What is an SQDCM Board?

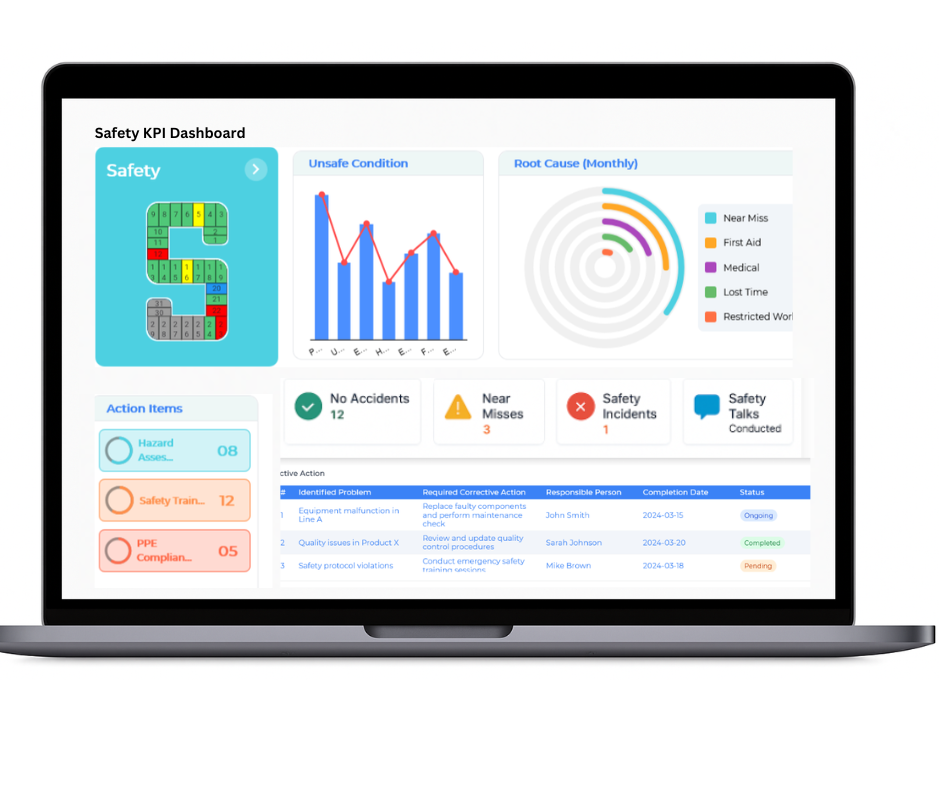

An SQDCM board is a visual management tool, often used in manufacturing, that displays metrics and performance data related to Safety, Quality, Delivery, Cost, and Morale. It's essentially a dashboard that allows teams to track their progress, identify areas for improvement, and visualise their performance against key performance indicators (KPIs).

- Safety: Fostering a safe work environment by identifying hazards, minimising risks, and preventing workplace incidents.

- Quality: Driving continuous improvement to ensure all products and processes consistently meet or exceed quality standards.

- Delivery: Enhancing delivery performance by ensuring timely completion and fulfillment of customer orders with minimal delays.

- Cost: Optimising resources and reducing waste to improve cost-effectiveness and maintain financial performance.

- Morale: Building a positive and engaging workplace culture that supports team motivation, collaboration, and well-being.

Safety

The Balanced Scorecard serves as a key tool for tracking and enhancing workplace safety. By monitoring on-site accidents and near-miss events, it provides critical insights into the effectiveness of current safety protocols and identifies opportunities for continuous improvement.

- Total Workplace Accidents Reported

- Significant Near-Miss Events Documented

- Recorded Safety Incidents and Root Cause Analysis

- Safety Briefings and Training Sessions Conducted

Quality

The Balanced Scorecard's quality metrics provide a comprehensive view of product and process integrity. By tracking defects, rework, and non-conformances—alongside customer feedback—organisations can drive continuous improvement and strengthen their quality assurance efforts.

- Product Defects Identified

- Failed Quality Inspections and Tests

- Rework and Repair Activities Logged

- Non-Conformance Reports Issued

- Supplier Material Issues Detected

Delivery

The Balanced Scorecard monitors the end-to-end delivery process to ensure consistent On Time In Full (OTIF) performance—from supplier dispatch to final customer receipt. It assesses logistics efficiency, warehouse operations, and inventory flow, delivering actionable insights that empower management to optimise supply chain performance.

