What Are Digital TCards and How Do They Work in Production?

Simplifying Task Management on the Shop Floor

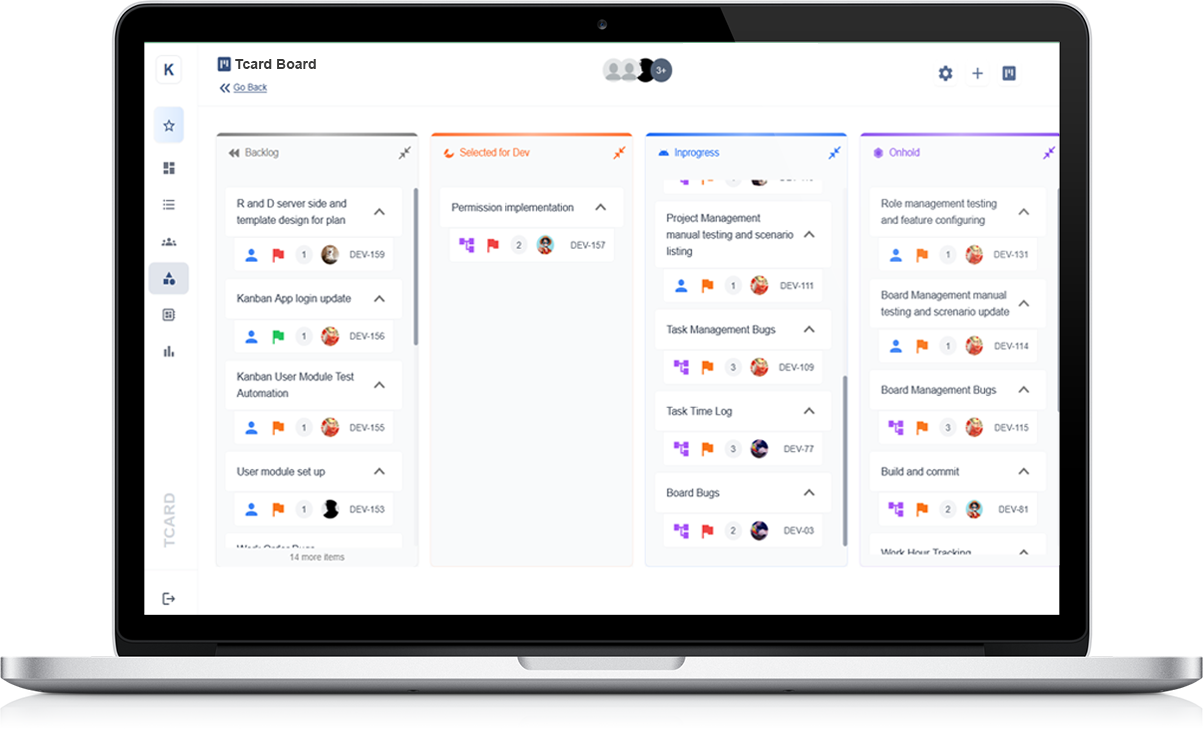

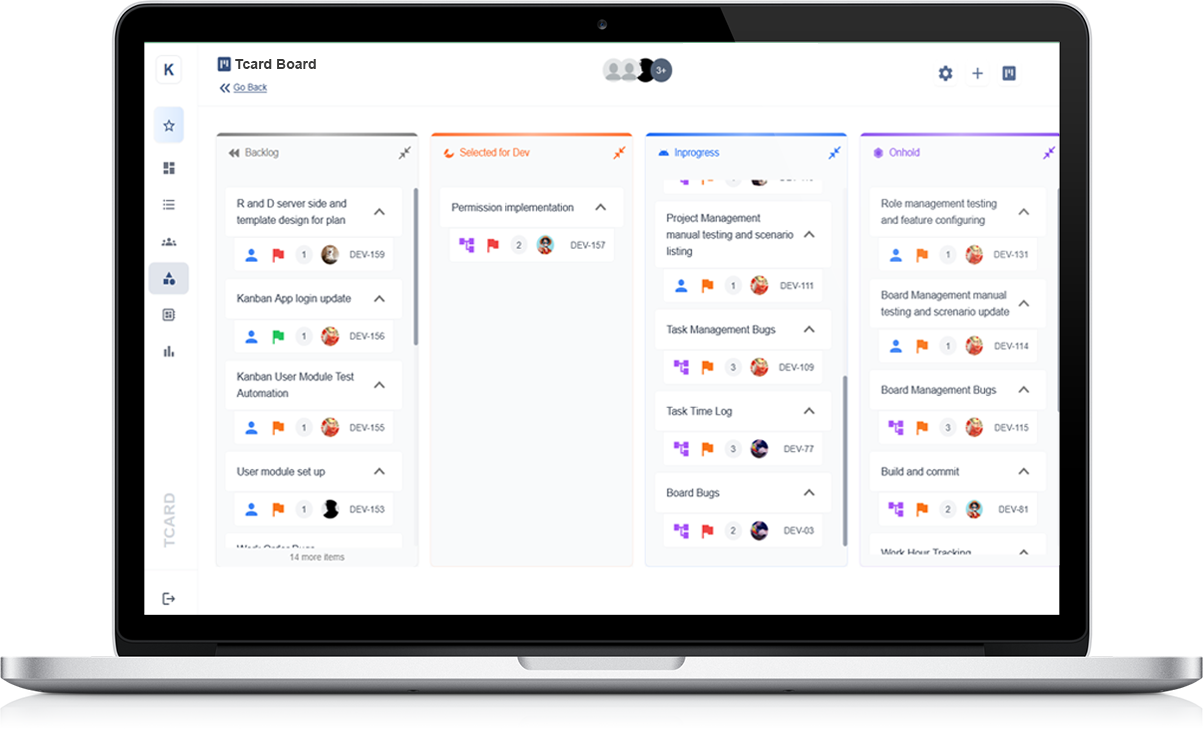

Digital TCards are modern tools designed to replace traditional manual card systems. They provide a clear and structured way to manage tasks, resources, and schedules in a production environment. By using a digital platform, teams can create, assign, and track tasks more efficiently without the need for physical boards or paper cards.

Real-Time Visibility for Better Control

One of the biggest advantages of Digital TCards is real-time visibility. Every task update is instantly available for supervisors, operators, and managers. This makes it easier to see what is being worked on, what has been completed, and where delays might occur. Such transparency helps reduce bottlenecks and improves workflow across departments.

Improving Collaboration and Accountability

Digital TCards allow different teams to work together seamlessly. When a task is assigned, progress can be tracked step by step, and responsibilities are clearly visible. This level of accountability ensures that everyone knows their role and helps avoid confusion or duplication of work.

Adapting to Changing Production Needs

Manufacturing environments often face sudden changes in demand or priorities. Digital TCards are flexible and can be updated quickly to reflect these changes. This adaptability helps production teams respond faster, keep schedules on track, and maintain consistent efficiency even in challenging situations.

Turning Complex Production Plans into Simple Visual Workflows

Making Production Tasks Easier to Understand

Production plans often involve many moving parts, from scheduling and resource allocation to task assignments and deadlines. Without the right system, these plans can feel overwhelming and difficult to manage. By using visual workflows, complex plans are broken down into smaller, manageable steps that are easy to follow and track. This approach ensures clarity for everyone involved in the process.

Enhancing Team Communication

Visual workflows help create a shared understanding across the team. Instead of going through long lists or complicated charts, workers can see progress and responsibilities at a glance. This improves communication between operators, supervisors, and managers, ensuring everyone stays aligned on what needs to be done and by when.

Reducing Errors and Delays

When processes are displayed visually, it becomes easier to spot gaps, delays, or overlapping tasks. This proactive approach helps reduce mistakes and avoids unnecessary downtime. Teams can act quickly to adjust plans when issues arise, keeping production running smoothly and efficiently.

