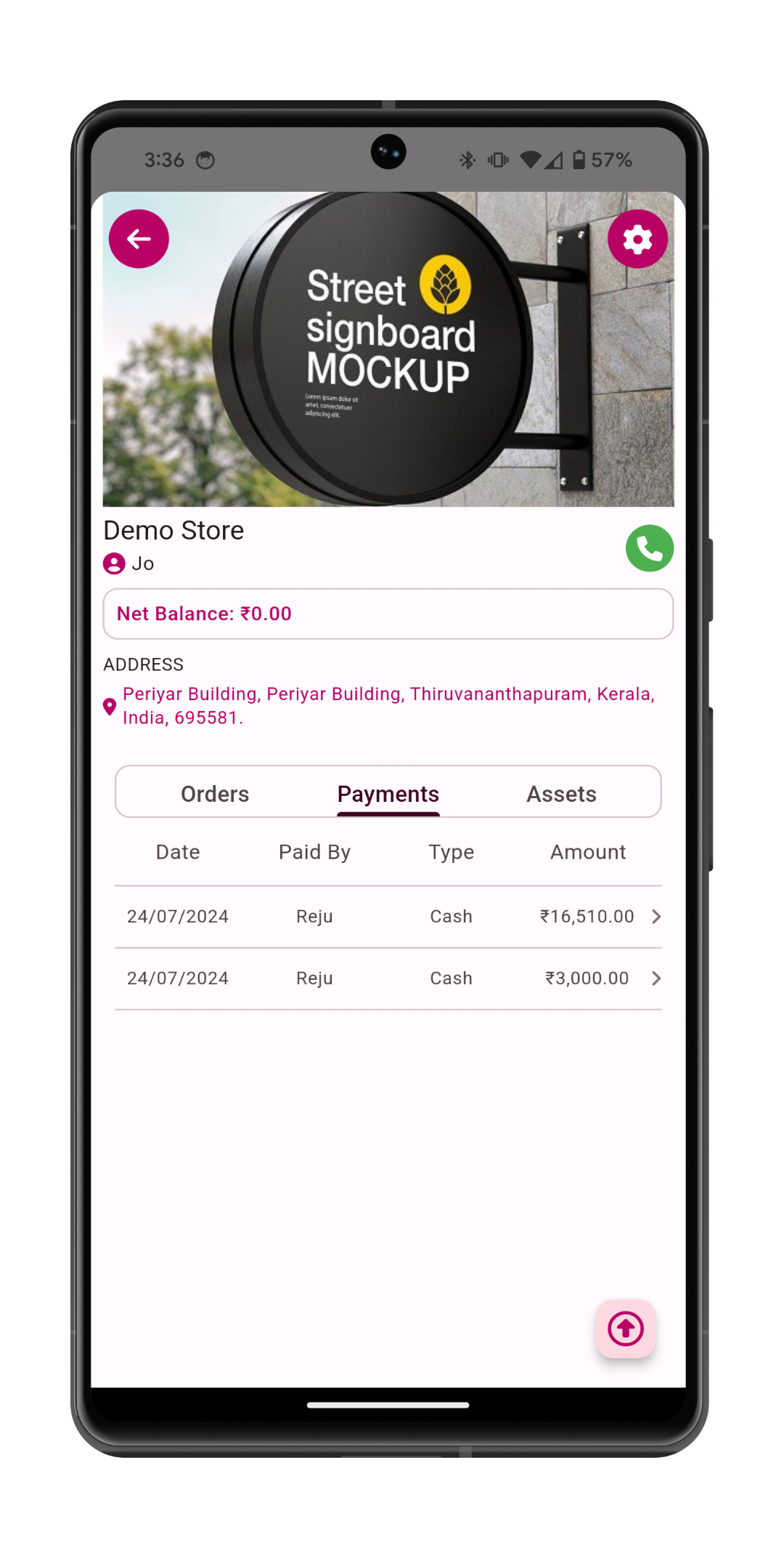

3. Pricing and Promotions:

Businesses can manage pricing strategies and promotional campaigns effectively. DMS allows for flexible pricing adjustments based on distributor agreements or market conditions.

The software can help track the performance of promotional efforts, enabling businesses to assess their impact on sales.