- Late Deliveries Tracked

- On Time In Full (OTIF) Rate

- Order Fulfillment Accuracy

- Warehouse and Inventory Turnover Efficiency

Cost

Effective cost management is crucial for controlling expenses and enhancing profitability. The Balanced Scorecard provides a detailed analysis of financial performance, enabling organisations to track cost metrics, identify savings opportunities, and make data-driven decisions to optimise financial efficiency.

- Cost Reduction Initiatives

- Expense Management and Oversight

- Operational Cost Efficiency

- Budget Compliance and Control

- Resource Allocation Optimisation

Morale

The Balanced Scorecard helps track and improve employee morale by evaluating key factors such as job satisfaction, team collaboration, and workplace engagement. By regularly assessing these metrics, organisations can foster a positive work environment, increase productivity, and enhance overall team performance.

- Employee Satisfaction and Engagement Scores

- Team Collaboration and Communication Effectiveness

- Employee Retention and Turnover Rates

- Workplace Health and Well-Being Initiatives

- Training and Development Opportunities

SQDCM Board for Shift Management

- Continuous Performance Monitoring: Provides ongoing tracking of Safety, Quality, Delivery, Cost, and Morale metrics during every shift, ensuring consistent performance and alignment with operational goals.

- Proactive Safety Management: Monitors and analyses safety-related incidents, near-misses, and audits, fostering a safety-first culture and driving continuous improvements in risk management.

- Quality Assurance at Every Stage: Tracks product quality, rework rates, and adherence to standards throughout production to maintain high-quality benchmarks and reduce defects.

- Delivery & Production Optimisation: Measures production output, OTIF (On Time In Full) performance, and identifies potential delays, ensuring optimised delivery times and operational efficiency.

- Effective Inventory Control: Ensures accurate inventory tracking, minimises waste, and supports efficient inventory turnover to sustain lean operations and reduce stockouts.

- Employee Engagement & Productivity: Assesses employee attendance, training, morale, and collaboration, promoting a motivated and efficient workforce that drives productivity and operational success.

- Rapid Issue Resolution: Enables fast detection and resolution of operational challenges, minimising downtime and ensuring continuous improvement in performance.

Breaking Down SQDCM: What Each Letter Means for Your Business Success

SQDCM is a powerful tool used by organisations to manage and improve their daily operations. It stands for Safety, Quality, Delivery, Cost, and Morale. Each pillar plays a vital role in helping teams focus on key performance areas, driving overall business success. Here's a closer look at what each letter represents and why it matters.

Safety (S)

Safety is always the top priority. Monitoring and addressing safety concerns daily helps reduce workplace incidents and ensures that everyone returns home safely. A strong safety culture also boosts trust and confidence among employees.

Quality (Q)

Quality reflects the organisation’s commitment to delivering error-free products or services. Tracking quality metrics, such as defects or rework rates, helps teams identify issues early and maintain high standards. This leads to greater customer satisfaction and fewer costly errors.

Delivery (D)

Delivery measures how well the team meets production or service deadlines. By monitoring performance against planned targets, teams can take corrective actions quickly, improve planning, and ensure timely completion of work. On-time delivery builds customer trust and supports long-term relationships.

Cost (C)

Cost focuses on how resources are used. Keeping an eye on waste, overtime, or material use allows businesses to control expenses. Efficient cost management leads to higher profit margins and better use of available resources.

Morale (M)

Morale tracks employee satisfaction and engagement. A motivated team is more productive, creative, and committed to improvement. Regular feedback, team discussions, and recognition help boost morale and reduce turnover.

When used effectively, SQDCM provides a balanced view of performance. It helps teams stay aligned, solve problems quickly, and achieve consistent improvements across all areas of the business.

Why SQDCM Boards Are a Must-Have for Operational Excellence

SQDCM boards are practical tools that support teams in achieving and maintaining operational excellence. They bring focus, structure, and clarity to daily work by visually tracking key performance areas: Safety, Quality, Delivery, Cost, and Morale. This simple yet effective layout ensures that nothing important is overlooked during day-to-day operations.

