Effective collaboration with vendors and suppliers is essential for maintaining smooth operations and ensuring timely delivery of products and services. Kanban, a visual project management tool, can significantly enhance collaboration and streamline processes in vendor and supplier management. Here’s how:

What is Kanban?

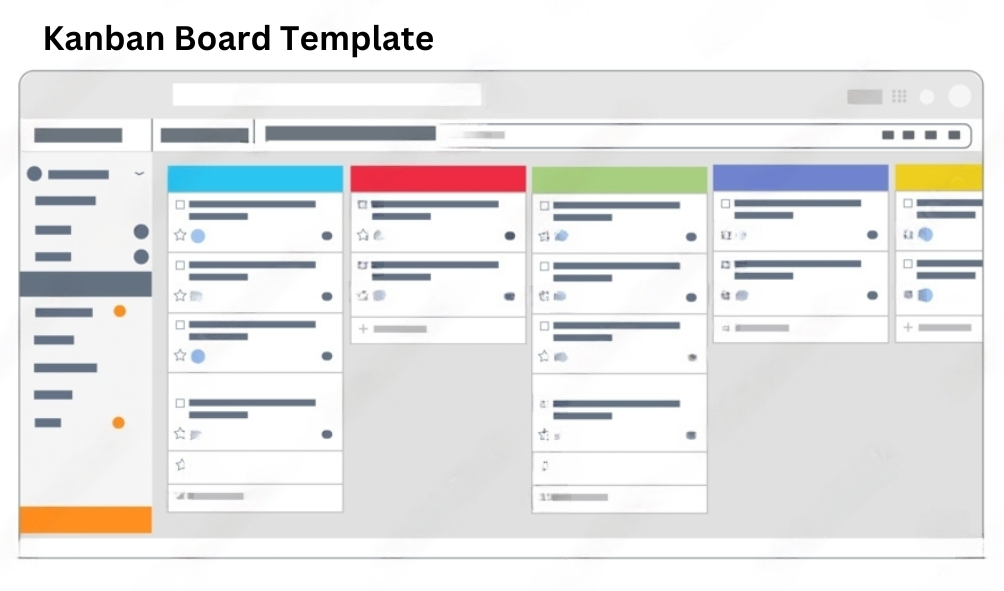

Kanban is a visual workflow management method that uses boards and cards to represent tasks and their progress. Originally developed for manufacturing, Kanban has been adapted for various industries and is widely used in project management to improve efficiency and collaboration.

Benefits of Using Kanban for Vendor & Supplier Management

Enhanced Visibility

Kanban boards provide a clear visual representation of the entire supply chain process. Each task, from order placement to delivery, is represented by a card that moves through different stages on the board. This visibility allows all stakeholders to see the status of each task, identify bottlenecks, and monitor progress in real time.

Improved Communication

With Kanban, communication becomes more streamlined. Instead of relying on lengthy email chains or multiple meetings, all relevant information is displayed on the Kanban board. Team members, vendors, and suppliers can easily access updates, leave comments, and share documents directly on the board, reducing the chances of miscommunication.

Increased Efficiency

Kanban helps to identify and eliminate inefficiencies in the supply chain. By visualizing the workflow, teams can pinpoint delays and implement strategies to address them. The ability to quickly spot issues and make adjustments ensures that tasks move smoothly from one stage to the next, improving overall efficiency.

Flexibility and Adaptability

Kanban is highly flexible and can be customized to fit the specific needs of vendor and supplier management. Whether managing a single supplier or coordinating with multiple vendors, Kanban boards can be tailored to represent different workflows, priorities, and deadlines. This adaptability makes it easier to manage varying supplier requirements and changing circumstances.

Better Workload Management

Kanban boards help balance workloads by visualizing task distribution. If one stage of the process becomes overloaded, it’s immediately visible, allowing managers to redistribute tasks or allocate additional resources to maintain a steady workflow. This ensures that no single team or supplier is overwhelmed, and tasks are completed on time.

Continuous Improvement

Kanban promotes a culture of continuous improvement. By regularly reviewing the Kanban board, teams can analyze performance, identify recurring issues, and implement process improvements. This ongoing optimization leads to more efficient workflows and better collaboration with vendors and suppliers over time.

Implementing Kanban for Vendor & Supplier Management

Set Up Your Kanban Board

Create a Kanban board that represents your vendor and supplier management workflow. Common stages might include Order Placement, Processing, Shipping, Delivery, and Payment. Customize the stages to fit your specific process.

Add Tasks as Cards

Each task or order is represented by a card on the Kanban board. Include relevant details such as order numbers, deadlines, responsible parties, and any specific requirements. This information helps keep everyone informed and ensures that nothing is overlooked.

Track Progress

As tasks move through the stages of the workflow, update the Kanban board by moving the corresponding cards. This visual progress tracking makes it easy to see which tasks are on track, which are delayed, and where intervention might be needed.

Facilitate Communication

Use the Kanban board as a central communication hub. Team members, vendors, and suppliers can leave comments, attach documents, and share updates directly on the cards. This centralized communication reduces the need for back-and-forth emails and ensures that everyone has access to the latest information.

Review and Optimize

Regularly review the Kanban board to assess performance and identify areas for improvement. Hold periodic meetings to discuss progress, address any issues, and brainstorm solutions. Use the insights gained from these reviews to continually refine your vendor and supplier management process.

Conclusion

Kanban is a powerful tool for enhancing collaboration in vendor and supplier management. By providing increased visibility, improving communication, and promoting efficiency, Kanban helps ensure that supply chain processes run smoothly and effectively. Implementing Kanban can lead to better workload management, continuous improvement, and ultimately, stronger relationships with vendors and suppliers.