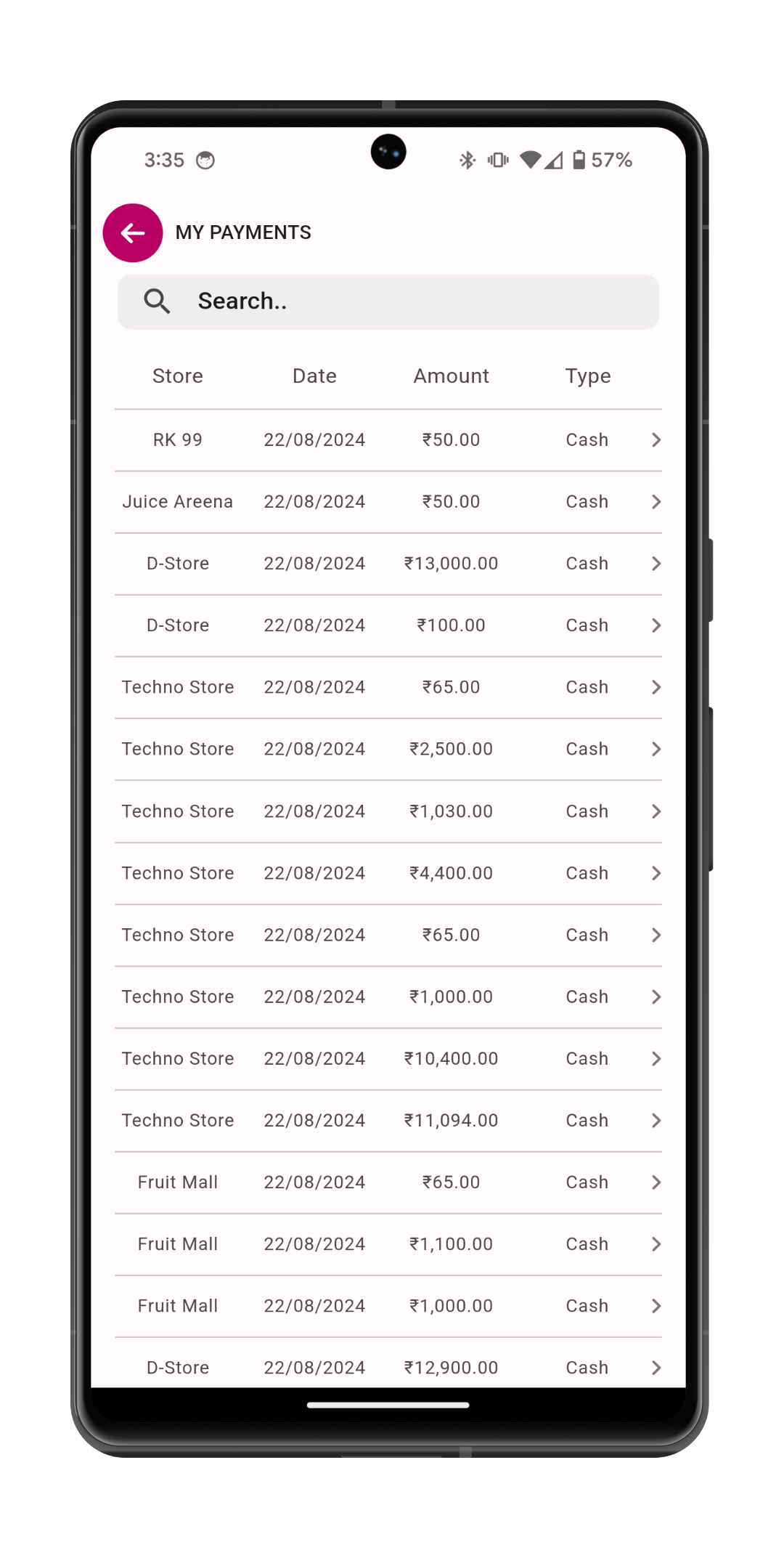

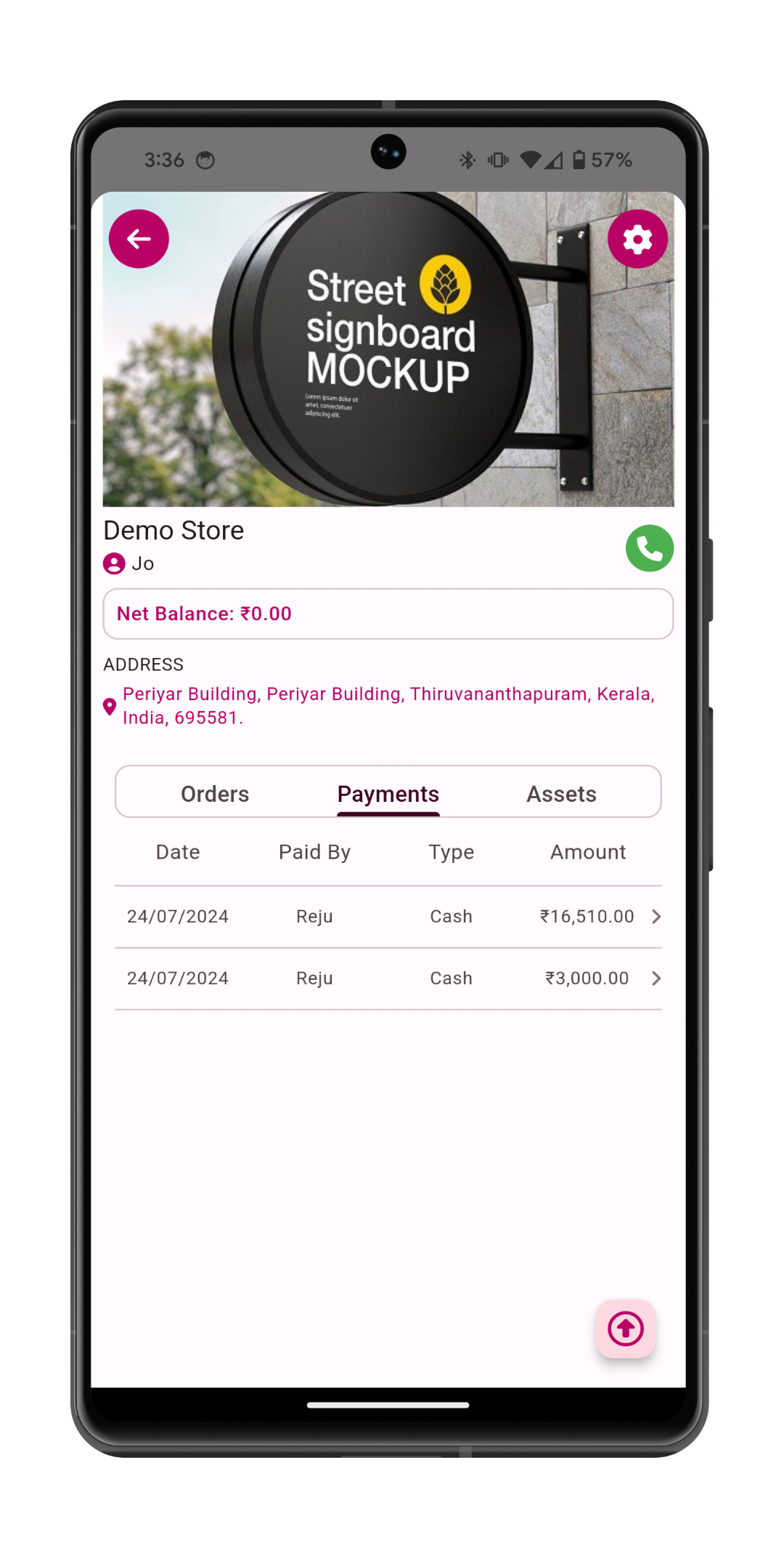

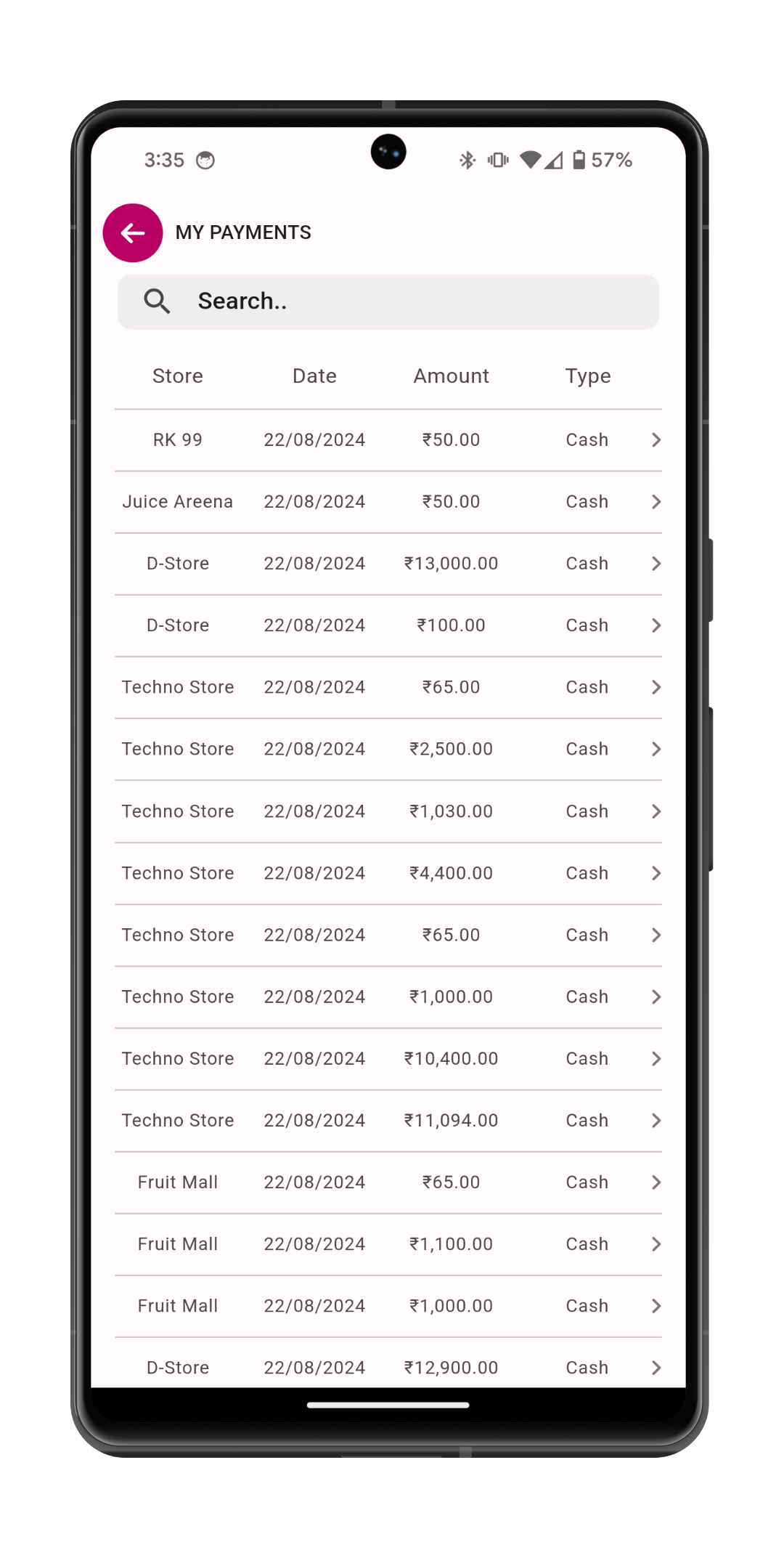

4. Reporting and Analytics:

DMS generates detailed reports on sales performance, inventory turnover, and distributor effectiveness. This data helps businesses make informed decisions about inventory levels, pricing strategies, and sales tactics.