Clear Visibility of Performance

With an SQDCM board in place, teams can see how they are performing in each area at a glance. This visibility helps everyone stay aligned with goals and quickly identify where support or improvement is needed. Problems are no longer hidden or delayed — they are brought to light and acted on in real time.

Encourages Daily Focus and Accountability

The daily use of SQDCM boards encourages routine check-ins, open discussions, and shared ownership of results. Each team member becomes more aware of their impact on safety, quality, and productivity. This builds a stronger culture of responsibility and team collaboration.

Supports a Culture of Continuous Improvement

By tracking trends over time, SQDCM boards help teams spot recurring issues and work together on sustainable solutions. This ongoing cycle of review and action drives continuous improvement, which is a key part of operational excellence.

In short, SQDCM boards act as a compass, guiding teams in the right direction and helping them make better decisions every day. They are essential tools for any organisation serious about improving performance and achieving long-term success.

Safety First: How the 'S' Keeps Your Team Protected and Proactive

The ‘S’ in SQDCM stands for Safety, and it holds a vital place in every workplace. Putting safety first means creating an environment where risks are identified early, accidents are reduced, and everyone feels confident about their well-being. It’s not just about following rules — it’s about building a culture that values care and responsibility.

Preventing Hazards Through Visibility

Using an SQDCM board helps highlight safety concerns in real time. Near misses, hazards, and safety observations are recorded clearly, making it easier to track trends and act before small issues become serious. By making safety a part of daily discussions, teams are encouraged to stay alert and proactive.

Encouraging Team Involvement

When safety becomes a shared responsibility, every team member plays a part. The SQDCM board invites workers to raise concerns and suggest improvements. This open communication leads to a safer and more inclusive work environment. It also builds trust between leadership and staff, showing that everyone’s health matters.

Creating a Strong Safety Culture

Consistently tracking safety performance sends a clear message — safety is a priority, not an afterthought. Over time, this creates a positive culture where safe habits become second nature, and teams look out for one another.

In short, the ‘S’ in SQDCM is a daily reminder to protect people first. When safety is strong, productivity and morale naturally follow.

Delivering Quality Every Day with the ‘Q’ in SQDCM

The ‘Q’ in SQDCM stands for Quality, and it plays a key role in driving consistency and trust in any workplace. Quality is not just about avoiding mistakes — it’s about doing things right the first time and making sure that every product or service meets the expected standard.

Tracking Daily Performance

Quality indicators on an SQDCM board make performance visible. Whether it's the number of defects, rework cases, or customer complaints, having this information clearly displayed helps the team stay focused on improvement. It also allows for quick action when issues arise, reducing waste and delays.

Encouraging Ownership

When teams see quality metrics every day, they start to take more pride in their work. Small changes in habits and attention to detail can lead to big improvements. By involving everyone in the quality process, teams build a stronger sense of ownership and responsibility.

Building Trust Through Consistency

High-quality output leads to satisfied customers and fewer errors. When customers can rely on your team to deliver consistent results, it builds long-term trust. Internally, a focus on quality also reduces stress and improves workflow.

The ‘Q’ in SQDCM ensures that quality is not an occasional check, but a core value practiced every single day. With visibility, accountability, and team effort, high standards become a natural part of daily operations.

Boosting Efficiency: How the ‘D’ Tracks Your Delivery Performance

The ‘D’ in SQDCM stands for Delivery, a crucial element for keeping customer satisfaction high and operations smooth. Tracking delivery performance helps organisations ensure that goods and services are completed and handed over on time, every time.

Monitoring On-Time Completion

The delivery section on an SQDCM board shows whether tasks, products, or services are being completed as scheduled. It often includes metrics such as orders dispatched on time, lead times, or production cycle times. By reviewing this data daily, teams can quickly identify delays and take immediate steps to get back on track.

Keeping the Team Focused

Visible delivery metrics serve as a constant reminder of targets and expectations. This encourages the team to manage their time well, avoid bottlenecks, and prioritise tasks that affect delivery. Everyone becomes more aware of their role in meeting deadlines, boosting team efficiency.

Improving Customer Satisfaction

When delivery is consistent and reliable, customers notice. Meeting deadlines builds trust and strengthens relationships. Internally, it also reduces stress and avoids last-minute rushes that can lead to mistakes or extra costs.