Building Confidence and Accountability

Visual workflows clearly show who is responsible for each task and when it should be completed. This creates accountability while also giving team members the confidence to focus on their roles. With less confusion and greater visibility, production goals can be achieved faster and more effectively.

How Digital TCards Improve Team Collaboration on the Shop Floor

Creating a Shared View of Tasks

On the shop floor, keeping everyone on the same page is vital for smooth production. Digital TCards provide a shared view of tasks, priorities, and progress in real time. This visibility ensures that operators, supervisors, and managers are aligned, reducing confusion and keeping the workflow clear for all team members.

Encouraging Open Communication

Digital TCards make it easier for teams to communicate quickly and effectively. Instead of relying on verbal updates or scattered notes, all information is available in one place. Teams can see updates instantly, which helps avoid misunderstandings and keeps discussions focused on solving problems rather than clarifying basic details.

Strengthening Accountability and Ownership

When tasks are assigned and tracked digitally, it is clear who is responsible for each step in the process. This strengthens accountability and builds ownership among team members. Workers can see their contributions within the bigger picture, which helps build trust and teamwork across different roles on the shop floor.

Improving Flexibility in Daily Operations

Production environments can change quickly, and Digital TCards give teams the flexibility to adapt. Updates can be made in real time, allowing quick adjustments to schedules or responsibilities. This adaptability ensures that the team can respond to challenges together and maintain efficiency, even when unexpected issues arise.

Real-Time Visibility of Tasks, Resources, and Deadlines

Keeping Everyone Informed Instantly

In a busy production environment, having access to up-to-date information is essential. Real-time visibility of tasks ensures that every team member knows what needs to be done, who is responsible, and when it must be completed. This shared clarity removes guesswork and helps teams stay focused on the priorities that matter most.

Tracking Resources Effectively

Resources such as people, tools, and materials often determine whether a task runs smoothly or faces delays. With real-time visibility, supervisors can quickly check the availability and status of these resources. This makes it easier to plan ahead, prevent shortages, and allocate support where it is needed most.

Staying Ahead of Deadlines

Deadlines are critical in any production schedule. Real-time updates allow teams to see how work is progressing against timelines, highlighting potential risks before they turn into delays. Early awareness means that corrective action can be taken promptly, keeping projects on track and ensuring customer expectations are met without last-minute pressure.

Building Confidence Across Teams

When tasks, resources, and deadlines are visible to everyone, it creates confidence across all levels of the team. Operators can work with clarity, supervisors can manage workloads more effectively, and managers can make better decisions based on accurate information. This transparency supports a culture of trust and efficiency on the shop floor.

Cutting Down Bottlenecks with Smarter Task Allocation

Understanding the Root of Bottlenecks

Bottlenecks often occur when tasks pile up at a single point in production, causing delays across the entire workflow. These slowdowns are usually the result of uneven task distribution, limited resources, or unclear responsibilities. Identifying where these issues arise is the first step in reducing downtime and keeping production flowing smoothly.

Distributing Work More Evenly

Smarter task allocation ensures that work is spread evenly across the team instead of being concentrated in one area. By assigning tasks based on skills, workload, and availability, managers can prevent unnecessary waiting times and reduce pressure on specific workstations. This balanced approach helps create a more consistent output across the line.

Making Use of Real-Time Information

Access to real-time data allows leaders to see how tasks are progressing and where bottlenecks might be forming. With this insight, tasks can be reassigned quickly to free capacity and maintain steady momentum. This flexibility ensures that production schedules are less affected by unexpected delays.

Boosting Productivity Through Smarter Planning

When tasks are allocated more effectively, teams can focus on what they do best without being overloaded. This not only reduces stress but also boosts productivity across the shop floor. Smarter planning means less wasted time, smoother workflows, and faster completion of projects, all while maintaining quality standards.