Advanced analytics can identify trends and patterns, providing insights that guide strategic planning.

5. Communication Tools:

Many DMS solutions include features that facilitate communication between manufacturers and distributors, such as shared dashboards, messaging systems, and document sharing.

This centralized platform helps ensure that all parties are informed about updates, product launches, and changes in policies or procedures.

6. Compliance Management:

DMS assists businesses in maintaining compliance with industry regulations and standards, which can vary by region and product type.

The software can help manage contracts and agreements with distributors, ensuring that terms are met and documented.

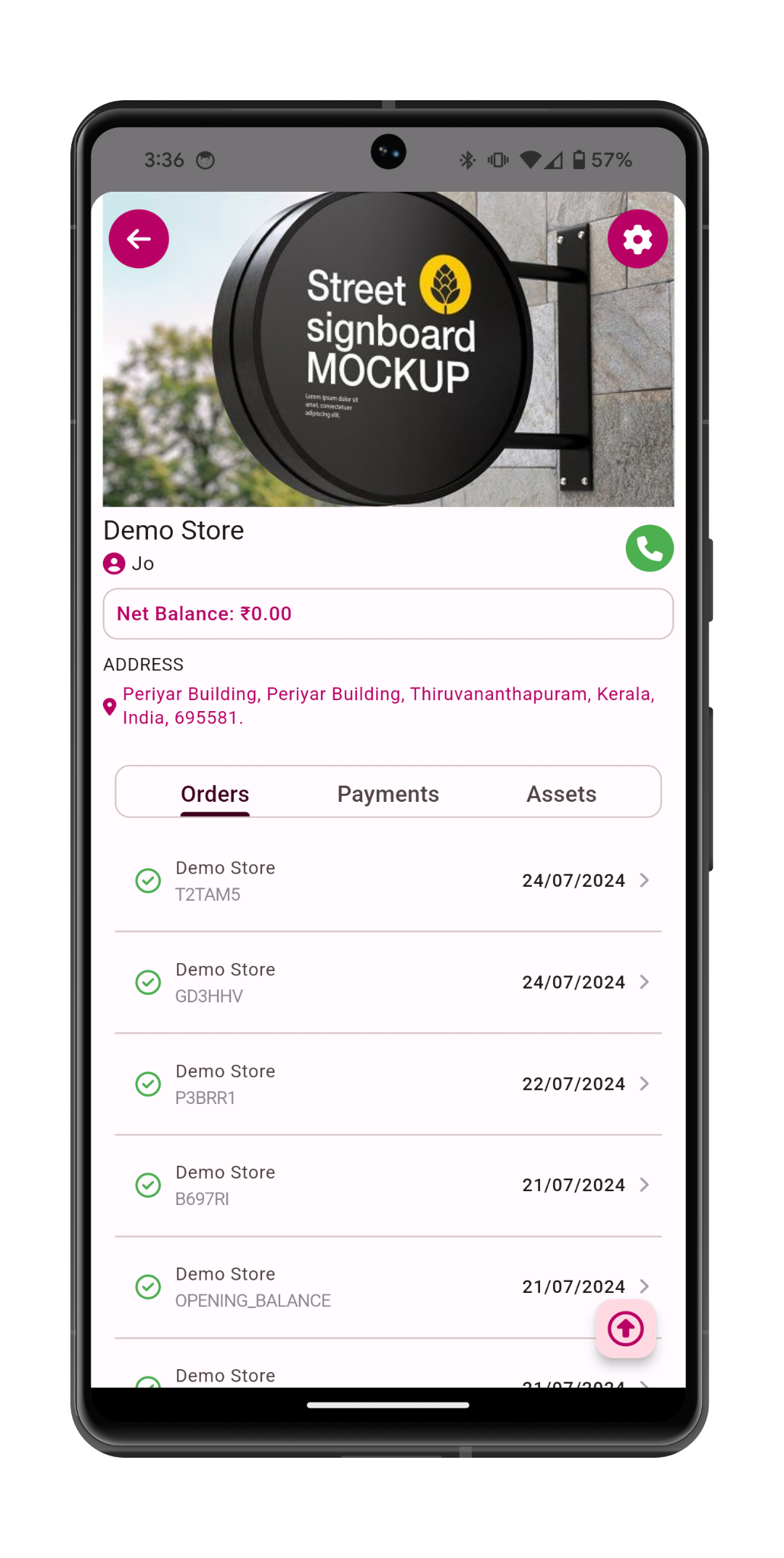

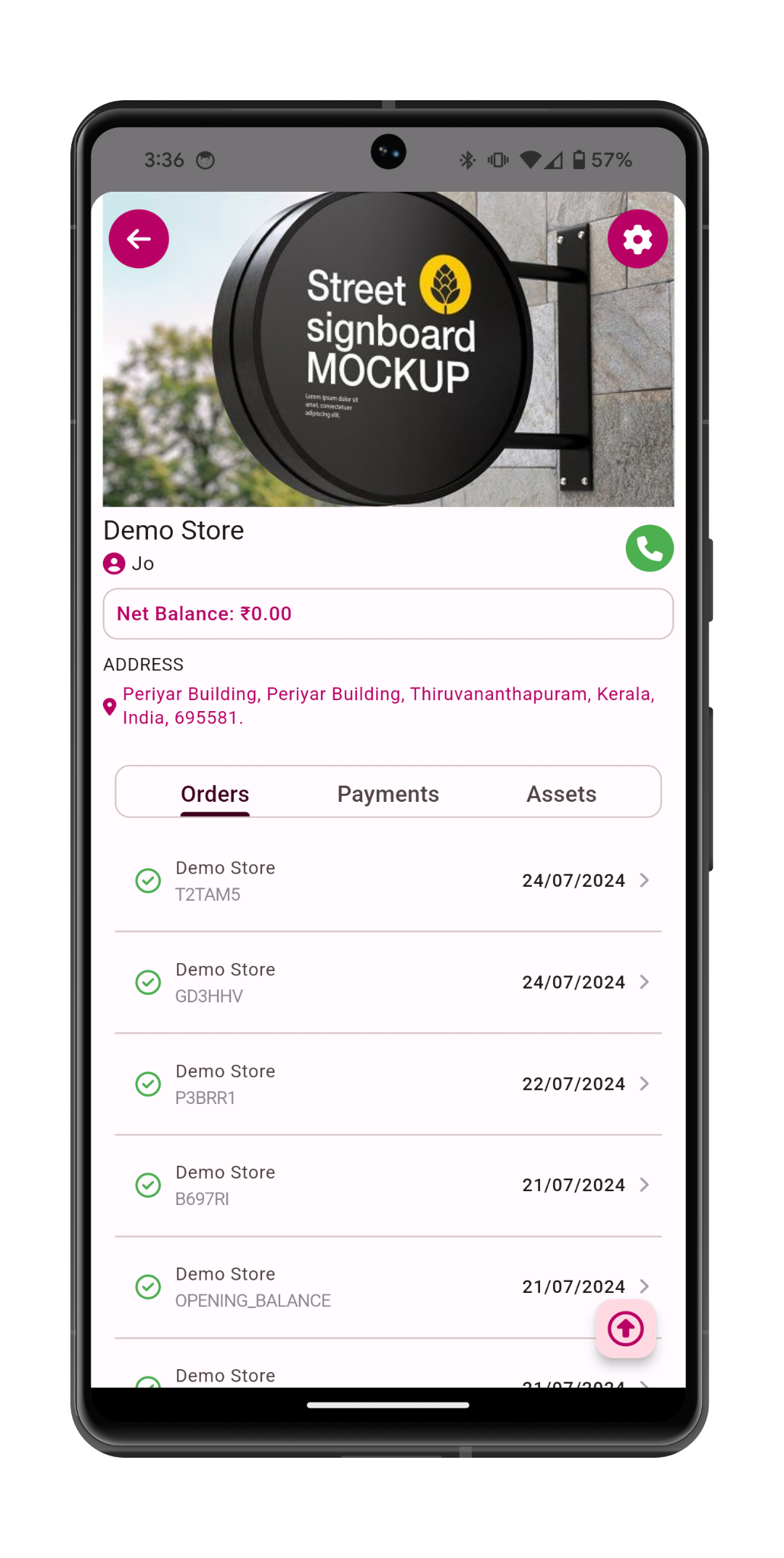

7. Performance Tracking:

DMS provides tools for monitoring distributor performance metrics, such as sales volume, order accuracy, and adherence to pricing agreements.

Businesses can use this information to identify high-performing distributors and those that may need additional support or intervention.

Benefits of Distributor Management Software

1. Improved Efficiency:

By automating key processes, DMS reduces manual workloads and minimizes the risk of human error. This leads to faster order processing and improved operational efficiency.