In short, the ‘D’ in SQDCM isn’t just about shipping products—it’s about building a reliable system that supports smooth, timely operations. With the right tracking in place, delivery performance becomes a driver of both customer satisfaction and team success.

Cutting Costs without Compromise: The Role of the ‘C’ in SQDCM

The ‘C’ in SQDCM stands for Cost, an essential aspect of ensuring that operations remain efficient while maintaining high-quality standards. By focusing on cost management, organisations can optimise resources and cut unnecessary expenses without sacrificing quality or safety.

Tracking Cost Effectively

Cost monitoring within the SQDCM framework involves tracking various expenses across production or service delivery processes. This includes materials, labour, energy, and overheads. By keeping a close eye on these factors, companies can identify areas where costs can be reduced without impacting product or service quality.

Optimising Resources

The key to reducing costs is optimising resources. By analysing performance data from the cost section of an SQDCM board, businesses can pinpoint inefficiencies, streamline processes, and improve resource allocation. For example, adjusting production schedules or minimising waste can significantly reduce operational costs.

Improving Profitability

Cost management doesn’t just save money—it also improves profitability. By reducing wastage, lowering overheads, and maximising efficiency, organisations can generate better profit margins, all while maintaining product standards and delivery timelines. This leads to a more sustainable business model in the long term.

In summary, the ‘C’ in SQDCM plays a vital role in balancing cost efficiency with operational effectiveness. By continuously monitoring and optimising costs, businesses can stay competitive without compromising on the core aspects that matter most—quality, safety, and delivery.

Mastering Maintenance: Why the ‘M’ Is Critical for Uptime and Reliability

The ‘M’ in SQDCM represents Maintenance, a crucial element for ensuring that machinery and equipment remain in optimal working condition. Regular maintenance is essential to reduce downtime, avoid costly repairs, and maintain consistent performance across operations.

Minimising Downtime

Effective maintenance practices help minimise unplanned downtime. By regularly servicing equipment and performing routine checks, businesses can identify and resolve potential issues before they lead to major failures. This proactive approach ensures that machinery is always ready for production, improving overall productivity and reducing delays.

Improving Reliability

Reliability is a key factor in any production process. Well-maintained equipment performs consistently and meets performance expectations. When the maintenance process is prioritised, it directly contributes to higher reliability, which in turn supports better quality and delivery performance. This creates a smoother workflow and strengthens customer trust.

Cost Savings and Longevity

Regular maintenance not only prevents costly breakdowns but also extends the life of equipment. By addressing wear and tear early, companies avoid the need for expensive replacements or repairs. Investing in preventive maintenance is often far more cost-effective than dealing with the consequences of equipment failure.

Daily Stand-Up Meetings Made Smarter with SQDCM Visual Boards

Daily stand-up meetings are a vital part of many businesses, offering teams the chance to discuss goals, progress, and obstacles. However, the key to making these meetings more effective is having a clear, visual representation of ongoing tasks. This is where SQDCM visual boards can transform your daily routines.

Clarity and Focus

By using SQDCM visual boards during stand-up meetings, teams can easily see the status of key metrics: Safety, Quality, Delivery, Cost, and Maintenance. These boards provide a real-time snapshot of performance, allowing everyone to quickly assess where attention is needed. This transparency fosters clear communication and keeps everyone focused on the most pressing issues.

Streamlining Communication

Visual boards help teams avoid the confusion that can come from long discussions. With all information visible, everyone stays aligned on priorities, and team members can directly address concerns. It eliminates the need for endless clarifications and ensures that conversations are more solution-oriented.

Improving Accountability

When key metrics are tracked on a visual board, it encourages ownership. Team members can quickly identify areas they are responsible for and see how their work impacts the larger objectives. This heightened accountability improves individual and team performance, driving continuous improvement.

Incorporating SQDCM visual boards into daily stand-up meetings enhances collaboration, ensures better focus, and accelerates problem-solving, making meetings smarter and more productive.

How Digital SQDCM Boards Enhance Real-Time Monitoring and Collaboration

In today’s fast-paced business environment, real-time monitoring and collaboration are essential for achieving operational excellence. Digital SQDCM boards offer a dynamic solution to enhance both these aspects, allowing teams to track performance and make informed decisions on the spot.