Tracking Production Progress at a Glance with Digital TCards

Clear Visibility of Ongoing Tasks

Digital TCards provide a quick and easy way to see the status of production activities in real time. With tasks displayed visually, teams can instantly identify what is in progress, what has been completed, and what still needs attention. This simple visibility helps reduce confusion and keeps everyone aligned on priorities.

Reducing Delays Through Transparency

By showing updates at a glance, digital TCards highlight potential delays before they become major problems. If one task is taking longer than expected, it is easy to spot and address quickly. This transparency ensures that managers and teams can act early, keeping production on schedule.

Helping Teams Stay Aligned

When all team members can view progress in the same place, communication improves naturally. Everyone knows what has been achieved and what remains pending, removing the need for repeated updates or lengthy meetings. This alignment helps create a more focused and cooperative shop floor environment.

Encouraging Accountability and Consistency

With tasks clearly assigned and visible, accountability becomes part of daily work. Each step is traceable, making it easier to maintain standards and track responsibilities. This consistent tracking method ensures that progress can be measured fairly and that improvements are easier to spot over time.

Why Manufacturers Are Moving from Manual to Digital TCards

Eliminating Paper-Based Limitations

Manual TCards often rely on boards and paper slips, which can be time-consuming to update and easy to misplace. Manufacturers are shifting to digital TCards to remove these limitations. With tasks managed digitally, updates are faster, more accurate, and accessible to everyone without the risk of lost information.

Improving Speed and Efficiency

Digital TCards allow instant updates, making it easier to keep production plans current. Teams no longer need to manually move cards or check physical boards, which saves valuable time. This efficiency ensures that managers and operators can focus on completing tasks rather than handling paperwork.

Providing Real-Time Visibility

One of the biggest advantages of digital TCards is the ability to view task status in real time. Production progress, resource availability, and deadlines can all be tracked at a glance. This transparency makes it easier to identify delays, allocate resources quickly, and keep the production flow smooth.

Supporting Continuous Improvement

Unlike manual systems, digital TCards can store historical data for analysis. Manufacturers can use this information to spot trends, track performance, and identify areas for improvement. This data-driven approach helps drive continuous improvement, making digital TCards an essential tool for modern production management.

Supporting Just-in-Time (JIT) Planning with Digital Tools

Making Production More Flexible

Just-in-Time (JIT) planning depends on completing tasks exactly when needed without holding excess stock. Digital tools make this possible by giving teams the flexibility to adjust schedules quickly. When demand changes, updates can be applied instantly, ensuring production stays aligned with actual requirements.

Reducing Waste and Delays

Manual systems often lead to overproduction or wasted time due to communication gaps. Digital tools reduce these risks by providing real-time visibility of tasks and resources. Teams can see what needs to be done, when it should be completed, and what resources are available. This reduces unnecessary steps and keeps processes running smoothly.

Improving Coordination Across Teams

Effective JIT planning requires clear communication between different departments. Digital tools support this by giving every team member access to the same updated information. Whether it’s materials management, scheduling, or task allocation, everyone works from a single source of truth, improving coordination and reducing errors.

Keeping Production on Track

With digital tools, managers can monitor progress in real time and quickly address issues before they cause disruptions. This proactive approach ensures that tasks are completed on schedule, making it easier to meet customer demand without overstocking or missing deadlines. By supporting JIT planning, digital solutions help manufacturers stay efficient and competitive.

How Digital TCards Aid in Resource Allocation and Capacity Planning

Making Better Use of Available Resources

Digital TCards help managers see exactly where resources are being used and where they may be underutilised. By presenting information in a clear visual format, they make it easier to identify gaps and redistribute people, machines, or materials to where they are most needed. This ensures that no resource is left idle while other areas struggle with shortages.

Balancing Workloads Effectively

One of the biggest challenges in production is balancing workloads across teams and shifts. Digital TCards simplify this by giving a complete view of task assignments and progress. Managers can quickly check which areas are overloaded and adjust responsibilities, making sure that work is spread evenly and efficiently across the workforce.