2. Enhanced Visibility:

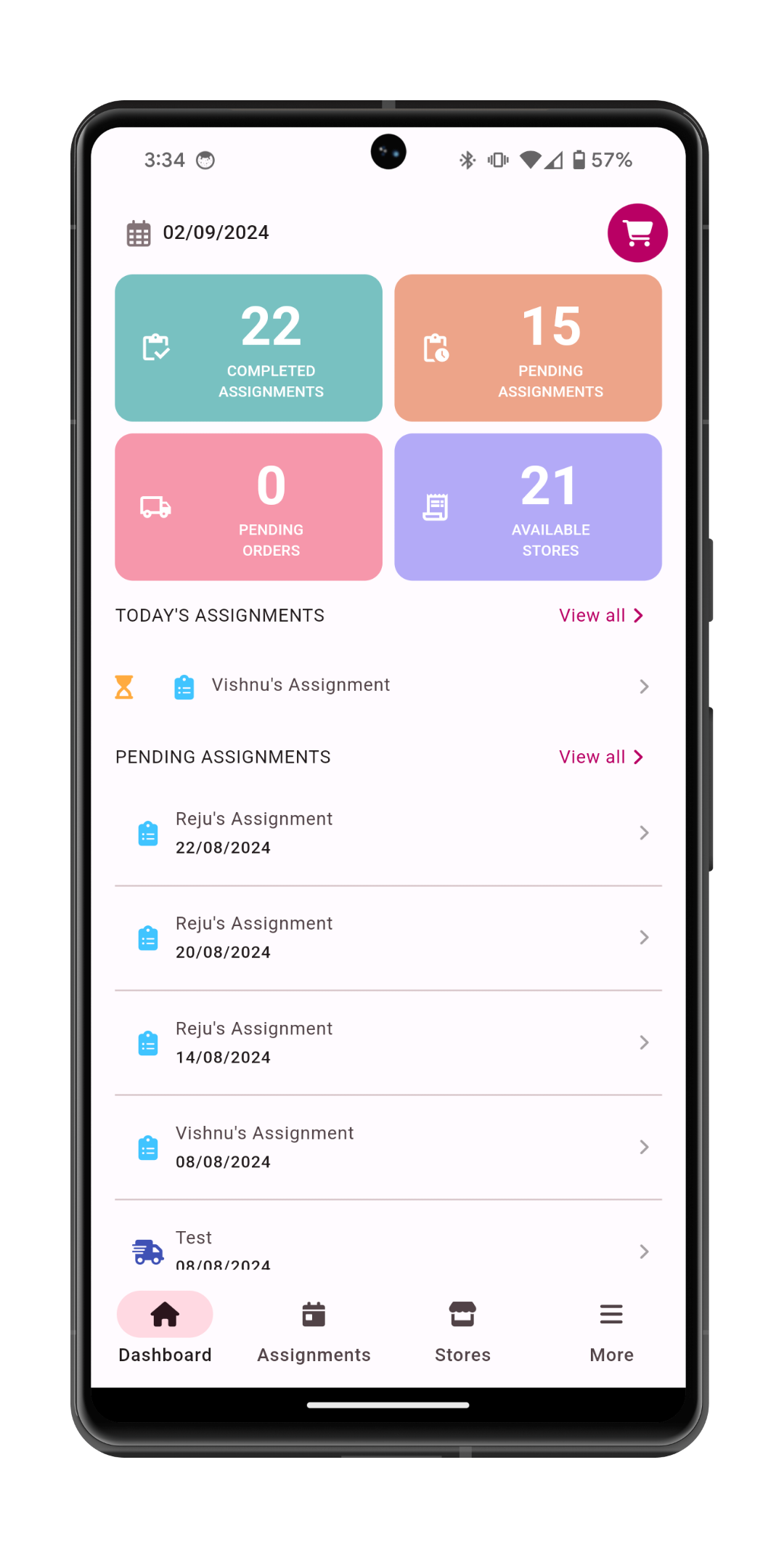

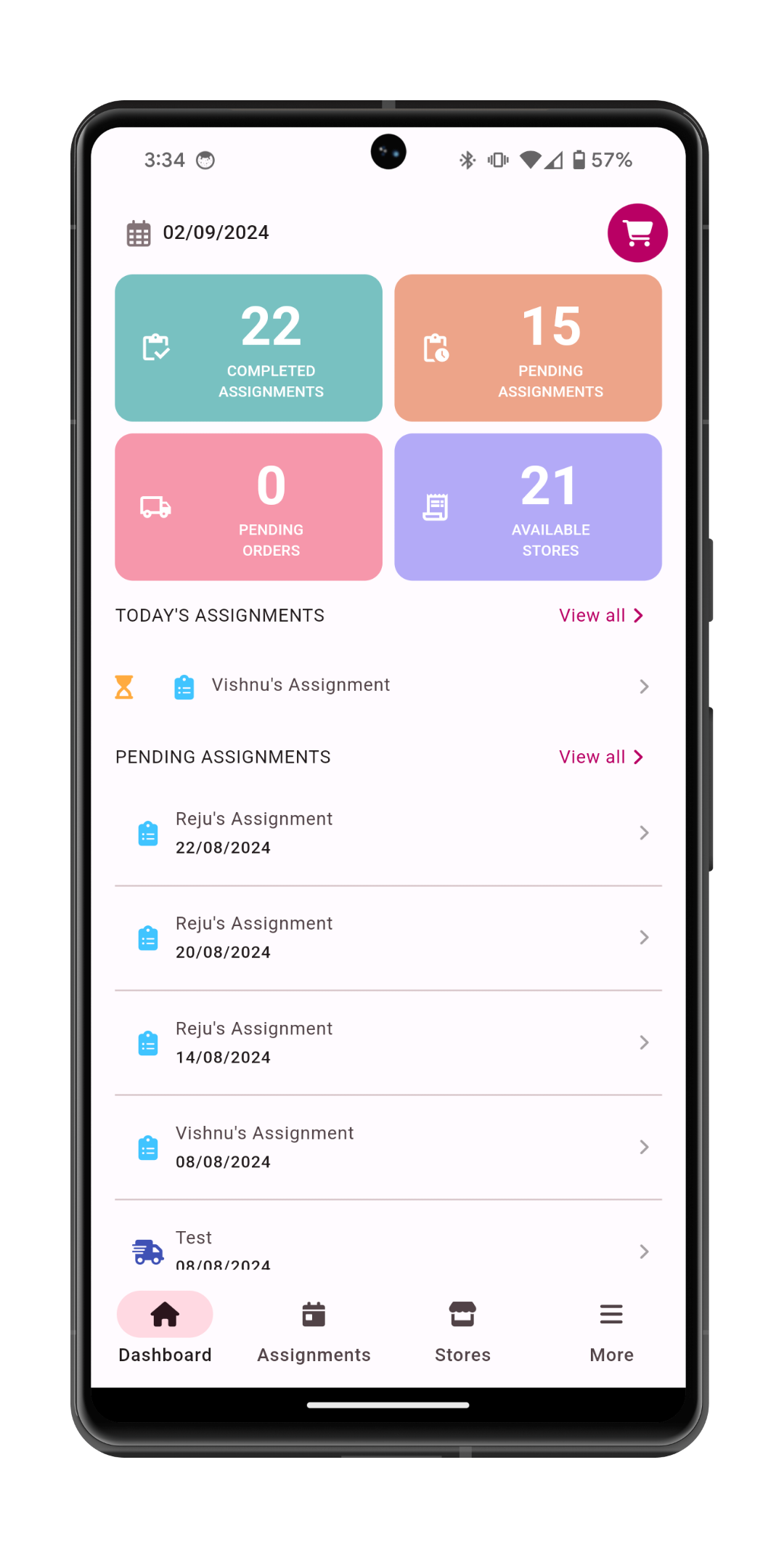

DMS offers real-time insights into inventory levels, order statuses, and sales data. This visibility allows businesses to respond quickly to changes in demand and make informed decisions.

3. Better Relationships:

Enhanced communication and collaboration capabilities foster stronger relationships between manufacturers and distributors. This can lead to improved loyalty and long-term partnerships.

4. Increased Sales:

By optimizing order fulfillment and inventory management, DMS helps businesses meet customer demand more effectively. This leads to improved customer satisfaction and potentially higher sales.

5. Data-Driven Decisions:

The analytics and reporting capabilities of DMS empower businesses to make informed strategic decisions based on actual performance data rather than assumptions.

Challenges in Distributor Management

While distributor management software offers numerous benefits, businesses may face challenges in its implementation and usage:

1. Integration with Existing Systems:

Integrating DMS with existing ERP, CRM, or supply chain management systems can be complex and may require significant IT resources.

2. User Adoption:

Ensuring that distributors and internal teams adopt the new software can be challenging. Training and support are essential for smooth transition and effective usage.

3. Cost Considerations:

Depending on the features and complexity of the DMS, costs can vary significantly. Businesses must evaluate their budget and determine the ROI of investing in such software.

Market Trends

The distributor management software market is evolving, influenced by several key trends:

1. Cloud-Based Solutions:

Many businesses are shifting to cloud-based DMS solutions for greater flexibility, scalability, and ease of access from anywhere.