Real-Time Data Tracking

Digital SQDCM boards provide an instant overview of key performance metrics such as Safety, Quality, Delivery, Cost, and Maintenance. This live data ensures that teams have up-to-date information at their fingertips, enabling quicker responses to issues and proactive problem-solving. With digital updates, teams no longer have to wait for manual input, ensuring that decisions are based on the most current data available.

Improved Collaboration

One of the biggest benefits of digital SQDCM boards is the enhanced collaboration they foster. These boards allow multiple team members from different departments to access and update information in real time, regardless of their location. This makes it easier for cross-functional teams to work together, share insights, and address challenges quickly, leading to improved decision-making and faster issue resolution.

Streamlined Communication

With digital SQDCM boards, communication becomes more efficient. As the data is visible to everyone in real time, there’s no need for lengthy discussions or constant follow-ups. Updates, changes, and alerts are automatically communicated to the relevant team members, keeping everyone on the same page and focused on the right tasks.

By leveraging digital SQDCM boards, businesses can optimise their operations, improve team collaboration, and stay agile in today’s competitive market.

The Link Between SQDCM Boards and Lean Manufacturing Principles

SQDCM boards are an essential tool for organisations looking to implement and sustain Lean manufacturing principles. By focusing on Safety, Quality, Delivery, Cost, and Maintenance (SQDCM), these boards provide a visual representation of key performance indicators that drive continuous improvement, one of the core tenets of Lean.

Enhancing Continuous Improvement

Lean manufacturing thrives on the principle of continuous improvement, or Kaizen. SQDCM boards help track and highlight areas where improvements are needed, allowing teams to take immediate action. By constantly monitoring Safety, Quality, and Delivery metrics, organisations can identify inefficiencies and implement small, incremental changes that have a large cumulative impact on performance.

Eliminating Waste

Lean focuses on the elimination of waste in all forms—whether it’s time, resources, or effort. The visual nature of SQDCM boards helps teams identify areas where resources are being wasted. By tracking performance data on a regular basis, these boards make it easier to pinpoint bottlenecks or inefficiencies, enabling teams to address them quickly and effectively.

Fostering Team Collaboration

Another key Lean principle is empowering teams to collaborate and problem-solve. SQDCM boards provide a platform for cross-functional teams to communicate and work together towards common goals. With real-time updates, teams can make decisions faster, increasing overall operational efficiency and contributing to Lean success.

By aligning SQDCM boards with Lean principles, organisations can foster a culture of continuous improvement, eliminate waste, and optimise processes to achieve operational excellence.

Identifying Trends and Taking Action: SQDCM for Continuous Improvement

SQDCM boards are powerful tools for identifying trends and driving continuous improvement in any organisation. By focusing on key areas such as Safety, Quality, Delivery, Cost, and Maintenance (SQDCM), these boards provide a clear, visual snapshot of performance, helping teams spot issues early and take proactive action.

Spotting Trends in Real Time

One of the greatest advantages of SQDCM boards is their ability to highlight trends in real time. Regular monitoring of safety incidents, quality levels, delivery performance, cost management, and maintenance issues allows teams to spot patterns and potential problems before they escalate. For example, a rising number of safety incidents could indicate a need for further training or equipment upgrades, while a dip in delivery performance might point to bottlenecks in the production process.

Taking Action for Continuous Improvement

Once trends are identified, organisations can take immediate action to address them. SQDCM boards encourage teams to make quick, data-driven decisions, fostering a culture of continuous improvement. For example, if quality metrics drop, root cause analysis can be conducted to find the issue and implement corrective actions. By tracking these actions and their results on the board, teams can ensure progress is made and sustained.

Using SQDCM boards effectively empowers teams to stay ahead of issues, improve processes, and achieve better outcomes. The constant evaluation of performance and adjustment of strategies ensures that organisations can continuously improve and adapt to changing needs.

Empowering Frontline Teams with Ownership Through SQDCM Metrics

Empowering frontline teams with ownership is essential for driving performance and fostering a culture of accountability. SQDCM (Safety, Quality, Delivery, Cost, and Maintenance) metrics are an excellent tool for enabling this ownership. By making key performance indicators visible and accessible, teams can take charge of their results and continuously improve operations.