Supporting Capacity Planning

Capacity planning requires accurate insights into current performance and future demand. Digital TCards provide real-time updates that show how much capacity is available at any point. With this information, teams can prepare for upcoming tasks, plan shifts more effectively, and avoid the risks of overproduction or missed deadlines.

Creating Flexibility in Operations

Production environments often face unexpected changes such as urgent orders or equipment downtime. Digital TCards make it easy to adjust quickly by reallocating resources and rescheduling tasks without confusion. This flexibility helps maintain smooth operations while supporting long-term planning and strategic decision-making.

Boosting Accountability by Assigning Clear Ownership of Tasks

Creating Clarity in Responsibilities

When every task has a clearly assigned owner, there is no confusion about who is responsible for completing it. Digital TCards make this process simple by displaying ownership in an easy-to-read format. This clarity ensures that everyone knows their role and what is expected of them, reducing delays caused by uncertainty.

Encouraging a Sense of Responsibility

Assigning ownership encourages individuals to take responsibility for their work. With their name attached to specific tasks, employees are more likely to follow through with care and commitment. This sense of accountability strengthens individual performance and helps the entire team deliver better results.

Improving Team Communication

When ownership of tasks is visible to the whole team, it improves communication on the shop floor. Team members know who to approach if they need updates, support, or clarification. This direct point of contact helps reduce miscommunication and ensures that information flows smoothly across departments.

Supporting Performance Tracking

Clear task ownership also makes it easier to track progress and measure performance. Managers can see which tasks are on schedule and which may need additional attention. By linking accountability with performance data, Digital TCards create a more transparent and efficient way of managing production activities.

Linking Digital TCards to Lean and Continuous Improvement Practices

Driving Efficiency in Daily Operations

Digital TCards align closely with lean practices by simplifying the way tasks are managed and monitored. They reduce wasted time, cut down on duplication, and keep processes flowing smoothly. By providing a clear and visual way of tracking work, they ensure that every task contributes directly to value creation without unnecessary delays.

Supporting Standardised Processes

One of the key principles of lean and continuous improvement is standardisation. Digital TCards help teams create repeatable and consistent workflows that can be easily followed and improved over time. This makes it simpler to spot inefficiencies, correct errors, and implement small changes that add up to big improvements.

Making Continuous Improvement Visible

Improvements are easier to achieve when they are clearly tracked and shared. Digital TCards make progress visible by showing real-time updates, completed tasks, and areas needing attention. This visibility encourages teams to discuss and act on opportunities for improvement during daily reviews, reinforcing a culture of learning and growth.

Encouraging Employee Involvement

Lean and continuous improvement rely heavily on employee participation. Digital TCards give staff a platform to suggest changes, identify challenges, and contribute ideas directly into the workflow. This involvement builds ownership, keeps teams engaged, and ensures that improvements are practical and effective across the production environment.

Reducing Errors and Miscommunication in Daily Operations

Creating a Clear Flow of Information

Errors in production often occur when information is missing, unclear, or misunderstood. Digital TCards provide a structured and visual way of presenting tasks, priorities, and updates. By removing guesswork and ensuring that instructions are easy to follow, they help teams stay aligned and reduce the chance of costly mistakes.

Minimising Confusion Between Shifts

Handovers between shifts can be a common source of miscommunication. With Digital TCards, updates are recorded in real time and made visible to everyone. This ensures that incoming teams have a complete view of what has been done, what is pending, and what issues need attention. It keeps work flowing smoothly without duplication or overlooked tasks.

Improving Communication Across Teams

In busy environments, quick verbal instructions can easily be forgotten or misheard. Digital TCards replace reliance on memory with a reliable record of task details, deadlines, and responsibilities. This promotes consistent communication across departments and helps prevent misunderstandings that can slow down production.