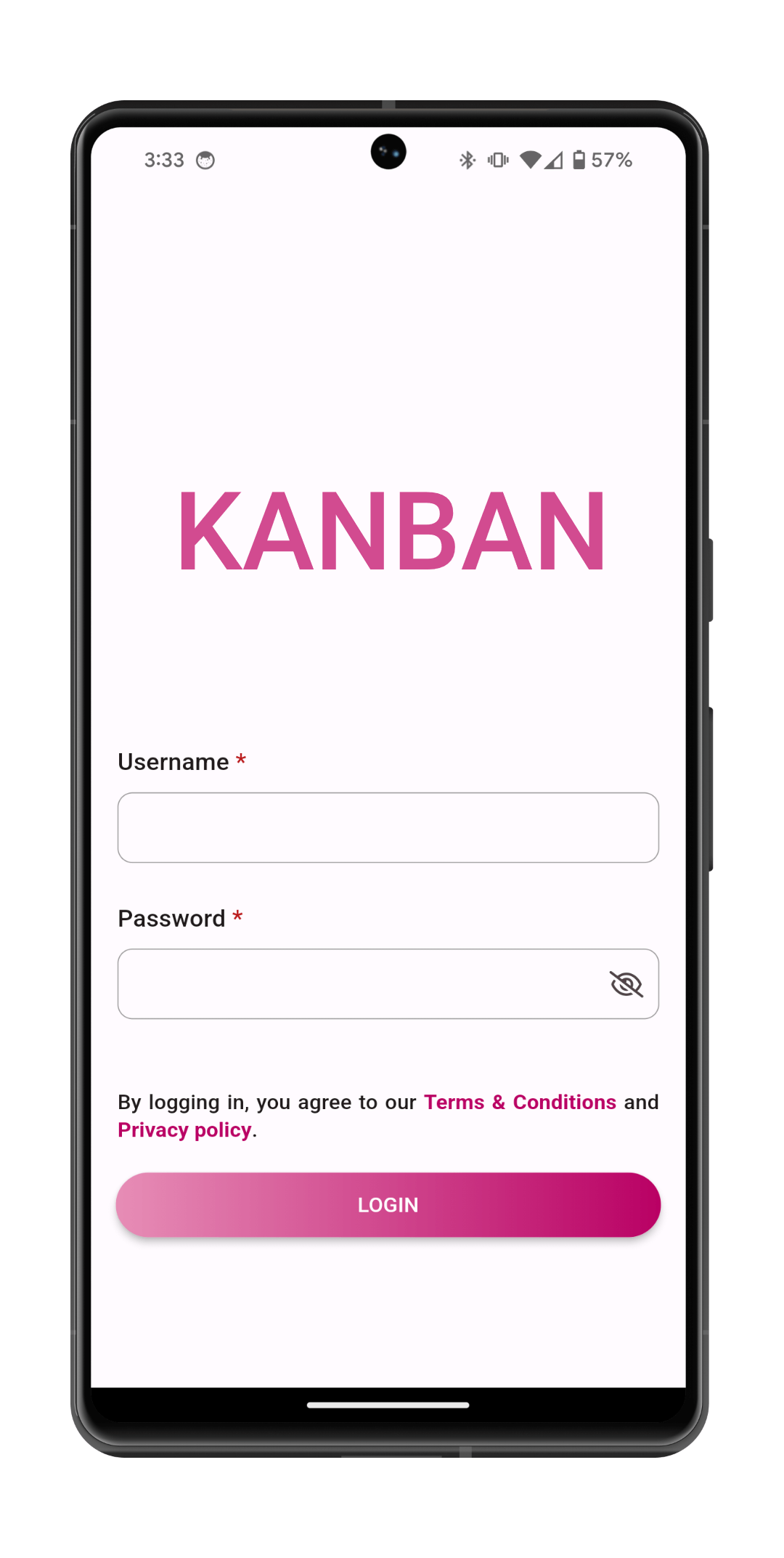

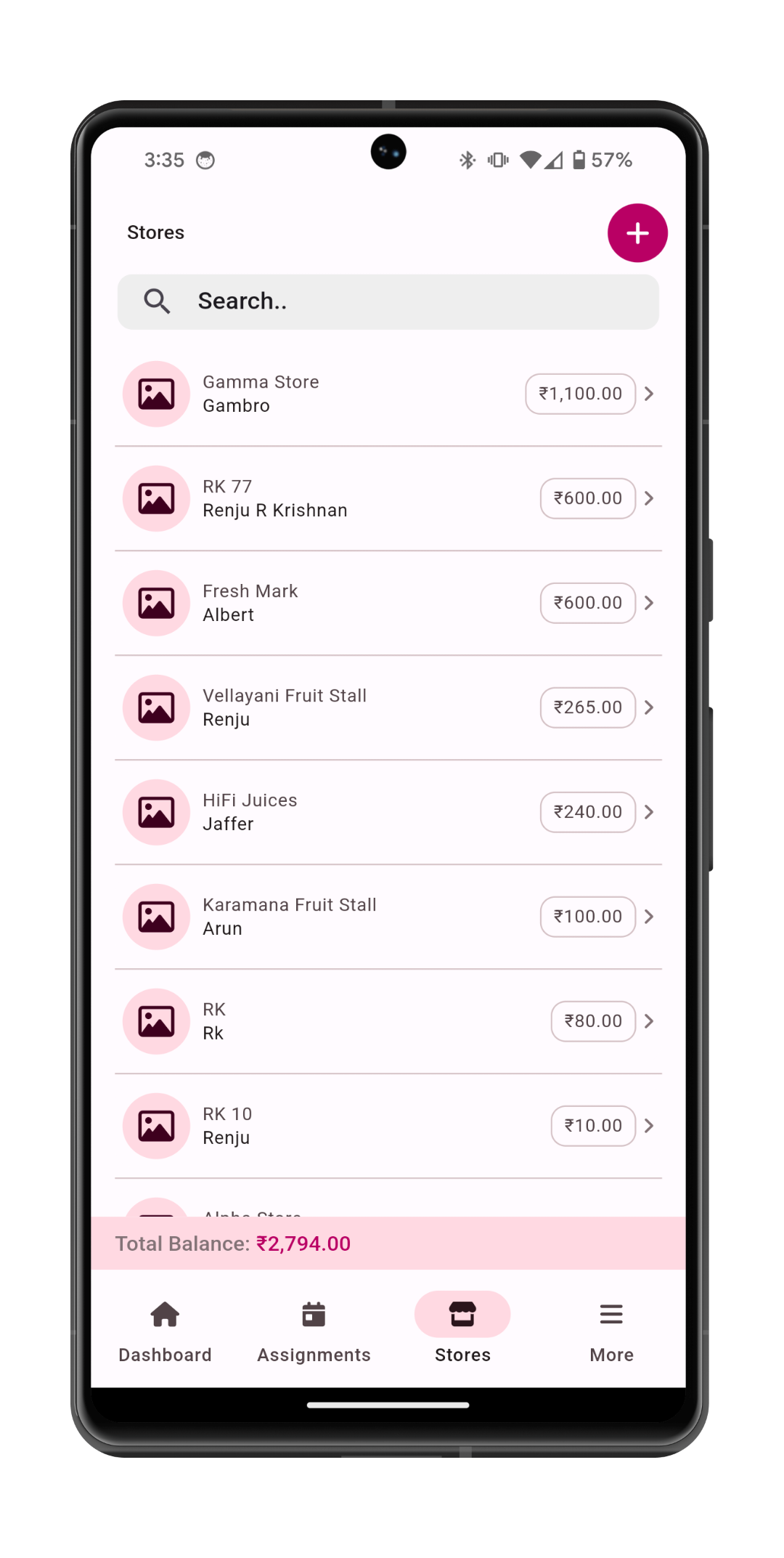

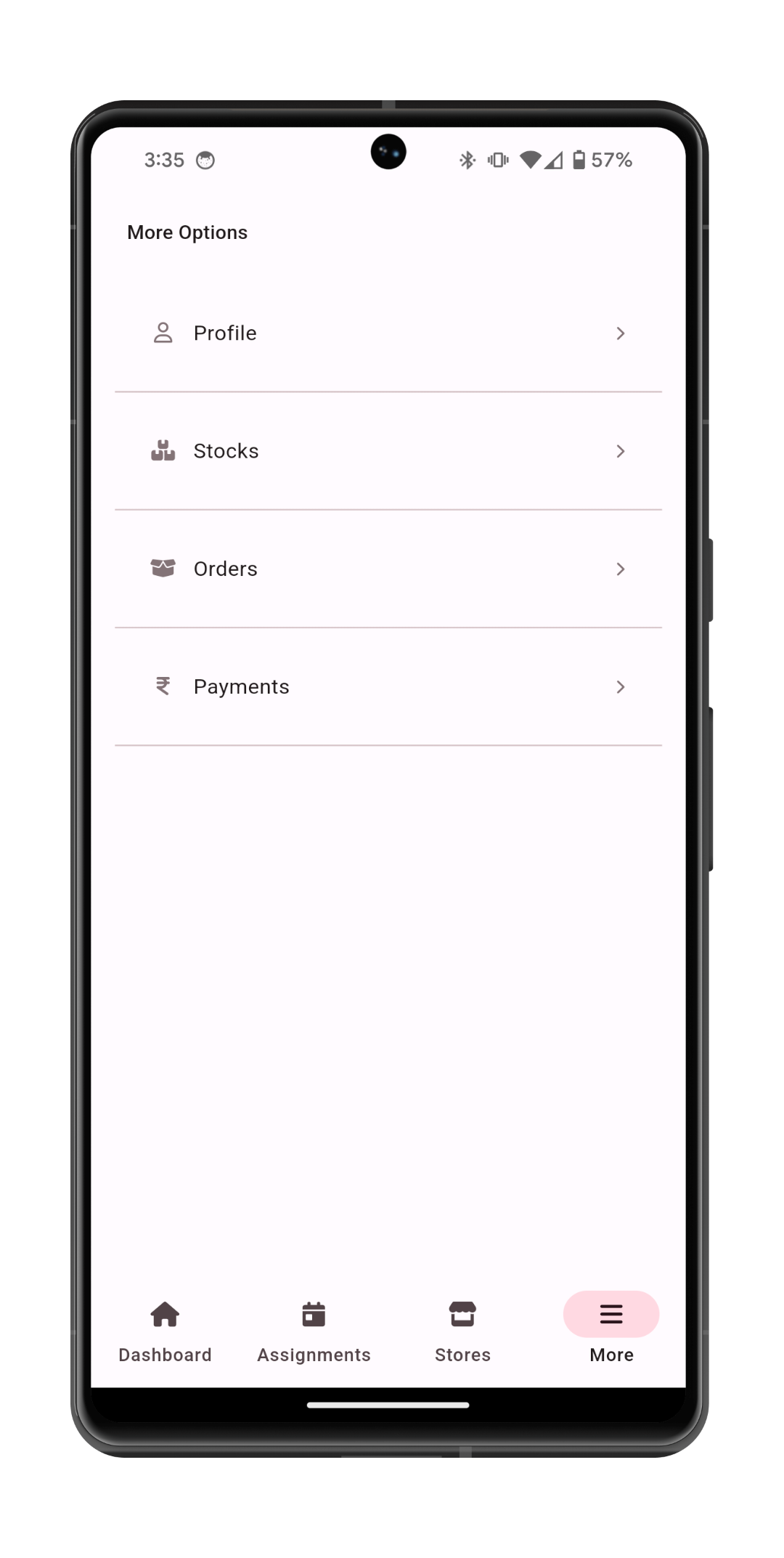

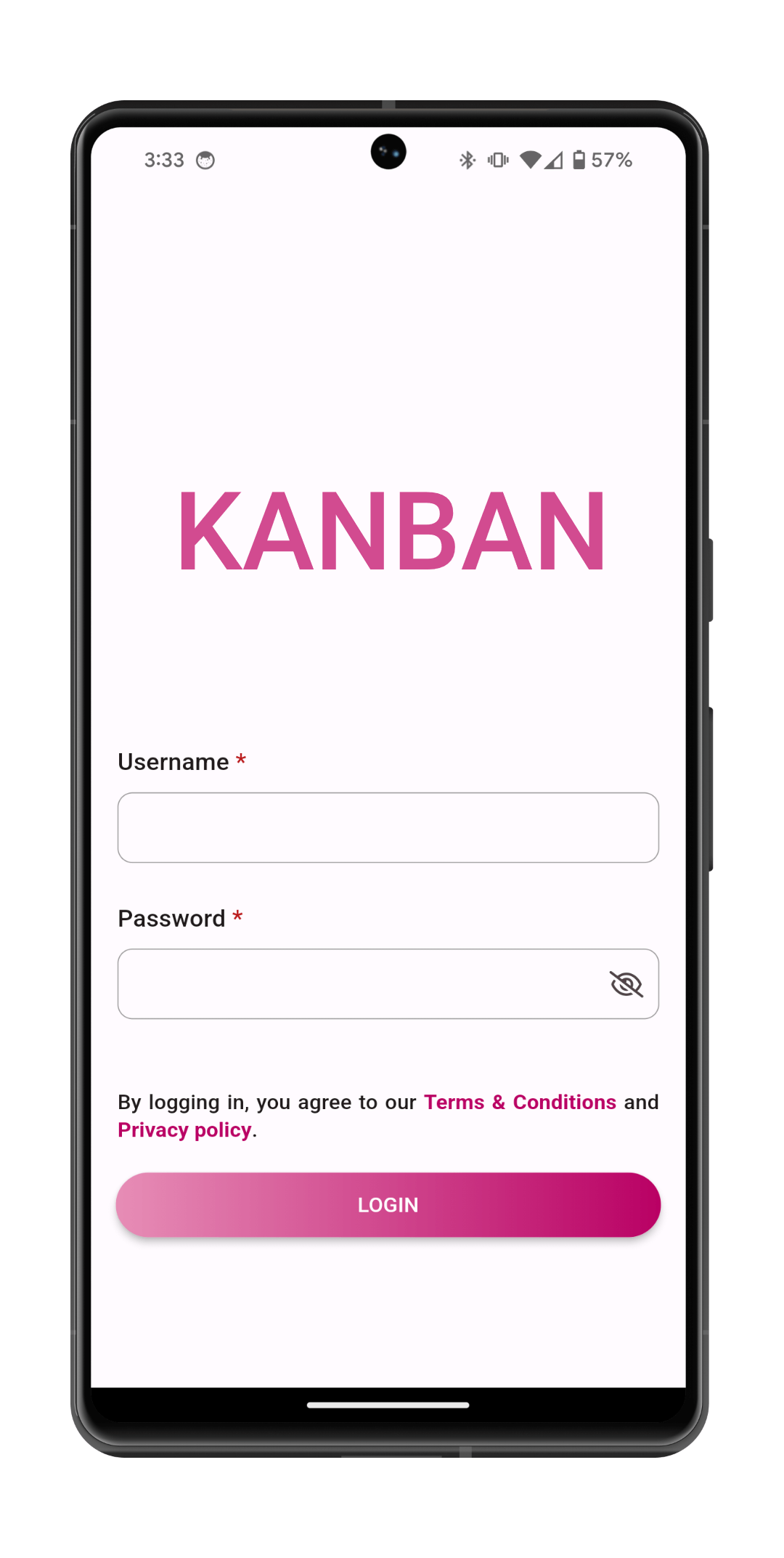

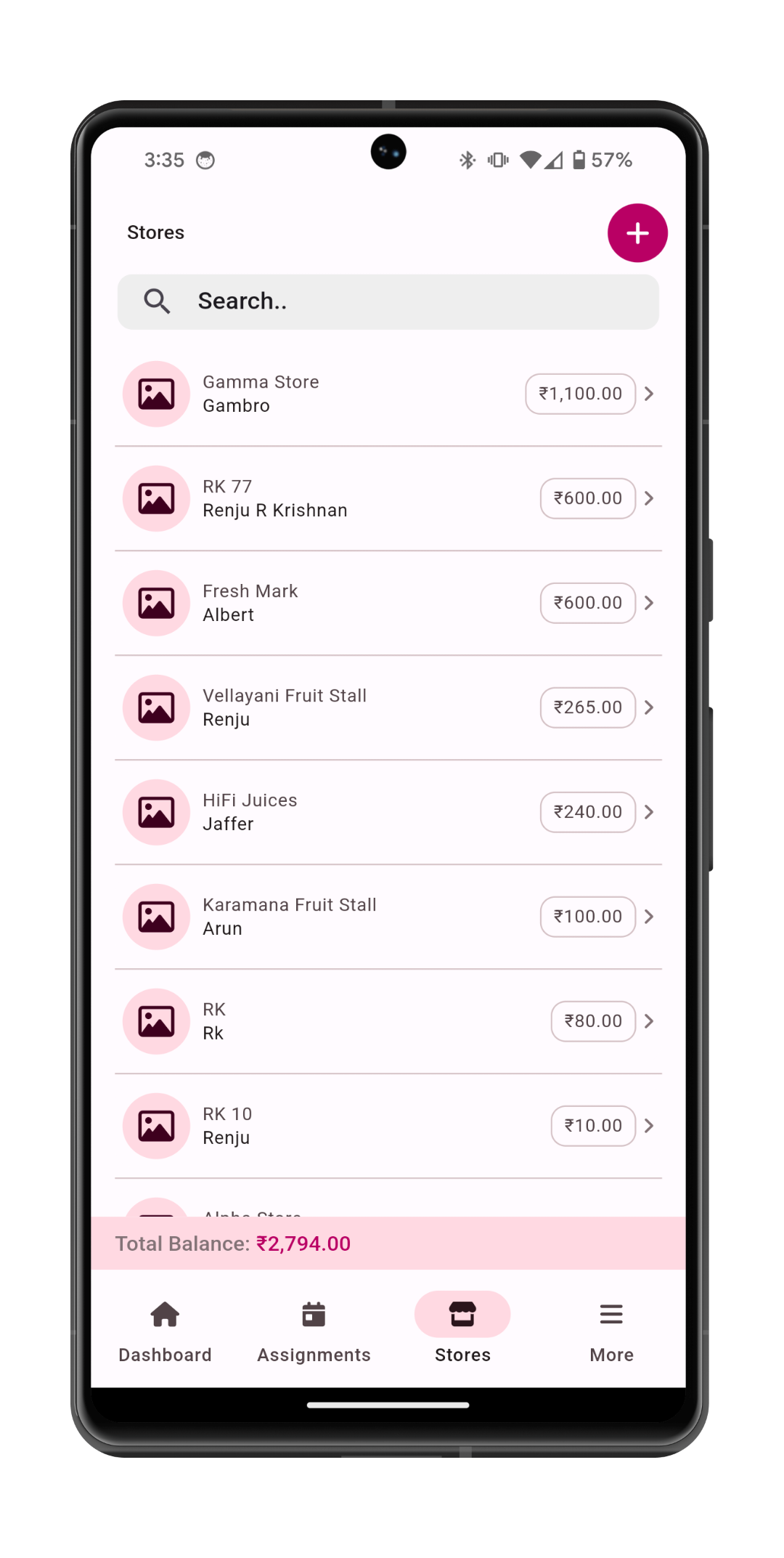

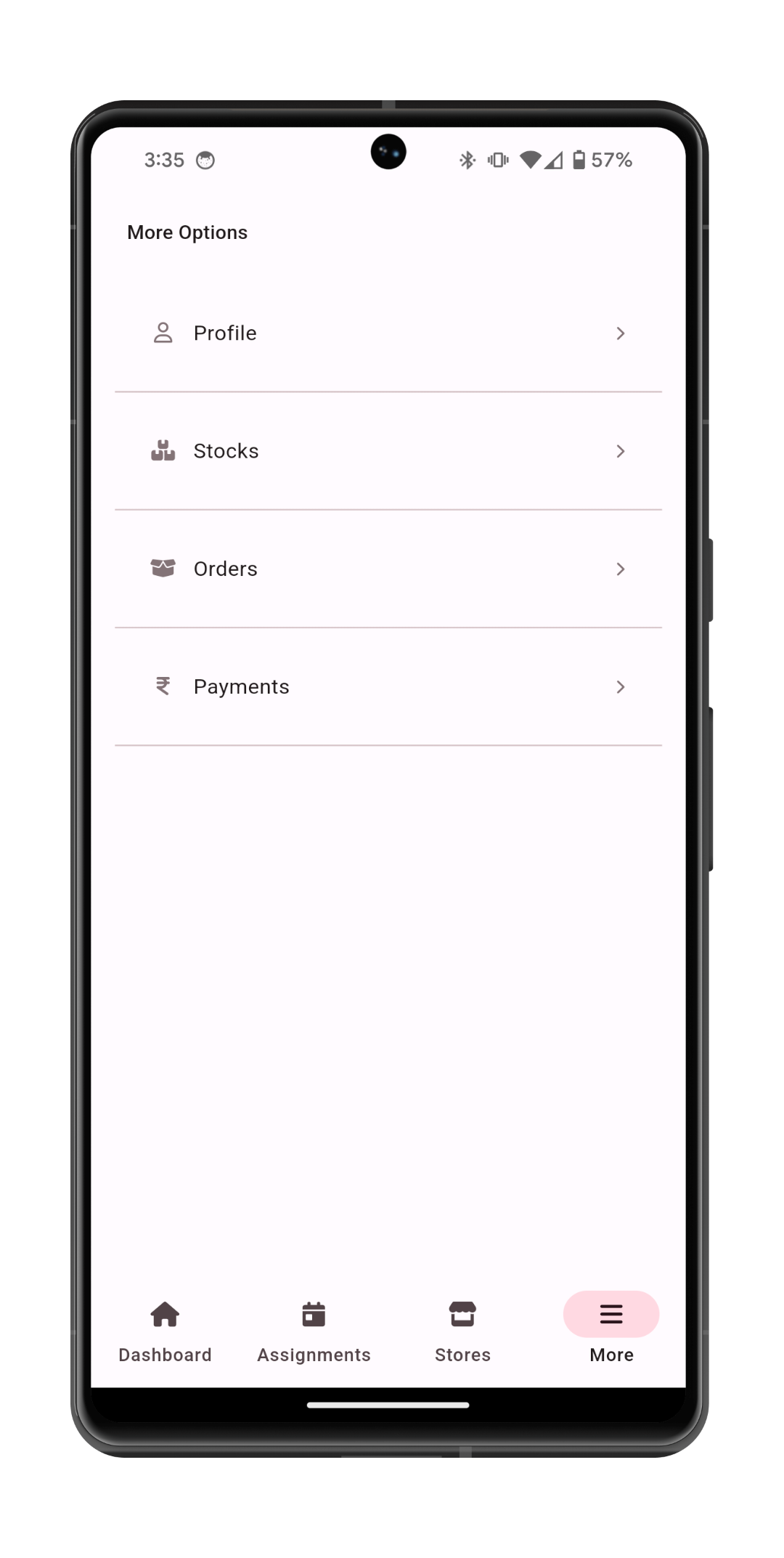

2. Mobile Compatibility:

Increasing demand for mobile access allows distributors and sales teams to manage orders and inventory on the go, enhancing responsiveness.

3. Advanced Analytics:

As data becomes more critical for decision-making, DMS providers are incorporating advanced analytics capabilities, including predictive analytics and AI-driven insights.

4. Focus on Sustainability:

With growing awareness of environmental issues, businesses are seeking solutions that support sustainable practices within their supply chains.

Overall,Distributor management software (DMS) is an essential tool for businesses that rely on distributors to reach their customers. By streamlining order processing, enhancing inventory management, and providing valuable insights through analytics, DMS helps organizations improve efficiency, strengthen relationships, and drive sales growth. While there are challenges to consider, the benefits of implementing a robust DMS far outweigh the obstacles, making it a worthwhile investment for companies looking to optimize their distribution operations. As market trends continue to evolve, businesses must stay informed and adapt their DMS strategies to remain competitive in an increasingly complex marketplace.

Best Distributor Management Software (DMS) - Faq