Fostering Accountability with Clear Metrics

When frontline teams have access to real-time SQDCM data, they can directly see how their actions impact safety, quality, delivery, cost, and maintenance. This transparency fosters a sense of ownership, as team members are able to track their contributions to organisational goals. For instance, a team can monitor safety metrics to reduce incidents, track quality performance to ensure consistent standards, or manage delivery times to meet customer expectations.

Encouraging Problem-Solving and Continuous Improvement

With ownership comes responsibility, and frontline teams can use SQDCM boards to identify trends and resolve issues. Whether it's addressing a quality dip or finding ways to reduce waste, these metrics empower teams to analyse problems and implement solutions. The visual nature of SQDCM boards makes it easier to spot areas for improvement, which teams can then focus on, ensuring continuous progress in operational performance.

Incorporating SQDCM metrics into daily operations not only drives better results but also boosts morale. When teams see the direct impact of their efforts, they are motivated to take more initiative and make continuous improvements, leading to enhanced productivity and greater success.

Simple Yet Powerful: How to Get Started with SQDCM in Your Workplace

Implementing SQDCM (Safety, Quality, Delivery, Cost, and Maintenance) in your workplace is a straightforward yet powerful way to improve performance across key areas. The best part is that you don’t need complex systems to get started. With a clear focus on essential metrics, SQDCM helps to streamline operations and foster continuous improvement.

Step 1: Identify Key Metrics

Begin by identifying the key metrics you want to track for each of the five pillars of SQDCM. For example, under Safety, you might track accident rates or near-misses. In Quality, focus on defect rates or customer complaints. For Delivery, consider on-time performance, while Cost could look at waste or operational expenses. Lastly, Maintenance should track equipment uptime and breakdowns. This clarity helps teams focus on areas that matter most to your business.

Step 2: Implement Simple Visual Tools

Once you’ve identified your metrics, create a simple visual board to track them. This could be a physical board in the workplace or a digital one for remote teams. The key is to make the data easily visible and accessible to everyone, enabling real-time tracking and fostering ownership of the results.

Step 3: Review and Act

Regularly review the data with your team and take action where necessary. Celebrate successes, and identify areas for improvement. This ongoing process of monitoring, analysing, and acting is what makes SQDCM a powerful tool for driving continuous improvement in any organisation.

Real-World Examples: SQDCM in Manufacturing, Healthcare, and Logistics

Implementing SQDCM (Safety, Quality, Delivery, Cost, and Maintenance) can drive operational improvements across various industries. Here are some real-world examples of how different sectors have successfully applied SQDCM principles.

Manufacturing

In manufacturing, SQDCM is often used to streamline production processes and reduce downtime. By tracking safety incidents, quality defects, and equipment reliability, companies can identify problem areas and take immediate corrective actions. For example, a manufacturer may use SQDCM boards to monitor machine performance, aiming to reduce breakdowns (Maintenance) and ensure products meet quality standards (Quality). This leads to improved production flow, reduced costs, and enhanced delivery times.

Healthcare

Healthcare organisations also benefit from SQDCM principles, particularly in areas like patient safety, treatment quality, and operational efficiency. For example, a hospital could track infection rates (Safety), patient satisfaction (Quality), and wait times (Delivery). By regularly reviewing these metrics, the hospital can implement targeted improvements, such as reducing patient wait times or enhancing staff training to improve care quality. This approach not only boosts patient outcomes but also optimises hospital operations.

Logistics

In logistics, SQDCM helps companies maintain smooth supply chains. For instance, delivery times (Delivery) and transportation costs (Cost) can be tracked alongside safety measures for drivers and vehicles. By using SQDCM boards, a logistics firm can optimise routes, improve delivery accuracy, and reduce transportation costs, while ensuring that safety standards are consistently met, which enhances overall service delivery.

Across all industries, SQDCM helps organisations make data-driven decisions that lead to continuous improvement and greater operational efficiency.

From Chaos to Clarity: Using SQDCM to Keep Teams Focused and Engaged

In today’s fast-paced work environment, it’s easy for teams to feel overwhelmed by the number of tasks and challenges they face daily. However, using the SQDCM framework—Safety, Quality, Delivery, Cost, and Maintenance—can bring structure and clarity, helping teams stay focused and engaged.