Supporting Accuracy in Daily Operations

By providing standardised and accessible information, Digital TCards reduce human error and encourage accurate task completion. Workers know exactly what to do, when to do it, and who is responsible. This clarity improves overall reliability, strengthens team collaboration, and supports smoother daily operations without unnecessary setbacks.

Enhancing Flexibility When Priorities or Plans Change

Adapting Quickly to Shifting Demands

Manufacturing environments often face sudden changes, whether it is an urgent customer order, supply delays, or unexpected equipment downtime. Digital TCards allow managers and teams to adjust plans quickly without confusion. Tasks can be reassigned or rescheduled instantly, giving teams the flexibility to respond effectively to new priorities.

Keeping Everyone Aligned During Changes

When priorities shift, communication gaps can cause delays and errors. Digital TCards ensure that updates are visible to all team members in real time. This keeps everyone informed and aligned, reducing the risk of wasted effort or duplicated tasks. The clarity they provide helps teams move forward confidently even in fast-changing situations.

Supporting Smooth Task Reallocation

In many cases, work needs to be redistributed when priorities change. With Digital TCards, managers can clearly assign new responsibilities without disrupting overall workflows. Each worker sees their updated tasks, deadlines, and requirements, making the transition smoother and avoiding uncertainty on the shop floor.

Strengthening Agility in Daily Operations

Flexibility is essential for maintaining efficiency under pressure. Digital TCards give organisations the ability to shift focus without losing track of progress. By offering a visual and structured approach to task management, they support agile operations, helping businesses stay productive even when plans need to change at short notice.

Integrating Digital TCards with Other Production Management Systems

Creating a Unified Flow of Information

Digital TCards become more powerful when integrated with other production management systems. By connecting with planning, scheduling, and reporting tools, they create a single source of truth that ensures all data is consistent. This integration reduces duplication of work and helps teams make better-informed decisions.

Improving Data Accuracy and Transparency

Manual updates across different platforms often lead to errors and delays. When Digital TCards are linked to existing systems, updates made in one place automatically reflect everywhere. This not only saves time but also improves accuracy, ensuring that managers and teams are working with the latest information at all times.

Streamlining Communication Between Departments

Production often requires coordination between multiple departments such as operations, maintenance, and quality. Integrated Digital TCards make it easier for these teams to share updates and stay aligned. Clear visibility across systems ensures that everyone understands the current status of tasks, reducing miscommunication and delays.

Supporting Smarter Planning and Reporting

Integration also supports advanced planning and reporting by bringing together real-time data from different areas. Managers can track performance, identify bottlenecks, and adjust resources more effectively. This seamless flow of information creates stronger control over production processes and promotes a more efficient working environment.

The Long-Term Benefits of Digital TCards for Manufacturing Success

Building a Culture of Continuous Improvement

Digital TCards provide more than just short-term efficiency gains. Over time, they help create a culture where continuous improvement becomes second nature. Teams can regularly review performance, identify areas for enhancement, and put changes into action with ease. This consistent focus on growth drives long-term success in manufacturing.

Strengthening Operational Consistency

One of the long-term benefits of using Digital TCards is improved consistency in operations. With clear task tracking, automatic updates, and real-time visibility, processes become more reliable and repeatable. This reduces the chances of variation and builds a strong foundation for maintaining high standards across production cycles.

Reducing Costs Through Better Resource Management

Effective resource use is crucial for manufacturing success. Over time, Digital TCards help cut costs by preventing waste, avoiding duplicate work, and ensuring that the right resources are allocated to the right tasks. The long-term result is smoother production and better use of available capacity without unnecessary expenses.

Increasing Workforce Engagement and Accountability

When employees clearly understand their roles and responsibilities, engagement naturally improves. Digital TCards assign ownership of tasks, making individuals accountable for outcomes while giving them visibility of their impact. This motivates teams, builds trust, and supports a culture of responsibility that benefits manufacturing in the long run.