1. What is a Distribution Management System (DMS) for wholesale distributors?

A Distribution Management System (DMS) is a software solution designed to streamline and automate the distribution processes of wholesale distributors. It helps manage the entire supply chain, from procurement and inventory management to order processing, warehousing, and logistics. By integrating various functions into a single platform, a DMS enhances efficiency, reduces errors, and improves visibility across the distribution network.

2. How can a DMS improve inventory management for wholesale distributors?

A DMS provides real-time inventory tracking, enabling wholesale distributors to monitor stock levels, track product movement, and optimize reorder points. This prevents overstocking or stockouts, reducing carrying costs and ensuring that the right products are available when needed. Additionally, a DMS can forecast demand based on historical data, helping distributors plan better and avoid inventory-related issues.

3. What are the key features of a DMS for wholesale distributors?

A DMS typically includes features such as order management, inventory control, warehouse management, transportation management, customer relationship management (CRM), and reporting and analytics. These features work together to automate processes, improve communication, and provide insights into the distribution operations, enabling distributors to make informed decisions and enhance customer satisfaction.

4. How does a DMS help in order processing and fulfillment?

A DMS streamlines order processing by automating order entry, tracking, and fulfillment. It allows for quick and accurate order placement, reduces manual errors, and ensures that orders are processed in the correct sequence. The system also integrates with warehouse and transportation management to coordinate picking, packing, and shipping, ensuring timely delivery to customers.

5. Can a DMS integrate with other systems used by wholesale distributors?

Yes, a DMS can integrate with other systems such as Enterprise Resource Planning (ERP) software, accounting systems, e-commerce platforms, and Customer Relationship Management (CRM) tools. This integration ensures that data flows seamlessly across all business functions, providing a unified view of operations and enabling better coordination and decision-making.

6. How does a DMS enhance customer satisfaction for wholesale distributors?

By providing accurate and real-time information on inventory levels, order status, and delivery schedules, a DMS enables wholesale distributors to respond promptly to customer inquiries and fulfill orders quickly. The system also helps in managing customer relationships by tracking customer preferences and purchasing history, allowing for personalized service and improved customer loyalty.

7. What are the benefits of using a cloud-based DMS?

A cloud-based DMS offers several advantages, including scalability, accessibility, and cost-effectiveness. It allows distributors to access the system from anywhere, enabling remote work and better collaboration. Additionally, cloud-based systems often have lower upfront costs, as they eliminate the need for expensive hardware and reduce IT maintenance expenses. Automatic updates and data security features are also key benefits of cloud-based DMS solutions.

8. How does a DMS support compliance and reporting requirements?

A DMS helps wholesale distributors comply with industry regulations by providing tools to track and document processes, manage product traceability, and ensure accurate record-keeping. The system also generates detailed reports and analytics, which can be used to demonstrate compliance during audits and to make informed decisions that align with regulatory requirements.

9. What should wholesale distributors consider when choosing a DMS?

When selecting a DMS, wholesale distributors should consider factors such as scalability, ease of use, integration capabilities, and the specific needs of their business. It's important to choose a system that can grow with the business, supports the required features, and integrates seamlessly with existing systems. Additionally, considering the total cost of ownership, including implementation, training, and ongoing support, is crucial.

10. How can a DMS contribute to business growth for wholesale distributors?

A DMS can significantly contribute to business growth by improving operational efficiency, reducing costs, and enhancing customer satisfaction. By automating key processes, optimizing inventory management, and providing valuable insights through analytics, a DMS enables wholesale distributors to scale their operations, enter new markets, and respond more effectively to market changes.