Clear Objectives

By defining clear metrics for safety, quality, delivery, cost, and maintenance, SQDCM gives teams a straightforward way to measure their performance. Teams know exactly what they need to focus on, whether it’s reducing safety incidents, improving product quality, meeting delivery deadlines, cutting costs, or ensuring equipment reliability. This clarity helps reduce distractions and ensures that everyone is aligned with the same goals.

Continuous Improvement

With SQDCM, teams can continuously monitor their progress and identify areas for improvement. Regular reviews of SQDCM boards provide opportunities to celebrate successes and address any issues before they escalate. This sense of progress keeps team members motivated and engaged, knowing that their efforts are directly contributing to the organisation’s success.

Increased Accountability

When performance is tracked transparently, team members are more likely to take ownership of their work. SQDCM encourages accountability, as everyone can see how their contributions impact the overall results. This shared responsibility fosters a stronger sense of teamwork and drives collaboration towards achieving common goals.

Incorporating SQDCM into your team’s workflow transforms chaotic environments into organised, productive spaces, helping keep everyone focused, engaged, and working towards continuous improvement.

Best Practices for Implementing an SQDCM Board

1. Involve Key Stakeholders

Involving key stakeholders—such as managers, team leads, and department heads—is crucial in the design and implementation of the SQDCM board. Their input ensures that the board reflects the organisation’s priorities and performance metrics accurately. Collaboration in the process ensures buy-in from all departments, creating a sense of ownership.

2. Regular Updates

To keep the SQDCM board relevant and useful, it must be updated regularly. Whether data is updated daily, weekly, or in real-time, timely updates help ensure the board reflects current performance. This also allows teams to address issues promptly and avoid delays in decision-making.

3. Use Clear and Simple Metrics

The SQDCM board should focus on clear and simple metrics that are easy to understand and act upon. Overcomplicating the board with too many metrics can lead to confusion. Keep the indicators straightforward and aligned with the most important operational goals.

4. Train Employees on Usage

For the SQDCM board to be effective, employees should be trained on how to interpret and use the board. This includes understanding the color codes, the meaning of each KPI, and how to act on the data presented. Providing training ensures that all team members are empowered to contribute to problem-solving and continuous improvement efforts.

5. Foster a Culture of Accountability

The SQDCM board promotes accountability by making performance visible. To maximise its impact, organisations must foster a culture where employees feel responsible for the metrics they influence. When employees are held accountable for their contributions, performance improves across all five areas.

Benefits of Using an SQDCM Board

1. Improved Visibility

One of the main advantages of an SQDCM board is the real-time visibility it provides. By having key performance indicators displayed in a central location, team members and managers can quickly identify issues, track progress, and understand how different factors impact overall performance. This visibility encourages accountability and ensures that everyone is aligned on the same objectives.

2. Enhanced Communication

The SQDCM board serves as a communication tool that facilitates transparency across all levels of the organisation. Whether it is safety concerns, quality improvements, or delivery challenges, the board serves as a clear visual cue to discuss issues and make data-driven decisions. Teams can collaborate effectively by using the board to address problems, share feedback, and improve performance.

3. Continuous Improvement

The SQDCM board encourages a culture of continuous improvement by regularly reviewing and addressing performance gaps. By tracking metrics across Safety, Quality, Delivery, Cost, and Morale, organisations can pinpoint areas that require improvement and develop action plans to address them. This ongoing feedback loop promotes sustainable growth and operational excellence.

4. Proactive Problem-Solving

By monitoring performance metrics in real-time, teams can identify problems before they escalate. For instance, if quality issues are detected early, corrective actions can be implemented immediately, preventing costly rework or product returns. This proactive approach minimises risks and ensures that teams stay ahead of potential issues.

5. Employee Engagement

Tracking morale and employee satisfaction on the SQDCM board demonstrates a commitment to employee well-being. It helps ensure that employees feel heard and that their concerns are addressed. Regularly addressing morale issues leads to higher levels of engagement, motivation, and retention. When employees feel involved in the continuous improvement process, they are more likely to contribute positively to the organisation’s success.